Abstract

Municipal sewage sludge (MSS) disposal is a major problem in different countries worldwide. Renewable energy recovery from waste is an efficient alternative to waste management options. Recovering energy from sludge increases resource efficiency as a renewable option and replaces fossil fuel in the long run. Using sewage sludge for production of energy will surely have a positive socio-economic effect. In the last few years, several efficient technologies have been invented for treating MSS and generalise energy. The objective of this study is to review different technologies of production of bioenergy from sewage sludge. Their utilisation in different Asian and European countries are shown and also to look into their supply chain sustainability is an important part of this area of work. The supply chain sustainability of these processes focusing on the operational and economical aspects is examined. An attempt at making these processes green is also studied. Finally, the paper gives a future research scope on cost-effectiveness and planning strategies in the technologies used. Very few reviews have been done on this topic. The work has great importance towards environmental and economical aspect.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Our world is modernising day by day with advanced technology and latest scientific innovations. And it definitely increases the global waste production at a quite high rate. Ten years ago about 0.68 billion tonnes of waste is produced per year. Hoornweg report estimated that today, this amount has increased to 1.3 billion tonnes of waste per year, and it is estimated that by 2025, this will increase to 2.2 billion tonnes per year. Again lots of municipal sewage sludge (MSS) are produced every day causing several environmental and health-related issues by polluting soil and water resources. So proper treatment and careful yet productive Waste Management is very much required nowadays (Aggelakis et al. 2005). With increasing growth curve of sludge production, decreasing disposal outlets and increasing economic pressure low-cost solution are encouraged. Moreover, production of energy from waste management is looked forward nowadays. Waste is no more valueless, but considered as resources. And different technologies are proposed for proper waste management these days [1]. Reduction in the amount of MSS and producing energy at the same time is definitely a beneficial outcome [2].

Nowadays, government policies are becoming more strict regarding proper waste disposal. Keeping that in mind waste management processes are only encouraged if it has some positive outcomes. Disposing sewage sludge as landfills is one of the old practises, but these days, it is only encouraged if methane recovery is associated with it. Alternative processes are also seen due to the limited capacity of landfills. The nutritional values of the sludge can be maintained by using the sludge it for conditioning soil and also as a fertiliser specially for fertile land and crop cultivation, though the use of sewage sludge as landfill are not too much in use nowadays, because it accelerates surface and groundwater pollution, odour and air emissions (ammonia and greenhouse gases), and the accumulation of heavy metals in soils. So currently several other waste management processes are experimented, which leads to the formation of energy. These processes are good keeping in mind the environmental and socio-economic aspects.

Among these, the thermochemical processes are mostly in use. Though having high cost of power is a major disadvantage for this, that can be considered if the production of energy is seen in these pathways [3]. Thermochemical processes include combustion/incineration, ‘advanced or emerging pyrolysis’ and gasification. Moreover, not only these processes but several co-processing are also encouraged these days like co-pyrolysis of sewage sludge and manure [4], co-digestion of MSS with poultry industry waste [5]. Not only pyrolysis but gasification process are also twisted nowadays by applying plasma gasification, steam gasification, etc. [6]. From the literature survey, [8–11] it is seen that there is very less work regarding review on MSS. Moreover, most of these works are from European countries. A very few number of works have been explored reviewing the condition of Asian countries as well as India. Again, most of the studies focus on physical and biological processes of waste treatment. Review on chemical processes of waste treatment is scarcely found. Some of the research questions that came out during the study are as follows: Which among all these processes are the most beneficial and why? Is the original process or the latest experiments with co-processing are more efficient? What are the temperature, pressure and condition in which the processes give the best result? What is the effectiveness of the process in different European and Asiatic countries.

In this study, an effort has been made for a detailed review about different thermochemical technologies of municipal sewage sludge, and tried to explore their advantages and disadvantages and to propose the best and most beneficial technology. Not only the basic ones but the paper also deals with the current co-processes which are extensively in use these days. According to the EII Brochure, 2007, co-processing can be termed as the practise where waste is used as a raw material or as a source of energy, replacing natural mineral resources and fossil fuels leading to a green technology. Some other major objectives of the paper are to show the use of these processes in different European and Asiatic countries including India. This study shows a detailed review about several thermochemical processes giving a basic idea to several industries and MSS treatment plant to move forward in which way to be benefitted to its maximum with maximum use of municipal wastes to energy. On the other hand, the paper gives a future scope for life cycle assessment (LCA) of each treatment processes individually and use of these treatment processes in other parts of the globe. Again, people can also study the technical, socio-economic and environmental aspects of these processes.

2 Research Methodology

First and foremost, a detailed literature survey was conducted and a thorough search using database like Science Direct, Google Scholar, Springer, etc. with keywords like ‘municipal sewage sludge treatment, different thermochemical process for treating MSS, sewage sludge (SS) pyrolysis, plasma gasification of SS, biological treatment of sludge, comparative study of different thermal treatment of MSS, Different Reactors and condition for pyrolysis and Gasification’, etc. is done. It helped to review all the scientific article regarding the subject from the last 20 years. Next, the references of these studies provided some further relevant documents. Several published articles, reports, news and presentation have been seen to get more knowledge about the study. Lastly, the help of different books was taken to understand the research gap and questions.

3 State-of-the-Art Waste-to-Energy Technologies

Different types of Waste-to-Energy technologies are discussed briefly in the followings.

3.1 Incineration

In this treatment unprocessed waste is used as a raw material and treated thermally. Incineration process takes place in presence of sufficient amount of air to oxidise feedstock. By this process, waste is converted to carbon dioxide(CO2), water (H2O) and non-combustible materials with solid residue state called incinerator bottom ash (IBA) in which always a small amount of residual carbon is present (DEFRA 2007). The advantages of incineration are as follows: reduction of large sludge volume, thermal destruction of several pathogens and germs, thus minimising waste odours and definitely recovery of renewable energy. The advantages are followed by some disadvantages, which are as follows: Incineration is mainly used for sludge minimization not complete disposal as 30% of the dry solids in MSS finally forms ash and combustion ash are hazardous material due to the presence of heavy metals and emission of greenhouse gases (GHG) during their combustion. Thus, additional expenses are there for ash control and disposal, though a large part of ash can be managed as construction material and in cement kiln [3, 12–15]. This disadvantage of incineration can be minimised by co-combustion of MSS with coal/lignite combustion units towards electricity production, which can improve the resulted GHG emissions and hence the public acceptability and concern.

3.2 Pyrolysis

Pyrolysis is a breakdown of chemical bonds by the use of thermal energy only according to Applied Pyrolysis Handbook-Thomas. P. Wampler, 2007. During the process of pyrolysis thermal cracking and condensation reaction are also witnessed. The products that are formed from pyrolysis can be grouped into three categories which are pyrolysis gas (containing the un-condensable low molecular gases), pyrolysis liquid or pyrolysis oil (containing the condensable volatile compounds) and char (the end solid residue). Pyrolysis is endothermic process compared to incineration process explained in Fytili and Zabaniotou 2008; Manara and Zabaniotou 2012. Some of the advantages of pyrolysis are as follows: It is less polluting than incineration because of lower operating temperature and absence of oxygen in the process. As the process of pyrolysis needs low temperature, the heavy metals are not found in the pyrolysis gas rather they are trapped in the resultant solid carbonaceous char. With these advantages, there are some disadvantages to the process like its economic viability is not so good and the process equipment are also a bit costly. Though the economic viability of the process can be improved by producing high-value pyro-oil, utilising pyrolysis gas as fuel and utilising char produced.

3.3 Gasification

Gasification is the thermochemical process that converts any carbonaceous fuel to a gaseous product with a high heating value by Gasification-Higman, Maarten Burgt 2003. Gasification mainly transforms organic solid materials to combustible gas or syngas, using O2 between 20 and 40% of the oxygen required for total combustion. The syngas formed is a mixture of CO, H2 and other gases, with by-products the char or slag, oils and water. The process has some benefits like steam gasification enhances H2 production in gas and thus increases the heating value of the gas; the process is self-sufficient and no energy supply is required for the steady-state operation, followed by certain backdrops like it consists of a series of complex sequential chemical and thermal decomposition reactions [16–25].

3.4 Co-processing Methods

It is surveyed that pyrolysis, gasification originally are not so economically sustainable or beneficial, so these days, co-processing methods are becoming more famous. Co-processing is the technology where wastes are used as raw material or as a source of energy which can replace natural mineral resources and fossil fuels such as coal, petroleum and gas (energy recovery) in industrial processes. Co-pyrolysis of sewage sludge with different products like manure, animal wastes, etc. is gaining attention nowadays. The process shows some advantages like it is a better option for energetic applications. Moreover, it utilises other kinds of wastes during its process, thus increasing the economical and environmental benefits. But it should be remembered that co-processing is not always the matter for encouragement because of few drawbacks.

3.5 Plasma Gasification

Plasma gasification process is a thermal process that needs external power to heat up and sustain the high temperatures. In the process, the materials are decomposed into elements in an oxidant starved medium. Extremely high temperature helps to each higher conversion efficiency. Products formed during the process are mainly syngas, slug and ash. Plasma with high temperature breaks down nearly all the materials to their elemental form excluding the radioactive materials. Due to the high temperature required in the process, toxic compounds decompose into harmless chemical products, which is one of the major advantages of the process. The classification of plasma gasification mainly depends on the different types of plasma discharge technique used and reactor used for the process. Different types of plasma discharge techniques are as follows: (i) direct current (DC), (ii) radio frequency (RF) and (iii) microwave (MC) [6]. Different types of plasma gasification reactors are as follows: plasma fixed bed reactor, plasma moving bed reactor, plasma entrained bed reactor or plasma spout bed reactor (Tang et al. 2013) (Table 1) .

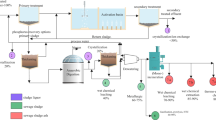

4 Technologies for Energy Recovery from Municipal Sewage Sludge (MSS)

Several types of technologies are in practise nowadays to recover energy from municipal sewage sludge (MSS) for their technical, social, economical and most importantly environmental feasibility. Some detailed studies and great technologies are already established utilising MSS to produce energy producing stuff like bio-oil, biochar, biofuel, etc., and these processes are also helpful in reducing the harmful substances of MSS to comparatively less toxic chemical compounds. In these study mainly the process of Pyrolysis and Gasification is focused. The following section shows a detailed review of these two processes.

4.1 Pyrolysis of MSS

Pyrolysis is a thermochemical decomposition of organic substances at high temperatures in the absence of oxygen (or any halogens). During the process, chemical composition and physical phases of the substance change. It is a process of thermolysis mostly seen in organic substances. The success of the process and the yield of the product formed from pyrolysis depend mainly on the process conditions like temperature, reactor design, pressure, residence time and the original sludge characteristics. The detailed review of the process is studied thereof. Mainly two types of pyrolysis are discussed in these. Fast pyrolysis is carried at a moderate temperature of 500 °C, short gas residence time of about >2 s and rapid quenching of the vapours. The major product from these process is pyrolysis liquid commonly called bio-oil or pyrolysis oil, which can be applied as a fuel and also act as a source of valuable chemical products. On the other hand, slow pyrolysis is characterised by mild temperature of about 350–600 °C at low heating rates, and obviously, the process takes place at inert, i.e. O2-free atmosphere. The reactors that are involved in MSS pyrolysis are fixed-fluid bed and rotary kiln reactors. But pyrolysis is less pollutant than incineration due to lower operating temperature and non-requirement of oxygen in the process.

The product of sewage sludge pyrolysis is a dark brown organic fluid with high water content. Mainly the properties of pyrolysed liquid which are helpful to serve that liquid as a fuel are important. On the other hand, Char which is the main by-product of sewage sludge pyrolysis is characterised as follows. The chars are having low calorific value, near about 5 MJ kg−1, which is not at all beneficial for incineration or other kinds of energy formulation. Again, the high heavy metal content of char requires high cost for their treatment. Again there are legal restrictions to use char as landfills. But using pyrolysis char as an adsorbent to remove pollutants like H2S and NOx are in practise these days. But many researchers are involved to utilise char in a more economical ways that would be a better socio-environmental sustainable process.

4.2 Gasification of MSS

Gasification is a thermochemical process that converts organic fossil fuels which are rich in carbonaceous materials into CO2, CO and H2O. The process takes place at high temperature about 680–900 °C without combustion, within a controlled atmosphere of oxygen, steam or air. During the process, the solid organic substances change to form syngas as certain by-products like char or slag–oil and water gasification works best if the sludge can be dried up to 90% (Spinosa et al. 2011). The gaseous products formed from waste gasification are used to prepare fuel cell and are utilised to produce electricity (Vierrath and Greil 2001). A typical gasification gas is characterised by a hydrogen content of about 8.89–11.17 (vol.%), CO (6.28–10.77 vol.%), CH4 (1.26–2.09), C2S (0.75–1.2 vol.%) and carbon dioxide (Fytili and Zabaniotou 2008). Gasification also contains a chain of chemical and thermal decomposition reactions. During the process, sludge undergoes a series of complex physical and chemical changes, starting with water removal. Dried MSS is then pyrolysed. The resulting volatile pyrolysis products and char undergo further reactions for the production of permanent gases. Basically, the process of gasification mainly burns out the solid wastes to form clear combustible gas having high energy value (Dogru et al. 2002). Moreover; compared to conventional gasification integrated gasification is more encouraged mainly due to intensive use of it for fuel cell (Maniatis 1999).

In the context of integrated gasification steam gasification and plasma gasification which are quite famous because of the production of high calorific value hydrogen, further several types of catalyst like K2CO3 are used in the process for forming ash-free coal char, which has great utility [7] (Table 2).

5 Discussions and Analysis

This paper mainly consists of a detailed review of different thermal, chemical and biochemical processes of municipal sewage sludge mainly focussing on pyrolysis and gasification. How different organic matters of sludge can be treated and how they can be transformed from Waste to resource is discussed over here. The review states that nowadays it’s meaningless to consider MSS as waste and stated how efficiently energy can be produced from it. Mainly the process of Pyrolysis and Gasification is discussed over here. Different effective temperature pressure, reactors for these processes are discussed. The characteristics of the effluent are also stated. Along with this the states of pyrolysis and gasification in different European and Asiatic countries are discussed briefly, including India [25–44].

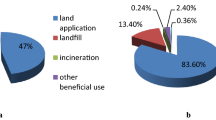

From the detailed literature study, it is found that, in several EU countries, sludge is greatly used as an agricultural manure, specially in small towns and in countrysides where the small industrial base can be localised using sludge. (Praspaliauskas et al. 2017). Latest thermal treatment techniques of sludge like incineration, pyrolysis, gasification, co-combustion, etc. are increasing day by day. These techniques are mainly used in cities or in many places are still under experimental phase. Incineration is one of the most rapidly developing sewage sludge treatment processes. It is widely used in the European countries like Germany, the United Kingdom and Denmark. Co-incineration is in huge practise in the Netherlands, France, Belgium and Czech. On the other hand, gasification is a much promising sludge disposal method (Kelessidis et al. 2012). Co-incineration is also a widely used thermal treatment technology where sewage sludge is incinerated along with other fuels. Some co-incinerated plants are cited in the cities like Klaipeda, Kaunas, Vilnius, etc. in Northern Europe. However, gasification and pyrolysis are still in an experimental phase and are in pilot scale. These processes are mainly practised in Southern part of Europe. Italy is the leading country for such studies; again, Germany and France are also some upcoming countries for this projects (Pyrolysis and Gasification, A. V.Bridgwater, Commission of the European Communities).

Several studies reviewed that in Asiatic countries, municipal sewage waste can be reduced by up to 90% by producing electricity from it. Several plants are successfully running by the energy produced from sludge waste through the process of Incineration and Combustion. Among the thermochemical process, incineration is mostly used for municipal sewage sludge treatment in different Asiatic countries mainly in Singapore and China. Other than incineration, biological treatment like aerobic and anaerobic digestion is also famous in Asiatic countries. Pyrolysis and gasification, on the other hand, are mainly under experimental condition over here. Further few pilot plants are in progress in several Asiatic countries (Economics 26800, Prof. Tolley & Berry).

In India, the objective of MSS treatment plant is to treat waste, reduce its volume and generate energy and electricity from it. This takes the process towards a greener approach. In India, there are several such treatment plants and several projects are studied to be under pipeline. In India, there are a total of 48 waste-to-energy plants present including 32 proposed, 4 under construction and 11 are in operation. Few plants are shut down due to some technical problems in the plant. More than thermal processes, biochemical degradation of sewage sludge is in practise. One reason behind this wide usage could be the high organic content in Indian municipal sewage waste (MSW) due to the presence of food waste. One of the upcoming plant presently under construction is the Gazipur Waste to Energy plant. India, being a multistate country, has different raw material availability in different areas. 18 plants in the country are dependent on MSW for power generation whereas 15 plants use biomass like recently a plant is proposed in South Andaman. There are three plants in Delhi and they all use MSW as raw material. Currently, Delhi is producing 16 MW/day power from waste and will be able to produce an additional 25 MW/day after the completion of construction of two more projects. Gujarat is producing 3.5 MW/day power from waste. Chhattisgarh has seven proposed projects that will be able to produce 119 MW/day of electricity in the near future (Research Article, [2]).

Lastly, this review thoroughly gives a description of different thermal processes together with some future scope. This paper will be really helpful for different municipality engineers and industrialist and for those aspirants who have research interest in this zone. Again, the work proposes some future scope like cost-estimation for these processes in detail. Anyone can further research on co-process or the biological process stated above. Other opportunities can be to find the life cycle assessment (LCA) of each of these processes or can find a detailed survey of condition of these processes in a particular country or zone.

6 Conclusion

The research work mainly contains a detailed survey of pyrolysis and gasification, two latest and efficient process of sludge treatment. Their mechanism, temperature as well as the characteristics of effluent produced in this process are given here. Not only these two but different other methods of sludge treatment are stated here. State of use of these processes in different countries in Europe and Asia including India is given.

References

Zaman AU (2010) Comparative study of municipal solid waste treatment technologies using life cycle assessment method. Int J Environ Sci Technol 7(2):225–234

Jain P, Handa K, Paul A (2014) Studies on waste-to-energy technologies in India and a detailed study of waste-to-energy plants in Delhi. Int J Adv Res 2(1):109–116

Samolada MC, Zabaniotou AA (2014) Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste Manag 34(2):411–420

Ruiz-Gómez N, Quispe V, Ábrego J, Atienza-Martínez M, Murillo MB, Gea G (2017) Co-pyrolysis of sewage sludge and manure. Waste Manag 59:211–221

Budych-Gorzna M, Smoczynski M, Oleskowicz-Popiel P (2016) Enhancement of biogas production at the municipal wastewater treatment plant by co-digestion with poultry industry waste. Appl Energy 161:387–394

Sanlisoy A, Carpinlioglu MO (2017) A review on plasma gasification for solid waste disposal. Int J Hydrogen Energy 42(2):1361–1365

Wu X, Wang J (2017) K2 CO3-catalyzed steam gasification of ash-free coal char in a pressurized and vertically blown reactor. Influence of pressure on gasification rate and gas composition. Fuel Process Technol 159:9–18

Abuşoğlu A, Özahi E, Kutlar Aİ, Al-jaf H (2017) Life cycle assessment (LCA) of digested sewage sludge incineration for heat and power production. J Clean Prod 142:1684–1692

Borowski S (2015) Temperature-phased anaerobic digestion of the hydromechanically separated organic fraction of municipal solid waste with sewage sludge. Int Biodeterior Biodegradation 105:106–113

Cao Y, Pawłowski A (2013) Life cycle assessment of two emerging sewage sludge-to-energy systems: evaluating energy and greenhouse gas emissions implications. Bioresour Technol 127:81–91

Di Fraia S, Massarotti N, Vanoli L, Costa M (2016) Thermo-economic analysis of a novel cogeneration system for sewage sludge treatment. Energy 115:1560–1571

Emami-Meibodi M, Parsaeian MR, Amraei R, Banaei M, Anvari F, Tahami SMR,… & Mostafavi SJ (2016) An experimental investigation of wastewater treatment using electron beam irradiation. Radiat Phys Chem 125:82–87

Fezzani B, Cheikh RB (2009) Extension of the anaerobic digestion model No. 1 (ADM1) to include phenol compounds biodegradation processes for simulating the anaerobic co-digestion of olive mill wastes at mesophilic temperature. J Hazard Mater 172(2):1430–1438

Gulyurtlu I, Boavida D, Abelha P, Lopes MH, Cabrita I (2005) Co-combustion of coal and meat and bone meal. Fuel 84(17):2137–2148

Ibrahimoglu B, Cucen A, Yilmazoglu MZ (2017) Numerical modeling of a downdraft plasma gasification reactor. Int J Hydrogen Energy 42(4):2583–2591

Johari K, Saman N, Song ST, Chin CS, Kong H, Mat H (2016) Adsorption enhancement of elemental mercury by various surface modified coconut husk as eco-friendly low-cost adsorbents. Int Biodeterior Biodegradation 109:45–52

Khalil AE, Gupta AK (2016) Fuel property effects on distributed combustion. Fuel 171:116–124

Kim D, Amy GL, Karanfil T (2015) Disinfection by-product formation during seawater desalination: a review. Water Res 81:343–355

Kwon EE, Yi H, Kwon HH (2013) Thermo-chemical process with sewage sludge by using CO2. J Environ Manag 128:435–440

Lutpi NA, Jahim JM, Mumtaz T, Harun S, Abdul PM (2016) Batch and continuous thermophilic hydrogen fermentation of sucrose using anaerobic sludge from palm oil mill effluent via immobilisation technique. Process Biochem 51(2):297–307

Lin T, Yu S, Chen W (2016) Occurrence, removal and risk assessment of pharmaceutical and personal care products (PPCPs) in an advanced drinking water treatment plant (ADWTP) around Taihu Lake in China. Chemosphere 152:1–9

Li K, Wang X, Wang J, Zhang J (2015) Benefits from additives and xylanase during enzymatic hydrolysis of bamboo shoot and mature bamboo. Biores Technol 192:424–431

Mandal S, Mahapatra SS, Patel RK (2015) Neuro fuzzy approach for arsenic (III) and chromium (VI) removal from water. J Water Process Eng 5:58–75

Maragkaki AE, Fountoulakis M, Gypakis A, Kyriakou A, Lasaridi K, Manios T (2017) Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag 59:362–370

Martins MNC, de Souza VV, da Silva Souza T (2016) Cytotoxic, genotoxic and mutagenic effects of sewage sludge on Allium cepa. Chemosphere 148:481–486

Magureanu M, Mandache NB, Parvulescu VI (2015) Degradation of pharmaceutical compounds in water by non-thermal plasma treatment. Water Res 81:124–136

McCrea M, Tan TK, Ting HH, Zuo X (2009) A cost-benefit analysis of different waste-to-energy technologies for the management of municipal solid waste in Singapore

Nowicki L, Markowski M (2015) Gasification of pyrolysis chars from sewage sludge. Fuel 143:476–483

Motlagh AM, Bhattacharjee AS, Goel R (2015) Microbiological study of bacteriophage induction in the presence of chemical stress factors in enhanced biological phosphorus removal (EBPR). Water Res 81:1–14

Niu S, Chen M, Li Y, Xue F (2016) Evaluation on the oxy-fuel combustion behavior of dried sewage sludge. Fuel 178:129–138

Orgill JJ, Atiyeh HK, Devarapalli M, Phillips JR, Lewis RS, Huhnke RL (2013) A comparison of mass transfer coefficients between trickle-bed, hollow fiber membrane and stirred tank reactors. Bioresour Technol 133:340–346

Pei J, Yao H, Wang H, Ren J, Yu X (2016) Comparison of ozone and thermal hydrolysis combined with anaerobic digestion for municipal and pharmaceutical waste sludge with tetracycline resistance genes. Water Res 99:122–128

Pala LPR, Wang Q, Kolb G, Hessel V (2017) Steam gasification of biomass with subsequent syngas adjustment using shift reaction for syngas production: an Aspen Plus model. Renew Energy 101:484–492

Rivera-Utrilla J, Sánchez-Polo M, Ferro-García MÁ, Prados-Joya G, Ocampo-Pérez R (2013) Pharmaceuticals as emerging contaminants and their removal from water. A Rev Chemosphere 93(7):1268–1287

Scarlat N, Motola V, Dallemand JF, Monforti-Ferrario F, Mofor L (2015) Evaluation of energy potential of municipal solid waste from African urban areas. Renew Sust Energy Rev 50:1269–1286

Shen Y, Linville JL, Urgun-Demirtas M, Mintz MM, Snyder SW (2015) An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: challenges and opportunities towards energy-neutral WWTPs. Renew Sustain Energy Rev 50:346–362

Wang ZH, Zhang K, Li Y, He Y, Kuang M, Li Q, Cen KF (2016) Gasification characteristics of different rank coals at H2O and CO2 atmospheres. J Anal Appl Pyrol 122:76–83

Wang J, Chu L (2016) Irradiation treatment of pharmaceutical and personal care products (PPCPs) in water and wastewater: an overview. Radiat Phys Chem 125:56–64

Xiao Y, Xu S, Tursun Y, Wang C, Wang G (2017) Catalytic steam gasification of lignite for hydrogen-rich gas production in a decoupled triple bed reaction system. Fuel 189:57–65

Yu H, Cao W (2016) Assessment of pharmaceutical and personal care products (PPCPs) of Dalong Lake in Xuzhou by concentration monitoring and bio-effects monitoring process. Environ Toxicol Pharmacol 43:209–215

Zhang XY, Chen MQ, Huang YW, Xue F (2016) Isothermal hot air drying behavior of municipal sewage sludge briquettes coupled with lignite additive. Fuel 171:108–115

Zhao Y, Xing W, Lu W, Zhang X, Christensen TH (2012) Environmental impact assessment of the incineration of municipal solid waste with auxiliary coal in China. Waste Manag 32(10):1989–1998

Acknowledgements

The authors would like to show her gratitude towards Prof. Sadhan Kumar Ghosh for his support and guidance during the execution of the review work and also towards Department of Chemical Engineering Jadavpur University, Centre for Quality Management, Jadavpur University and International Society of Waste Management, Air and Water (ISWMAW) for their support and help.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Bhattacharyya, S., Ghosh, S.K. (2019). A Review on Various Thermochemical Technologies for Resource Recovery from Sewage Sludge. In: Ghosh, S. (eds) Waste Valorisation and Recycling. Springer, Singapore. https://doi.org/10.1007/978-981-13-2784-1_1

Download citation

DOI: https://doi.org/10.1007/978-981-13-2784-1_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2783-4

Online ISBN: 978-981-13-2784-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)