Abstract

Designing an adequate municipal solid waste (MSW) system has proven a complex task in recent years due to the unpredictable combination of increased waste categories and new technological developments. Finding the optimal system for selecting such a suitable combination for a certain technology is a persisting issue. Hence, the development of a quantitative and applicable evaluation methodology is urgent. This paper develops an MSW management system, namely, Best Available System (BAS) methodology, which provides analysis from both environmental load and economic evaluation perspectives. Generally, it provides assessments from Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) viewpoints and aims to propose the approach of a best available system. This study develops the BAS methodology concept, offers an optimal methodology of waste management evaluation system, builds databases, and applies the proposed methodology in a certain Japanese municipality.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Waste management

- Life cycle assessment

- Life cycle costing

- Best available system (BAS)

- Municipal solid waste (MSW)

- Incineration

- Melting

1 Introduction

Concern over waste management problems has heightened lately owing to the escalation of environmental issues. Meanwhile, the diversity of waste continues to increase due to the expansion of economic and social activities and associated lifestyle changes. Simultaneously, it is a trend that municipal solid waste (MSW) systems are becoming more diverse and better-equipped due to pressures owing to maintaining pressures from final disposal site, reducing dioxin, and conducting 3Rs (Reduce, Reuse, Recycle) policies [1].

Under these circumstances, and with the intention of encouraging the development of a recycling society, revising the MSW system is an urgent task from both environmental load and economic evaluation perspectives [2]. Recently, there are various Life Cycle Assessment (LCA) researches in the MSW system field. For instance, Tabata et al. [3] investigated the LCA efficiency based on statistical data of incineration facilities. And, they also offered integrated environmental influence evaluation of waste treatment scenario through DTT (Distance-to-Target) method [4]. Furthermore, Nakatani et al. [5] conducted integrated assessment based on cost-benefit analysis [6]. Meanwhile, Amano et al. studied on LCA evaluation of MWS system from GHG emissions and landfill disposal perspective. Besides, Matsuto et al. [7] developed a practical calculation program H-IWM, an Excel version, for simulating municipal waste treatment planning from treatment amount, cost, and energy consumption view. Other researchers analyzed waste energy recycling society using LCA and discussed the advantages and disadvantages of waste management regional expansion.

However, in the previous studies, both economic and environmental simulations with multiple cases (e.g., incineration, gasification melting, power generator, ash melting, fly ash recycle, crushing process) are hardly found, because plant makers’ LCI databases are insufficient and literatures are mainly focusing on a single incineration plant, and it is seemingly found to be competent categories of technologies. In this research, we develop a LCI database through collecting data from 14 representative plant makers that occupy most market share in Japan and investigate on their intermediate process plants (e.g., incinerator, power generator melting, fly ash recycle).

Meanwhile, we develop a more accurate management system targeting MSW system through applying this database. In details, MSW management system, namely, Best Available System (BAS) methodology, is developed based on LCA (Life Cycle Assessment) and LCC (Life Cycle Cost) analysis. This BAS methodology aims to improve and sophisticate the MSW recycling system and provides quantitative indicators for evaluations from both environmental load and economic evaluation perspectives.

In the LCA analysis, we apply ELP (environmental load point), an index previously developed by the authors, which solves the single index issues of previous studies. And different with other integrated method, ELP reflects the changes of human environmental awareness with changes of time.

2 Concept of BAS Methodology

It has been necessary for municipalities to conduct quantitative environmental load evaluations and cost estimation when establishing waste treatment practices. Hence, the BAS methodology focuses on MSW agencies and provides analysis from their perspective by applying LCA and LCC. Meanwhile, it evaluates waste treatments (including collection and recycling, midterm treatment, transport, final disposal, and use) and the recycling system.

The environmental load evaluation is calculated using Technology Life Cycle Assessment (TLCA), which applies for technology and evaluates treatment and recycle based on LCA method. The TLCA is a quantitative assessment of input and output to the environmental load carried by humans and ecosystems. For instance, the assessment involves quantifying not only the recycling and waste management done by the plant but accounts for environmentally important metrics of the plant’s actual equipment as well. The BAS has the following advantages:

-

1.

It evaluates a series of MSW processes that range from collection and recycling to final use and disposal treatments.

-

2.

The environmental load evaluation database of incineration and melting (e.g., input and output amounts at different treatment scales, power generation efficiency) is compiled based on the plant maker’s design and estimated value.

-

3.

It enables calculation of indices for recycling rate, energy expended in the recycling process, and final disposal treatment for different evaluation scenarios.

-

4.

The BAS methodology makes it possible to develop the ELP (environmental load point), introduced by the authors in a previous study, into a more comprehensive system [8].

3 Outline of ELP Integrated Index

In the LCA field, expressing the impact category within a single index is called integrated evaluation [9]. The authors developed this integrated evaluation method based on the Panel Method in the previous study. The Panel Method suggests environmental improvement priorities and provides a comparison of the suitability of different decisions. The ELP is developed by setting up nine impact categories (e.g., energy depletion and climate change) and making weight values for each category by applying the survey results [10].

As shown in Table 8.1, there are nine impact categories, and analysis of their characteristics is conducted in each by applying weight coefficients, sorted by importance of CO2, NOx, BOD, heavy metal, and so on. This allows us to estimate the index of each category and thereby conclude the degree of importance of each. The ELP integrated index is calculated by multiplying the outcome of the characteristic analysis with the degree of importance [11]. The formula is shown in Fig. 8.1.

ELP integrated index formula [12]

In this method, assessing product pairs with different functional units such as automobiles and PET bottles becomes efficient.

4 Methodology of BAS

4.1 Evaluation Flow

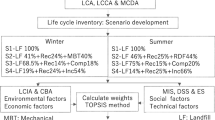

The BAS methodology integrates waste components and classifies collections based on the current state of the evaluation system. And it contains the collection, midterm treatment, and final disposal (recycle); see Fig. 8.2.

Meanwhile, the BAS methodology creates databases so as to categorize MSW systems. It also sets default values based on common designs and anticipated value from Japanese plant makers in case measured data is insufficient when evaluating the environmental load data (input and output). BAS methodology provides an evaluation outcome including cost, ELP integrated index, and specific index (e.g., GHG emissions, landfill reduction amount, energy consumption, SOx, and NOx). Besides, it offers comparable analysis among various cases through case studies. Furthermore, the BAS proposes recommendations for MSW system improvement and judgment of new system introduction based on users’ financial situation and purposes.

4.2 Waste Components and Chemical Elements Setting

After setting the types and components of waste and inputting data of a target city, the BAS methodology enables us to calculate the amount of air supply for combustion, gas emission from combustion, heating value, and power generation from incineration treatment. In this method, heating value means low calorific value, which is the same as regular heat load calculation. Measuring data or using a similar value is required when applying the Steuer formula (8.1 for calculating combustibles’ high heating value based on chemical element analysis [13]. Meanwhile, the low heating value is calculated using the following formula (8.2):

-

Hh: Waste high heating value (kJ/kg)

-

Hl: Waste low heating value (kJ/kg)

-

h: Hydrogen content in Wetness waste (%)

-

W: Moisture content in Wetness waste (%)

-

o, h, c, s: Weight in combustible material (%)

The BAS develops a database of waste in 59 categories to cope with classifications in different municipalities. Hence, it is able to evaluate and set detailed waste components. For those municipalities whose data is insufficient, this study develops a default value database (Table 8.2) [6].

4.3 Building LCA Databases

Midterm and final disposal treatments (recycled) are shown in Fig. 8.3. The input, output, and cost are added, and environmental load is calculated using the ELP methodology. Contrasting with the ELP method, this research enables us to illustrate individual indices such as CO2 emissions, primary energy consumption, final disposal amounts, etc.

This research participated in Osaka Science & Technology Center waste treatment technology LCA workshop, which compiles LCA and LCC databases based on MSW information collected from member companies. This research covers almost all plant categories through applying data (facility design and plan values) collected from 14 major Japanese MSW treatment plant designers. Nowadays in Japan, the number of waste incineration treatment facility has reached a peak, and there is a decreasing trend currently. Constructions of incineration facilities in large scale have started after conducting wide-area waste treatment plan (dioxins control countermeasures, 1997). In this study, we select incineration facility data between 2000 and 2006 considering the machines’ working life. The evaluable technologies and building characteristics used in the BAS methodology are shown in Table 8.3.

As an example of a common MSW treatment, incineration technology’s database building and default value setting will be described in detail.

4.3.1 Building a Database of Incineration Treatment and Setting Default Values

We have collected LCA data (1997–2006) from plant designers about incineration treatment, stoker-type incineration, ash melting, and gasification melting. The default values of incineration treatment are created based on the average values of these processes. Regarding the default values of stoker incineration and gasification melting, we assume waste input is 600 t/day and the heating value is 2400 kcal/kg. Meanwhile, the plant electricity consumption and fuel subsidy are decided by the waste input per ton. Emission gas treatment medicine and relative input amounts are decided by the type of treatments. Furthermore, the calculation of ash melting follows the ratio that the incineration’s main ash is composed of 90% total ash, while incineration ash accounts for 10%. Details of incineration LCI defaults are shown in Table 8.4.

4.3.2 Building Database of Incineration Power Generation and Setting Default Values

To assess the power generation of incinerated waste, the survey “analysis of waste incineration facilities’ power generation efficiency” is conducted among plant designers. The LCI database is created based on this survey and the incineration power generation value. Efficiency is analyzed via relationships among treatment scale, steam conditions, and input heating values. For the 12 cases in Table 8.5, we conducted a survey about waste power generation. The outcome of the survey is presented in the database (excerpt) and shown in Table 8.6.

Based on the above survey, we analyzed the influence of treatment scale, steam conditions, and input heating values of waste power generation efficiency. Regarding treatment scale, efficiency will increase by 3% if the facility is 600 t/day, and by 4% if. Regarding the steam conditions, it was found that the efficiency will be significantly improved under high temperature and high pressure. For instance, the efficiency will be 10–15% if under 300 °C × 30 ata and 14–21% if under 500 × 100 ata. The survey outcome also shows that the efficiency will drop sharply when the treatment scale is reduced.

The BAS methodology enables the calculation of the proportion interpolating according to the treatment scale and heating value of input waste.

4.3.3 Building Database of Emission Gas Treatment and Setting Default Value

A suitable emitted gas treatment is necessary because the gas emitted accounts for more than 50% of the environmental load during MSW’s incineration process. Utility and cost databases were created based on a survey called “Emitted gas treatment and cost efficiency” about NOx, SOx, HCl, and DXN treatments. The investigated treatment is illustrated in Table 8.7. As a sample, the outcome of NOx treatment (extract) is shown in Table 8.8.

This study found that facility fees and initial cost of denitration catalyst and wet smoke gas cleaning methods increase sharply compared with urea blowing and slaked lime blowing methods. Regarding running cost, NOx and HCl increase 3–4 times.

5 Application of BAS Methodology in Municipalities

5.1 Evaluation Background

We conducted a case study and applied BAS methodology in municipality city A. The waste (excluding resource waste) treatments are conducted by an incineration power generation facility and a crushing facility. The incineration ash emitted from the incineration facility and incombustible residue from the crushing treatment facility were treated by landfilling in a final disposal site outside the city. In this research, we assess the current situation of the waste treatment system in city A and provide improvement proposals, which range from evaluating its collection (recycling) to its final disposal (use). In cases where data is insufficient to perform analyses, we apply BAS’s default values.

5.2 Evaluation of Current Treatment

Table 8.9 summarizes the incineration facilities in city A. Figure 8.4 shows the calculation outcome of ELP based on the current treatment cost of different processes. It illustrates that the incineration power generation process is the process most expected to go down in cost as it has the highest cost and largest ELP. We recommend improving the level of detail in the classification of kitchen garbage. Besides, the final disposal treatment (landfill) of incineration ash also has a high cost and ELP. Hence, we suggest that city A introduce and apply melting technology to reduce the amount of incineration ash produced.

5.3 Case Study

The hypothetical scenarios in each case and their parameters are shown in Fig. 8.5. Through applying the BAS methodology, the ELP and cost database of input and output amounts for treatment processes are able to inform a variety of improvement scenarios. In this study, using kitchen garbage as an example waste type, we attempt to create a scenario following an incineration ash reduction policy, which is based on incineration output reduction perspectives and involves introduction of melting technology. Regarding the cost, we calculate it based on treatment expense (see Table 8.10). And about ELP, we calculate it based on BAS methodology databases.

The cost and ELP outcomes of each case are shown in Fig. 8.6. About the cost, it becomes larger than current situation (case 1) in cases 2–6 due to the introduction of ash melting and change of gasification melting. And about the fly ash recycle, it is found that there is almost no expense variation due to the little recycle amount. And, we also found that the cost is larger in case 6 than that of case 1, which is because the expense increases with recycling and bio-gasification treatment. However, the ELP in case 6 decreases significantly, which is smaller than that in cases 2–5 due to the decrease of final disposal, ash technology, and incineration amount. Hence, case 6 is the most effective one for ELP reduction if conducting bio-gasification, but the cost also increases relatively.

The ELP relative reduction effectiveness that represents ELP mitigation amount in step with increasing each cost unit is illustrated in Table 8.11. And we found out that ELP reduction effectiveness of CASE 5 is the highest.

BAS is an integrated evaluation method that analyzes the cost and ELP, and it also provides assessment value of material recycling, energy recycling, CO2 emission, and final disposal amount. And comparisons among cases are shown in Table 8.12.

The material recycling is the process that collects iron, metal, and melting slag that come from facilities like crush treatment and direct recycling. Moreover, a trend of relation is also found from the outcome. In cases 2–6, the results demonstrate that the final disposal amounts decrease while the CO2 emissions increase. And the scenario varied according to the preference for policies between landfill and CO2 reduction. In this study, we are able to analyze and assess the trade-off factors by applying the BAS based on ELP, and it is proofed that the ELPs of cases 2–6 are more effective and integrated than the current situation (case 1).

However, the cost has to be increased in each scenario. Hence, it is necessary to conduct deep consideration of each system based on the municipal financial situations. And, corporations among neighboring municipalities are recommended so as to enlarge the scale merit and reduce the economic burden.

6 Summary

The development of evaluation tools for MSD treatment systems’ ELP and cost and verification of their applicability is summarized in the following points:

-

1.

We developed a Best Available System (BAS) methodology using LCA and LCC.

-

2.

By applying the BAS in a municipality, we found that it is able to assess ELP and cost of current MSW treatments. Furthermore, the BAS’ applicability is verified through a case study.

Moreover, through the case study, we found that it is necessary to understand ELP and cost of treatment processes so as to offer detailed improvement proposals for municipalities. Regarding ELP reduction, this study indicates that the cost will increase when the ELP decreases, which is conceptually comprehensible. However, this research provides quantitative data and emphasizes the significance of assessing the importance of recycling in more nuanced ways. Besides, with strained municipal finances, reducing the ELP and cost is a crucial issue. Hence, it is urgent and necessary to consider applying the BAS methodology so as to achieve the minimum cost and a society where recycling is the norm. We expect this debate to be resolved soon and the BAS methodology be selected among a large number of LCA evaluation approaches.

References

Onoda H. Life cycle assessment of incineration ash recycling and treatment methods. J Waste Manag Assoc. 2010;63:43–434. Available in Japanese.

Onoda H. Recycling society from LCA view, The 23rd National Congress for Environmental Studies Conference paper: 47–52, Available in Japanese. 2009.

Tabata T, Li Y, Hishinuma T. Study on effectiveness of simplified LCA using statistical data: about MSW incineration facilities. J Jpn Waste Manag. 2011;64(303):509–19. Available in Japanese.

Tabata T, Ihara T, Nakazawa H, Genchi Y. An application of LCA methodology for assessment and decision-making in design of municipal solid waste management system. J Life Cycle Assess Jpn. 2009;5(1):54–76. Available in Japanese.

Nakatani J, Aramaki T, Hanaki K. Integrated assessment based on cost-benefit analysis considering the preferences for multi-aspect impacts. J Environ Sci. 2007;20(6):435–48. Available in Japanese.

Amano K, Sowa T. Study on comprehensive evaluation of municipal solid waste disposal systems focused on combination of intermediate processing. J Jpn Soc Civil Eng G. 2007;63(4):391–402. Available in Japanese.

Matsuto T. Analysis, plan and evaluation of urban waste treatment system: material flow and LCA plan program. Tokyo: Gihodo Shuppan; 2005. Available in Japanese.

Nagata K, Nohtomi M, Sekiai H, Okachi T, Ohashi Y, Osada M. Study on the environment load assessment techniques for the effective use of water resources. Soc Mech Eng. 2003;3:406–9.

ISO 14040. Environmental management—life cycle assessment—principles and framework. ISO 14040:2006. Geneva, Switzerland: International Organization for Standardization; 2006.

Pandyaswargo AH, Onoda H, Nagata K. Integrated LCA for solid waste management in developing country. Proc EcoDes 2011 Int Symp; 2011. https://doi.org/10.1007/978-94-007-3010-6_232.

Shimizu H, Nagata K. Integrated life cycle assessment (LCA) approach for printing service by using environmental load point (ELP) method. Soc Print Sci Technol. 2010;47:177–85.

Hu H, Onoda H, Nagata K. Life cycle assessment of municipal waste management processes based on real data. J Waste Manag Assoc. 2011;64:83–9. Available in Japanese.

New Energy and Industrial Technology Development Organization. Introduction of waste power generation manual (edited version), p. 300; 2002.

Acknowledgment

We sincerely thank the corporations of Osaka Science & Technology Center waste treatment technology LCA work shop and its members. We also would like to express our gratitude to Ministry of the Environment, who provide grants-in-aid for scientific research expenses.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Hu, H., Zhao, R., Omura, K., Onoda, H. (2019). Development of a Municipal Waste Management System from Environmental and Economic Evaluation Perspectives: A Best Available System Methodology. In: Hu, A., Matsumoto, M., Kuo, T., Smith, S. (eds) Technologies and Eco-innovation towards Sustainability II. Springer, Singapore. https://doi.org/10.1007/978-981-13-1196-3_8

Download citation

DOI: https://doi.org/10.1007/978-981-13-1196-3_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1195-6

Online ISBN: 978-981-13-1196-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)