Abstract

High strength concrete (HSC) is predominantly used in high-rise reinforced concrete buildings. While excellent from strength point of view at room temperature, HSC is known to be prone to spalling, when exposed to high temperatures (e.g., in case of a fire). Fire resistance evaluated from building codes (CEN in Design of concrete structures. Part 1–2: general rules—structural fire design, Eurocode-2, Brussels, 2004; Bureau of Indian Standards in Indian code of practice for fire safety of buildings (General): details of construction code of practice. IS-1641, New Delhi, 1989) [1, 2] and simulation-based studies typically does not consider the effects of spalling. To alleviate these difficulties, a 2-D hydrothermal model has been developed for predicting the extent of spalling in HSC. The numerical model evaluates pore pressure inside the concrete as a function of time using the laws of thermodynamics. Spalling is said to occur when the pore pressure built-up within concrete exceeds its tensile strength. The model depends on several parameters such as permeability, initial moisture content, and thermomechanical properties of concrete. All of these parameters are considered by the model through a two-way coupling between the pore pressure analysis and thermal analysis, both implemented using the finite element method. Validity of the numerical example is established by comparing the spalling predictions obtained from the numerical model against standard experiments available in the literature. Parametric studies have also been performed using the numerical model to quantify the effects of model parameters such as permeability, grade of concrete, and type of fire scenario on the prediction of spalling.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Reinforced concrete structures are extensively utilized as load-bearing mechanisms in residential, office, and industrial buildings. In addition to the usual service loads, these buildings carry the risk of being exposed to fire during their design life. Hence, quantification of their response against fire is vital. In recent years, use of high strength concrete in structural engineering applications like high-rise buildings, bridges, etc. has increased significantly. This is mainly due to economic and architectural advantages associated with HSC compared to conventional normal strength concrete (NSC). For performance-based design of these HSC structures, understanding the behavior of HSC at elevated temperatures is vital. Concrete structures, in general, exhibit good fire resistance compared to steel and timber structures. However, they are prone to explosive spalling which enhances the risk of structural collapse during fire. Previous studies on spalling in concrete structures [3, 4] revealed that HSC structures are more prone to spalling compared to NSC when subjected to rapid heating. HSC is characterized by high density, high strength, and low permeability and hence, it is more susceptible to spalling at elevated temperatures. Spalling occurs due to the accumulation of built-up pore pressure inside concrete. Low permeability and high density of HSC can cause internal pore pressures of as high as 6 MPa. Such internal vapor pressures can be critical for materials like concrete which possess low tensile strength and eventually result in explosive spalling at elevated temperatures.

Fire-induced spalling is a key physical behavior which needs to be incorporated in coupled thermomechanical analysis of concrete structures, especially for HSC, primarily because spalling can cause significant reduction in the cross section/thickness of the structural member which, in turn, accelerates the heat transfer to the embedded steel rebars and eventually affects the load carrying capacity of the structure. Experimental investigations as reported in the literature [3, 4] infer contradictory picture of spalling mechanism as well as spalling occurrences. Many research investigations reported explosive spalling during laboratory fire tests as well as full-scale tests on HSC structures [5]. At the same time, there were tests on HSC where almost no spalling has been reported [5]. The main reason for this phenomenon is that spalling is dependent on several interdependent physical parameters. In terms of spalling mechanisms, in-built pore pressure based and thermal dilatation based spalling mechanisms are most widely accepted. Present study focuses mainly on in-built pore pressure based spalling mechanism.

A very limited number of numerical models [6, 7] are available to quantify the pore pressure across a concrete section at elevated temperatures. Aforementioned numerical models perform combined 3-D heat and mass transfer analysis in concrete structures and are computationally intensive. Also, to accurately capture the spalling phenomenon using the aforementioned numerical models, input parameters like mass of liquid, mass of vapor, and material permeability tensor coupled with material stiffness tensor should be known at elevated temperatures. However, some of these parameters are not accurately defined even at room temperatures. To alleviate these difficulties, few researchers suggested simplified analytical methods to predict spalling in concrete structures. Kodur et al. [8] proposed temperature-based spalling criteria. Their spalling criteria had been developed from the experimental observations of full-scale fire tests on HSC structures. However, these simplified analytical methods cannot be relied upon due to the uncertainties pertaining in spalling monitoring system. Also, the effects of parameters like grade of concrete, permeability, porosity, etc. are not accounted for in the aforementioned analytical method. In terms of codal provisions, very few guidelines are available regarding spalling in concrete structures without actually integrating it into the design philosophy. Eurocode-2 [1] provides simplified guidelines to prevent spalling in concrete structures. It suggests that concrete structures with moisture content less than 3% are not prone to spalling. However, it ignores the effects of permeability and strength of concrete which can accelerate spalling phenomenon even at low moisture contents. ACI 216.1 [9] suggests that spalling can be avoided with the aid of polypropylene fibers in the design mix. Abovementioned guidelines are developed on the basis of laboratory tests on small samples without accounting for built-up pore pressure due to moisture migration. Also, abovementioned laboratory test uses standard fire curves and does not account for design fire curves. The lack of reasonably accurate spalling prediction framework is the principle reason for ignoring spalling effects in building codes as well as in typical thermomechanical analysis frameworks. Hence, a reasonably accurate, computationally efficient framework is required for spalling prediction in concrete structures.

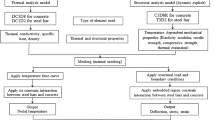

Pore pressure inside concrete sections can be computed in a computationally efficient manner using a pore pressure analysis coupled to a heat transfer analysis. The hydrothermal model is essentially derived from the laws of thermodynamics and structural mechanics. Dwaikat and Kodur [10] developed a 1-D hydrothermal model for pore pressure computations inside concrete structures utilizing laws of thermodynamics and validated against standard experiments. However, parameters like critical state of water and permeability of concrete were not addressed properly. In the present study, utilizing the laws of thermodynamics, a-2D coupled heat transfer pore pressure analysis framework is developed for spalling prediction in concrete structures. Due consideration is given to critical state of water while computing the Bazant’s isotherms [11], which are required for pore pressure analysis. In case of permeability, a non-uniform permeability suggested by Gawin et al. [6] is followed for realistic structures utilizing a thermomechanical solver developed by Prakash and Gaurav [12]. Utilizing the developed framework, validation studies are performed for standard experiments available in the literature. Also, parametric studies are demonstrated to quantify the effect of permeability and grade of concrete on the extent of explosive spalling in HSC structures.

2 Thermal Analysis

3 Pore Pressure Analysis

To quantify the extent of spalling in concrete structures, a 2-D two-way coupled pore pressure and heat transfer analysis needs to be performed. Two-way coupling between thermal and pore pressure analysis is required to cater for cross-sectional reduction due to spalling and is accounted for in the subsequent heat transfer analysis. In the present study, the following assumptions are considered while performing the pore pressure analysis.

-

Concrete is assumed to be an isotropic continuum medium.

-

Water vapor is treated as an ideal gas with due consideration to the critical state of water in the numerical model.

-

Mass transport of liquid water is ignored as permeability of liquid water in concrete is much smaller compared to that of water vapor.

-

Mass transport of water vapor through concrete is modeled using Darcy’s law.

-

Spalling is assumed to occur when the built-up pore pressure exceeds the temperature-dependent tensile strength of concrete.

Based on the abovementioned assumptions, 2-D pore pressure inside concrete is modeled by

where \( k_{\text{p}} = m_{\text{v}} \frac{{\kappa_{\text{t}} }}{\mu } \), \( A = \left[ {\left( {1 - \frac{{m_{\text{v}} }}{{V_{\text{v}} \rho_{\text{l}} }}} \right)\frac{{dm_{\text{l}} }}{{dP_{\text{v}} }} + \frac{{V_{\text{v}} \zeta }}{RT}} \right] \), Pv is the pore pressure, μ is the coefficient of dynamic viscosity, mv is the mass of water vapor, Vv is the volume of water vapor, ρl is the density of liquid water, ζ is the molar mass of water, R is the ideal gas constant, κt is the coefficient of intrinsic permeability, and Qp is the mass flow rate of water vapor computed using Bazant’s isotherms and can be found in [10, 11]. The initial condition for above vapor diffusion model is given by

where Pvo is the initial pore pressure in concrete, Rho is the initial relative humidity in concrete, and Pso is the initial saturation pressure. Equation (6) is discretized in spatial domain using four-noded bilinear quad elements and is solved using the Galerkin method [14]. Upon spatial discretization, a first-order nonlinear ordinary differential equation in time is obtained as

Furthermore, a generalized trapezoidal scheme is applied to Eq. (8) and series of nonlinear algebraic equations are obtained and are solved iteratively using NR method as discussed in the thermal analysis. Spalling is said to occur in an element when the built-up pore pressure exceeds temperature-dependent tensile strength of concrete (η.Pv≥ \( f_{\text{T}}^{ '} \)), where η is the porosity of concrete and \( f_{\text{T}}^{ '} \) is the temperature-dependent tensile strength of concrete and is taken from constitutive relationship proposed by Rots et al. [15].

4 Numerical Examples

This section illustrates validation studies on spalling in HSC structures. For validation studies, the following examples are considered.

-

HSC block exposed to fire and

-

HSC concrete beam exposed to fire.

4.1 HSC Block Subjected to Fire

An HSC block shown in Fig. 1 with specifications in Table 1 is subjected to ASTM-E1529 fire exposure. Bilodeu et al. [16] investigated the experimental spalling response of aforementioned HSC block (Fig. 2) exposed to a 2 h ASTM-E1529 [6] fire. Reduced block thickness due to spalling had been measured only at the end of experiment. 2-D hydrothermal analysis is performed for this HSC block and temperature-dependent spalling prediction is obtained and compared against experimental counterpart as shown in Fig. 2. The developed numerical model is able to predict the reduction in the thickness of the block due to spalling with reasonable accuracy.

4.2 HSC Beam Exposed to Fire

An HSC beam with specifications in Table 2 is considered. Dwaikat and Kodur [17] experimentally characterized the spalling response history of this beam which is subjected to a long-term design fire as shown in Fig. 3.

In case of HSC structures subjected to flexure, initial intrinsic permeability is non-uniform depending upon the extent of mechanical damage in compression and tension regimes. Gawin et al. [6] addressed this issue by proposing a modification factor which is a function of damage in concrete. In the present study, mechanical damage in concrete is quantified from the thermomechanical analysis framework developed by Prakash and Srivastava [12] and is utilized in permeability computations. Also, spalling is assumed to occur outside of the confinement as observed from many full-scale fire tests. Incorporating abovementioned phenomena, 2-D hydrothermal analysis is performed for the HSC beam under consideration. Volume of concrete spalled is compared against experimental observations as shown in Fig. 4. The spalling response history computed by the model shows good agreement with the experimental observations. Further, parametric studies are performed to study the effects of intrinsic permeability and grade of concrete on the response of this beam, as shown in Figs. 5 and 6. Parametric studies indicate that intrinsic permeability and grade of concrete have a significant effect on spalling response of concrete structures under fire.

5 Conclusions

A simplified framework for the prediction of the spalling response of HSC structures at elevated temperatures has been developed. The developed framework considered two-way coupling between thermal and pore pressure analysis with temperature-dependent thermal and mechanical properties. The accuracy of the developed framework was demonstrated through two numerical examples. The numerical examples indicate that developed framework is reasonably accurate for spalling prediction in HSC structures. Furthermore, parametric studies were performed to study the effect of permeability and grade of concrete on spalling in HSC structures. Parametric studies showed that permeability of concrete has significant effect on the extent of concrete spalling. Higher permeability leads to lower spalling and vice versa. Also, higher tensile strength of concrete leads to lower spalling and vice versa.

References

CEN (European committee for Standardization). (2004). Design of concrete structures. Part 1–2: General rules—Structural fire design. Brussels: Eurocode-2.

Bureau of Indian Standards. (1989). Indian code of practice for fire safety of buildings (General): Details of construction-code of practice. New Delhi: IS-1641.

Phan, L. T. (1996). Fire performance of high-strength concrete: A report of the state-of-the art. US Department of Commerce, Technology Administration, National Institute of Standards and Technology, Office of Applied Economics, Building and Fire Research Laboratory.

Diederichs, U., Jumppanen, U. M., & Schneider, U. (1995). High temperature properties and spalling behaviour of high strength concrete. In Proceedings of Fourth Weimar Workshop on High Performance Concrete (pp. 219–235). Germany: HAB Weimar.

Kodur, V. K. R. (2000). Spalling in high strength concrete exposed to fire—Concerns, causes, critical parameters and cures. In Proceedings, ASCE Structures Congress (pp. 1–8), Philadelphia, PA, USA.

Gawin, D., Majorana, C. E., & Schrefler, B. A. (1999). Numerical analysis of hygro-thermal behaviour and damage of concrete at high temperature. Mechanics of Cohesive-fictional Materials, 4(1), 37–74.

Gawin, D., Pesavento, F., & Schrefler, B. A. (2006). Towards prediction of the thermal spalling risk through a multi-phase porous media model of concrete. Computer Methods in Applied Mechanics and Engineering, 195(41), 5707–5729.

Kodur, V. K. R., Wang, T. C., & Cheng, F. P. (2004). Predicting the fire resistance behaviour of high strength concrete columns. Cement and Concrete Composites, 26(2), 141–153.

ACI 216.1 M-07. (2007). Standard method for determining fire resistance of concrete and masonry construction assemblies. Detroit, USA: American Concrete Institute.

Dwaikat, M. B., & Kodur, V. K. R. (2009). Hydrothermal model for predicting fire-induced spalling in concrete structural systems. Fire Safety Journal, 44(3), 425–434.

Bazant, Z. P., & Thonguthai, W. (1978). Pore pressure and drying of concrete at high temperature. Journal of Engineering Mechanics, 104(5), 1059–1079.

Prakash, P. R., & Srivastava, G. (2015). Development of a matrix method based framework for the thermo-mechanical analysis of RCC frames. In Response of Structures Under Extreme Loading: Proceedings of PROTECT-2015, pp. 972–980.

ASTM. (2001). Standard methods of fire test of building construction and materials, Test Method. West Conshohocken: American Society for Testing and Materials.

Cook, R. D., Malkus, D. S., Plesha, M. E., & Witt, R. J. (2007). Concepts and applications of finite element analysis. Berlin: Wiley.

Rots J. G., Kusters, G. M. A., & Blaauwendraad, J. (1984). The need for fracture mechanics options in finite element models for concrete structures. In International Conference on Computer Aided Analysis and Design of Concrete Structures, pp. 19–32.

Bilodeau, A., Kodur, V. K. R., & Hoff, G. C. (2004). Optimization of the type and amount of polypropylene fibres for preventing the spalling of lightweight concrete subjected to hydrocarbon fire. Cement and Concrete Composites, 26(2), 163–174.

Dwaikat, M. B., & Kodur, V. K. R. (2010). Fire induced spalling in high strength concrete beams. Fire Technology, 46(1), 251–274.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Prakash, P.R., Srivastava, G. (2019). Numerical Modeling of Spalling in High Strength Concrete at High Temperature. In: Rao, A., Ramanjaneyulu, K. (eds) Recent Advances in Structural Engineering, Volume 1. Lecture Notes in Civil Engineering , vol 11. Springer, Singapore. https://doi.org/10.1007/978-981-13-0362-3_34

Download citation

DOI: https://doi.org/10.1007/978-981-13-0362-3_34

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0361-6

Online ISBN: 978-981-13-0362-3

eBook Packages: EngineeringEngineering (R0)