Abstract

This paper presents analysis and interpretation of monitored vertical settlements and pressures of a rehabilitated bridge approach slab located in Johnson County, Texas. Four horizontal inclinometer casings and pressure cells (equipped with thermometers) were installed at the test site during the rehabilitation process. In this paper, collected data from the inclinometers, pressure cells, and thermometers were employed in an attempt, to understand the effect of climate changes on the vertical settlements and pressures of the approach slab. It has been observed that with an increase in temperature, the bridge structure enforced the movements of the geofoam blocks causing vertical settlement. Whereas, the bridge structure movements after a temperature decrease, induced vertical swelling at the top of the geofoam blocks. The pressure cells that were installed at the top and bottom of the geofoam embankment revealed that the stresses observed at the top of the geofoam were significantly reduced. Also, the pressure cells installed at the sides of the bridge and geofoam structure to evaluate the lateral pressure response lost contact and provided negative results. The loss of contact can be a response to the movement of the structure with respect to thermal changes in the structure. This research highlights the important observations of a bridge structure and its approach soil-geofoam embankment movements with respect to temperature and precipitation variations.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The differential settlement between bridge approach and bridge deck, also known as ‘bump phenomenon’ is a common problem faced by approximately 25% of the 600,000 bridges across the United States [1, 2]. Millions of dollars are spent annually in an attempt to repair these bridges [1]. Recent studies on bridge infrastructure demonstrated that more than 28 states in the United States use an approach slab as an interface to the pavement and bridge deck. In a survey conducted in Texas, it was estimated that it costs annually more than 100 million dollars for the Texas Department of Transportation (TxDOT) to repair the bridges with bump problem in Texas [3,4,5].

Several researchers have tried to determine the probable causes of bump phenomenon at bridge approaches [3, 6,7,8,9,10,11,12,13,14,15,16,17,18,19]. Based on the previous literatures, the primary factors causing the approach bump problem include consolidation settlement of foundation soil, poor embankment soil compaction close to the bridge approach, poor drainage system and soil erosion due to the age of the bridge, types of bridge abutment, and traffic volume.

In the past decade, extensive studies were performed to identify the causes of the bump phenomenon and several techniques have been proposed to mitigate the problem [8, 9, 12, 14, 15, 20,21,22]. Some of the widely-accepted techniques to resolve differential settlement problem include excavation and replacement, deep soil mixing (DSM) column, geosynthetic reinforcement, mechanically stabilized earth (MSE) wall, effective drainage, and erosion control method and use of lightweight materials to decrease the effective overburden pressure.

Thermally induced displacements generally occur at integral abutment bridges due to seasonal temperature changes [18, 23,24,25,26,27,28]. These long-term deformations mainly take place because of the continuity of superstructure and substructure of bridges with integral abutment systems and can make a progressive contribution to accelerating the development of bump phenomenon. As per the seasonal temperature variations, lateral interaction at the studied bridge structure and the integrated hybrid soil-geofoam approach embankment system was monitored and presented.

In this research study, lightweight geofoam blocks were used in place of the top 1.83 m (6 ft) of the soil in order to reduce the approach slab-bridge deck differential settlement. The geofoam blocks despite being 100 times lighter than the soil, can provide comparable strength and stiffness properties as soils. Effect of temperature and precipitation was studied to monitor the performance of a Geofoam-soil hybrid system installed at a site which was facing the menace of the “bump phenomenon”. The following sections provide the details of the instrumentation and analysis.

2 Site Description

The US 67 bridge over SH 174, located at Johnson County, Cleburne, Texas was constructed in 1995. The approach slab was constructed on the 12.2 m (40 ft) moderately high plastic clay embankment which was laterally supported by concrete retaining walls. More than 406.4 mm (17 in.) settlement was experienced by the approach slab over a period of 16 years. Excessive settlement happened primarily due to the consolidation settlement of the embankment soil, insufficient compaction of soils near the abutment and erosion [11]. During this period, several soil improvement techniques include soil nailing, grout injections, and hot mix overlays were tried but none of the applied techniques were found to be effective to mitigate the differential settlements at the bridge approach slab.

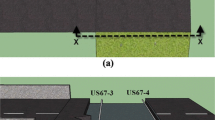

In January 2012, the Texas Department of Transportation (TxDOT) replaced the top 1.83 m (6 ft) of the embankment soil by the lightweight EPS 22 Geofoam. In order to monitor the long-term vertical deformations of the Geofoam layer under diverse environment and loading conditions, four horizontal inclinometer casings (US67 -1, US67 -2, US67 -3, US67 -4) were installed on the top of the Geofoam layer during the construction. Data monitoring in two years depicted a differential settlement of less than 38.1 mm (1.5 in.). This was considered as the allowable design settlement to evaluate long-term performance of the rehabilitation technique [11]. In addition, four pressure cells were installed at the top and bottom of the Geofoam layer to assess the lateral and vertical pressures transferred to and from the EPS Geofoam layer respectively (see Fig. 1). Figure 1(a) and (b) presents the pressure cells installed on top and bottom of the geofoam blocks for monitoring vertical pressures that were transferred from pavement layers. Whereas, Fig. 1(c) and (d) depicts the pressure cells installed laterally on the retaining wall and attached to the Geofoam blocks to monitor the lateral pressure that is subjected onto geofoam blocks. The laterally installed pressure cell at the top side of the bridge structure and geofoam interface as shown in Fig. 1(c) showed occasional negative values. This led us to analyze the role of thermal expansion and contraction of the bridge structure on the Geofoam material.

3 Data Analysis and Interpretation

The data of two pressure cells installed vertically at the top and bottom of the Geofoam blocks were used to analyze the performance of the Geofoam layer under dynamic traffic loadings, temperature variations, and precipitation. Figure 2 shows a typical monthly (a) and daily (b) pressure diagram at the top and the bottom of the Geofoam layer for a given month and day respectively.

The recorded pressures include the dynamic traffic loading in addition to the static overburden pressure of 0.61 m (2 ft) rigid pavement. A significant decrease of the average pressure from the top (35.8 kPa) to the bottom (12.4 kPa) of the Geofoam layer is evident from both plots (Fig. 2(a) and (b)). However, no time-dependent viscous behavior can be observed under the combination of static and dynamic loadings in the either plots. Although Geofoam material has good damping characteristics, it was observed that the amplitude of recorded pressure by the bottom pressure cell was higher than that recorded by the ones at the top (Fig. 2(a)). This can be attributed to the stronger pressure cell rigid soil base at the bottom as opposed to the Geofoam blocks at the top.

3.1 Influence of Temperature Variation on Lateral Pressures

The temperature and pressure data were collected from the installed pressure cell (equipped with the thermometer) at the top side of the geofoam layer and the bridge structure interface (retaining wall). Because of the integral bridge-approach embankment system of the infrastructure, thermally induced lateral pressure interaction was recorded at the bridge and the approach embankment interface. Figure 3 shows the variation of temperature and pressure versus time at the top of the Geofoam layer. In the following plots, the left vertical axis represents the temperature variations and the right vertical axis depicts the lateral pressure changes. It should be noticed that both parameters (temperature and lateral pressure) were recorded simultaneously each 15 min’ time intervals. It can be observed from the Fig. 3 that a consistent trend of lateral pressure variations was observed with change in temperature for the years 2012 and 2013. From January 2012, the lateral pressures increased gradually with the rise in temperature till the end of June 2012 and reached their peak magnitudes (see Fig. 3(a)).

As long as the retaining wall and the Geofoam layer were in contact, the lateral dynamic response to the traffic loading was amplified. Whereas, with a slight decrease in the temperature in July 2012, a rapid drop in lateral pressures was recorded which finally reached negative values at a temperature of 28.8 °C. In other words, with a decrease in temperature, bridge started to move back to its initial position. However, the difference in thermal induced stress-strain behavior of the concrete and Geofoam materials caused a quick decline on the lateral pressures in July 2012. Figure 3(b), shows a similar trend of the lateral pressure fluctuations with the seasonal temperature variations for 2013. This pattern reveals important information about the physical interaction between the bridge structure and the geofoam layer due to the seasonal temperature changes.

3.2 Influence of Temperature Variation on Vertical Pressures

This section presents the influence of temperature variations on the vertical pressure at the top and bottom of the Geofoam layer. The temperature variations recorded by the top pressure cell was negligible since the vertically installed pressure cell was wrapped in geomembrane and embedded in the Geofoam, a material with negligible thermal conductivity (see Fig. 1a). Therefore, the variation in the recorded pressure data was due to the dynamic traffic loading rather than changes in temperature. However, the pressure cell at the bottom of the Geofoam layer (see Fig. 1b), has recorded reasonable temperature variations.

Figure 4(a) and (b) depicts vertical pressure changes and deformations corresponding with the thermal fluctuations at the bottom of the Geofoam layer. The behavior of Geofoam under the seasonal temperature changes can be better assessed at the soil-Geofoam interface due to the thermal insensitivity of the soil. Hence, a similar trend was observed for both vertical pressure change and temperature variation at the bottom of the Geofoam layer (see Fig. 4a and b). The effects of seasonal temperature variations were also studied on the collected vertical deformations at the top of the Geofoam blocks (Fig. 4(b)). It was observed that by increasing the temperature, settlements were raising up and by decreasing the temperature, swelling behavior was observed in the average vertical deformations.

3.3 Precipitation Effect

This section presents the effect of precipitation on the vertical settlements obtained from the inclinometer data. Precipitation data were obtained from database recorded from U.S. Climate Data. Figure 5 presents the precipitation data for 2012 and 2013.

Preliminary analysis of the data showed no immediate effect of precipitation on the vertical deformations in two years. This could be due to the very low permeability of the high plasticity clayey soil present in the embankment. A close study on the plots depicted the swell and shrink cycles after heavy rainfall and dry periods respectively [29]. However, a more detailed analysis is required before attributing the effects of precipitation on vertical deformation.

4 Conclusion

-

Vertical pressure cell data at the bottom of the Geofoam shows a considerable decrease in the average vertical pressures. This is due to the stress absorption of the geofoam material. The dynamic response from the traffic loading was studied, where the stress amplitude was increased due to the stronger rigid soil base at the bottom as opposed to the Geofoam blocks at the top.

-

Analysis of the seasonal temperature variation on vertical deformations and lateral pressure showed that the Geofoam blocks were laterally pushed by the thermal expansion of the bridge structure. Also, it has been observed that the variation in the vertical deformation was consistent with the temperature variation.

-

The effect of the precipitation data on the vertical settlement was studied for two years and no immediate effect was observed. This could be due to the low permeability of the embankment soils present in the considered test section and also the geomembrane wrapped around the geofoam block which provides an impermeable interface.

References

Islam, A.A.: On reducing bumps at pavement-bridge interface. Final report submitted to: YSU Center for Transportation and Materials Engineering (CTME). Youngstown State University, Youngstown, OH 44555 (2010)

Thiagarajan, G., Gopalaratnam, V., Halmen, C., Ajgaonkar, S., Ma, S., Gudimetla, B., Chamarthi, R.: Bridge Approach Slabs for Missouri DOT: Looking at Alternative and Cost-Efficient Approaches (No. OR 11.009) (2010)

Briaud, J.L., James, R.W., Hoffman, S.B.: Settlement of Bridge Approaches: (The Bump at the End of the Bridge), vol. 234. Transportation Research Board (1997)

Nassif, H., Abu-Amra, T., Shah, N.: Finite element modeling of bridge approach and transition slabs (No. FHWA-NJ-2002–007) (2002)

Saride, S., Puppala, A.J., Archeewa, E.: Bridge Approach Settlements—An Issue Due to Design or Construction Practices, pp. 210–214. The University of Texas at Arlington (2009)

Hopkins, T.C., Deen, R.C.: The Bump at the End of the Bridge (1969)

Yasrobi, S.Y., Ng, K.W., Edgar, T.V., Menghini, M.: Investigation of approach slab settlement for highway infrastructure. Transp. Geotech. 6, 1–15 (2016)

Seo, J.B.: The bump at the end of the bridge: an investigation (Doctoral dissertation, Texas A&M University) (2005)

White, D.J., Mekkawy, M.M., Sritharan, S., Suleiman, M.T.: “Underlying” causes for settlement of bridge approach pavement systems. J. Perform. Constructed Facil. 21(4), 273–282 (2007)

Stewart, C.F.: Highway structure approaches. FHWA/CA/SD-85-05, Office of Applied Research, Division of Structures, California Department of Transportation, Sacramento, California (1985)

Ruttanaporamakul, P., Puppala, A.J., Pedarla, A., Bheemasetti, T.V., Williammee, R.S.: Settlement Mitigation of a Distressed Embankment in Texas by Utilization of Lightweight EPS Geofoam Material. In: Transportation Research Board 95th Annual Meeting (No. 16-4179) (2016)

Puppala, A.J., Saride, S., Archeewa, E., Nazarian, S., Williammee Jr., R.: Bridge approach settlements: lessons learned from present case studies and ground improvement solutions. In: Ground Improvement and Geosynthetics, pp. 228–238 (2010)

Bhaskar, C.S., Saride, S., Puppala, A.J.: Superstructure Design, vol. 647 (2010)

Tadros, M.K., Benak, J.V.: Bridge abutment and approach slab settlement: Phase 1. Nebraska Department of Roads (1989)

Wahls, H.E.: Design and construction of bridge approaches, vol. 159. Transportation Research Board (1990)

Mahmood, I.U.: Evaluation of causes of bridge approach settlement and development of settlement prediction models (Doctoral dissertation, University of Oklahoma) (1990)

Kramer, S.L., Sajer, P.: Bridge Approach Slab Effectiveness. Final Report (No. WA-RD 227.1) (1991)

Puppala, A.J., Saride, S., Archeewa, E., Hoyos, L.R., Nazarian, S.: Recommendations for design, construction, and maintenance of bridge approach slabs: Synthesis report. Report No. FHWA/TX-09/6022, 1 (2009)

Chen, Y.T., Chai, Y.H.: Experimental study on the performance of approach slabs under deteriorating soil washout conditions. J. Bridge Eng. 16(5), 624–632 (2010)

Dupont, B., Allen, D.: Movements and Settlements of Highway Bridge Approaches (No. KTC-02-18/SPR-220-00-1F) (2002)

Abu-Hejleh, N., Hanneman, D., White, D.J., Wang, T., Ksouri, I.: Flowfill and MSE Bridge Approaches: Performance, Coast, and Recommendations for Improvements (No. CDOT-DTD-R-2006-2). Colorado Department of Transportation, Research Branch (2006)

Hsi, J.: Bridge approach embankments supported on concrete injected columns. In: Geo-Congress 2008: Geo-sustainability and Geohazard Mitigation, pp. 612–619 (2008)

Arsoy, S., Barker, R.M., Duncan, J.M.: The behavior of integral abutment bridges, vol. 3, p. 13. Virginia Transportation Research Council, Charlottesville, VA (1999)

Puppala, A.J., Archeewa, E., Saride, S., Nazarian, S., Hoyos, L.: Recommendations for design, construction, and maintenance of bridge approach slabs (No. FHWA/TX-11/0-6022-2) (2012)

Seo, J., Ha, H., Briaud, J.L.: Investigation of settlement at bridge approach slab expansion joint: Numerical simulations and model tests (No. FHWA/TX-03/0-4147-2) (2002)

Rodriguez, L.E.: Temperature effects on integral abutment bridges for the long-term bridge performance program. Utah State University (2012)

White, H.: Integral abutment bridges: Comparison of current practice between European countries and the United States of America. Transportation Research and Development Bureau, New York State Department of Transportation (2007)

Onsa, E.H., Ahmed, A.A.: Effect of temperature variation and type of embankment soil on integral abutment bridges in Sudan. J. Civ. Environ. Eng. (2015)

Shafikhani, A., Bheemasetti, T.V., Puppala, A.J.: Effect of seasonal changes on a hybrid soil-geofoam embankment system. Int. J. Geosynthetics Ground Eng. 3(4), 39 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Shafikhani, A., Bheemasetti, T.V., Puppala, A.J., Banerjee, A. (2018). Analysis and Interpretation of Inclinometer and Pressure Cell Data on a Soil-Geofoam Embankment. In: Hu, L., Gu, X., Tao, J., Zhou, A. (eds) Proceedings of GeoShanghai 2018 International Conference: Multi-physics Processes in Soil Mechanics and Advances in Geotechnical Testing. GSIC 2018. Springer, Singapore. https://doi.org/10.1007/978-981-13-0095-0_46

Download citation

DOI: https://doi.org/10.1007/978-981-13-0095-0_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0094-3

Online ISBN: 978-981-13-0095-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)