Abstract

In Japan, sanitation for 26% of the population is covered by decentralized treatment facilities called Johkasou and night soil treatment plants (NSTPs). The former is installed to treat black water from small communities or individual households. Johkasou is a general term for compact on-site wastewater treatment unit and/or facility and is applicable to a population of several to several thousands, depending on the installation condition. The latter is installed to treat mainly night soil (human feces) coming from 6% out of the 26% population that uses decentralized treatment facilities. Since the sludge extracted from Johkasou is also treated in NSTPs, they play a key role in the Japanese sanitation system. As part of a social sustainability policy, the “Plan of Sludge Resource Recycling Treatment Center” (SRRTC) was enacted as a bylaw in 1997. It demands that NSTPs be furnished with facilities for resource and/or energy recovery from organic wastes including night soil and Johkasou sludge. Facilities implemented by this plan are categorized as sludge resource recycling treatment centers. This chapter describes the first SRRTC project in which a chemical precipitation process was applied to the recovery of phosphorus as calcium phosphates from night soil and Johkasou sludge.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Phosphorus (P) is an essential element for human growth, and it is the only nutritional food element for which Japan depends completely on importation. About 170 kt P/a, which was equivalent to 75% of the import, was consumed in the Japanese fertilizer and livestock feed industries in 2014. As the world population grows, the global agricultural and livestock industries will increase their demand for phosphorus. This may pose a serious risk to Japan’s P availability (Phosphorus Atlas Research Institute 2015). The key to mitigating the P shortage risk would be the phosphorus recovery from phosphorus-rich wastes such as steelmaking slag and organic wastes including sewage sludge, night soil, and food waste. The phosphorus recovery from steelmaking slag and sewage sludge is discussed elsewhere (see Chap. 1).

The traditional and most economical method for recycling organic wastes is composting. However, as the demand of composts varies both seasonally and regionally, composting is not always a successful option in Japan. From a resource recycling perspective, user-friendly products for agriculture may be chemical compounds without heavy metal contamination. Chemical precipitation technologies have been considered as practical means of obtaining recycleable P products. Typical P products from chemical precipitation processes are struvite and calcium phosphate compounds (CaPs). However, the applicability of these technologies depends on coexisting substances, in particular ammonium nitrogen. The struvite precipitation method is applicable to ammonium and phosphate (Pi)-rich waste streams such as digested sewage sludge and animal manure, while the CaP precipitation method is suited to ammonium-free streams.

Human waste sanitation in Japan is based, in principle, on centralized systems for both black water and solid waste. Regarding black water, about 74% of the population is served by the sewer system, whereas the remainder, who lives in remote and/or geographically isolated areas, depends on decentralized systems such as compact on-site wastewater treatment tanks (called Johkasou) installed in individual households. Community wastewater treatment plants for apartment houses and small towns are also categorized as Johkasou. About 6% of the population living in individual households without access to centralized or Johkasou systems depends on specialized systems, that is, a combination of truck collection and disposal at night soil treatment plants (NSTPs). The excess sludge extracted from Johkasou is also treated by the NSTP systems. Therefore, sanitation for 26% of the population directly or indirectly depended on NSTPs in Japan in 2015 (Japanese Waste Treatment 2014), which means that phosphorus recovery from night soil and Johkasou sludge is worthy of investigation.

Because the “Plan of Sludge Resource Recycling Treatment Center” (SRRTC) was enacted in 1997 as a bylaw, in order to enhance energy and resource savings required by sustainability policies, newly built and renovated NSTPs need to incorporate facilities for energy production and/or resource recovery. NSTPs equipped with these facilities are categorized as sludge resource recycling treatment centers and can receive financial support from the national government. Since the plan was enacted 20 years ago, Japan has accelerated the development of resource recovery technologies such as composting, phosphorus recovery, and biogas cogeneration.

This chapter describes an outline of phosphorous recovery from night soil and Johkasou sludge using the CaP precipitation method in SRRTCs. The struvite precipitation method for night soil treatment is described elsewhere (Japan Waste Research Foundation 2010, 2012).

2 Phosphorus Material Flow

According to a study of phosphorus material flow in Japan for 2006, out of 60 kt P/a from all domestic drainage, 5 kt P/a and 2 kt P/a were drained to NSTPs as night soil and Johkasou sludge, respectively. Phosphorus in the effluent from NSTPs was only 20 t P/a. That is, almost 6 kt P/a ended up in sludge at NSTPs. The NSTP sludge consists of both biomass and chemical sludge because night soil must be treated through a combination of biological and physicochemical processes to cope with multiple pollutants (Tsurumaki et al. 2008). A more recent study showed that Johkasou and NSTPs served for about 35 million people, treating approximately 4600 t P/a in 2013 (Phosphorus Atlas Research Institute 2015).

3 Phosphorus Recovery Using Precipitation Methods

The form of phosphorus that is recovered by precipitation methods is mainly inorganic phosphate (Pi). The top priority of NSTPs, which need to discharge the final effluent to public water bodies, is given to the decomposition of highly concentrated organic matter using a biological treatment process. Therefore, it is unavoidable that most of the insoluble phosphorus and a portion of the phosphate end up in the biological sludge. In addition, conventional NSTPs remove the remaining phosphate by a chemical coagulation process, where phosphate is insolubilized as chemical sludge. Precipitation methods can be applied, instead of chemical coagulation methods, to recover phosphorus in more user-friendly forms from the waste streams.

There are mainly two methods for generating user-friendly products from night soil and Johkasou sludge: CaP precipitation and struvite precipitation. Phosphorus recovery processes using these precipitation methods can be placed upstream or downstream of biological processes. At the upstream stage of a biological treatment process, high concentrations of ammonium and phosphate ions are present, and, therefore, the struvite precipitation method is preferable for P recovery. On the other hand, the CaP precipitation method is more rational for the recovery of P after biological processes, because essentially no ammonium ion remains.

The CaP precipitation reaction is given as:

Among typical CaP products, hydroxyapatite is the most stable compound having the low solubility in water. With sufficient Ca2+ at appropriate pH, CaP precipitation occurs on seed CaP particles. Once precipitation starts, the CaP particles grow and/or are split into fine particles which can serve in series as a seed. Therefore, it is not necessary to feed CaP particles continuously to the reaction mixture under appropriate operating conditions. CaP particles larger than around 400 μm can be recovered from the mixture as a product.

4 Phosphorus Recovery in SRRTC

4.1 Outline of the SRRTC

Name | Senboku-shi Sludge Resource Recycling Treatment Center |

Location | Senboku-shi, Akita-ken, Japan |

Plant capacity | 60 kL/day (night soil, 35 kL/day plus Johkasou sludge, 25 kL/day) |

Process | Biological high-load denitrification MBR with CaP precipitation process |

Schematic flow diagram is shown in Fig. 18.1 |

4.2 Process Description

4.2.1 Pretreatment Process

After grit and debris separation, night soil and Johkasou sludge were stored separately for a maximum of 3 days. During the storage, both were well mixed to ensure homogenization. Debris is incinerated after dewatering by screw press.

4.2.2 Biological Treatment Process

Pretreated night soil and Johkasou sludge were independently fed to the membrane bioreactor (MBR) where both nitrification and denitrification occurred. The aeration of the MBR was performed using the IZ jet aeration system (Fig. 18.2) which could supply enough oxygen required for a high rate of nitrification at the upper part of the tank. Thanks to a unique tank configuration and the control of feeding rate of night soil and Johkasou sludge, the lower part of the tank could be kept anaerobic for promoting denitrification. The mixture of the nitrification-denitrification tank was then filtered using an immersion-type microfiltration (MF) membrane.

4.2.3 Phosphorus Recovery Process

The filtrate was fed to a crystallizer where calcium chloride was dosed under controlled pH. The crystallizer consists of two zones: the continuously stirred crystallization zone in the center and the CaP particle settling zone in the outer region (Fig. 18.3 and Appendix).

The mixture in the crystallization zone moved to the settling zone where CaP particles settled and returned to the crystallization zone by gravity. The treated water overflowed from the reactor. CaP particles accumulated at the bottom of the settling zone were withdrawn using a drain pump and poured into a drainer bag. Finally, CaP particles were stored in the bag as a product. A woven container bag was used as the drainer bag in this process.

4.2.4 Advanced Treatment Process

The effluent of the phosphorus recovery process was discharged to a river after an advanced treatment process consisting of coagulation, filtration, activated carbon (AC) adsorption, and ultraviolet (UV) disinfection. The effluent quality met the regulation criteria specified by the local government.

5 Performance

5.1 Phosphorus Balance

5.1.1 Water Analysis

Table 18.1 shows the flow rate and water quality data at the process points specified in Fig. 18.4. The flow rates of night soil and Johkasou sludge were 18.6 and 24.0 m3/day, respectively. Thus a total of 42.6 m3/day was fed into the STRRC. BOD5, CODMn, T-N, T-P, and PO4-P were effectively decreased during the biological treatment process:

BOD5 | 4300–3600 mg/L to 1.0 mg/L |

CODMn | 8200–8400 mg/L to 130 mg/L |

T-N | 760–2500 mg/L to 16 mg/L |

T-P | 150–280 mg/L to 43 mg/L |

PO4-P | 87–250 mg/L to 41 mg/L |

5.1.2 Phosphorus Recovery Rate in the SRRTC

The material balance on phosphorus was calculated using the data shown in Table 18.1. Overall, 23.5% of input phosphorus was recovered, while 76.5% ended up in sludge. The phosphorus recovery rate of the crystallizer was 72.5%.

5.1.3 Summary of Operation Data

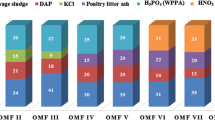

The operation data collected from January 2013 to December 2015 are shown in Fig. 18.5. The night soil ratio (night soil/(night soil + Johkasou sludge)) in the feed varied from 0.45 to 0.7. The peak ratio occurred in March, August, and January when the local population temporarily increased because of consecutive holidays. The feed rate of night soil and Johkasou sludge varied seasonally with a peak in summer. The influent PO4-P concentration of the crystallizer varied depending mainly on the night soil ratio.

Summary of operation. (a) The total and night soil feed rates to the SRRTC, (b) relationships between the night soil ratio (% night soil in the total feed) and the inflow PO4-P concentration of the crystallizer, (c) the effluent PO4-P concentration of the crystallizer, (d) the phosphorus recovery rate, and (e) the suspended solid (SS) concentration in the crystallizer

5.2 Properties of the Product

5.2.1 Component Analysis

The total phosphorus (T-P) content in the recovered product ranged from 15.4 to 19.9 (%) on a dry weight basis. This is comparable to the theoretical T-P content of hydroxyapatite (Ca10(PO4)6(OH)2) (18.5%). The citic acid-soluble P content of the product ranged from 27.4 to 37.8 (%) (Table 18.2) (Japan Waste Research Foundation 2010, 2012). The heavy metal contents were much lower than the levels specified by the regulations on sludge fertilizer in the Fertilizer Control Law, Japan.

5.2.2 Elution Test

The test of heavy metal elution from recovered products was conducted according to the method described previously [*]. The heavy metal concentrations in the eluate were less than one-tenth of the levels specified by the regulations on “Verification concerning industrial wastes containing metals” (the ordinance of the Prime minister’s office, Japan) (Table 18.3) (Japan Waste Research Foundation 2010, 2012; Ministry of the Environment 1973).

5.2.3 Appearance and Size of Products

The product was brawny particles (Fig. 18.6a, b). The coloring was likely due to endocrine compounds or bile pigments. The particle size distribution is shown in Fig. 18.6c. The median diameter was 370 μm.

5.2.4 Fertilizer Potential

The fertilizer potential of the product was compared with commercial phosphate fertilizers based on two items: (1) pot trials for relative agronomic efficiency and (2) phosphorus uptake by bok choy (Table 18.4 and Fig. 18.7) (Japan Waste Research Foundation 2010, 2012). The reference commercial fertilizers were calcium superphosphate and fused magnesium phosphate.

6 Product Property

The composition of recovered products was analyzed using X-ray fluorescence and X-ray diffraction technologies. Recovered CaP samples were obtained from the Senboku-shi SRRTC. Reagent-grade apatite was used as reference. To examine the influence of heating on the composition of recovered products, the samples were dried by two different methods: heating at 100 °C or vaccum drying at room temperature (about 20 °C) for 2 days. X-ray fluorescence analysis was performed using EDX-700HS (SHIMAZU), while X-ray diffraction analysis was carried out by RINT2000 (RIGAKU).

As expected, the major elements of the samples were Ca and P (Table 18.5). Sight differences were detected with the Mg and Na contents between the recovered products and reagent-grade apatite. The recovered products contained Mg which is derived from human excreta, whereas the reference contained Na in place of Mg. Overall, the composition of the recovered products was similar to that of reagent-grade apatite.

6.1 Crystal Structure

X-ray diffraction analysis showed a significant difference between the recovered products (samples A and B) and the reference (Fig. 18.8). Many spike-like peaks were detected with the reference (reagent-grade apatite). Among them are two peaks that were also detected with the products. The recovered products showed several broad peaks. There was no significant difference between samples A and B, indicating that the crystal structure of the recovered products was not influenced by the two different drying methods. These results suggested that the recovered products were amorphous calcium hydroxyapatite.

7 Conclusions

The Senboku-shi Sludge Resource Recycling Treatment Center (SRRTC) recovers phosphorus from night soil and Johkasou sludge using the CaP precipitation method. The average phosphate recovery rate was 70.3%. The P content of recovered products varied from 15.5 to 19.9 (%) on a dry weight basis. The critic acid-soluble phosphate in the product ranged from 27.4 to 37.8 (%). Contamination by heavy metals was negligible. The recovered product showed the fertilizer potential similar to those of commercial phosphorus fertilizers. Although the number of SRRTCs equipped with phosphorus recovery facilities is expected to increase, the amount of night soil is predicted to decrease mainly because of the falling population in rural areas. To promote phosphorus recovery from night soil and Johkasou sludge, SRRTCs may need to accept phosphorus-rich waste such as livestock manure and food waste.

References

Funaishi K et al (2010) About collection and utilization of the phosphorus by the apatite method in night soil treatment plant. J Jpn Waste Manag Assoc 63(295)

Japan Waste Research Foundation (2010) The study on phosphorus recovery from sludge of night soil/Johkasou and phosphorus recycling (Summary), Japanese Fiscal Year 2010, Japan

Japan Waste Research Foundation (2012) The study on phosphorus recovery from sludge of night soil/Johkasou and phosphorus recycling (Summary), Japanese Fiscal Year 2012, Japan

Japanese Waste Treatment (2014) Ministry of the Environment Government of Japan

Ministry of the Environment (1973) Assey methods of metals contained in the industrial waste

Phosphorus Atlas Research Institute (2015) Fiscal year 2015 research report. Waseda University, Tokyo

Tsurumaki M et al (2008) Research on fundamental conditions for building the recycling system of phosphorus resources. Environ Syst Res 36, Japan

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendix: Computational Fluid Dynamics of the Crystallizer

Appendix: Computational Fluid Dynamics of the Crystallizer

Computational fluid analysis was carried out to visualize the water movement in the continuously stirred crystallizer.

1.1 Conditions

The conditions for the computer simulation are shown in Table 18.6, and the modeling of crystallizer is shown in Fig. 18.9b.

1.2 Software

The software, SCRYU/Tetra (Software Cradle Co., Ltd.), was used for the fluid movement analysis. The steady-state simulation was carried out using a Reynolds average-type turbulence model RANS (Reynolds-averaged Navier-Stokes) simulation.

1.3 Result of Simulation

The simulation results of the velocity distribution in the crystallizer are shown in Fig. 18.9b. The particle settling velocity calculated by the Allen’s law is shown in Table 18.7.

In the crystallization zone, the vertical gyrate movement of 0.0–0.08 m/s was observed over the upper paddle and streamline directions were a mix of upward and downward. The synthesis velocity at the bottom of crystallization zone was more than 0.1 m/s, and the streamline direction was roughly from the center to the periphery. This means small particles less than 300 μm could be suspended in the upper paddle zone, while the possibility of particle accumulation on the bottom of crystallizer was small. There was some potentiality of accumulation of particles more than 600 μm on the bottom of the crystallizer. In the settling zone, the streamline direction was a mix of upward and downward. The upward stream of 0.01 m/s or higher was observed near the surface. This means small potentiality of washout of particles less than 100 μm.

Figure 18.10 shows the distribution of suspended solid (SS) in the crystallization zone and settling zone (Ministry of the Environment 1973). The concentration gradient of SS was clear in the settling zone. The SS concentration was only 4.4 mg/L at the surface layer of the settling zone. On the other hand, the vertical change in the concentration of SS in the crystallization zone was relatively small. These results suggested that a gravitational particle separation was possible while avoiding the influence of stirred mixture in the crystallizer.

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Okuno, Y., Nakata, Y., Isse, M. (2019). Phosphorus Recovery from Night Soil and Johkasou Sludge. In: Ohtake, H., Tsuneda, S. (eds) Phosphorus Recovery and Recycling . Springer, Singapore. https://doi.org/10.1007/978-981-10-8031-9_18

Download citation

DOI: https://doi.org/10.1007/978-981-10-8031-9_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8030-2

Online ISBN: 978-981-10-8031-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)