Abstract

Printing processes are gaining much prominence in sensing technologies through which smart materials can be deposited over flexible substrates. The attractive features of inkjet printing processes to replace other material deposition techniques are in terms of simplicity, low cost, environment friendliness, high resolution, less waste generation and mass production. This chapter presents a summary of various thin-film smart sensors as developed by inkjet printing processes over flexible substrates. The critical parameters for the printable ink, materials for the sensing applications, substrates for flexible electronics, advantages and challenges of inkjet printing method and its exploration for future flexible electronics sensors are visited through this chapter.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

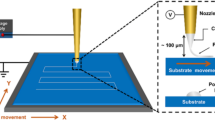

Recently, a lot of attention is provided to find out efficient methods and materials for low-cost flexible sensors and electronics. Inkjet printing is a mature and versatile micromanufacturing tool which has assisted and revolutionized the rapidly increasing field of flexible sensors by providing a simple and cost-effective solution for their realization (Komuro et al. 2013). The important features associated with the printing process like simplicity, low waste generation, mask-free approaches, reduced usage of toxic chemicals, low cost, shape and size flexibility, no contact with substrate and many others make it suitable for flexible sensor manufacturing (Singh et al. 2010). Also, the emergence of desktop printers for sensor and electronics device fabrication has drastically reduced sensor costs by several orders (Zheng et al. 2013; Andò and Baglio 2013; Sundriyal and Bhattacharya 2017). Due to the advancement of compact, on-chip and flexible sensors, thin-film flexible sensor markets are continuously growing. Initially, Kimura et al. reported inkjet printing of biosensors by enzyme deposition on the surface of a field effect transistor (Kimura et al. 1989). Recently, several research groups have reported many inkjet-printed sensors such as strain sensor (Andò and Baglio 2013), gas sensors (Stempien et al. 2016a), vapour sensors (Belsey et al. 2017), touch sensors (Ma et al. 2015), glucose sensors (Song et al. 2017) and wearable sensors (Morse et al. 2016).

Compatibility of inkjet printers with various flexible substrates (like paper, polymer, textile fabric and metal foils) (Ma et al. 2015; Wang et al. 2016; Stempien et al. 2016b) and sensor material inks (such as metallic ink, conducting polymer ink and carbon-based ink) (Stempien et al. 2016b; Arrese et al. 2017; Qin et al. 2016; Lee et al. 2016) has boosted its applications for printed sensor technologies. Despite many efforts and several advantages, some limitations of inkjet printing process still hinder its full utilization. One major challenge is the requirement of ink with rigid physical properties controllable by surface tension, viscosity and density of the ink. The range of these properties, their effect on print quality and optimum range of required physical properties have previously been reported by several researchers (Jang et al. 2009; Fromm 1984; Derby and Reis 2003).

All the components of sensor devices can be deposited on flexible substrates by inkjet printing. A sensor device has three main components: the conducting layer, the active sensing layer and the insulating layer. With the development of conducting material’s ink, semiconducting material’s ink and dielectric material’s ink, the complete sensor can now be fabricated by using printing-assisted deposition in extremely short-time scales just by selecting different ink cartridges. The reported materials for conducting inks are silver (Arrese et al. 2017), copper (Lee et al. 2016), graphene (Das et al. 2016), carbon nanotube (CNT) (Qin et al. 2016) and conducting polymers (Crowley et al. 2008; Hwang et al. 2011). Inks used for active sensing layers are basically metal oxides (Kukkola et al. 2012; Rieu et al. 2015; Tsangarides et al. 2016), and dielectric material inks are based on polyvinyl alcohol, poly (methyl methacrylate), polyimide, poly (4-vinylphenol), polystyrene and terephthalate (Hamad et al. 2016; Pease and Chou 2008). Development of ink based on organic and inorganic materials for sensing applications still needs active research efforts. Another important component of flexible sensing devices is the substrate material over which the printing is carried out. The role of the substrate to be inked is very prominent due to adhesion issues between the ink and the substrates and also other mechanical properties associated with the device development. Some of the properties involved are flexibility, mechanical strength, wettability and stability of the substrates. Some investigations have been carried out for printing of sensors and other associated electronics in substrates like polymers (Ma et al. 2015; Rieu et al. 2015), paper (Wang et al. 2016), metal foils (MacDonald et al. 2007) thin glasses (Zardetto et al. 2011) and textile fabrics (Stempien et al. 2016a). The choice of a substrate depends on the type of material deposited over it and also the required post-treatment temperature needed for settling and adhering the print to the substrate and also on sensing applications related to the concerned device (Lee et al. 2016; Das et al. 2016). The rapidly growing market of flexible electronics needs a high level of flexibility of involved substrates, high operational temperature ranges, wettability and long-term stability of devices. The main reason for their exploration is the emerging trend associated with flat and light weight electronic consumer goods and also the general market need for aesthetics and better form factors of electronic products. Also, the direct use of this technology for the development of microfluidic channels (Bhatt et al. 2016) can drastically increase the market of low-cost diagnostic devices and biosensors.

This chapter is an overview of this very new area of flexible electronics using printing technology and is organized as a series of basic technical issues related to the device development using flexible printed substrates. These issues are a thorough study of required physical properties of the printable inks, the inkjet printable materials constituting the ink required for sensor fabrication such as conductive materials, semiconductive materials, dielectric materials, substrates for printed sensors along with their compatibility and limitation for a particular application, advantages and limitations and future scope of inkjet-printed sensors.

2 Required Physical Properties of the Printable Ink

Most of the inkjet printing patterns as used by the industry are based on drop-on-demand (DOD) method which demands optimum physical properties of the ink for good quality printing. The droplet generation in DOD printers is a complex process which is governed by viscosity, surface tension and density of the printing ink (Fromm 1984). These properties affect the drop formation process and the drop size at a given injection voltage. Performance parameters that are involved in the drop formation process for inkjet printing can be characterized by the following dimensionless numbers:

Reynolds number (Re): It is the ratio of inertial to viscous forces.

Weber number: It is the ratio of inertial force and surface tension forces.

Ohnesorge number: It is the ratio of square root of Weber number and Reynolds number.

where v, a, ⍴, η and γ represent average velocity, characteristic length (diameter of the printing nozzle), density, dynamic viscosity and surface tension of the fluid, respectively. The suitability of a fluid for inkjet printing is evaluated by finding out the Z number, which is the inverse of the Ohnesorge number.

At the initial stages of understanding the drop formation process, Fromm et al. (1984) suggested Z > 2 for a stable drop formation in DOD printers. This range was further refined by Reis and Derby as 1 < Z < 10, and it was further observed that lower limit of Z depends on fluid viscosity which prevents droplet ejection while upper limit is restricted by the formation of satellite drops rather than a single droplet (Derby and Reis 2003). Again, Jang et al. (2009) have proposed this range as 4 < Z < 14 by considering various factors like single drop formation, jet frequency, positional accuracy and required stand-off distance. Figure 1 shows image of inkjet-printed droplet formation for Z number variation from 2 to 17 at a constant voltage of 25 V.

Images of inkjet-printed droplet formulation for inks with Z value: a 2.17; b 3.57; c 4.08; d 6.57; e 7.32; f 13.68 and g 17.32. Reproduced from Jang et al. (2009) with permission from the American Chemical Society

3 Materials for Printed Sensors

Material choice is an important determinant of the sensor performance. To make a low-cost and flexible printed sensor, various materials (organic and inorganic) have been widely explored. Printing ink of the selected material must fulfil the requirement of specific rheological properties which is the most challenging task in the fabrication of printed sensor technology, and it is a limiting factor for the selection of the ink material. The sensor materials could be classified as follows: (i) conducting; (ii) semiconducting and (iii) dielectric, respectively.

3.1 Conducting Materials

Conducting materials play an important role in all electronic devices as a fundamental material due to its application in generating interconnects and other device layers. Inkjet printing provides an attractive feature of controlling the overall thickness, resolution and shape of the conducting patterns. Some conducting materials are used extensively for printing technology and have gained much attention by research community as they satisfy the physical properties of the printable ink (surface tension, viscosity, particle size, good colloidal dispersion, etc.). These are metal-based, carbon-based and conducting polymer-based inks as detailed in subsequent sections.

3.1.1 Metal-Based Ink

Among all the explored metallic inks, silver-based ink is the most dominating choice for printed electronics due to its excellent electrical conductivity, resistance to oxidation and other suitable physical properties enabling such ink to have good adhesion with substrates. Silver paste has been explored from almost time immemorial for developing interconnects for MEM grade sensorwork, printed circuit boards, etc. The high cost of silver limits its use for low cost flexible electronics and thus utilization of other inexpensive materials is required for its replacement. Aresse et al. (2017) have studied inkjet-printed silver patterns and compared them to conventional silver epoxy and solders. The printed silver circuit patterns and their conductivity change with different substrates, and processes are demonstrated in Fig. 2.

Shows a–i the silver pattern on flexible substrate (paper and kapton) and glass by inkjet printing, silver epoxy and soldering; j printed circuit pattern and k dependence of electrical resistance on material and substrate used. Reproduced from Arrese et al. (2017) with permission from the American Institute of Physics

Copper-based ink has also been investigated for printed electronics; however, its oxidation after printing makes it highly unsuitable for high-performance devices (Kim et al. 2011). Recently, Lee et al. (2016) have reported copper patterns with good electrical performance (resistivity ~15.18 µΩ) by using hydrazine treatment at low temperature. Using post-treatments with such chemicals, the printing can enable the metallic ink to be suitable for flexible sensors. Other than copper, aluminium-based ink is also a good choice for conducting patterns on flexible substrates, but its poor conductivity due to Al2O3 layer formation in air limits its use although the inexpensive nature of this material may provide a good solution if it can be coated by another anti-oxidation material layer to prevent oxidation (Foley et al. 2005). Future research is required to make conducting Al ink patterns by optimizing its processing parameters and using multilevel ink layers of different materials.

3.1.2 Carbon-Based Ink

Carbon-based materials like graphene and CNT have secured their place quite prominently in inkjet technology due to their excellent electrical conductivity, mechanical properties and ease of forming good dispersing inks (Qin et al. 2016; Das et al. 2016). Due to their superior electrical and mechanical properties, these materials have gained much attention in the area of fabrication of flexible electronics and also studied as possible replacement of indium tin oxide (ITO) printing. Though these materials have been extensively explored for printing, still more efforts are required to utilize the green chemistry based or biowaste extracted carbon materials (Sundriyal and Bhattacharya 2017) for printed electronics and sensors.

Recently, Das et al. (2016) have reported a laser irradiation technique to improve the performance of a printed graphene pattern and used this pattern for detection of H2O2. They have explained graphene ink formation by sonication and filtration processes and printed the prepared ink on flexible polyimide sheets by using a dimatix materials printer. These printed patterns have been further annealed through laser irradiation which has been found to significantly improve the electrical conductivity of the printed patterns. Figure 3 shows a schematic of ink formation, printing, annealing, variation of sheet resistance with laser energy and flexibility of the studied substrate.

a Schematic diagram of graphene ink formation; b inkjet printing of graphene ink; c schematic of post-printing laser annealing of printed electrodes; d variation of sheet resistance with laser energy density and thickness of the printed layer; e printed electrode in flat position; f printed electrode in bend position; g printing on paper and after DI water and detergent washing; h electrical conductivity after 100 washing and bending cycles; i H2O2 sensing of printed electrodes using amperometry and j linear regression analysis of current versus concentration. Reproduced from Das et al. (2016) with permission from the Royal Society of Chemistry

CNT-based ink is also widely applied to printed electronics. Qin et al. (2016) have reported inkjet printing of single-walled carbon nanotubes (SWCNT) as both conducting interconnects and pH sensing layers. A constant increase of electrical conductivity has been observed up to 200 passes of printing, with a response time of 7 s. They have also observed pH sensitivity of 48.1 mV as shown in Fig. 4.

a Variation of electrical resistance and electrode thickness with number of printing layers (inset shows optical microscope image of printed films with different number of passes on 100-mm scale bar); SEM image of CNT film using b 20 passes; c 200 passes and d printed CNT pH sensing electrode calibration curve. Reproduced from Qin et al. (2016) with permission from the Elsevier

3.1.3 Conducting Polymer-Based Ink

Beside metals and carbon-based materials, conducting polymers like polyaniline, polypyrole, polyacetylene, PEDOT: PSS (3, 4-polyethylenedioxythiphene—polystyrene sulfonic acid), etc., have also been explored for inkjet-printed sensors (Crowley et al. 2008; Hwang et al. 2011; Mabrook et al. 2006). Previously, Crowley et al. (2008) showed an inkjet-printed polyaniline electrode for ammonia sensing using amperometric techniques. The electrode performance was recorded to be excellent with four printing layers at neutral pH. Relationship of amperometric response with a number of printing layers and ammonia concentration and stability of electrodes were thoroughly characterized as shown in Fig. 5.

a Dependence of amperometric response with printing layer thickness of PANI electrode; b stability of the printed PANI electrodes to 18 ppm ammonium as ammonium chloride; amperometric response of electrodes to the ammonium concentration; c 0–1.44 ppm and d 1.8–450 ppm. (Potential applied was −0.3 V vs. AgCl reference electrode.) Reproduced from Crowley et al. (2008) with permission from the Royal Society of Chemistry

Inkjet-printed PEDOT electrodes have also been widely studied by various researchers (Hwang et al. 2011; Mabrook et al. 2006). Mabrook et al. have investigated sensing of organic vapours using PEDOT-printed patterns. AFM microscopy of one printed layer of PEDOT-PSS hybrid ink before and after exposure to methanol vapours have been studied in great detail. The sensitivity of the printed layers after exposure to methanol and ethanol vapours and the comparative response of printed layers at different methanol concentrations were also investigated (Mabrook et al. 2006).

3.2 Semiconducting Materials

Semiconducting materials work as an acting sensing layer, and this sensing layer is a critical component for a sensing device. Their electronic properties and hence sensitivity largely depends on the doped impurities, and desired properties can be obtained by changing doping levels in a controlled way. Till date, the materials that are utilized under this category are metal oxides (Kukkola et al. 2012; Rieu et al. 2015; Tsangarides et al. 2016) and silicon (Pi et al. 2012; Drahi et al. 2014).

Pi et al. (2012) have efficiently used Si quantum dots for solar cells by inkjet printing methods. There has been no recordable deterioration in device efficiency even after 30 days which shows high stability of the printed patterns. It has been reported that the printed quantum dots were highly resistant to the air oxidation due to hydrosilylation reaction which resulted in no change of printed layer properties for a long time. Figure 6 shows schematic of Si ink printing on Si surface and dependence of layer thickness and porosity with drop spacing while Fig. 7 shows variation of different performance parameters of solar cell with the drop spacing. Drahi et al. (2014) have characterized inkjet-printed Si nanoparticles for thin-film devices and investigated change in its properties with varying sintering temperature. Si has been explored for the inkjet printing processes by some researchers, but its high sintering temperature makes it unfit for use in most of the flexible substrates. Also, its high cost makes it unsuitable for low-cost electronics.

a Schematic of inkjet-printed Si quantum dots on Si solar cell surface (D—drop space, S—step of printhead movement, θ—angle between printhead and edge of solar cell) and b variation of porosity and thickness with drop space. Reproduced from Pi et al. (2012) with permission from the American Chemical Society

Variation of a efficiency (η); b short-circuit current (I sc); c open-circuit voltage (V oc) and d fill factor (FF) of solar cell after Si quantum dot printing. Reproduced from Pi et al. (2012) with permission from the American Chemical Society

Carbon-based materials have also been investigated as semiconducting active layers in inkjet-printed sensor devices. These materials have already been introduced in the above section. Other important class of materials for the printed sensors is metal oxides although such materials necessitate a post-printing sintering (300–500 °C) step to get optimum performance. Tsangarides et al. (2016) have reported the effect of temperature on the growth, layer uniformity and morphology of ZnO nanowires from inkjet-printed patterns of zinc acetate dehydrate. Uniform layers of ZnO were obtained at 60 °C, which are suitable for all flexible substrates. Also, there is no coffee-ring effect on the printed layers at this temperature. Thus, this method can be used for the inkjet-printed flexible sensors based on ZnO nanostructures. Figure 8 shows particle distribution mechanism on drying drops and SEM images of ZnO nanowire arrays grown over one printed layer at different temperatures.

Schematic of particle distribution mechanism of drying drops: a thermo-capillary flow due to temperature gradient; b particles follow the flow and attach to the droplet contact line; c uniform dispersion of particles at high temperatures. SEM images of ZnO nanowires with single printing layer at temperature: d 25 °C; e 40 °C; f 50 °C; g 60 °C; h ZnO nanowire dots (60 °C). Reproduced from Tsangarides et al. (2016) with permission from the Royal Society of Chemistry

Kukkola et al. (2012) have investigated gas-sensing properties of inkjet-printed WO3 nanoparticles on Si substrates decorated with various metal particles. Inkjet-printed patterns with different layers and different drying times are shown in Fig. 9, and gas-sensing responses of the printed sensors were found to be highly dependent on the metal modified surface as shown in Fig. 10. In yet another work, Riet et al. (2015) have developed inkjet-printed SnO2 gas sensors on polyimide foil with an annealing temperature of 400 °C. This sensor has been used for sensing of CO and NO gases under dry and wet air conditions. Bernacka-Wojcik et al. have investigated the electrical properties of the inkjet-printed TiO2 layers and found that these films have more porosity and surface area and hence higher efficiency than the doctor blade-made films of the same material with the same thickness. The printed layers also have better transport properties due to increased diffusion lengths (Bernacka-Wojcik et al. 2016).

Inkjet-printed patterns of WO3 nanoparticles: a printed droplet at a single location. Inkjet printing of four drops with 25 mm spacing using drying time of: b 0.2 ms and c 1.8 s between two subsequent printing drops. Reproduced from Kukkola et al. (2012) with permission from the Royal Society of Chemistry

Gas-sensing response of metal modified WO3 printed sensors to a CO, b H2, c H2S and d NO. Reproduced from Kukkola et al. (2012) with permission from the Royal Society of Chemistry

Till date some metal oxides have been explored for inkjet printing and successfully used for various electronic applications. However, their wide acceptability for flexible sensors is limited because of their requirement of high post treatment temperatures. This is not suitable for low temperature substrates. Hence, further research is needed to fully utilize such material ink for inkjet-printed sensor devices and also metal oxide-based sensor devices that are based on green chemistry approach (Patel et al. 2017).

3.3 Dielectric Materials

Dielectric materials are required in high-capacitance multilayer devices as an insulating layer to prevent leakage currents particularly in low-voltage applications. Both organic and inorganic (silica, alumina, etc.) materials are used as dielectric materials; however, inorganic materials have not yet been explored as dielectric layers for printed devices. Some organic materials have been explored for the printed electronics such as: polyvinyl alcohol, poly (methyl methacrylate), polyimide, poly (4-vinylphenol), polystyrene and terephthalate (Hamad et al. 2016; Pease and Chou 2008).

4 Substrates for Flexible Sensors

The requirement of foldable, bendable, malleable, smart and compact sensor devices has emerged from the requirements posed by printable flexible electronics. Fortunately, a lot of low-cost flexible substrates are available which are suitable for inkjet printing. The essential properties of a substrate which can be employed for flexible sensors are as follows: thermal stability, low coefficient of thermal expansion, flexibility, low cost, resistant to moisture and gases, transparency and high surface area to volume ratio. To date, flexible substrates used for inkjet-printed sensors are thin glasses (Zardetto et al. 2011), metal foils (MacDonald et al. 2007), papers (Wang et al. 2016), polymer sheets (Mabrook et al. 2006) and textile fabrics(Stempien et al. 2016a). Thin glass structures with good bending properties may also serve as a good choice, but their brittleness limits their utility for making flexible electronic devices. On the other hand, metal foils and tapes have good flexibility and high temperature resistance thus providing the possibility for practical use of inkjet-printed inorganic materials which need high sintering temperature, but their high cost, high material density and surface roughness make them unsuitable for low-cost flexible electronics.

4.1 Polymer-Based Substrates

Polymer-based materials have gained much attention for low-cost printed flexible electronics due to their suitable chemical, physical, mechanical and optical performance as depicted in Table 1. Despite the above suitable properties of polymers for printed electronics, its low glass transition temperature hinders its use for inorganic materials. Glass transition temperatures for various polymer substrates are shown in Fig. 11.

Polymer substrates for printable electronic structures can be divided as:

-

(i)

Semicrystalline substrate such as polyethylene terephthalate (PET), polyetheretherketone (PEEK) and polyethylene napthalate (PEN) (MacDonald et al. 2007; Zardetto et al. 2011; Choi et al. 2008).

-

(ii)

Amorphous substrates such as polyethersulphone (PES), polycarbonate (PC), polyimide (PI), polyaraylate (PAR), etc., (MacDonald et al. 2007; Zardetto et al. 2011; Choi et al. 2008).

One example of inkjet-printed patterns on flexible PET substrate is shown in Fig. 12 as developed by Ma et al. for application in touch sensors (Ma et al. 2015). Electrical resistance and transparency of the device decreased with increasing printing passes.

Images of inkjet-printed sensor on PET substrate with one printing layer under: a flat position; b bend position and c touch sensing visualization of the printed sensor. Reproduced from Ma et al. (2015) with permission from the American Chemical Society

4.2 Paper-Based Substrates

Paper has also been an attractive choice for inkjet-printed electronics due to its easy availability, environment friendliness, low cost, light weight and flexibility. It is a biodegradable and renewable substrate, and its surface properties can be easily modified by some chemical and other treatments which add extra flexibility to the structure (Sundriyal and Bhattacharya 2017). Although it is a potential candidate for the inkjet-printed electronics, however, its incapability to sustain high temperatures required for sintering of most of the metal-based inks limits its utility. Recently, Wang et al. (2016) have shown pre-treated papers with stannous chloride to decrease the ink absorption levels and have reported inkjet-printed copper patterns for disposable RFID tags and three-dimensional flexible and foldable devices as shown in Fig. 13.

a Printed circuit on paper. b Clipping of paper circuit with LED’s. c Working LED’s with folded paper circuit. Paper-based LED device in: d flat position and e bend position. f Optical image of disposable RFID tag on paper substrate. g Burning of RFID tag. h Burned RFID tag. Reproduced from Wang et al. (2016) with permission from the American Chemical Society

4.3 Textile-Based Substrates

Another class of substrates for inkjet-printed sensors are textile-based substrates which are an active topic of research for various applications in sectors like health care, military and aerospace for smart, wearable and disposable sensors. The special feature of this substrate is its wear-ability and biocompatibility. Wearable sensors have the ability to automatically detect the various life processes and activities and physical status of its own user, and any change in the surrounding environment will be able to provide feedback accordingly. An example of inkjet-printed textile for transmission lines is shown in Fig. 14 (Stempien et al. 2016b).

Digital images of inkjet-printed silver electrodes on: a polyacrylonitrile, b polypropylene and c basalt fabric. d Inkjet-printed silver transmission line on polypropylene textile and e impedance behaviour of printed transmission line. Reproduced from Stempien et al. (2016b) with permission from the Elsevier

4.4 Adhesion of Printable Ink with Substrate

Till date, various research groups have optimized several key factors of inkjet printing process like jet stability, physical properties of ink and post-printing treatments of the printed patterns to obtain good performance of the printed sensors. However, one of the unresolved issues is improper adhesion between printed patterns and the substrate which affects the overall performance and reliability of the printed sensors. Adhesion is the ability of a film to remain bonded to its substrate and depends on the morphology, chemical properties and interfacial properties of the interacting surfaces. Surface energies of the contacting surfaces and interface play an important role for adhesion control and governed by the Young’s equation (Young 1805) as follows:

where γ s is the surface energy of substrate, γ l is the surface energy of the ink droplet and γ sl is the interfacial free energy and θ is the contact angle between the interacting surfaces. For good adhesion, γ s should be very high than γ l.

Adhesion can be improved by modification of substrate’s surface using physical or chemical treatments, using an adhesion enhancing layer of Ni or Cr metals and by using silane coupling agents (Agina et al. 2015; Lee and Choa 2012). Lee et al. have used oxygen plasma treatment to generate hydrophilic groups to promote adhesion between the polyimide substrates and printed Cu patterns. Figure 15 shows comparative variation in contact angle before and after oxygen plasma treatment (Lee and Choa 2012). A drastic decrease in contact angle after substrate treatment exhibits incremental hydrophilic groups on the surface of the substrate, thus promotes the adhesion between interacting surfaces.

Contact angle variation between ink and polyimide substrate before and after oxygen plasma treatment. Reproduced from Lee et al. (2012) with permission from the Royal Society of Chemistry

5 Inkjet-Printed Sensors for Health care

One of the important applications of printed flexible electronics along with wireless networking is the development of smart health monitoring sensors. Recently, a number of inkjet-printed healthcare sensors have been reported for point-of-care diagnostics (Lesch et al. 2017), wireless monitoring of chronic wounds (Farooqui and Shamim 2016; Zhang et al. 2016), bacterial detection (Creran et al. 2014), detection of human chorionic gonadotropin by ELISA (Apilux et al. 2013) and wearable sensor for monitoring human physiological performance (Wang and Loh 2017). Lesch et al. (2017) reported an inkjet-printed microchip consisting carbon nanotube (CNT) as working and counter electrode while Ag/AgCl as reference electrode for point-of-care diagnostics application. The sample volume capacity of the developed sensor was 50 µL, and sensor can be used up to 20 times when using complex samples like blood. It is also reported that the printed CNT sensor shows better electrochemical response than the commercial carbon paste electrodes. Figure 16 shows inkjet-printed CNT sensor and its electrochemical response while Fig. 17 shows inkjet-printed sensor with a microfluidic channel for the measurement of blood sample and comparative linear sweep voltammograms of inkjet-printed CNT electrode and commercial carbon paste.

a Inkjet-printed CNT sensor (inset shows cyclic voltammogram of the three-electrode sensor in 2 mM FcMeOH and 0.1 M KCl at a scan rate of 50 mV/s), b microtitre plate with eight wells or eight units each with a sample capacity of 50 µL and an individual electrode cell (below image shows magnet location to fix magnetic beads for immunoassay-based detection), c plate holder with universal potentiostatic adapter and d multichannel for immunoassay-based detection. Reproduced from Lesch et al. (2017) with permission from the Electrochemical Society

a Blood sample uptake in the printed three-electrode sensor with a microfluidic channel and b comparative linear sweep voltammogram for inkjet-printed CNT electrode and commercial carbon paste at a scan rate of 100 mV/s. Reproduced from Lesch et al. (2017) with permission from the Electrochemical Society

6 Advantage, Limitation and Future Scope of Inkjet Printing Technology for Printed Sensors

Inkjet printing technology is a promising tool for flexible printed electronics including sensors. Its advantages, limitation and future scopes are as following:

6.1 Advantages

-

Simple and low cost: It is a simple method which is at a mature stage in industry for a variety of applications. Its comparative low cost other than competing deposition methods like photolithography, microcontact printing, etc., makes it attractive for printed electronics.

-

Material Saving: It is a direct deposition tool with negligible wastage of material. Unlike other processes, it does not require any mask, and material can be deposited only at the required area on the substrates.

-

Good resolution: It provides high-resolution printing.

-

Non-contact deposition: As it is a non-contact printing process thus eliminating/minimizing any contamination and distortion issues of the print layers.

-

Flexibility: Any shape or pattern can be easily printed by this process, and also patterns can be changed just by modifying the drawing in the software of the printer system.

6.2 Limitation

-

Rigid physical properties of ink: One of the major limitations of inkjet-printed sensor is the requirement of ink which follows strict rheological conditions with small range of viscosity and surface tension. It also limits concentration of sensing material in an ink and leads to the requirement of multiple printing cycles to achieve adequate packing density of the deposited material.

-

Requirement of additives and stabilizers: Additional materials like additives required to control the surface tension and viscosity and need for stabilizing agents to prevent agglomeration of nanoparticles that can negatively affect the sensing behaviour of the printed devices.

-

Coffee-ring patterns: Uneven drying of deposited materials lead to the coffee-ring effects which are undesirable for the sensing performance.

-

Slow speed: High printing speed is desired to compete with other processes. Speed can be increased by modifying drop frequency, number of nozzles, material concentration in ink and stand-off distance. However, modification of these parameters is very complex.

6.3 Future Scope

For the future of the electronics industry, inkjet printing is considered as an effective tool for compact, low cost and disposable flexible sensors. Its cost effectiveness and utility in combination to low-cost substrates may significantly shift the economy levels of the modern electronics industry. Its combination with other printing tools can efficiently develop the highly sensitive and low-cost sensors. Its compatibility with functional materials paves the path for further material research for inkjet-printed sensors. It can possibly replace the requirement of high-cost materials for sensing application and boosts the low-cost printed electronics market.

7 Conclusion

In summary, inkjet printing approach for flexible sensors is gaining much attention due to its suitability for large area flexible electronics. Researchers are in continuous surge to benefit sensor and other electronics from this micromanufacturing tool and have established a strong base for printed flexible electronics. Although some inherent limitations of this technology exist still with the advancement of this process, exploration of improved ink and new flexible substrates can certainly overcome the existing challenges.

References

Agina EV, Sizov AS, Yablokov MY, Borshchev OV, Bessonov AA, Kirikova MN, Bailey MJ, Ponomarenko SA (2015) Polymer surface engineering for efficient printing of highly conductive metal nanoparticle inks. ACS Appl Mater Interfaces 7(22):11755–11764

Andò B, Baglio S (2013) All-inkjet printed strain sensors. IEEE Sens J 13(12):4874–4879

Apilux A, Ukita Y, Chikae M, Chailapakul O, Takamura Y (2013) Development of automated paper-based devices for sequential multistep sandwich enzyme-linked immunosorbent assays using inkjet printing. Lab Chip 13(1):126–135

Arrese J, Vescio G, Xuriguera E, Medina-Rodriguez B, Cornet A, Cirera A (2017) Flexible hybrid circuit fully inkjet-printed: Surface mount devices assembled by silver nanoparticles-based inkjet ink. J Appl Phys 121(10):104904

Belsey K, Parry A, Rumens C, Ziai M, Yeates S, Batchelor JC, Holder SJ (2017) Switchable disposable passive RFID vapour sensors from inkjet printed electronic components integrated with PDMS as a stimulus responsive material. J Mater Chem C 5(12):3167–3175

Bernacka-Wojcik I, Wojcik P, Aguas H, Fortunato E, Martins R (2016) Inkjet printed highly porous TiO2 films for improved electrical properties of photoanode. J Colloid Interface Sci 465:208–214

Bhatt G, Kumar S, Sundriyal P, Bhushan P, Basu A, Singh J, Bhattacharya S (2016) Microfluidics overview. Microfluidics for biologists. Springer, Berlin, pp 33–83

Choi M-C, Kim Y, Ha C-S (2008) Polymers for flexible displays: from material selection to device applications. Prog Polym Sci 33(6):581–630

Creran B, Li X, Duncan B, Kim CS, Moyano DF, Rotello VM (2014) Detection of bacteria using inkjet-printed enzymatic test strips. ACS Appl Mater Interfaces 6(22):19525–19530

Crowley K, O’Malley E, Morrin A, Smyth MR, Killard AJ (2008) An aqueous ammonia sensor based on an inkjet-printed polyaniline nanoparticle-modified electrode. Analyst 133(3):391–399

Das SR, Nian Q, Cargill AA, Hondred JA, Ding S, Saei M, Cheng GJ, Claussen JC (2016) 3D nanostructured inkjet printed graphene via UV-pulsed laser irradiation enables paper-based electronics and electrochemical devices. Nanoscale 8(35):15870–15879

Derby B, Reis N (2003) Inkjet printing of highly loaded particulate suspensions. MRS Bull 28(11):815–818

Drahi E, Gupta A, Blayac S, Saunier S, Benaben P (2014) Characterization of sintered inkjet-printed silicon nanoparticle thin films for thermoelectric devices. Phys Status Solidi A 211(6):1301–1307

Farooqui MF, Shamim A (2016) Low cost inkjet printed smart bandage for wireless monitoring of chronic wounds. Sci Rep 6:28949

Foley TJ, Johnson CE, Higa KT (2005) Inhibition of oxide formation on aluminum nanoparticles by transition metal coating. Chem Mater 17(16):4086–4091

Fromm J (1984) Numerical calculation of the fluid dynamics of drop-on-demand jets. IBM J Res Dev 28(3):322–333

Hamad E, Bilatto S, Adly N, Correa D, Wolfrum B, Schöning MJ, Offenhäusser A, Yakushenko A (2016) Inkjet printing of UV-curable adhesive and dielectric inks for microfluidic devices. Lab Chip 16(1):70–74

Hwang H, Kim S-H, Kim T-H, Park J-K, Cho Y-K (2011) Paper on a disc: balancing the capillary-driven flow with a centrifugal force. Lab Chip 11(20):3404–3406

Jang D, Kim D, Moon J (2009) Influence of fluid physical properties on ink-jet printability. Langmuir 25(5):2629–2635

Kim DS, Khan A, Rahman K, Khan S, Kim HC, Choi KH (2011) Drop-on-demand direct printing of colloidal copper nanoparticles by electrohydrodynamic atomization. Mater Manuf Process 26(9):1196–1201

Kimura J, Kawana Y, Kuriyama T (1989) An immobilized enzyme membrane fabrication method using an ink jet nozzle. Biosensors 4(1):41–52

Komuro N, Takaki S, Suzuki K, Citterio D (2013) Inkjet printed (bio) chemical sensing devices. Anal Bioanal Chem 405(17):5785–5805

Kukkola J, Mohl M, Leino A-R, Tóth G, Wu M-C, Shchukarev A, Popov A, Mikkola J-P, Lauri J, Riihimäki M (2012) Inkjet-printed gas sensors: metal decorated WO3 nanoparticles and their gas sensing properties. J Mater Chem 22(34):17878–17886

Lee Y-I, Choa Y-H (2012) Adhesion enhancement of ink-jet printed conductive copper patterns on a flexible substrate. J Mater Chem 22(25):12517–12522

Lee Y-I, Kwon Y-T, Kim S, Lee K-J, Choa Y-H (2016) Hydrazine vapor-based rapid and low temperature post-processing for inkjet printed conductive copper patterns. Thin Solid Films 616:260–264

Lesch A, Jović M, Baudoz M, Zhu Y, Tacchini P, Gumy F, Girault HH (2017) Point-of-care diagnostics with inkjet-printed microchips. ECS Trans 77(7):73–81

Ma S, Ribeiro F, Powell K, Lutian J, Møller C, Large T, Holbery J (2015) Fabrication of novel transparent touch sensing device via drop-on-demand inkjet printing technique. ACS Appl Mater Interfaces 7(39):21628–21633

Mabrook MF, Pearson C, Petty MC (2006) Inkjet-printed polymer films for the detection of organic vapors. IEEE Sens J 6(6):1435–1444

MacDonald WA, Looney M, MacKerron D, Eveson R, Adam R, Hashimoto K, Rakos K (2007) Latest advances in substrates for flexible electronics. J Soc Inform Display 15(12):1075–1083

Morse J, Zhao Y, Rotello V, Nugen S, Watkins J (2016) Wearable microfluidic biomarker sensor for human performance assessment. In: Electronic system-integration technology conference (ESTC), 2016 6th, IEEE, pp 1–3

Patel V, Sundriyal P, Bhattacharya S (2017) Aloe-vera vs. poly (ethylene) glycol-based synthesis and relative catalytic activity investigations of ZnO nanorods in thermal decomposition of potassium perchlorate. Part Sci Tech 35:1–8

Pease RF, Chou SY (2008) Lithography and other patterning techniques for future electronics. Proc IEEE 96(2):248–270

Pi X, Zhang L, Yang D (2012) Enhancing the efficiency of multicrystalline silicon solar cells by the inkjet printing of silicon-quantum-dot ink. J Phys Chem C 116(40):21240–21243

Qin Y, Kwon H-J, Subrahmanyam A, Howlader MM, Selvaganapathy PR, Adronov A, Deen MJ (2016) Inkjet-printed bifunctional carbon nanotubes for pH sensing. Mater Lett 176:68–70

Rieu M, Camara M, Tournier G, Viricelle J, Pijolat C, de Rooij N, Briand D (2015) Inkjet printed SnO2 gas sensor on plastic substrate. Procedia Engineering 120:75–78

Singh M, Haverinen HM, Dhagat P, Jabbour GE (2010) Inkjet printing—process and its applications. Adv Mater 22(6):673–685

Song E, da Costa TH, Choi J-W (2017) A chemiresistive glucose sensor fabricated by inkjet printing. Microsys Tech 23(8):1–7

Stempien Z, Kozicki M, Pawlak R, Korzeniewska E, Owczarek G, Poscik A, Sajna D (2016a) Ammonia gas sensors ink-jet printed on textile substrates. In: Sensors, 2016 IEEE, pp 1–3

Stempien Z, Rybicki E, Rybicki T, Lesnikowski J (2016b) Inkjet-printing deposition of silver electro-conductive layers on textile substrates at low sintering temperature by using an aqueous silver ions-containing ink for textronic applications. Sens Actuators B Chem 224:714–725

Sundriyal P, Bhattacharya S (2017) Inkjet-Printed Electrodes on A4 Paper Substrates for Low-Cost, Disposable, and Flexible Asymmetric Supercapacitors. ACS Applied Materials & Interfaces 9(44):38507–38521

Tsangarides CP, Ma H, Nathan A (2016) ZnO nanowire array growth on precisely controlled patterns of inkjet-printed zinc acetate at low-temperatures. Nanoscale 8(22):11760–11765

Wang L, Loh KJ (2017) Wearable carbon nanotube-based fabric sensors for monitoring human physiological performance. Smart Mater Struct 26(5):055018

Wang Y, Guo H, Chen J-J, Sowade E, Wang Y, Liang K, Marcus K, Baumann RR, Feng Z-S (2016) Paper-based inkjet-printed flexible electronic circuits. ACS Appl Mater Int 8(39):26112–26118

Young T (1805) An essay on the cohesion of fluids. Philos Trans R Soc Lond 95:65–87

Zardetto V, Brown TM, Reale A, Di Carlo A (2011) Substrates for flexible electronics: a practical investigation on the electrical, film flexibility, optical, temperature, and solvent resistance properties. J Polym Sci Part B Polym Phys 49(9):638–648

Zhang X, Wasserberg D, Breukers C, Terstappen LW, Beck M (2016) Temperature-switch cytometry releasing antibody on demand from inkjet-printed gelatin for on-chip immunostaining. ACS Appl Mater Interfaces 8(41):27539–27545

Zheng Y, He Z, Gao Y, Liu J (2013) Direct desktop printed-circuits-on-paper flexible electronics. Scientific reports 3

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sundriyal, P., Bhattacharya, S. (2018). Inkjet-Printed Sensors on Flexible Substrates. In: Bhattacharya, S., Agarwal, A., Chanda, N., Pandey, A., Sen, A. (eds) Environmental, Chemical and Medical Sensors. Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-10-7751-7_5

Download citation

DOI: https://doi.org/10.1007/978-981-10-7751-7_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7750-0

Online ISBN: 978-981-10-7751-7

eBook Packages: EngineeringEngineering (R0)