Abstract

Printed electronics is an electronic device manufacturing technology that combines printing technology and high-end conductive materials. Compared with traditional electronic manufacturing methods, it does not rely on substrate materials, can be manufactured in large areas and in batches, reduce manufacturing costs, and is green and other advantages. Printed electronics technology can prepare sensors, flexible display devices, radio frequency identification tags, printed circuit boards, etc. This article mainly introduces the research progress in these four fields. The development of Printed electronics should focus on strengthening the research on printable electronic materials and printing substrates. Performance enhancements will further expand the range of printed electronics applications.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Printed electronics

- Flexible sensors

- Flexible printed circuit boards

- Radio Frequency Identification

- Flexible display device

1 Introduction

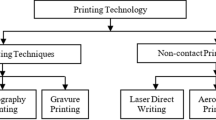

Printing mainly electronic components of the specific design as a guide, with all kinds of printing process will be conductive, dielectric, piezoelectric or semiconductor electronic characteristics of electronic ink through layer by layer printing complete electronic ink in different substrate graphical transfer printing, and then realize the science and technology of manufacturing electronic circuits or component products by printing [1].

The printing electronics processing process only needs to deposit conductive ink containing functional materials on the surface of the substrate in a patterned manner, and then only needs to perform a sintering process to sinter the ink material into a solid material, and the same graphic structure as the traditional process can be achieved [2].

Printed electronic device manufacturing not only has a big difference in the composition and performance of conductive inks from traditional printing inks, but also has special pre-press and post-press treatment processes. Printed electronics has higher requirements for the uniformity of the conductive ink layer, surface flatness, and line edge smoothness. Therefore, the traditional printing process must adjust the plate-making parameters, printing conditions and other aspects according to the printed graphics.

2 Flexible Sensor

A sensor is a detection device that can detect relevant information and its changes, and convert the detection information into electrical signals or other forms of information through certain rules, which can meet the functional requirements of information transmission, processing, storage, display and recording [3]. However, with the continuous changes in the test environment and detection information, sensors are required to be more integrated and intelligent, while also having the advantages of transparency, flexibility, durability and portability.

Therefore, the flexible sensor came into being. The flexible sensor is based on a flexible material, and different functional materials are printed on the substrate according to the design to realize the detection function [4], as shown in the Fig. 1a Flexible printing technology is the main way to manufacture flexible sensors, and in flexographic printing technology, screen printing is the most widely used printing method [5].

Biosensors have the characteristics of high selectivity and specificity, short response time, fast speed, and can be used to detect bioactive molecules with a variety of instruments. Huang et al. [6] designed and manufactured a H2O2 biosensor based on PSACD nanoparticle-modified screen-printed electrode, which has excellent electrochemical properties. The lowest detection limit is 0.02 mmol/L, the response speed is fast, and the specific selectivity and anti-interference ability are good. Dong et al. [7] designed an aflatoxin B1 biosensor based on screen-printed electrodes and acetylcholinesterase amperes, which used nano-gold, graphene and its complexes enhance the current response of electrochemical immunosensors. Therefore, the made sensor has a linear detection range of 1–64 μg/mL and a minimum detection limit of 0.05 μg/mL, and has excellent performance such as high sensitivity, stability, and selectivity. Zhang et al. [8] also use graphene as a modified material, add graphene to the flexible substrate and then make the sensor (Fig. 1b), using the excellent pressure change effect of the graphene material, the sensor has a super high Sensitivity, can be applied to the human body and precision instruments.

Zheng et al. [9] made a flexible micro-nano sensor based on SWNTs, as shown in Fig. 1d. The sensor has the advantages of high precision, and low hysteresis, and shows a certain application prospect in the field of flexible micro-nano device manufacturing, paving the way for the realization of ultra-miniaturization and high-function density flexible devices. Liu et al. [10] printed conductive carbon paste on the substrate by screen printing to prepare piezoresistive conversion elements. And further manufactured them into piezoresistive acceleration sensor. The sensor is based on high temperature photosensitive resin and has a sensitivity coefficient of 10.6798. It also has the advantages of good Young's modulus and bending strength. Piezoresistive acceleration sensor as shown in Fig. 1c.

The development of flexible and stretchable substrates, geometric circuit design, printed electronic ink development, and the combination of new material concepts can develop flexible sensors with the perfect combination of sensitivity and flexibility. The future research direction will be to develop more economical, multi-functional and biocompatible flexible sensors, and to broaden the prospects of various innovative applications of flexible sensors in the fields of medicine, healthcare, environment and biology [11].

3 Flexible Display Device

Flexible electronic display is to make TFT (thin film transistor) devices on a flexible substrate. It is different from the liquid crystal display, the OLED and QLED inside the flexible electronic display are self-luminous devices and can be bent and deformed at will. With the continuous innovation of OLED technology, printed display materials and equipment skills have achieved rapid development.

Jack et al. [12] prepared a flexible display that can realize colorful display by lithography method. The display can be made with different substrates, and the electrode preparation is not only low in cost, but also in mass production. Wu et al. [13] fabricated a high-resolution flexible AMOLED display integrated with a new gate drive circuit using metal oxide TFTs with a BCE structure on a polyimide (PI) substrate, as shown in Fig. 2a. The flexible panel has good full-color display quality and no obvious defects in bending state. Output signal of the proposed gate driver is not distorted and has good noise suppression characteristics, and can remain stable under continuous long-term operation for up to 15 days.

James et al. [14] used staggered electrodes to prepare electrochromic displays by screen printing, as shown in Fig. 2b. Qian et al. [15] designed a printed flexible display based on double-layer polymer dispersed liquid crystal film. The PDLC thin-film electronically controlled optical switch has the advantages of high contrast, low cost, simple process and easy colorization. And the display screen uses natural light as the light source, forms color vision through reflected light, which is more suitable for human eyes to read, as shown in Fig. 2c. Simon et al. [16] use personalized digital inkjet printing or screen printing to make customized thin-film displays on substrates of any shape, as shown in Fig. 2d. This method can adjust the printing method according to the substrate, and produce a personalized display screen on almost any surface. The flexible display screen can also integrate input sensing and TFEL display to realize interactive use by users.

4 Radio Frequency Identification

Radio Frequency Identification (RFID) is a technology that automatically identifies targets through radio frequency signals and reads and writes data on the targets. The radio frequency identification system mainly consists of electronic tags, card readers and processors. Compared with traditional barcodes, magnetic cards and IC cards, RFID have the advantages of non-contact, fast reading and writing, low environmental impact, long durability and convenience. Thanks to these advantages, RFID is combined with the Internet of Things, Big Data and Cloud Computing, and is widely used in production, logistics, transportation, anti-counterfeiting, tracking, and asset management applications.

Shen et al. [17] With the help of GS1 global unified identification, a coding system was established, data exchange standards were developed, and a unified gas cylinder safety management system was built, as shown in Fig. 3a. In this way, it is not only possible to analyze the management organization, responsible personnel and equipment information in the transportation process through the Internet of Things, but also to master various data of the gas cylinder. It can effectively guarantee the safety of production, sales, transportation and use.

Li et al. [18] combined the characteristics of the electroplating industry and electroplating production process to design a quality traceability system of electroplating parts based on radio frequency identification technology, as shown in Fig. 3b. The system can write electroplating production information and electroplating parts batch information into electronic tags. Created a product quality traceability system applicable to the electroplating industry, realized product quality traceability services, better checked for omissions, and made up for losses.

Wang [19] designed a tool management system based on radio frequency identification technology, as shown in Fig. 3c, taking full advantage of the non-contact and fast recognition speed of RFID electronic tags, combining software and PDA handheld terminals, realize quick tool loan, return and inventory functions. Greatly simplify the tool management process and improve work efficiency.

Ren [20] designed a real-time optimization system of logistics distribution route based on Radio Frequency Identification technology. The system uses RFID tag identification technology to achieve active identification of the type of logistics, delivery speed and load information, and combines GPS positioning and ZigBee network technology to design a logistics distribution route self-organizing network to realize instant optimization of logistics distribution routes. Yang et al. [21] developed an intelligent cold storage and RFID seed storage tag, which can help relevant management departments to achieve Strict monitoring of seeds. It not only can improve the protection of seed property rights, but also guarantee the rights and interests of consumers.

Ran et al. [22] designed a photoelectric radio frequency identification (ORID) tag with chip antenna (OCA), as shown in Fig. 3d. A reader with a radio frequency output of 20 dbm can successfully respond to the tag at a distance of 6 mm. This technology can reduce to a certain extent the environmental pollution of high-power radio frequency signals in space and the damage to human health.

5 Flexible Printed Circuit Board

Flexible printed circuit board uses polyimide (PI) and other materials as the base material, and uses conductive materials on its surface to form a circuit. Printed circuit with good flexibility. Flexible printed circuit boards have the advantages of light weight, small size, good heat dissipation and arbitrarily bending, so they are widely used in aerospace, military, electronics and medical equipment and other fields [23].

At present, the performance of flexible printed circuit boards is mainly improved by introducing some new materials with excellent performance. Mei et al. [24] made a flexible graphene conductive circuit board, as shown in Fig 1b. The conductive lines of the graphene oxide paste screen printed on the flexible substrate are reduced by hydrogen in the MCVD device, so the produced graphene wires have high electrical conductivity, thermal conductivity and diamagnetism. Wang et al. [25] by adding boron nitride nanoparticles, polyvinyl alcohol and glass fiber mesh to prepare special composite paper substrates, and then Make a flexible printed circuit board, as shown in Fig. 4a. The circuit board prepared in this way has good thermal conductivity, tensile strength and stable high-frequency signal transmission performance. Song et al. [26] used the vacuum-assisted hot pressing method to produce a sandwich bonded graphene laminate (GCL), as shown in Fig. 4b2, c, which could be of great application value as a new generation PCB in fluorinated electronics and wearable devices.

Inkjet printing is convenient and environmentally friendly. Therefore, Kang et al. [27] used inkjet printing technology to prepare chromatographic paper-based two-layer flexible circuit boards, as shown in Fig. 4d, which have good flexibility and low resistance, and can be made into simple paper-based FPCB circuit board, meet the use of various shapes. Yan et al. [28] used conductive silver glue as the printing material, fabric as the printing substrate, and screen printing to make flexible circuit boards. The fabric circuit boards have good conductivity, flexibility, and wash ability. And tensile properties. The flexible printed circuit board not only has various printing methods, but also can print the circuit board on the surface of different materials.

6 Conclusions

Compared with traditional electronic manufacturing technology, the field of printed electronics has huge advantages such as large area, flexibility, low cost, and environmental protection. The development of inorganic nanomaterials technology has led to simultaneous progress in various fields of printed electronics. In the past decade, the research on printed electronics technology has increased significantly, and there have been many scientific research results.

Printed electronics is limited by the performance of current printed electronic materials, substrates and printing methods, and has not become the mainstream manufacturing method of organic electronic devices. The development of printed electronics should focus on strengthening the research on printable electronic materials and printing equipment, improving electrical performance, printing performance and environmental stability. Developing corresponding high-performance printable electronic materials for different applications. Improved performance can drive the growth of printed electronics applications. In the future, printed electronic systems can be combined with different materials to achieve different applications.

References

Xin ZQ, Hu K (2018) Principles and technology of printing manufacturing. Cultural Development Press, Beijing, 5:1

Cui Z, Wang Z (2019) Analysis and development trend of flexible printed electronic technology. Integr Circ Appl 036(002):26–29

Zhang MR, Zhao JN et al (2019) A flexible sensor for reduced graphene oxide. Science and Technology Wind

Duan JR, Li B, Li SZ (2015) Research progress of commonly used new flexible sensors. Sens Microsyst 11:1–4

Jiang Y, Ma JL, Zhu N (2020) Flexible printed wearable electrochemical sensor. Chem Bull 83(4)

Huang XW, Xu S, Zhao W et al (2020) Polymer nano-assembly modified screen-printed electrode to construct hydrogen peroxide sensor. Chin J Appl Chem 37(2):235–241

Dong YJ, Wang YR, Zhao SC et al (2019) Aflatoxin detection method based on screen-printed electrodes and acetylcholinesterase amperometric biosensor. Mod Food Sci Technol

Zhang MR, Mou CY, Zhao JN et al (2019) A flexible sensor for reduced graphene oxide. Sci Technol Wind

Zheng FZ, Wu Y, Zhang J et al (2019) Piezoresistive flexible sensor based on single-walled carbon nanotubes. J Sens Technol (7)

Liu CQ, Zhao YL, Liu MJ et al (2019) Design of 3D printing acceleration sensor based on photosensitive resin analysis. Navig Control 018(004):45–51, 70

Han ST, Peng H, Sun Q et al (2017) An overview of the development of flexible sensors. Adv Mater 29(33):1700375.1–1700375.22

Jack S, Robert W, George RF et al (2008) Manufacture of miniaturized electrode wiring of electroluminescent display by lithography method. Electron Dev 01:18–22

Wu WJ, Chen JW, Wang JS et al (2018) High resolution flexible AMOLED display integrating gate driver by metal oxide TFTs. IEEE Electron Dev Lett,1–1

James P, Coleman, AT, Lynch PM et al (1999) Printed, flexible electrochromic displays using interdigitated electrodes. Solar Energy Mater Solar Cells 56(3):395–418

Qian J, Wen SQ, Tang CQ et al, Method for printed flexible display based on double-layer pdlc film: CN

Olberding, S, Wessely, M, Steimle, J et al (2014) PrintScreen: fabricating highly customizable thin-film touch-displays. User interface software and technology, 281–290

Shen SS (2019) The role of RFID electronic tags in gas cylinder safety supervision. China Autom Identif Technol 77(02):72–73

Li B, Guo T, Chen HW (2019) Electroplated parts quality traceability system based on radio frequency identification technology. Electroplating Environ Protect 039(002):62–64

Wang C (2020) Design of tool management system based on radio frequency identification technology. Electron Prod

Ren XC (2019) Real-time optimization system design of logistics distribution route based on radio frequency identification technology. Autom Instrument

Yang BL, Wu SQ (2019) The application of intelligent storage cold storage and RFID radio frequency identification technology in seed resources. Trop Agric Eng (3)

Ren CY, Mao LH, Xie S (2018) A new kind of visible light-RFID technology and verified by an optical-RFID tag with on-chip antenna. Acta entiarum Naturalium Universitatis Nankaiensis

Chen A (2013) Research on key technologies of automatic production equipment for flexible printed circuit boards. South China University of Technology

Mei CR, Chen GG, He MQ et al (2019) Trial production and performance testing of flexible graphene circuit boards. Printed Circ Inf (8)

Wang T, Ou DI, Liu HH et al (2018) Thermally conductive boron nitride nano sheet composite paper as a flexible printed circuit board. Acs Appl Nano Mater acsanm.8b00160

Song R, Zhao X, Wang Z et al (2020) Sandwiched graphene clad laminate: a binder-free flexible printed circuit board for 5G antenna application. Adv Eng Mater

Kang MY, Kang YT (2018) Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics. Int J Precis Eng Manuf Green Technol

Yan YS, Guo Y, Wang LM et al (2019) Preparation and properties of printed circuits on fabric surface. Printing Dyeing 21:27–32

Acknowledgments

This study is funded by Beijing Municipal Education Commission Scientific Research Project Funding-3D printing composite gel material for cartilage repair research (Grant No. KM201910015009), Science and Technology Major Project Foundation of Fujian Province (Grant No. 2015YZ0003), and Study on hyaluronic acid-based hydrogel for cartilage repair (Grant No. 22150120041/033), and Surface printing coating technology of cerebrovascular stent (Grant No. 11000300378), and 3D printing and its application in biomedicine (Grant No. 11000300653), and Cultivation of Innovative Talents Cultivation and Curriculum Development of Soaring College, Beijing No. 5 Middle School Chemistry Base (Grant No. 11000300731), and 3D printing customized bone material and mold design and preparation (Grant No. 11000300880),and Preparation of 3D printing educational model (Grant No. 11000300897).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wang, J. et al. (2021). Development Status and Trends of Several Major Flexible Printed Electronics. In: Zhao, P., Ye, Z., Xu, M., Yang, L., Zhang, L., Zhu, R. (eds) Advances in Graphic Communication, Printing and Packaging Technology and Materials. Lecture Notes in Electrical Engineering, vol 754. Springer, Singapore. https://doi.org/10.1007/978-981-16-0503-1_53

Download citation

DOI: https://doi.org/10.1007/978-981-16-0503-1_53

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0502-4

Online ISBN: 978-981-16-0503-1

eBook Packages: EngineeringEngineering (R0)