Abstract

This chapter highlights and discusses the important research studies that have been carried out previously on sulphate removal from wastewaters under anaerobic conditions. Moreover, the role of electron donor addition on biological sulphate reduction and the beneficial role of sulphate-reducing bacteria (SRB) are reviewed in this chapter. This chapter describes the fundamentals of the anaerobic sulphate reduction process, the factors affecting biological sulphate reduction and the different bioreactor configurations used for sulphate removal from wastewater.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Biological sulphate reduction

- Sulphidogenesis

- Bioreactors

- Electron donors

- Sulphate-reducing bacteria

- Sulphate-rich wastewater

1 The Sulphate Reduction Process

1.1 Sulphur Cycle

The tenth most abundant element on the surface of the earth is sulphur. Microorganisms require sulphur for the processing of vitamins, amino acids and hormones. Microbes play a major role in the biogeochemical sulphur cycle. The sulphur oxidation states are −2 (sulphide), 0 (elemental sulphur), +4 (sulphite) and +6 (sulphate), among which sulphate is very important for nature. Sulphur biogeochemical pathways are known to interact with those of other elements, especially metals (Pepper et al. 2004).

Wastewaters with high sulphate concentrations are produced through leaching from landfills (Nedwell and Reynolds 1996), and this leaching process can cause an unbalance to the natural biological sulphur cycle by altering the biodegradation pathways and the kinetic rates. A different oxidation state (−2 up to +6) of sulphur can be found in other sources such as wastewater from the textile industry. Cirik et al. (2013) reported that sulphate in textile industries is added to dye baths for regulating the ionic strength. Deep sea venting, volcanic activity, bacterial activities, fossil fuel combustion and industrial emissions are some of the major sources of sulphate in the atmosphere. Sulphate oxidized from sulphur in the atmosphere can be deposited in wet or dry form.

Redox reactions generally characterize the sulphur cycle as shown in Fig. 1. Sulphur can be reduced to sulphide, which in turn can be oxidized to elemental sulphur or sulphate by microbes. However, sulphate can be reduced back to sulphide by sulphate-reducing bacteria (SRB) (Robertson and Kuenen 2006). The release of sulphur aerobically or anaerobically from its organic form is known as sulphur mineralization.

Chemoautotrophic and heterotrophic microorganisms, including bacteria and fungi under aerobic conditions oxidize sulphur to sulphate or thiosulphate. Phototropic or chemolithotrophic bacteria fix carbon dioxide (CO2) by utilizing light energy in order to oxidize sulphide to sulphur or sulphate. When there is an imbalance in the reductive or oxidative pathways, an accumulation of intermediates such as elemental sulphur, iron sulphide or hydrogen sulphide occurs. The process of sulphur disproportionation is an energy-generating process carried out by SRB, wherein elemental sulphur or thiosulphate acts as both the electron donor and the electron acceptor and results in the formation of sulphate and sulphide, respectively (Tang et al. 2009).

1.2 Biological Sulphate Reduction

Two anaerobic microbial degradation pathways (Fig. 2) are well documented in the literature. The sulphate removal can be assimilatory or dissimilatory (Fig. 3). In the assimilatory pathway, sulphate is reduced to sulphide, in small quantities, and later the sulphide is converted to cysteine. This amino acid is the source of other biological sulphur-containing molecules (Leustek et al. 2000). The dissimilatory pathway is confined to two archaeal and five bacterial genera, wherein the terminal electron acceptor (sulphate) produces large quantities of sulphide and the process is also known as sulphidogenesis (Grein et al. 2013). The two pathways have a similar starting point: the activation of sulphate by reaction with adenosine-5ʹ-Triphosphate (ATP) forming adenosine-5ʹ-phosphosulphate (APS). Sulphate adenylyl transferase (SAT) acts as a catalyst in this step, also referred to as ATP sulphurylase (Taguchi et al. 2004).

Pathway for anaerobic degradation of organic substrates: a sulphidogenesis and b methanogenesis (adapted from Muyzer and Stams 2008)

Prokaryotic assimilatory and dissimilatory pathways for sulphate reduction (adapted from Grein et al. 2013)

Sulphate is reduced using an electron donor to produce sulphide and SRB are responsible for this process (Hao et al. 1996). Table 1 summarizes sulphate reduction (Eqs. 1–14) using electron donors such as lactate, propionate, acetate and hydrogen.

In the first step of sulphate reduction, the exogenous sulphate is transferred through the bacterial cell membrane into the cell. In the next step, the ATP sulphurylase facilitates the sulphidogenesis process in the cell membrane (Fig. 3). In the presence of sulphate, the highly activated molecule APS, and pyrophosphate (PPi) is produced by the ATP. The cytoplasmic enzyme APS reductase converts the APS to sulphite (SO3 2−), which in turn can be reduced to form the sulphide ion via several intermediates. The physiology and growth of SRB have been studied extensively and discussed in the literature (Hao et al. 1996; Matias et al. 2005; Muyzer and Stams 2008; Rabus et al. 2006; Zhou et al. 2011).

1.3 Sulphate-Reducing Bacteria (SRB)

SRB can be categorized into two classes depending on their biodegradation potential: those leading to incompletely degradable organic compounds forming acetate and those completely degrading organics to CO2 (Muyzer and Stams 2008). The availability of substrate is sometimes affected by the competition between SRB and the methanogens. Several factors facilitate SRB in outcompeting methanogens. These factors include anaerobic respiration in the presence of sulphate as the final electron acceptor leading to more energy for the growth of SRB and at conditions difficult for methanogens to survive. In addition, SRB are able to consume substrates to very low concentrations because of their high affinity for hydrogen and acetate (Rabus et al. 2006). It is noteworthy to mention that SRB have a higher specific growth rate compared to methanogens (Moestedt et al. 2013). Desulfovibrio species has a high affinity for hydrogen and this is contemplated to be the rational for outcompeting hydrogenotrophic methanogens under sulphidogenic conditions (Widdel 2006). Desulfobacter, Desulfobulbus, Desulfococcus, Desulfocarcina, Desulfomaculum, Desulfonema and Desulfovibro use sulphate as the terminal electron acceptor, using acetate, lactate and methanol as the electron donor (Pepper et al. 2004). Polymeric compounds such as protein, starch and cellulose are not utilized directly by SRB as the substrates, but they depend on other microorganisms to ferment these compounds to products which can be used as substrates by the SRB.

An analysis of 16S ribosomal ribonucleic acid (rRNA) by Muyzer and Stams (2008) grouped SRB into seven different lineages, two of which were archaea and five were bacteria (Fig. 4). From an application viewpoint, the SRB are classified by their oxygen sensitivity and their affinity towards using sulphate as an electron acceptor. Besides, different species within the same genus can also show great differences in their selectivity towards a particular type of electron donor. For example, the genus Desulfotomaculum can use acetone, aniline, acetate, catechol, ethanol, indole and other carbon sources for its growth. The genus Desulfovibrio uses lactate, pyruvate and hydrogen as electron donors for its growth. Thus, depending on the species, different organic substrates can be used by the SRB, leading to acetate or CO2 as the end product.

Phylogenetic tree on 16S ribosomal RNA (rRNA) sequence of SRB species (adapted from Muyzer and Stams 2008)

The ecology, bioenergetics and physiology of SRB have been discussed in a number of review articles (Barton and Fauque 2009; Gibson 1990). SRB are known to exist in different environments such as: anoxic estuarine sediment, acid mine water, saline water, freshwater and in several soil types. The temperature range at which they grow is also diverse, and thermophilic SRB have been isolated at temperatures >60 ℃ in deep aquifers (Hao et al. 1996). According to Mizuno et al. (1998), hydrogen-consuming and lactate-consuming SRB can be enumerated using the most probable number (MPN) counting technique, while qualitatively, the presence of SRB can be confirmed by the presence of black FeS precipitates.

2 Electron Donors for SRB

Al-Zuhair et al. (2008) determined the appropriate sulphate concentration required for pure cultures of SRB and their sulphate reduction capacities. As shown in Table 2, several electron donors have been studied as energy and carbon sources for the growth of SRB. The commonly used electron donors for biological sulphate removal are products from fermentation, monomers or cell components from other sources. As shown in several studies, hydrogen is one of the most important substrates for SRB. According to Widdel (2006), Desulfovibrio species has a high affinity for hydrogen, and this property facilitates them to outcompete hydrogenotrophic methanogens in sulphate-rich environments.

Furthermore, SRB require nitrogen, phosphorus and iron. Complex organic carbon sources can also serve as energy sources for SRB. Sewage sludge was one of the first carbon sources considered because of its complexity (Butlin et al. 1956). van Houten et al. (1996) studied the use of synthesis gas (H2, CO and CO2 mixture) as energy source, and a stimulation of biological sulphate reduction was observed in the presence of SRB. A wide variety of commonly available organic waste matrices such as mushroom, leaf mulch, wood chips, sewage sludge, sawdust, compost, animal manure, whey, vegetable compost and other agricultural waste has also been used as carbon sources and electron donors for biological sulphate reduction (Liamleam and Annachhatre 2007).

2.1 Organic Polymeric Compounds

2.1.1 Starch

Potato is a staple food in Europe and other parts of the world. It is produced in large quantities in the Netherlands, and according to a recent report, the estimated potato production in the year 2011 was ~73 million metric tons (FAOSTAT 2011). Table 3 shows the composition of fresh potato. They contain ~70–80% water and starch counts for 16–24% of the total weight. Potato is considered to be the fourth most important tuberous food crop in the world after wheat, rice and maize. Kang and Weiland (1993) ascertained the biodegrading characteristics of potato using batch tests and reported that ~90% potato could be degraded at 35 ℃, at a substrate to inoculum ratio of 0.8.

2.1.2 Cellulose

Cellulose exists in abundance on the earth under different forms. The anaerobic degradation of cellulose begins with depolymerisation and is followed by solubilisation. Besides, the degradation products of cellulose (i.e. cellobiose) can be converted to CH4 and CO2 through acidogenesis, acetogenesis and methanogenesis. When anaerobic microorganisms excrete cellulosomes from their cell wall, they are attached to the cellulose particles. Several studies have argued whether the bacterial hydrolysis or methanogenesis phase is the rate-limiting step for the biotransformation of polymeric compounds rich in cellulose content (Jeihanipour et al. 2011). Recent studies have demonstrated the anaerobic digestion of cellulose under mesophilic and thermophilic conditions (O’Sullivan et al. 2008; Xia et al. 2012). According to Yang et al. (2004), in batch experiments, thermophilic cellulose digestion is less effective compared to mesophilic conditions. In that study, 16% volatile solids were removed under thermophilic conditions, while 52% volatile solids were removed under mesophilic conditions in 30 d.

2.1.3 Proteins

The hydrolysis products of proteins under anaerobic conditions include peptides and amino acids, which are further degraded to ammonium, carbon dioxide, short-chain fatty acids and hydrogen. According to Örlygsson et al. (1994), the hydrolysis of protein is frequently affected by the electron acceptor availability. The hydrolysis rate under anaerobic conditions is lower than that observed under aerobic conditions. Deamination is the initial step of the degradation of protein, which is favoured under aerobic rather than anaerobic conditions (Shao et al. 2013). Only a few members of the Desulfobacterium, Desulfotomaculum and Desulfovibrio genera utilize amino acids. Baena et al. (1998) reported that the addition of thiosulphate to the growth media enabled to optimize the degradation of amino acids by an SRB (Desulfovibrio aminophilus sp. nov. DSM 12254), indicating the role played by sulphate and thiosulphate in the degradation of proteinaceous compounds.

2.1.4 Chitin

Chitin is a polymer, occurring naturally as a white, hard, inelastic and nitrogenous polysaccharide. It can be found in the exoskeletons of crabs and shrimps in the alpha-chitin form (Rinaudo 2006). The beta-chitin form has a higher affinity for solvents than the alpha form because it has weak hydrogen bonds (Pillai et al. 2009). One of the derivatives of chitin is chitosan which is obtained by the alkaline deacetylation of chitin in a strong alkaline solution.

2.2 Selection of Electron Donors for Biological Sulphate Reduction

According to van Houten et al. (1996), the following three criteria’s can be used for selecting a suitable electron donor for biological sulphate reduction: (i) high sulphate efficiency complemented by a low COD effluent concentration, (ii) electron donor availability and (iii) cost of sulphate converted to sulphide. Thermodynamic parameters such as physiological free energies ΔG0ʹ (kJ mol−1) of the sulphidogenesis (Table 1) are also important for the sulphate reduction efficiency.

2.2.1 Efficiency of Sulphate Removal

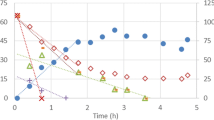

The information presented in Table 4 indicates that acetate (28.5 g L−1 d−1), ethanol (21 g L−1 d−1) and hydrogen (51 mmol L−1 d−1) support the highest sulphate redection rates. On the other hand, lactate (0.41 g L−1 d−1) and molasses (<6.5 g L−1 d−1) support lower sulphate removal rates. The electron donors summarized in Table 4 indicate different affinities of SRB for the carbon source (Stams et al. 2005). Additionally, the bioreactor configuration also plays an important role in determining the sulphate reduction efficiency (Kijjanapanich et al. 2014). The key factor affecting the sulphidogenesis during long-term bioreactor operation is the capability of retaining the active SRB in the bioreactor.

2.2.2 Availability and Cost of Electron Donor

Lactate and molasses are cost-effective, but they are not completely oxidized by SRB. They also generate high COD concentrations in the effluent (Liamleam and Annachhatre 2007). Hydrogen and ethanol are used as electron donors when the sulphate load exceeds 200 kg SO4 2− h−1. Besides, hydrogen and ethanol are not cost-effective; however, due to safety reasons, ethanol is preferred over hydrogen.

2.3 Environmental Parameters Affecting Sulphate Reduction

2.3.1 Temperature

A very important factor in the anaerobic digestion process is temperature, and the performance of bioreactors usually varies depending on the operating temperatures and the adaptability of the microbes to different temperature ranges (Table 5). SRB comprise both mesophilic and thermophilic strains which are affected by temperature. Weijma et al. (2000) showed a significant increase in sulphate reduction when temperature was increased from 20 to 35 ℃, but bacterial activity decreased at 40 ℃. According to Tsukamoto et al. (2004), the efficiency of acid mine drainage (AMD) treatment was not affected by temperature due to the acclimatization of SRB to low-temperature conditions over prolonged time. Thermophilic processes lead to H2S stripping, thereby reducing its concentration (S2−) in the liquid phase. Therefore, the treatment of sulphate-rich wastewater can be more efficient at temperatures ranging between 55 and 70 ℃ (Sarti and Zaiat 2011).

2.3.2 pH and S2− Concentration

SRB show high specific activities in the pH range of 5.0–8.0. Beyond this range, their metabolic activity reduces and inhibition effects set in (Dvorak et al. 1992). Sheoran et al. (2010) reported that some SRB are able to remove 38.3% of sulphate from the influent at a pH of 3.3, but their removal performance dropped when the pH was reduced to ~3.0. The hydrogen sulphide and bicarbonate present in the system buffers the solution pH; however, the buffering capacity depends on the type and quantity of organic end products (Dvorak et al. 1992). This can cause inhibition of anaerobic digestion (AD) and could lead to a complete failure of the process. The effect of sulphide is believed to be caused by non-ionized H2S, because neutral molecules can permeate through the cell membranes (Sarti and Zaiat 2011).

2.3.3 Hydraulic Retention Time (HRT)

The HRT determines the time allowable for the SRB to adapt to the environment, initiate growth and metabolic activity, thereby increasing the amount of sulphate or COD reduced. In bioreactors for sulphate reduction, a long HRT may lead to high sulphate reduction efficiencies and a complete oxidation of the electron donor used with minimal residual acetate concentrations (Kaksonen et al. 2006). However, according to Sheoran et al. (2010), a short HRT may reduce the time available for the SRB to metabolize the substrate and could lead to complete washout of biomass from the reactor.

3 Bioreactors for Sulphate Reduction

Several branches of biotechnology use bioreactors, such as the production of biofuels (Ozmihci and Kargi 2008), food products (Genari et al. 2003), pharmaceutical compounds (John et al. 2007) and the treatment of environmental pollutants (Show et al. 2011). Anaerobic wastewater treatment systems use mixed microbial consortia, which is somewhat different compared to other biotechnological processes where isolation or/and sterilization is required (Goršek and Tramšek 2008). Setting different steps of a process in one stage can make the process more attractive in terms of process intensification. Therefore, the use of flocs, granules and biofilms is of great interest in the field of environmental biotechnology. This is possible by facilitating solid–liquid–gas separation, and these coupled to the reactor configuration make the separation of the three phases and downstream processing feasible.

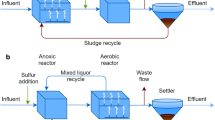

Laboratory-scale experiments have shown promising results for the treatment of wastewater rich in sulphate by using different bioreactor configurations. A variety of bioreactors (Fig. 5) such as expanded granular sludge bed reactors (EGSB), fluidized bed reactors (FBR), gas-lift bioreactors (GLB), inverse fluidized bed reactors (IFB), membrane bioreactors (MBR), sequencing batch reactors (SBR) and upflow anaerobic sludge blanket (UASB) reactors have been applied for sulphate reduction in wastewaters (Sheoran et al. 2010). Numerous two-stage processes combining anaerobic biological sulphate reduction with an aerobic step have also been used at the laboratory scale (du Preez et al. 1992; Maree and Hill 1989). Upflow packed bed reactors (Fontes Lima and Zaiat 2012; Peixoto et al. 2011), stirred tank reactors (Kieu et al. 2011), sulphate-reducing columns (Baskaran and Nemati 2006) and biofilm reactors (D’Acunto et al. 2011) have also been studied. These bioreactors have shown efficient sulphate reduction efficiencies alongside the selective removal of heavy metals from effluents by sulphide precipitation (Sampaio et al. 2010; Villa-Gomez et al. 2011).

3.1 UASB Reactor

The UASB reactor is a mature technology for wastewater treatment (van Lier et al. 2015). The UASB reactor is operated at upward velocities <2 m h−1 (Hulshoff Pol et al. 2004; van Haandel et al. 2006). A UASB is considered as a high-rate bioreactor because of its capability to deconvolute the solid retention time (SRT) from the HRT. The deconvolution of the HRT from the SRT is possible due to granule formation that ensures high biomass concentrations (van Lier et al. 2015; van Haandel et al. 2006). UASB reactors are designed to handle a volumetric loading rate of 4–15 kg COD. m3 d−1 (van Lier et al. 2015). The UASB bioreactor (Fig. 5d) is intensified by the gas–liquid–solid separator placed at the top with a shape of an inverted funnel.

The UASB reactor has been used for sulphate reduction from sulphate-rich wastewaters. A long HRT is beneficial for acetate consumption by SRB. Increasing the mixing capacity of the UASB reactor by applying higher recirculation rates and increasing the upward velocity can increase the performance of SRB (Alphenaar et al. 1993). According to Lopes et al. (2008), using sucrose as an electron donor and at pH <7.0, the sulphate reduction efficiency was higher in a UASB (>50%) at a HRT ~23 h compared to a CSTR that showed sulphate reduction efficiencies <38% at a HRT of ~20 h. In contrast, high sulphate reduction efficiencies (>80%) have been reported for a UASB reactor after 500 d of operation using lactate as electron donor at 25 ℃ and a HRT of 24 h (Bertolino et al. 2012). In another study, using either ethanol or acetate as the carbon source and at low HRT (>6 h), the sulphate reduction efficiency was only 30% at a limiting COD/sulphate ratio of 1 (Jing et al. 2013).

3.2 Inverse Fluidized Bed Reactor

An inverse fluidized bed (IFB) reactor (Fig. 6) is a modification of the fluidized bed reactor where the liquid is recirculated from the top (downwards recirculation) of the reactor making it different from a UASB bioreactor, where liquid is recirculated upwards. The IFB reactor uses a carrier material lighter than water onto which the sulphate-reducing biofilm attaches. In an IFB reactor, the growing biofilm on the carrier material is advantageous as it results in a higher surface area for biomass growth, leading to high biomass concentrations and low space requirements for the reactors. However, biomass growth in the liquid suspension is difficult to avoid due to shear forces and abrasion between the carrier materials (Davey and O’toole 2000; Escudié et al. 2011).

Schematic of an inverse fluidized bed reactor (adapted from Villa-Gomez et al. 2014)

Industrial and municipal wastewater treatments have been using biofilm-based reactors since the last decades. Several studies have been done to establish the factors that affect biofilm formation and growth. In an IFB, the volumetric conversion rate of the pollutant depends on the liquid velocity and the substrate concentration. According to the results obtained by Eldyasti et al. (2012), the substrate concentration has a greater effect on the diffusion rates than the liquid velocities, whereas Diez Blanco et al. (1995) showed contradictory results indicating a reduction in the external mass transfer velocity when the liquid velocity was increased. From a hydrodynamics point of view, Andalib et al. (2012) found that the diffusion rates were affected more by the liquid flow rate, i.e. under turbulent flow conditions, rather than under laminar flow.

Table 6 summarizes the recent studies on sulphate reduction using IFB bioreactors. Recent studies on sulphate reduction use anaerobic sludge from methanogenic bioreactors as inoculum and low-density polyethylene is the most preferred carrier material for IFB bioreactors (Table 6). Till to date, sulphate reduction has been studied at the lowest HRT of 0.37 d. In a study by Villa-Gomez et al. (2011), the sulphate reduction efficiencies were 74 and 38% at a COD/sulphate ratio of 5 and 1, respectively. The influence of different electron donors on the sulphate reduction has been studied in the IFB bioreactor where the most commonly used electron donors were acetate, propionate, butyrate, ethanol and lactate. These electron donors have been studied at different COD/sulphate ratios, however, sulphate reduction is hampered at ratios <1.0 and optimal at ratios >1.0 (Papirio et al. 2013a; Villa-Gomez et al. 2011).

Kijjanapanich et al. (2014) showed that sulphate reduction is possible with an efficiency of 75–85% regardless of the bioreactor configuration, e.g. IFB, UASB or gas-lift anaerobic membrane bioreactor, and at a HRT of 0.64 d. In that study, the IFB bioreactor reached steady state after 20 d of operation compared to the UASB bioreactor that required 35 d (Kijjanapanich et al. 2014). Sulphate reduction efficiencies of ~50% are also possible at low pH (5.0) in an IFB bioreactor and at a COD/sulphate ratio of 1 (Janyasuthiwong et al. 2016). The sulphidogenesis is robust to transient feeding conditions using lactate as an electron donor, at an HRT of 0.5 d (Reyes-Alvarado et al. 2017). Reyes-Alvarado et al. (2017) showed that the sulphate reduction is more affected by the COD/sulphate ratio (i.e. at values <1) than to ten successive (10×) transient feeding condition applied to the IFB. For instance, the average sulphate reduction efficiency was 67 (±15)% during the feast periods and this performance was comparable to that of the IFB bioreactor operation under continuous operating conditions (61 ± 15%) (Reyes-Alvarado et al. 2017).

3.3 Factors Affecting Bioreactor Performance

3.3.1 Characteristics of the Organic Substrate

Different organic substrates can be used as carbon source and electron donor for sulphate reduction (Table 2). The characteristics of the substrate are important for the bioreactor performance, mainly because the anaerobic biodegradability and the composition (VS, COD and TS) of organic matter are interconnected. Furthermore, the concentration of the substrate introduced into the reactor can also affect the metabolic activity of the microbes (Raposo et al. 2011). The VS content of organic substrates is not essentially the same, because of different proteins, lipids and carbohydrates content, which represent the soluble and the easily biodegradable part. The lignin composition represents the almost non-biodegradable part of the VS. Therefore, the biodegradation and the solubility of the electron donors depend on their cellulose and lignin content which means that the hydrolysis–fermentation rate is also affected (Houbron et al. 2008). The cellulose and chitin crystallinity or degree of polymerization show different rates of degradation, and this depends on the content or pretreatment done prior to their use in the methanogenesis or a sulphidogenic process. The crystallinity or degree of polymerization refers to the order of the molecules in the polymer such as the α, β and γ-cellulose (Foston 2014). Similarly, even though the COD content of electron donors with heterogeneous characteristics is different, it is also an important factor because it helps in controlling the growth rate of the SRB.

3.3.2 Particle Size of Electron Donors

The particle size is normally considered as an important design factor because a reduction in the particle size will increase the surface area which in turn improves the performance of the biological process (De la Rubia et al. 2011; Mshandete et al. 2006). Sometimes, hydrolytic-fermentative bacteria find it difficult to biodegrade the organic solid waste because of its size, and therefore, it is suggested to cut or break them to allow more surface area for these microorganisms to metabolize. Since the initial hydrolysis process may take time, it is important to provide an adequate/favourable environment for the SRB to increase their metabolic activity. Failure to do so might pose a delay in the start-up or even complete failure of the bioprocess.

3.3.3 Source of the Inoculum

The adaptation of the inoculum to the bioreactor depends a lot on its origin (Behera et al. 2007). Sources from thermophilic, mesophilic and halophilic conditions adapt differently when introduced into the bioreactors. For the sulphate reduction process, if the origin of the inoculum is from sulphate-rich environments, it will be easier for the microorganisms to adapt themselves to the bioreactor conditions because of the sulphate content. Whereas for sulphate deprived environments, it will take a while for the microorganisms to adapt to their new environment. But the time of adaptation depends on the syntrophic network established in the inoculum (Alon et al. 1999; Barkai and Leibler 1997). An inoculum from wastewater treatment plants can vary in its characteristics due to different operating conditions and daily variations, but it is mostly preferred because they all share common characteristics (Table 6). The effects of the inoculum origin, concentration, activity and storage have been reported in the literature (Raposo et al. 2011). In general, start-up of sulphate-reducing bioreactors could be enhanced by the introduction of inoculum from sulphate-rich origins.

3.3.4 Physical and Chemical Conditions in a Bioreactor

Physical and chemical operational conditions of the reactors affect the sulphate reduction process. Physical conditions, such as volume, temperature and stirring speed have significant effects on the biodegradation rate. Zagury et al. (2006) studied the effect of chemical conditions such as headspace gas concentrations, pH and alkalinity adjustments on the biodegradation of substrates. The majority of the bioreactor experiments are performed under mesophilic conditions (20–45 ℃) and a few under thermophilic conditions (45–60 ℃). Thermophilic conditions are sometimes avoided due to cost implications. Although the effect of stirring is contested, for organic solid electron donors, the stirring process will favour its contact with the SRB, increasing the microbial activity and facilitating better sulphate reduction.

3.3.5 Biomass Morphology

Different morphological features of biomass can develop during bioreactor operation. The factors that might affect the cell performance and behaviour are the ones increasing stress, which at the same time can also affect the syntrophic structure.

-

(a)

Flocs: Flocs are a conglomeration of cells and microcolonies enmeshed in exopolymers, related to the hydrodynamics, wastewater composition and dissolved oxygen concentrations (Dangcong et al. 1999). One advantage is the fast diffusional transport compared with those in granules or biofilms (Morgan-Sagastume et al. 2008). The filamentous bacteria play an important role in these structures. Mielczarek et al. (2012) reported that during warm periods, activated sludge flocs preserve an open structure. A high concentration of filamentous bacteria might cause settling problems.

-

(b)

Granules: The anaerobic granular sludge develops spontaneously due to auto-immobilization. This aggregation occurs in the absence of any support material, in contrast to biofilms. As a single bacterium is not able to degrade organic matter to methane, different bacteria, as present in granules, develop a complex and unique microbial ecosystem.

-

(c)

Biofilms: Planktonic cells are found in media as free-floating microorganisms, but their attachment to surfaces enhances their survival in diverse environments (Rivas et al. 2007). A biofilm can be defined as a complex coherent structure of cells and cellular products, like extracellular polymers (exopolysaccharide), which form and grow spontaneously attached on a static suspended solid surface (Davey and O’toole 2000).

The process of biofilm formation is a multistage development, which includes attachment of microbes to the surface, cell to cell adhesion and proliferation, maturation and detachment. In the bioreactor, osmolarity, pH, oxygen and temperature are other environmental variables that can also influence the initial biomass attachment, apart from the nature of the support material used (Ishii et al. 2008). For instance, the stratification of microbial communities in biofilms can be influenced by the electron acceptors and donors (Satoh et al. 2009), as well as the degradability of the carbon source (Shen et al. 2013).

4 Conclusions

The variations in concentrations of sulphate and carbon source, pH and the presence of competing ions affect the biochemical activities in wastewater treatment systems. The use of sulphate-reducing bacteria (SRB) technology for sulphate-rich wastewater treatment is advantageous due to minimal sludge production, ability to perform simultaneous oxidation of organic matter and the reduction of sulphate. Sulphate reduction in bioreactors is affected by parameters such as the type of electron donor, COD/sulphate ratio, pH, HRT and reactor configuration. Sulphate reduction efficiencies >90% are achieved when COD is not a limiting factor in a bioreactor, and a COD/sulphate ratio >2.0 is recommended in such cases. Most of the sulphate-reducing bioreactors are also able to handle fluctuations in COD or sulphate-loading rates. The ability of the SRB to overcome feast and famine periods clearly shows the application of this technology for industrial wastewaters.

References

Alon U, Surette MG, Barkai N, Leibler S (1999) Robustness in bacterial chemotaxis. Nature 397:168–171. https://doi.org/10.1038/16483

Al-Zuhair S, El-Naas MH, Al-Hassani H (2008) Sulfate inhibition effect on sulfate reducing bacteria. J Biochem Technol 1:39–44

Alphenaar AP, Visser A, Lettinga G (1993) The effect of liquid upward velocity and hydraulic retention time on granulation in UASB reactors treating wastewater with a high sulphate content. Bioresour Technol 43:249–258. https://doi.org/10.1016/0960-8524(93)90038-D

Andalib M, Zhu J, Nakhla G (2012) A new definition of bed expansion index and voidage for fluidized biofilm-coated particles. Chem Eng J 189–190:244–249. https://doi.org/10.1016/j.cej.2012.02.065

Baena S, Fardeau ML, Labat M, Ollivier B, Garcia JL, Patel BK (1998) Desulfovibrio aminophilus sp. nov., a novel amino acid degrading and sulfate reducing bacterium from an anaerobic dairy wastewater lagoon. Syst Appl Microbiol 21:498–504. https://doi.org/10.1016/S0723-2020(98)80061-1

Barkai N, Leibler S (1997) Robustness in simple biochemical networks. Nature 387:913–917. https://doi.org/10.1038/43199

Barton LL, Fauque GD (2009) Biochemistry, physiology and biotechnology of sulfate‐reducing bacteria. Adv Appl Microbiol. pp. 41–98. doi:https://doi.org/10.1016/S0065-2164(09)01202-7

Baskaran V, Nemati M (2006) Anaerobic reduction of sulfate in immobilized cell bioreactors, using a microbial culture originated from an oil reservoir. Biochem Eng J 31:148–159. https://doi.org/10.1016/j.bej.2006.07.007

Behera SK, Rene ER, Murthy DVS (2007) Performance of upflow anoxic bioreactor for wastewater treatment. Int J Environ Sci Technol 4:247–252. https://doi.org/10.1007/BF03326281

Bertolino SM, Rodrigues ICB, Guerra-Sá R, Aquino SF, Leão VA (2012) Implications of volatile fatty acid profile on the metabolic pathway during continuous sulfate reduction. J Environ Manage 103:15–23. https://doi.org/10.1016/j.jenvman.2012.02.022

Butlin KR, Selwyn SC, Wakerley DS (1956) Sulphide production from sulphate-enriched sewage sludges. J Appl Bacteriol 19:3–15. https://doi.org/10.1111/j.1365-2672.1956.tb00036.x

Celis LB, Villa-Gómez D, Alpuche-Solís AG, Ortega-Morales BO, Razo-Flores E (2009) Characterization of sulfate-reducing bacteria dominated surface communities during start-up of a down-flow fluidized bed reactor. J Ind Microbiol Biotechnol 36:111–121. https://doi.org/10.1007/s10295-008-0478-7

Celis-García LB, Razo-Flores E, Monroy O (2007) Performance of a down-flow fluidized bed reactor under sulfate reduction conditions using volatile fatty acids as electron donors. Biotechnol Bioeng 97:771–779. https://doi.org/10.1002/bit.21288

Cirik K, Dursun N, Sahinkaya E, Çinar Ö (2013) Effect of electron donor source on the treatment of Cr(VI)-containing textile wastewater using sulfate-reducing fluidized bed reactors (FBRs). Bioresour Technol 133:414–420. https://doi.org/10.1016/j.biortech.2013.01.064

D’Acunto, B., Esposito, G., Frunzo, L., Pirozzi, F., 2011. Dynamic modeling of sulfate reducing biofilms. Comput Math Appl 62:2601–2608. doi:https://doi.org/10.1016/j.camwa.2011.07.064

Dangcong P, Bernet N, Delgenes J, Moletta R (1999) Aerobic granular sludge-a case report. Water Res 33:890–893. https://doi.org/10.1016/S0043-1354(98)00443-6

Davey, M.E., O’toole, G.A., 2000. Microbial biofilms: from ecology to molecular genetics. Microbiol Mol Biol Rev 64:847–867. doi:https://doi.org/10.1128/MMBR.64.4.847-867.2000

De la Rubia MA, Fernández-Cegrí V, Raposo F, Borja R (2011) Influence of particle size and chemical composition on the performance and kinetics of anaerobic digestion process of sunflower oil cake in batch mode. Biochem Eng J 58–59:162–167. https://doi.org/10.1016/j.bej.2011.09.010

Diez Blanco V, García Encina PA, Fdz-Polanco F (1995) Effects of biofilm growth, gas and liquid velocities on the expansion of an anaerobic fluidized bed reactor (AFBR). Water Res 29:1649–1654. https://doi.org/10.1016/0043-1354(95)00001-2

du Preez LA, Odendaal JP, Maree JP, Ponsonby M (1992) Biological removal of sulphate from industrial effluents using producer gas as energy source. Environ Technol 13:875–882. https://doi.org/10.1080/09593339209385222

Dvorak DH, Hedin RS, Edenborn HM, McIntire PE (1992) Treatment of metal contaminated water using bacterial sulfate reduction: results from pilot-scale reactors. Biotechnol Bioeng 40:609–616

Eldyasti A, Nakhla G, Zhu J (2012) Influence of particles properties on biofilm structure and energy consumption in denitrifying fluidized bed bioreactors (DFBBRs). Bioresour Technol 126:162–171. https://doi.org/10.1016/j.biortech.2012.07.113

Escudié R, Cresson R, Delgenès J-P, Bernet N (2011) Control of start-up and operation of anaerobic biofilm reactors: an overview of 15 years of research. Water Res 45:1–10. https://doi.org/10.1016/j.watres.2010.07.081

Fontes Lima DM, Zaiat M (2012) The influence of the degree of back-mixing on hydrogen production in an anaerobic fixed-bed reactor. Int J Hydrogen Energy 37:9630–9635. https://doi.org/10.1016/j.ijhydene.2012.03.097

Foston M (2014) Advances in solid-state NMR of cellulose. Curr Opin Biotechnol 27:176–184. https://doi.org/10.1016/j.copbio.2014.02.002

Gallegos-Garcia M, Celis LB, Rangel-Méndez R, Razo-Flores E (2009) Precipitation and recovery of metal sulfides from metal containing acidic wastewater in a sulfidogenic down-flow fluidized bed reactor. Biotechnol Bioeng 102:91–99. https://doi.org/10.1002/bit.22049

Genari AN, Passos FV, Passos FML (2003) Configuration of a bioreactor for milk lactose hydrolysis. J Dairy Sci 86:2783–2789. https://doi.org/10.3168/jds.S0022-0302(03)73875-2

Gibson GR (1990) Physiology and ecology of the sulphate-reducing bacteria. J Appl Bacteriol 69:769–797. https://doi.org/10.1111/j.1365-2672.1990.tb01575.x

Goršek A, Tramšek M (2008) Kefir grains production-an approach for volume optimization of two-stage bioreactor system. Biochem Eng J 42:153–158. https://doi.org/10.1016/j.bej.2008.06.009

Grein F, Ramos AR, Venceslau SS, Pereira IAC (2013) Unifying concepts in anaerobic respiration: insights from dissimilatory sulfur metabolism. Biochem Biophys Acta-Bioenerg 1827:145–160. https://doi.org/10.1016/j.bbabio.2012.09.001

Hansen TA (1993) Carbon metabolism of sulfate-reducing bacteria. In: Odom JM, Singleton JR (eds) The sulfate-reducing bacteria: contemporary perspectives. Springer, New York, NY, pp 21–40. doi:https://doi.org/10.1007/978-1-4613-9263-7_2

Hao OJ, Chen JM, Huang L, Buglass RL (1996) Sulfate-reducing bacteria. Crit Rev Environ Sci Technol 26:155–187. https://doi.org/10.1080/10643389609388489

Hoover R (2001) Composition, molecular structure, and physicochemical properties of tuber and root starches: a review. Carbohydr Polym 45:253–267. https://doi.org/10.1016/S0144-8617(00)00260-5

Houbron E, González-López GI, Cano-Lozano V, Rustrían E (2008) Hydraulic retention time impact of treated recirculated leachate on the hydrolytic kinetic rate of coffee pulp in an acidogenic reactor. Water Sci Technol 58:1415–1421. https://doi.org/10.2166/wst.2008.492

Hulshoff Pol LW, De Castro Lopes SI, Lettinga G, Lens PNL (2004) Anaerobic sludge granulation. Water Res 38:1376–1389. https://doi.org/10.1016/j.watres.2003.12.002

Ishii S, Shimoyama T, Hotta Y, Watanabe K (2008) Characterization of a filamentous biofilm community established in a cellulose-fed microbial fuel cell. BMC Microbiol 8:1–12. https://doi.org/10.1186/1471-2180-8-6

Janyasuthiwong S, Rene ER, Esposito G, Lens PNL (2016) Effect of pH on the performance of sulfate and thiosulfate-fed sulfate reducing inverse fluidized bed reactors. J Environ Eng 142:1–11. https://doi.org/10.1061/(ASCE)EE.1943-7870.0001004

Jeihanipour A, Niklasson C, Taherzadeh MJ (2011) Enhancement of solubilization rate of cellulose in anaerobic digestion and its drawbacks. Process Biochem 46:1509–1514. https://doi.org/10.1016/j.procbio.2011.04.003

Jing Z, Hu Y, Niu Q, Liu Y, Li Y-Y, Wang XC (2013) UASB performance and electron competition between methane-producing archaea and sulfate-reducing bacteria in treating sulfate-rich wastewater containing ethanol and acetate. Bioresour Technol 137:349–357. https://doi.org/10.1016/j.biortech.2013.03.137

John RP, Nampoothiri KM, Pandey A (2007) Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Appl Microbiol Biotechnol 74:524–534. https://doi.org/10.1007/s00253-006-0779-6

Kaksonen AH, Plumb JJ, Robertson WJ, Riekkola-Vanhanen M, Franzmann PD, Puhakka JA (2006) The performance, kinetics and microbiology of sulfidogenic fluidized-bed treatment of acidic metal- and sulfate-containing wastewater. Hydrometallurgy 83:204–213. https://doi.org/10.1016/j.hydromet.2006.03.025

Kang H, Weiland P (1993) Ultimate anaerobic biodegradability of some agro-industrial residues. Bioresour Technol 43:107–111. https://doi.org/10.1016/0960-8524(93)90168-B

Kieu HTQ, Müller E, Horn H (2011) Heavy metal removal in anaerobic semi-continuous stirred tank reactors by a consortium of sulfate-reducing bacteria. Water Res 45:3863–3870. https://doi.org/10.1016/j.watres.2011.04.043

Kijjanapanich P, Do AT, Annachhatre AP, Esposito G, Yeh DH, Lens PNL (2014) Biological sulfate removal from construction and demolition debris leachate: effect of bioreactor configuration. J Hazard Mater 269:38–44. https://doi.org/10.1016/j.jhazmat.2013.10.015

Leustek T, Martin MN, Bick J-A, Davies JP (2000) Pathways and regulation of sulphur metabolism revealed through molecular and genetic studies. Annu Rev Plant Physiol Plant Mol Biol 51:141–165. https://doi.org/10.1146/annurev.arplant.51.1.141

Liamleam W, Annachhatre AP (2007) Electron donors for biological sulfate reduction. Biotechnol Adv 25:452–463. https://doi.org/10.1016/j.biotechadv.2007.05.002

Lopes SIC, Dreissen C, Capela MI, Lens PNL (2008) Comparison of CSTR and UASB reactor configuration for the treatment of sulfate rich wastewaters under acidifying conditions. Enzyme Microb Technol 43:471–479. https://doi.org/10.1016/j.enzmictec.2008.08.001

Maree JP, Hill E (1989) Biological removal of sulphate from industrial effluents and concomitant production of sulphur. Water Sci Technol 21:265–276

Matias PM, Pereira IAC, Soares CM, Carrondo MA (2005) Sulphate respiration from hydrogen in bacteria: a structural biology overview. Prog Biophys Mol Biol 89:292–329. https://doi.org/10.1016/j.pbiomolbio.2004.11.003

Mielczarek AT, Kragelund C, Eriksen PS, Nielsen PH (2012) Population dynamics of filamentous bacteria in Danish wastewater treatment plants with nutrient removal. Water Res 46:3781–3795. https://doi.org/10.1016/j.watres.2012.04.009

Mizuno O, Li YY, Noike T (1998) The behavior of sulfate-reducing bacteria in acidogenic phase of anaerobic digestion. Water Res 32:1626–1634. https://doi.org/10.1016/S0043-1354(97)00372-2

Moestedt J, Nilsson Påledal S, Schnürer A (2013) The effect of substrate and operational parameters on the abundance of sulphate-reducing bacteria in industrial anaerobic biogas digesters. Bioresour Technol 132:327–332. https://doi.org/10.1016/j.biortech.2013.01.043

Morgan-Sagastume F, Larsen P, Nielsen JL, Nielsen PH (2008) Characterization of the loosely attached fraction of activated sludge bacteria. Water Res 42:843–854. https://doi.org/10.1016/j.watres.2007.08.026

Mshandete A, Björnsson L, Kivaisi AK, Rubindamayugi MST, Mattiasson B (2006) Effect of particle size on biogas yield from sisal fibre waste. Renew Energy 31:2385–2392. https://doi.org/10.1016/j.renene.2005.10.015

Muyzer G, Stams AJM (2008) The ecology and biotechnology of sulphate-reducing bacteria. Nat Rev Microbiol 6:441–454. https://doi.org/10.1038/nrmicro1892

Nedwell DB, Reynolds PJ (1996) Treatment of landfill leachate by methanogenic and sulphate-reducing digestion. Water Res 30:21–28. https://doi.org/10.1016/0043-1354(95)00128-8

O’Sullivan C, Burrell PC, Clarke WP, Blackall LL (2008) The effect of biomass density on cellulose solubilisation rates. Bioresour Technol 99:4723–4731. https://doi.org/10.1016/j.biortech.2007.09.070

Örlygsson J, Houwen FP, Svensson BH (1994) Influence of hydrogenothrophic methane formation on the thermophilic anaerobic degradation of protein and amino acids. FEMS Microbiol Ecol 13:327–334. https://doi.org/10.1111/j.1574-6941.1994.tb00079.x

Ozmihci S, Kargi F (2008) Ethanol production from cheese whey powder solution in a packed column bioreactor at different hydraulic residence times. Biochem Eng J 42:180–185. https://doi.org/10.1016/j.bej.2008.06.017

Papirio S, Esposito G, Pirozzi F (2013a) Biological inverse fluidized-bed reactors for the treatment of low pH- and sulphate-containing wastewaters under different COD conditions. Environ Technol 34:1141–1149. https://doi.org/10.1080/09593330.2012.737864

Papirio S, Villa-Gomez DK, Esposito G, Pirozzi F, Lens PNL (2013b) Acid mine drainage treatment in fluidized-bed bioreactors by sulfate-reducing bacteria: a critical review. Crit Rev Environ Sci Technol 43:2545–2580. https://doi.org/10.1080/10643389.2012.694328

Peixoto G, Saavedra NK, Varesche MBA, Zaiat M (2011) Hydrogen production from soft-drink wastewater in an upflow anaerobic packed-bed reactor. Int J Hydrogen Energy 36:8953–8966. https://doi.org/10.1016/j.ijhydene.2011.05.014

Pepper IL, Rensing C, Gerba CP (2004) Environmental microbial properties and processes, In: Environmental monitoring and characterization. Elsevier, USA, pp 263–280. doi:https://doi.org/10.1016/B978-012064477-3/50016-3

Pillai CKS, Paul W, Sharma CP (2009) Chitin and chitosan polymers: chemistry, solubility and fiber formation. Prog Polym Sci 34:641–678. https://doi.org/10.1016/j.progpolymsci.2009.04.001

Rabus R, Hansen TA, Widdel F (2006) Dissimilatory sulfate- and sulfur-reducing prokaryotes. In: The prokaryotes. Springer New York, NY, pp 659–768. doi:https://doi.org/10.1007/0-387-30742-7_22

Raposo F, Fernández-Cegrí V, de la Rubia MA, Borja R, Béline F, Cavinato C, Demirer G, Fernández B, Fernández-Polanco M, Frigon JC, Ganesh R, Kaparaju P, Koubova J, Méndez R, Menin G, Peene A, Scherer P, Torrijos M, Uellendahl H, Wierinck I, de Wilde V (2011) Biochemical methane potential (BMP) of solid organic substrates: evaluation of anaerobic biodegradability using data from an international interlaboratory study. J Chem Technol Biotechnol 86:1088–1098. https://doi.org/10.1002/jctb.2622

Reyes-Alvarado LC, Okpalanze NN, Kankanala D, Rene ER, Esposito G, Lens PNL (2017) Forecasting the effect of feast and famine conditions on biological sulphate reduction in an anaerobic inverse fluidized bed reactor using artificial neural networks. Proc Biochem 55:146–161. https://doi.org/10.1016/j.procbio.2017.01.021

Rinaudo M (2006) Chitin and chitosan: properties and applications. Prog Polym Sci 31:603–632. https://doi.org/10.1016/j.progpolymsci.2006.06.001

Rivas L, Dykes GA, Fegan N (2007) A comparative study of biofilm formation by Shiga toxigenic Escherichia coli using epifluorescence microscopy on stainless steel and a microtitre plate method. J Microbiol Methods 69:44–51. https://doi.org/10.1016/j.mimet.2006.11.014

Robertson, L.A., Kuenen, J.G., 2006. The colorless sulfur bacteria. In: The prokaryotes. Springer New York, NY, USA, pp 985–1011. doi:https://doi.org/10.1007/0-387-30742-7_31

Sampaio RMM, Timmers RA, Kocks N, André V, Duarte MT, van Hullebusch ED, Farges F, Lens PNL (2010) Zn-Ni sulfide selective precipitation: the role of supersaturation. Sep Purif Technol 74:108–118. https://doi.org/10.1016/j.seppur.2010.05.013

Sarti A, Zaiat M (2011) Anaerobic treatment of sulfate-rich wastewater in an anaerobic sequential batch reactor (AnSBR) using butanol as the carbon source. J Environ Manage 92:1537–1541. https://doi.org/10.1016/j.jenvman.2011.01.009

Satoh H, Odagiri M, Ito T, Okabe S (2009) Microbial community structures and in situ sulfate-reducing and sulfur-oxidizing activities in biofilms developed on mortar specimens in a corroded sewer system. Water Res 43:4729–4739. https://doi.org/10.1016/j.watres.2009.07.035

Shao L, Wang T, Li T, Lü F, He P (2013) Comparison of sludge digestion under aerobic and anaerobic conditions with a focus on the degradation of proteins at mesophilic temperature. Bioresour Technol 140:131–137. https://doi.org/10.1016/j.biortech.2013.04.081

Shen Z, Zhou Y, Wang J (2013) Comparison of denitrification performance and microbial diversity using starch/polylactic acid blends and ethanol as electron donor for nitrate removal. Bioresour Technol 131:33–39. https://doi.org/10.1016/j.biortech.2012.12.169

Sheoran AS, Sheoran V, Choudhary RP (2010) Bioremediation of acid-rock drainage by sulphate-reducing prokaryotes: a review. Miner Eng 23:1073–1100. https://doi.org/10.1016/j.mineng.2010.07.001

Show KY, Lee DJ, Chang JS (2011) Bioreactor and process design for biohydrogen production. Bioresour Technol 102:8524–8533. https://doi.org/10.1016/j.biortech.2011.04.055

Stams AJM, Plugge CM, de Bok FAM, van Houten BHGW, Lens P, Dijkman H, Weijma J (2005) Metabolic interactions in methanogenic and sulfate-reducing bioreactors. Water Sci Technol 52:13–20

Taguchi Y, Sugishima M, Fukuyama K (2004) Crystal structure of a novel zinc-binding ATP Sulfurylase from Thermus thermophilus HB8. Biochemistry 43:4111–4118. https://doi.org/10.1021/bi036052t

Tang K, Baskaran V, Nemati M (2009) Bacteria of the sulphur cycle: an overview of microbiology, biokinetics and their role in petroleum and mining industries. Biochem Eng J 44:73–94. https://doi.org/10.1016/j.bej.2008.12.011

Tsukamoto TK, Killion HA, Miller GC (2004) Column experiments for microbiological treatment of acid mine drainage: low-temperature, low-pH and matrix investigations. Water Res 38:1405–1418. https://doi.org/10.1016/j.watres.2003.12.012

van Haandel A, Kato MT, Cavalcanti PFF, Florencio L (2006) Anaerobic reactor design concepts for the treatment of domestic wastewater. Rev Environ Sci Bio/Technol 5:21–38. https://doi.org/10.1007/s11157-005-4888-y

van Houten RT, van der Spoel H, van Aelst AC, Hulshoff Pol LW, Lettinga G (1996) Biological sulfate reduction using synthesis gas as energy and carbon source. Biotechnol Bioeng 50:136–144

van Lier JB, Zee FP, Frijters CTMJ, Ersahin ME (2015) Celebrating 40 years anaerobic sludge bed reactors for industrial wastewater treatment. Rev Environ Sci Bio/Technology 14:681–702. https://doi.org/10.1007/s11157-015-9375-5

Villa-Gomez D, Ababneh H, Papirio S, Rousseau DPL, Lens PNL (2011) Effect of sulfide concentration on the location of the metal precipitates in inversed fluidized bed reactors. J Hazard Mater 192:200–207. https://doi.org/10.1016/j.jhazmat.2011.05.002

Villa-Gomez DK, Cassidy J, Keesman KJ, Sampaio R, Lens PNL (2014) Sulfide response analysis for sulfide control using a pS electrode in sulfate reducing bioreactors. Water Res 50:48–58. https://doi.org/10.1016/j.watres.2013.10.006

Weijma J, Stams AJM, Hulshoff Pol LW, Lettinga G (2000) Thermophilic sulfate reduction and methanogenesis with methanol in a high rate anaerobic reactor. Biotechnol Bioeng 67:354–363

Widdel F (2006) The genus Desulfotomaculum. In: The prokaryotes. Springer, New York, NY, pp 787–794. doi:https://doi.org/10.1007/0-387-30744-3_25

Xia Y, Cai L, Zhang T, Fang HHP (2012) Effects of substrate loading and co-substrates on thermophilic anaerobic conversion of microcrystalline cellulose and microbial communities revealed using high-throughput sequencing. Int J Hydrogen Energy 37:13652–13659. https://doi.org/10.1016/j.ijhydene.2012.02.079

Yang Y, Tsukahara K, Yagishita T, Sawayama S (2004) Performance of a fixed-bed reactor packed with carbon felt during anaerobic digestion of cellulose. Bioresour Technol 94:197–201. https://doi.org/10.1016/j.biortech.2003.11.025

Zagury GJ, Kulnieks VI, Neculita CM (2006) Characterization and reactivity assessment of organic substrates for sulphate-reducing bacteria in acid mine drainage treatment. Chemosphere 64:944–954. https://doi.org/10.1016/j.chemosphere.2006.01.001

Zhou J, He Q, Hemme CL, Mukhopadhyay A, Hillesland K, Zhou A, He Z, Van Nostrand JD, Hazen TC, Stahl DA, Wall JD, Arkin AP (2011) How sulphate-reducing microorganisms cope with stress: lessons from systems biology. Nat Rev Microbiol 9:452–466. https://doi.org/10.1038/nrmicro2575

Acknowledgements

This research was funded by the European Union through the Erasmus Mundus Joint Doctorate Programme, Environmental Technologies for Contaminated Solids, Soils and Sediments [ETeCoS3, grant agreement FPA no. 2010-0009].

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Reyes-Alvarado, L.C., Rene, E.R., Esposito, G., Lens, P.N.L. (2018). Bioprocesses for Sulphate Removal from Wastewater. In: Varjani, S., Gnansounou, E., Gurunathan, B., Pant, D., Zakaria, Z. (eds) Waste Bioremediation. Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-10-7413-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-10-7413-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7412-7

Online ISBN: 978-981-10-7413-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)