Abstract

“Asbestos” has been used since the historical period for the manufacture of around 3000 products; the reasons are attributed to its characteristic properties such as high tensile strength, lightweight, heat resistance capacity and most importantly its usability as an insulating material. But, due to its unambiguous links with diseases such as ‘Mesothelioma’ and ‘Lung-fibrosis’, many of the developed nations have already imposed a ban on its usage. However, it is still extensively used in other nations including India, China, Nepal, Pakistan, Iran, Malaysia, Philippines, Indonesia, Thailand, Burma and Vietnam. These countries persistently produce and consume asbestos and other associated asbestos-containing products. In a developing economy like India, the occupational exposure of asbestos is usually encountered during mining of asbestos, manufacturing asbestos-containing construction products, in asbestos processing industries as well as in asbestos-containing product (ACP) (insulation material) manufacturing industries. A major quantum of asbestos wastes (AW) is generated during refurbishment activities such as demotion of old buildings (corrugated cement sheets) and dismantling of end-of-life ships. There are a large number of asbestos products manufacturing and utilizing industries in India, both in large- and medium-scale sectors. But a huge significant amount of small-scale and unorganised sectors is located around the major rural and urban centres. This study articulates the current trend of production of asbestos and consumption in India as well as the generation of asbestos wastes (AW) and asbestos-containing wastes (ACW) in various industries in India. As asbestos is known for its resistance to fire and being lightweight, it has been widely used in chemical plant machinery, infrastructural framework of industrial plants and manufacture of fire and chemical-resistant protective clothing for chemical plant workers. Therefore, it is imperative to estimate various asbestos-containing materials (ACM) and generation of AW and ACW in industries for adopting the precautionary measures while handling such materials. To address the asbestos problem, effective government policies and regulations are imperatively associated with technical interventions. Self-regulation by the concerned industries, including the adoption of cleaner production and management strategies during planning, design and operations, will significantly help to ensure proper asbestos wastes management and minimization of exposure to the workforce. The strategies for preventive environmental management of AW and ACW have been discussed in this work.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Asbestos

- Asbestos-containing wastes (ACW)

- Asbestos wastes (AW)

- Asbestos-related diseases (ARD)

- Personal protective equipment (PPE)

- Treatment, storage and disposal facility (TSDF)

1 Introduction

Asbestos is commonly referred to a group of naturally occurring six types of silicate minerals which are thin, flexible and elongated. These groups of minerals can be woven and spun into fabrics with high resistance to heat and chemicals and are non-biodegradable [1–3]. It is basically a poly-silicate fibre, formed due to the Si–O–Si bond formation. It consists of six minerals, namely chrysotile, amosite, crocidolite, anthophyllite, tremolite and actinolite [4]. All the minerals, except chrysotile, come under the category of amphibole. Chrysotile is classified as serpentine asbestos, which is a hydrated magnesium silicate with stoichiometric chemical formula as Mg3Si2O5(OH)4. It forms a sheet-like structure of silicate crystals. Chrysotile fibre is very thin with a diameter of approximately, 25 nm. The fibre length ranges from fraction of millimetres to a few centimetres [5, 6]. Most of the industrial asbestos used nowadays is chrysotile [7–9]. Amphiboles are widely found in earth’s crust. They form polymeric structure, but are linear and longer and not sheet-like as that of serpentine.

Asbestos has high tensile strength, good heat-resistant capacity, chemically inert and is inflammable, non-biodegradable. The tensile strength of chrysotile is about 1.1–4.4 GPa [5, 6]. Due to a polymeric sheet-like structure of chrysotile, it has high friability. However, the negative effects of asbestos were recognized in 1899, thereafter, it is considered as a carcinogenic material [10]. Its prolonged exposure can cause “Asbestosis”, “Mesothelioma” and “Lung Fibrosis” [11, 12]. They have small diameter, which helps it to get into the respiratory tract despite the presence of ciliated airways. Also, it has long length; due to which, it cannot be enclosed by macrophages, thereby producing incomplete phagocytosis. The asbestos fibre is also characterized by biological persistence, which helps in its long-term persistence in the lungs [13]. The biological persistence of chrysotile is comparatively less than that of amphiboles. Chrysotile can leach out, while amphiboles remain for a longer time in the lungs [14]. However, each type of asbestos is carcinogenic.

Many of the developed nations have already imposed ban on usage of ACP. However, it is still extensively used in other nations including India, China, Nepal, Pakistan, Iran, Malaysia, Philippines, Indonesia, Thailand, Burma and Vietnam [15]. India not only mines chrysotile, but also imports a major portion from other countries. In India, the latency period, i.e. the duration between the exposure to hazardous asbestos fibres and occurrence or developing symptoms of disease for “Mesothelioma”, is approximately 20–37 yr [16]. This might be a potential reason for vague records of mesothelioma and lung fibrosis cases in India, as the major chunk of labourers work on contract basis due to which it becomes difficult to monitor their health in a long run. In India, it is observed that asbestos-related diseases (ARDs) occur at comparatively younger ages as compared to other countries in the world, since these workers are employed at very early stages of their life in the asbestos-related industries. Moreover, due to more involvement of Indian women workers, female workforce becomes more vulnerable to ARDs [17]. Industrial application of asbestos has created a huge demand for environmental sound management of AW and ACW in order to minimize the adverse environmental and health impacts.

2 Production and Consumption of Asbestos in India

In India, there is rapid increase in the consumption of asbestos from the period 1930–2013. Though in the last few years, there is not a definite pattern seen in the consumption rate. The consumption is fluctuating in the range of 3,00,000–4,70,000 MT/annum [18]. Besides a huge number of industries manufacturing and processing asbestos products, there are a large number of unorganized sectors for asbestos processing. Ninety per cent of the total asbestos produced in the country originates from Rajasthan wherein 60% of this production is centred upon unorganized industrial units which include asbestos milling units as well as industries manufacturing asbestos-containing products [14]. Milling of asbestos-containing rocks and the production of ACP constitute a major fraction of the unorganized small-scale industries, particularly in Beawer and Deogarh districts of Rajasthan.

As the developing world is phasing out the use of asbestos, India is trying to come forward as the primary manufacturer and consumer of asbestos after China. It is estimated that more than 25 asbestos mines actively operate in India having a monthly production rate of nearly 3,000 tonnes. Beside this, greater than 70% of the quantity of white asbestos is being imported from other asbestos producing nations [16]. Asbestos imports are around 3,00,000 metric tonnes/annum as per US Geological Survey report. As discussed earlier, Rajasthan constitutes 90% in production of asbestos. Other major producers and consumers include Andhra Pradesh, Bihar, Karnataka, Manipur and Tamil Nadu (Fig. 1).

There are over 3000 commercial products which constitute asbestos. These ACPs are in various forms and concentrations depending on the end use. In developing nations, it is found that various construction materials like corrugated asbestos cement sheets, cement pipes, floor tiles, vinyl carpets, cooking appliances like stoves, pipes all contain asbestos. Asbestos is commonly used in sound proofing (like in lecture halls or theatres), fireproofing (e.g. hospitals, bank vaults), insulating pipelines (like pipes carrying hot water or steam), filler material, brake pads and insulation lining of clutch, textile products particularly for industrial applications and floor or roof tiles [40]. Owing to the growing public awareness about the health risks associated with asbestos, asbestos consumption declined by 36% from 2010 to 2011 in India. But this is not sufficient enough to save us from the unacknowledged imminent public health crisis. As per Indian bureau of mines, the apparent demand of white asbestos in India was assessed to be 393,000 MT in 2011–12 and is projected to touch around 6,05,000 MT by 2016–17 with a growth rate of 9% as per the report of the working group for 12th Plan [18]

3 Use of Asbestos in Industries

Among the class of six silicate minerals of asbestos, the white asbestos variant, namely chrysotile asbestos, is the widely used (approximately 95%) one for all the major ACPs produced and consumed. It is used in the manufacture of a broad range of industrial products and applications due to its peculiar properties such as ability to easily wove, blend with a wide range of inorganic as well as polymeric additives to derive composite products [1, 3]. The huge quantum of asbestos consumption and thereby production of various asbestos-containing goods produce a considerable amount of wastes residues which is termed as asbestos-containing wastes (ACW). Asbestos wastes from industries are generated from either from industries which require mined asbestos for manufacture of asbestos products such as building materials, protective clothing, textiles or other insulation material or in the form of end-of-life insulation material (ACM) from other type of industries (such as textile industries, dye industries and other chemical industries). In chemical industries, asbestos is widely used in following installations:

-

As an insulation material for boilers, gaskets, pipes

-

In protective clothing for the workers

-

In building material.

A huge quantum of asbestos is released from industries where mined asbestos is used for manufacture of various ACMs. The production and processing in an asbestos industry are organized in the following manner. First, the mining of asbestos ore is carried out followed by milling to attain a homogeneous material which is shipped to the primary asbestos industries. During mining and milling activities, a huge quantum of AW is generated in the form of mine tailings and wastes residue. Further, the primary industries process and convert the raw asbestos into an intermediate product. Secondary industries are then employed for the final processing and conversion of the intermediate product into finished goods. The finished ACP is further sold to consumer industries which then utilize or install or consume the product in their industrial structural components and installations. All of these activities have great potential to generate enormous amount hazardous asbestos fibres in the atmosphere as well as to contribute potentially in generation of AW and ACW. Figure 2 illustrates movement within the asbestos industry.

Being an excellent insulating material, it is widely used in chemical plant machinery, where insulation is required, such as gaskets, pipelines, valves, pumps, boiler units, exhaust ducts, furnaces, ovens and drying units, burner pads, radiator stop-leak materials, blenders, crushers and grinders. It is extensively used in the infrastructural framework of chemical plants particularly in the form of cement corrugated sheets, cement block primer sand elastomers, adhesives and moulded flexible parts. Also, a major use is in the manufacture of fire and chemical-resistant personal protective equipment (PPE) which covers a wide range of products like fire-resistant suits for workers engaged in chemical industries. It is installed majorly in pipes, furnaces, boilers, heat exchangers, ovens, driers and extruders.

4 Potential Health Impacts Due to Chrysotile Asbestos

As per the statutory norms in India, the Factories Act [41] notifies about asbestos and Schedule 3 lists out asbestosis under the section of notifiable diseases. The Air and Water Act of the country also regulates asbestos and is listed in Schedule I of Hazardous and Other Wastes (Management and Transboundary Movement) Rules, [42] under aegis of Environment Protection Act (1986). Furthermore, there are few of the national standards and guidelines for controlling and regulating the hazards due to asbestos mining, manufacturing of ACP and asbestos handling under Indian Standards Institution (ISI). Reportedly, India has very relaxed standards for air-borne asbestos and no guidelines for AWs and ACWs management in comparison to the European countries and USA.

There are a number of studies which claims that industrial hygiene conditions of unorganized sectors dealing with asbestos processing are very poor [43]. Ansari et al. [14] studies stated that the fibre concentration at workplaces in Beawer and Deogarh districts of Rajasthan is multiple times higher than Indian as well as worldwide standards. The mine workers were found not using any PPE, and the milling industries were lacking any pollution control devices for controlling and mitigating the pollution caused by asbestos.

In a similar study done on health hazard at ship dismantling yards, an elevated trend of asbestos exposure with cases of cancer (oesophagus cancer, trachea, bronchus and lung cancer) among the ship-breaking workers was observed [44]. It has been observed that cases of mesothelioma and the accurate measurement of their numbers in a systematic manner at the national level are often found insufficient. As reported by World Health Organization, the latency period (time between exposure to asbestos fibres and developing conditions of mesothelioma) may stretch as far as 40 years or much more; thus, the systems of monitoring need to be far stretched and long sighted [45]. Numerous countries have acted at their nationwide level to control and restrict of asbestos in most of its usage to minimize the exposure, thereby preventing and ultimately eradicating the diseases associated with asbestos. As per the WHO reports, at least 107,000 people die globally due to asbestos-related diseases (ARDs). However, there are still a number of countries that have yet to restrict and act in a similar way. India is one among them due to lack of epidemiological studies done on ARD. Very nominal efforts have taken to protect workers who are potentially exposed to asbestos, and no efforts have been done to compensate those who are suffering due to the hazardous exposure of asbestos fibres. There is no inventorization of ARD (mesothelioma/asbestos cancer) patients in India, and no data collection is available on occupational diseases in India.

5 Asbestos Wastes Management in Industries

There are typically two ways in which asbestos could be a matter of concern for the industries. First, if the industry is engaged in manufacture of any asbestos-containing products and second if there is installations where asbestos-containing materials are used inside the industrial plant. In both the cases, the operator has to ensure proper handling and disposal of the waste asbestos. The International Labour Organization (ILO) convened the Asbestos Convention in [46] to control the global use of asbestos. As per this convention, Article 10, a need for a systemic approach for replacing the asbestos materials is explained keeping workers’ health at high priority. The Article 11 sternly prohibits the consumption and use of the crocidolite and other products containing this class of fibre. The end-of-life ACMs need to be managed and disposed of in accordance with Hazardous and Other Wastes (Management and Transboundary Movement) Rules, 2016, as per the Indian legal framework.

5.1 Strategies for AW Management at Industry Level

There is enough literature available that validates the ill effects of airborne AW in the form of asbestos fibres. In order to avoid the deleterious health impacts to the workforce potentially exposed to fibres, there is a stern need to use PPEs or application of some in situ technology to reduce the friability of the asbestos or combination of both of these.

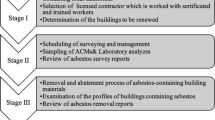

In indoor working areas, while performing dust-related work, the secondary release of the collected dust can adversely impact the work activity as well as the surrounding environment. This secondary release needs to be controlled and mitigated as these dust particulates may induce issues of serious concern to health of the workers. Adequate precautionary measures need to be geared up before the operations which may include installing a high-efficiency particulate air (HEPA) filter behind the dust-collecting equipment. Thus, clean-up is essential to suppress and control the secondary emanation of the fibres of asbestos. Removal of asbestos at ship recycling industry is performed by licenced contractors. These skilled asbestos professionals first designate the locations, label them and performs the dismantling operations in controlled conditions (Fig. 3).

In case of management of end-of-life ACM which is called asbestos-containing wastes (ACW), sometimes it is recommendable to treat the wastes before its final disposal. There are various methods for converting hazardous AW and ACW into non-hazardous material, which can be further utilized or recycled for various purposes. There are different methods for removing asbestos-containing materials such as asbestos coatings and/or plastering materials from the structural and building materials upon which such asbestos-containing materials have been incorporated. The simplest method is wet stripping of the ACW [47]. To control the emanation of the dust containing asbestos fibres, wetting using a suitable liquid carrier is an effective method. In this method, water is showered or sprayed. This technique employs devices like shower, sprinkler or atomizer wherein fine water droplets are sprinkled in the air which will capture the airborne dust by the sedimentation. By this method, the dust dispersal can be controlled by pre-moisturizing the raw materials which can be the potential sources of the dust fibres.

Out of other different methods proposed and studied by different authors for altering hazardous nature of chrysotile asbestos, the major ones were treating the ACM with acids [48, 49] and thermal treatment [50–52]. This method includes wetting the asbestos fibres with an aqueous solution containing about 1–10% by weight acid solution [53]. The crystal structure of the chrysotile asbestos is attacked by the acid solution which hydrolyzes the brucite layer (magnesium oxide) of the crystal, which ultimately destroys the crystal lattice and thus the fibrous nature of the asbestos. In addition, this mode of treatment can be used in situ by spraying chrysotile-containing insulation material installed in various machinery structures. Up to 90% conversion of asbestos can be achieved depending on the type of acid used. When 90% or more of chrysotile asbestos is converted, the remaining unconverted asbestos is not sufficient to impart a fibrous nature to the product. AW and ACW produced are ultimately bagged and transported to the hazardous wastes TSDF for final disposal in secured landfills. The schematic representation of ACW management is given in Fig. 4.

5.2 PPE for Asbestos Handling and Collection

ACMs may pose a serious risk to human health if they are disturbed from their dormant state that can eventually lead to the release of the microscopic fibres to the surrounding working environment. Environmentally safe and sound handling as well as final disposal of the end-of-life ACMs in industrial premises, therefore, demands systematic sequential actions to be undertaken so that potential exposure to the workforce is minimized. Workers engaged in AW handling should be provided with required personal protective gears, ancillary machinery, appropriate training and information for safe handling and disposal of AW and ACW [47].

While handling asbestos fibres, the workers are mandated to use a half-face filter respirator which may encompass a class P1 or P2 filter cartridge. Class P1 or P2 disposable respirator is also considered appropriate for handling asbestos fibres [45]. During the dismantling activity, the workers should wear other adequate protective devices like coveralls, safety boots, hat and gloves which all must be disposable in nature. At the closure of each day work, the used PPEs must be sprinkled with water, then sealed, double bagged and properly labelled for disposal. During these operations, the respirator must be worn so as to prevent the exposure to fibres while removing and disposing of the coveralls worn during the dismantling activity. After the completion of work, onsite washing facilities must be made available to the workers so as to decontaminate them before doing their routine works like eating, drinking and returning home (Fig. 5).

6 Disposal of AW and ACWs

The process of dismantling and removal of ACM from industries generates friable AWs which when airborne causes carcinogenic impacts. Hence, for workers, a decontamination area is very much essential to handle this class of work. The enclosure is kept at negative pressure to handle the friable asbestos components.

After proper dismantling of industrial components in a separate enclosure, three possible options for the final disposal of AWs and ACWs can be adopted, and these include:

-

Recycle and reuse

-

Secure/engineered landfilling

-

High-temperature transformation.

6.1 Recycling and Reuse

Recycling waste asbestos has become one of the emerging fields of research especially in developing nations, where it is still in massive application. Development of a secondary raw material (SRM) as a replacement for cement in concrete will help to recycle asbestos as well as suffice the concept of green concrete. It has been reported that the thermal transformation product of cement asbestos has the potential to be used as an SRM, which has chemical characteristics much similar to a magnesium-rich clinker [51]. The pozzolanic property of treated asbestos-containing wastes (roof sheets) was studied, and it was found suitable to be used as construction material [54]. Xiaoming and Linrong [55] had studied the asbestos tailing and claims to have no heavy metals in the matrix and hence lower toxicity, which implies to their prospect of being used as an aggregate material. A wide range of products including composite materials, glass-ceramics, ceramic pigments, plastic materials and bricks can be produced by using the asbestos cement conversion product.

6.2 Secure Landfilling

Land disposal of properly packed AW is practised all over the world [56,34,58]. In the disposal of asbestos in secure landfills, due care has to be taken to avoid the dispersal of fibres during handling. These landfills should have installed all the infrastructural requirements such as liner systems and leachate collection systems. Burning of asbestos-contaminated wastes is not a suitable disposal strategy. The occupier (waste generator) should send the wastes to the dedicated hazardous wastes TSDF (treatment, storage disposal facility) authorized by the pollution control authorities. The collected asbestos wastes are usually double bagged and are sent for disposal in specially reserved cells along with other kinds of wastes. During disposal of large items like asbestos sheets, pipelines, tiles or boards, the material has to be wrapped and well sealed in polyethylene bags. Adequate precautions must be taken to prevent the sharp edges of these wrapped up waste contents to cause any scratches/dents/cuts to these polythene bags. While disposing of these wastes, a comprehensive record of location of waste must be made available which includes the precise geographical coordinates also which will aid proper mitigation and management of these wastes.

6.3 High-Temperature Transformation

It has been reported that at high temperatures the crystal structure of asbestos gets altered which ultimately leads to formation of non-hazardous constituents [59]. Considering the risk of asbestos emission from landfill sites, some researchers developed thermal transformation of needle-shaped crystalline of asbestos into harmless form usually under 1200–1500 °C [60]. In a study conducted on microwave inertization treated ACW, the treated products were recycled to produce good-quality porcelain stoneware tiles, ceramic materials as well as porous single-fired wall and roof tiles [61]. The high-energy milling product of asbestos cement is asbestos-free and can be gainfully recycled in the manufacturing of construction products [54]. It is imperative to note that making the AWs inert by chemical–physical techniques and transformations (vitrification, hydrothermal, re-crystallization, mechano-chemical) and then recycling the products of transformation as an SRM will indeed assure a lower environmental footprint as well as reduce the usage of the primary raw materials. These processes are appropriate for small-scale disposal of waste asbestos.

7 Summary and Discussion

The management of fibrous hazardous wastes such as asbestos is very challenging in the present era of industrialization. India consumes around 4–5 MT of asbestos per annum for its industrial requirements. A considerable amount of chrysotile is mined in various parts of the country, and a major portion of quantity consumed is being imported from other nations.

Due to lack of identification technology, the AW and ACW are dumped along with all kinds of other wastes like garbage and construction wastes. This may lead to public health hazards. Eventually, workers engaged in ship-breaking yards, construction labourers, electricians, mechanics and other workforce employed in various industries that are potentially exposed to asbestos are forced to breathe-in hundreds and thousands of fibres. This may lead to “Asbestosis” and “Mesothelioma”. Industries must take precautionary measures in order to avoid the potential exposure to the workforce due to asbestos, whether it occurs in the form of raw material or is present in products. If the utilization of asbestos substitute materials is not possible for the industries, scientific and systematic waste minimization strategies and environmental sound handling of AW should be implemented to reduce the environmental and health impacts. Disposal must be done only at a site authorized by pollution control boards to accept waste asbestos.

An attempt is required to be made for assessment of various technologies available for the pre-treatment and recycling of asbestos-containing wastes and strategies for minimization of exposure to the workforce, who is potentially exposed to asbestos fibres due to their occupation. Various techniques such as solidification, stabilization, chemical fixation, thermal treatment, encapsulation can serve for the purpose of immobilizing various kinds of contaminants in hazardous wastes into physically and chemically stable form which could have a better environmental acceptance. Affordability, acceptability and sustainability should be the approach road of effective AWs and ACWs management.

References

Foresti, E., Fornero, E., Lesci, I. G., Rinaudo, C., Zuccheri, T., & Roveri, N. (2009). Asbestos health hazard: A spectroscopic study of synthetic geoinspired Fe-doped chrysotile. Journal of Hazardous Materials, 167, 1070–1079.

Ross, M., Langer, A. M., Nord, G. L., Nolan, R. P., Lee, R. J., Van Orden, D., et al. (2008). The mineral nature of asbestos. Regulatory Toxicology and Pharmacology, 52, S26–S30.

Thompson, S. K., & Mason, E. (2002). Asbestos: Mineral and fibres. Chemical Health and Safety, 9, 21–23.

Bernstein, D. M., & Hoskins, J. A. (2006). The health effects of chrysotile: Current perspective based upon recent data. Regulatory Toxicology and Pharmacology, 45(3), 252–264.

Virta, R. L. (2002). Asbestos, U.S. geological survey minerals yearbook 2001 (Vol. 1, pp. 9.1–9.6).

Virta, R. L. (2002). Asbestos: Geology, mineralogy, mining, and uses. Open-File Report 02-149. US Department of the Interior. US Geological Survey. Available from: http://pubs.USGS.gov/of/2002/of02-149/index.html.

Kanarek, M. S. (2011). Mesothelioma from chrysotile asbestos: Update. Annals of Epidemiology, 21(9), 688–697.

World Health Organization. (2006). Elimination of asbestos-related diseases.

UCGS. (2006). Worldwide asbestos supply and consumption trends from 1900 through 2003. Reston, VA: US Geological Survey.

Gidarakos, E., Anastasiadou, K., Koumantakis, E., & Nikolaos, S. (2008). Investigative studies for the use of an inactive asbestos mine as a disposal site for asbestos wastes. Journal of Hazardous Materials, 153(3), 955–965.

Paglietti, F., Malinconico, S., Della Staffa, B. C., Bellagamba, S., & De Simone, P. (2016). Classification and management of asbestos-containing waste: European legislation and the Italian experience. Waste Management, 50, 130–150.

Ying, C., Maeda, M., Nishimura, Y., Kumagai-Takei, N., Hayashi, H., Matsuzaki, H., et al. (2015). Enhancement of regulatory T cell-like suppressive function in MT-2 by long-term and low-dose exposure to asbestos. Toxicology, 338, 86–94.

Donaldson, K., Poland, C. A., Murphy, F. A., MacFarlane, M., Chernova, T., & Schinwald, A. (2013). Pulmonary toxicity of carbon nanotubes and asbestos—Similarities and differences. Advanced Drug Delivery Reviews, 65(15), 2078–2086.

Ansari, F. A., Ahmad, I., Ashquin, M., Yunus, M., & Rahman, Q. (2007). Monitoring and identification of airborne asbestos in unorganized sectors, India. Chemosphere, 68, 716–723.

Li, J., Dong, Q., Yu, K., & Liu, L. (2014). Asbestos and asbestos waste management in the Asian-pacific region: Trends, Challenges and Solutions. Journal of Cleaner Production, 81, 218–226.

Ramanathan, A. L., & Subramanian, V. (2001). Present status of asbestos mining and related health problems in India—A Survey. Industrial Health, 39, 309–315.

Dave, S., & Beckett, W. S. (2005). Occupational asbestos exposure and predictable asbestos-related diseases in India. American Journal of Industrial Medicine, 48, 137–143.

Indian Bureau of Mines. (2015). Indian mineral year book-2014, asbestos (pp. 2–10).

USGS. (1995). Asbestos, U.S. geological survey minerals yearbook 1994 (Vol. 1, pp. 1-68.1-8.5).

USGS. (1996). Asbestos, U.S. geological survey minerals Yearbook 1995 (Vol. 1, pp. 1–7).

USGS. (1997). Asbestos, U.S. geological survey minerals yearbook 1996 (Vol. 1, pp. 1–5).

USGS. (1998). Asbestos, U.S. geological survey minerals yearbook 1997 (Vol. 1, pp. 8.1–8.5).

USGS. (1999). Asbestos, U.S. geological survey minerals yearbook 1998 (Vol. 1, pp. 8.1–8.5).

USGS. (2000). Asbestos, U.S. geological survey minerals yearbook 1999 (Vol. 1, pp. 8.1–8.6).

USGS. (2003a), Asbestos in metals and minerals: U.S. geological survey minerals yearbook 2001 (Vol. 1, pp. 8.1–8.7).

USGS. (2003). Asbestos, U.S. geological survey minerals yearbook 2002 (Vol. 1, pp. 8.1–8.6).

USGS. (2004). Asbestos, U.S. geological survey minerals yearbook 2003 (Vol. 1, pp. 8.1–8.12).

USGS. (2005). Asbestos, U.S. geological survey minerals yearbook 2006 (Vol. 1, pp. 8.1–8.6).

USGS. (2006). Asbestos, U.S. geological survey minerals yearbook 2005 (Vol. 1, pp. 8.1–8.6).

USGS. (2006). Worldwide asbestos supply and consumption trends from 1900 through 2003, U.S. geological survey (pp. 1–22).

USGS. (2007). Asbestos, U.S. geological survey minerals yearbook 2006 (Vol. 1, pp. 8.1–8.7).

USGS. (2008). Asbestos, U.S. geological survey minerals yearbook 2007 (Vol. 1, pp. 8.1–8.5).

USGS. (2009). Asbestos, U.S. geological survey minerals yearbook 2009 (Vol. 1, pp. 8.1–8.6).

USGS. (2010). Asbestos, U.S. geological survey minerals yearbook 2009 (Vol. 1, pp. 8.1–8.7).

USGS. (2011). Asbestos, U.S. geological survey minerals yearbook 2010 (Vol. 1, pp. 8.1–8.5).

USGS. (2012) Asbestos, U.S. geological survey minerals yearbook 2011 (Vol. 1, pp. 8.1–8.6).

USGS. (2013). Asbestos, U.S. geological survey minerals yearbook 2012 (Vol. 1, pp. 8.1–8.7).

USGS. (2014). Asbestos, U.S. geological survey minerals yearbook 2013 (Vol. 1, pp. 8.1–8.7).

Virta, R. L., & Flanagan D. M. (2015). Asbestos, U.S. geological survey minerals yearbook 2014 (Vol. 1, pp. 8.1–8.8).

Harris, L. V., & Kahwa, I. A. (2003). Asbestos: Old foe in 21st-century developing countries. Science of the Total Environment, 307, 1–9.

The Factories Act. (1948). (Act No. 63 of 1948). International Labour Organization. Available at https://www.ilo.org/dyn/natlex/docs/WEBTEXT/32063/64873/E87IND01.htm.

Hazardous and Other Wastes (Management and Transboundary) Rules. (2016). Central Pollution Control Board. Available at http://www.cpcb.nic.in/Hazardous_waste.php.

Sengupta, B. (2008). Human health risk assessment studies in asbestos based industries in India. CPCB, PROBES/123/2008-2009.

Wu, W.-T., Lin, Y.-J., Li, C.-Y., Tsai, P.-J., Yang, C. Y., & Liou, S.-H. (2015). Cancer attributable to asbestos exposure in ship-breaking workers: A matched-cohort study. PLoS ONE, 10, 7.

WHO. (2014). Neira, M. Chrysotile asbestos. World Health Organization.

ILO. (1986). C162 asbestos convention. Geneva: International Labour Organization. Available: http://www.itcilo.it/english/actrav/ telearn/osh/legis/c162.htm.

Lim, J. W., Koh, D., Khim, J. S. G., Le, G. V., & Takahashi, K. (2011). Preventive measures to eliminate asbestos-related diseases in Singapore. Safety and health at work, 2(3), 201–209.

Turci, F., Tomatis, M., Mantegna, S., Cravotto, G., & Fubini, B. (2008). A new approach to the decontamination of asbestos-polluted waters by treatment with oxalic acid under power ultrasound. Ultra sonicssonochemistry, 15(4), 420–427.

Valouma, A., Verganelaki, A., Maravelaki-Kalaitzaki, P., & Gidarakos, E. (2016). Chrysotile asbestos detoxification with a combined treatment of oxalic acid and silicates producing amorphous silica and biomaterial. Journal of Hazardous Materials, 305, 164–170.

Granat, K., Nowak, D., Pigiel, M., Florczak, W., & Opyd, B. (2015). Application of microwave radiation in innovative process of neutralising asbestos-containing wastes. Archives of Civil and Mechanical Engineering, 15(1), 188–194.

Gualtieri, F., Veratti, L., Tucci, A., & Esposito, L. (2012). Recycling of the product of thermal inertization of cement-asbestos in geopolymers. Construction and Building Materials, 31, 47–51.

Gualtieri, A. F., Cavenati, C., Zanatto, I., Meloni, M., Elmi, G., & Gualtieri, M. L. (2008). The transformation sequence of cement–asbestos slates up to 1200 C and safe recycling of the reaction product in stoneware tile mixtures. Journal of Hazardous Materials, 152(2), 563–570.

Brown, P., & Brown Paul W. (2004). In-situ treatment of asbestos-containing material. U.S. Patent Application 10/989,805.

Colangelo, F., Cioffi, R., Lavorgna, M., Verdolotti, L., & De Stefano, L. (2011). Treatment and recycling of asbestos-cement containing waste. Journal of Hazardous Materials, 195, 391–397.

Xiaoming, L. I. U., & Linrong, X. U. (2011). Asbestos tailings as aggregates for asphalt mixture. Journal of Wuhan University of Technology—Materials Science Edition, 335–338.

Jantzen, C. M., & Pickett, J. B. (2000). How to recycle asbestos containing materials. WSRC-MS-2000–00194, Westinghouse Savannah River Company.

Luther, L. (2006). Disaster debris removal after hurricane Katrina: Status and associated issues. Congressional Research Service, Library of Congress.

World Bank Group. (2009). Good practice note: Asbestos: Occupational and community health issues.

Kusiorowski, R., Zaremba, T., Piotrowski, J., & Adamek, J. (2012). Thermal decomposition of different types of asbestos. Journal of Thermal Analysis and Calorimetry, 109(2), 693–704.

Kodera, Y., Sakamoto, K., & Sekiguchi, H. (2013). Demonstration on thermal treatment of asbestos-containing disaster waste for safe disposal and energy recovery. In 7th International Symposium on Feedstock Recycling of Polymeric Materials, New Delhi, India.

Leonelli, C., Veronesi, P., Boccaccini, D., Rivasi, M., Barbieri, L., Andreola, F., et al. (2006). Microwave thermal inertization of asbestos containing waste and its recycling in traditional ceramics. Journal of Hazardous Materials, 135, 149–155.

USGS. (2001). Some facts about asbestos (USGS Fact Sheet FS-012–01). (4 pp).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, R., Sontakke, M., Vivek, J.M., Rao, B., Asolekar, S.R. (2019). Environmental Sound Management of Asbestos-Containing Wastes Generated from Industries in India. In: Ghosh, S. (eds) Waste Management and Resource Efficiency. Springer, Singapore. https://doi.org/10.1007/978-981-10-7290-1_50

Download citation

DOI: https://doi.org/10.1007/978-981-10-7290-1_50

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7289-5

Online ISBN: 978-981-10-7290-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)