Abstract

The present study deals with the evaluation of in-vessel co-composting as a treatment option for septage management. Optimization of process parameters such as carbon: nitrogen (C/N) ratio, moisture content, pH, temperature and oxygen supply can accelerate the naturally occurring composting process. Since the C/N ratio of septage is <10, it needs to be composted with complementary waste having higher C/N. Hence, in this study, efforts were made to understand the compost dynamics of septage co-composting in a laboratory-scale in-vessel system. Co-composting of septage was done with mixed organic fraction which includes mainly paper waste, vegetable waste and food waste to increase the overall C/N ratio. The parameters such as pH, moisture content, temperature, carbon and nitrogen were monitored during the process. The results showed that the compost mixture has an initial C/N ratio of 20 and organic matter (OM) content of 83%. The OM content was reduced to 62% and C/N ratio to 11 after a composting operation of 20 days, which indicated the effective degradation of organic waste. Temperature above 55 °C for more than 5 days ensured significant pathogen inactivation during the composting process. Final compost quality indicated that it can be used as a fertilizer since it has enough organic and nutrient content for plants to grow.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The management of waste generated from onsite sanitation systems (OSS) is a looming problem in many developing nations. In India, the usage of septic tanks is 14.7% in rural area and 38.2% in urban area, which can increase in the near future [1]. As a result, large quantities of septic tank waste (septage) are generated which do not have proper management strategy at present. It has been reported that in India, the faecal sludge or septage generation from both OSS and open defecation contributes to 0.12 million tons per day (EAI estimate) [2]. Disposal of large quantity of untreated or partially treated septage to the environment will lead to significant greenhouse gases emission [3], water sources contamination [4] and serious health threats [5, 6]. Though septage is harmful, it has got significant nutrient value. The usage of septage as manure was justified by the study conducted by Jönsson et al. [7], where it was reported that excreta contain valuable nutrients. The estimated nutrient content from excreta was 4.5, 0.6 and 1.2 kg/person/year for nitrogen, phosphorus and potassium, respectively.

Vincent et al. [8] conducted feasibility studies to treat septage in sludge drying reed bed and were succeeded in removing >80% of chemical oxygen demand (COD), suspended solids (SS) and ammonia-nitrogen (NH4+-N). Lin et al. [9] investigated the anaerobic co-digestion of septage and landfill leachate in an upflow anaerobic sludge blanket (UASB) reactor and found significant removal of organic matter and nutrients. Similarly, other treatment options like aerobic digestion [10], waste stabilization ponds [11], vertical flow constructed wetlands [12] and combination of both waste stabilization ponds and vertical flow constructed wetlands [13] were also investigated for septage treatment. Lime treatment, activated sludge process and anaerobic digestion are also widely used technologies for treating septage [14]. But seldom studies were conducted to recover nutrients from septage. Cofie et al. [15] reported that co-composting of organic solid waste and faecal sludge helps in the recycling of nutrients. As septage is a highly variable kind of waste [16,17,18,19], a complementary waste needs to be mixed with septage in order to provide lacking components to use as a fertilizer. They carried out studies to co-compost septage with municipal solid waste, household waste and market waste. In India, proper septage treatment is rarely practiced due to the lack of knowledge on sustainable management options. Even though co-composting can be considered as a sustainable treatment technology for septage management, only very few research studies have been carried out to understand the efficiency of co-composting of septage. This study aims at understanding the composting dynamics during septage co-composting using mixed organic waste by closely monitoring the in-vessel system. Additionally, the correlation between different operational parameters and organic matter decomposition was also investigated.

2 Materials and Methods

2.1 Sample Collection

Septage, obtained from different parts of Chennai city, was then pooled together to get a representative septage. Septage dewatering was achieved using drying beds and alum coagulation. The dewatered septage solids thus obtained were subjected to co-composting. Green vegetable waste and food waste were collected from Himalaya mess, IIT Madras campus, Chennai, India. Cow dung and wood chips were procured from the nearby shops of IIT Madras campus. Coir pith waste was obtained from Kancheepuram district. The particle size in the mixed waste was limited to 2–5 cm in order to ensure moisture control aeration by using a mechanical shredder with 2.2 kW motor. About 50 g of each grab sample was collected from different locations without disturbing the neighbouring materials. The grab samples thus obtained were mixed together to produce homogenized sample.

2.2 Analytical Procedure

The homogenized samples were collected in triplicate and analysed for electrical conductivity and pH (1:10 waste: water extract). The moisture content of the compost was determined after drying to a constant weight at 105 °C in a hot-air oven [20]. Sub-samples were air dried, grounded to pass through a 0.2 mm sieve and were analysed for the following parameters: ammonia nitrogen (NH4+-N) using potassium chloride (KCl) extraction [21], organic matter content (550 °C for 2 h), total phosphorus (TP) (acid digest) using the stannous chloride method [20] and total organic carbon (TOC) determined by a Shimadzu (TOC-VCSN) solid sample module (SSM-5000A). The total carbon (TC) and total nitrogen (TN) contents of the solids from septage were determined using CHNS analyzer (Elementar, Germany).

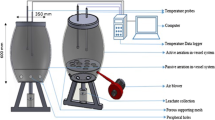

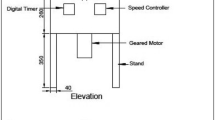

2.3 Experimental Set-Up

The composting experiment was carried out in a vertical drum having a diameter of 320 mm and height of 600 mm. Aeration was achieved by providing 50 mm diameter holes along the perimeter at the bottom side of the drum. The compost matrix was supported by a perforated metal mesh. The mesh not only supported the matrix but also provided a pathway for air exchange. A leachate collection system was provided at the bottom of the drum. The entire set-up was insulated using glass wool for the prevention of heat loss during the process. Temperature probes were inserted at the top and bottom of compost matrix, and the data was stored using a temperature data logger. Figure 1 shows the experimental set-up of in-vessel system.

2.4 Statistical Analysis

All the results reported are the mean of three replicates except the temperature data in order to ensure reproducibility and representativeness of the samples. Pearson’s correlation test (p test) was conducted using IBM SPSS 22.0 in order to understand the correlation of organic matter reduction with various composting parameters.

3 Results and Discussion

Composting is the most sustainable treatment option for managing organic wastes. Septage is a waste which is rich in nitrogen content. Composting septage with the acceptable organic wastes in a proper compost system will turn waste into value-added products such as compost. It can be used as fertilizer that enhances soil condition and aids the plant growth. Co-composting of complementary wastes could reduce the GHG emissions of the subsequent composting process and could even enrich the nutrient content significantly [22]. Moreover, the quality of final compost is influenced by initial feedstock materials and process conditions. In this study, the feasibility of in-vessel system for septage co-composting with mixed organic waste was investigated.

3.1 Feedstock Material Composition

The dewatered septage solids having an average moisture content of 74% were co-composted with mixed organic waste. The mixed organic fraction includes vegetable waste, cooked waste and paper waste which provide readily available carbon and nitrogen for the composting microbes [23]. The feedstock composition and initial characteristics of the waste mixture for co-composting are given in Tables 1 and 2, respectively. In addition to the organic wastes, coir pith and wood chips were added as bulking material and structural material, respectively. Malińska and Zabochnicka-Świątek [24] suggested the need of adding bulking material for wastes which are high in moisture content, low C/N ratio and with high susceptibility to compaction. Wood chips act as a structural support and resist compaction during composting which results in maintaining air filled porosity throughout the composting pile (Haug 1993). Since the water holding capacity and C/N ratio of coir pith is high, the addition of coir pith to the compost matrix absorbed excess moisture and increased the C/N ratio [25, 26]. Cow dung (3.3% of total waste on wet basis) was also added to dewatered septage along with organic waste as it as a booster which can result in faster degradation of organic wastes. The mixing is done based on water content and C/N ratio [27]. Proper mixing of the wastes was ensured by using a rotary drum mixer. The total weight of waste treated in each system was 30 kg. The initial waste mixture is having an optimum C/N ratio of 23.4 [28]. The initial water content of waste is 77% where the optimum range is of 55–70% [29].

3.2 Temperature Profile

The temperature plays a significant role in the establishment of various microbial communities in the compost pile [23]. The rate of raw material decomposition is dependent on the growth of composting microbes which is in turn influenced by ambient air temperature. Therefore, it is important to monitor both the ambient and compost pile temperature during the process. The temperature of composting pile and ambient air are shown in Fig. 2. The temperature rise from 35 to 45 °C observed within 24–36 h clearly shows the quick establishment of mesophilic micro-organisms. The initial increase in temperature was due to the high microbial activity in composting pile. The composting matrix was dominated by mesophilic micro-organisms during the first 4 days and later occupied by thermophilic micro-organisms. The major organic matter transformations happen during thermophilic temperature. The higher temperature rise indicated that the feedstock composition is adequate especially in terms of C/N ratio as it supported aerobic microbial degradation. This further resulted in the prolonged thermophilic stage during the composting process [30, 31]. Temperature above 55 °C for more than 5 days ensured significant pathogen inactivation during composting [32]. The composting pile reached the ambient temperature after 20 days of composting and indicated a good degree of stability.

3.3 Patterns of pH and Electrical Conductivity

The pH is considered as one of the crucial parameters controlling the biodegradation process in composting. In the current study, the initial pH of the compost mixture was found to be in the range of 3.8–4.0 which is less when compared to most of the compost systems [33]. Though the initial pH is low, an increasing trend in pH (Fig. 3) was observed during the composting period. Even though composting started at an extreme end, the process continued without a lag due to the establishment of a diverse group of microbes [34]. The increasing pattern of pH level observed during composting was due to the net release of CO2 from the system and also due to release of ammonia by protein degradation [35]. The change in pH is found to be highly negatively correlated with loss in organic matter with a P value of 0.956 (p < 0.05).

The electrical conductivity (EC) directly indicates the salinity in the composting matrix. Higher salinity in the compost can cause phytotoxic effects. The trend of electrical conductivity observed in this study is in agreement with Huang et al. [36]. The early high EC is attributed to the release of ammonium ions and mineral salts during the mineralization process, whereas the decrease in EC at the later phase of composting was due to the precipitation of mineral salts and volatilization of ammonia. The final compost has an EC value of 1.6 mS/cm which is not toxic for plant growth [37].

3.4 Moisture Content

Loss in moisture content is an index of organic matter decomposition rate. Heat evolution occurred during microbial decomposition of organic matter resulted in moisture loss [33]. Moisture content decreased from an initial value of 77–68% during 20 days of composting. Figure 4 clearly depicts the change in moisture content during in-vessel composting. The loss in moisture content is proportional to the leachate production. The change in moisture content is found to be highly positively correlated with loss in organic matter with a P value of 0.966 (p < 0.05). Thus, the organic matter degradation will be more with higher moisture content.

3.5 Carbon Decomposition and Organic Matter Content

The loss of organic matter occurred due to the decomposition of organic compounds such as sugars, lipids and proteins in the composting mass into CO2 water vapour and heat. The total mass of the compost will be gradually decreased with higher degree of degradation, and the loss can be directly noticed by the decrease in TOC content [38]. The carbon decomposition during composting period is presented in Fig. 5. Initially, the TC and TOC content were 45 and 39%, respectively. The TC and TOC content were reduced to 33.2 and 30.2% after 20 days of the composting operation, respectively. Around 22.5% of the available carbon is utilized by micro-organisms as source of energy. The change in TOC content was found to be highly positively correlated with loss in organic matter with a P value of 0.886 (p < 0.05). The OM content was decreased from 83 to 62.5% within 20 days. Loss in OM is due to the rise in temperature during composting. The OM loss during composting is shown in Fig. 6. Similar trend was observed by Kalamdhad and Kazmi [30]. The results showed effective organic matter degradation during the process.

3.6 Nitrogen and Phosphorous Dynamics

The change in TN and ammonia during composting is clearly depicted in Fig. 7. TN (% dry weight) increased from 1.9 to 2.9% within 20 days of composting. This is attributed to net loss of dry mass as CO2, loss of water by evaporation and significant organic matter oxidation [36]. As a result, the change in TN content showed a highly negative correlation with loss in organic matter with a P value of 0.924 (p < 0.05). Ammoniacal nitrogen showed an increasing trend till 17th day of composting and decreased at the later days of composting. The breakdown of organic nitrogen during composting and the availability of H+ ions (pH < 7) resulted in the initial increase in NH4-N concentration [39]. Hirai et al. [40] suggested that the decrease in NH4-N is an indicator of a high-quality composting process. In the present study, the NH4-N content <0.4% indicated the stabilization of final compost [41].

Phosphorus present in the organic material is released by the mineralization process which involves micro-organisms. During the process, the negatively charged inorganic phosphorus reacts with positively charged ions like calcium (Ca), aluminium (Al) and iron (Fe) to form comparatively insoluble substances. As a result, the phosphorus is considered to be fixed up [42]. The fractional value of total phosphorus (TP) depends on the dry mass in the system. In this study, TP (g/kg) showed an increasing pattern due to the net dry mass loss. Figure 8 clearly shows the increase in phosphorous during composting. As a result, the change in TP content showed a highly negative correlation with loss in organic matter with a P value of 0.959 (p < 0.05).

3.7 Carbon to Nitrogen Ratio

The change in C/N ratio is a sign of degree of stabilization and degree of organic matter decomposition attained during composting [43]. Figure 9 shows the change in C/N ratio with respect to time. The ideal C/N ratio to enable composting is 25:1–30:1. Composting micro-organisms decompose organic matter by utilizing nitrogen as the source for cell build-up and carbon as source of energy which results in the reduction of C/N ratio [35]. The compost mixture with C/N ratio > 30 may hinder microbial growth due to insufficient N [44], while too much N results in higher losses of N as ammonia and nitrogen oxides [39]. In this study, the initial C/N ratio of the compost mixture was found to be 23.4. The C/N ratio gradually decreased to 11.4 after 20 days of composting process which indicates that the bioavailability of carbon was high [45]. A similar trend in C/N ratio was noticed with in-vessel composting of different organic waste mixtures [23, 35]. Van Heerden et al. [46] suggested that a C/N < 20 ensures proper compost maturity, where with a ratio of ≤15 is also preferred. In the present study, the final compost has a C/N ratio of 11.4 which indicates that it is stabilized. The change in C/N content showed a highly positive correlation with loss in organic matter with a P value of 0.945 (p < 0.05).

4 Conclusion

The feasibility of septage co-composting using in-vessel system was investigated. A suitable feedstock composition was formulated for the effective co-composting of septage. The close monitoring of in-vessel system helped in the detailed understanding of compost dynamics during septage co-composting. Moreover, proper feedstock materials’ mixing resulted in obtaining the matured compost within 20 days of composting process. The ripened compost has a TOC content of 30.2 ± 0.5%, TN value of 2.92 ± 0.3% and a TP value of 0.31 ± 0.01%. The compost stability was assured by a low temperature (37 °C) and low C/N ratio (11.4 ± 0.5) of final compost. Therefore, the present study revealed that in-vessel co-composting is a better decentralized sustainable treatment option for converting septic tank waste into a valuable resource.

References

Census of India. (2011). Availability of type of Latrine facility 2001–2011. http://censusindia.gov.in/2011census/hlo/Data_sheet/India/Latrine.pdf.

EAIestimate. (2016). Retrieved July 15, 2016, 11.30 pm from http://www.eai.in/ref/ae/wte/typ/clas/fecal_sludge.html.

Diaz-Valbuena, L. R., et al. (2011). Methane, carbon dioxide, and nitrous oxide emissions from septic tank systems. Environmental Science and Technology, 45(7), 2741–2747.

Verstraeten, I. M., et al. (2005). Use of tracers and isotopes to evaluate vulnerability of water in domestic wells to septic waste, 107–117.

Romdhana, M. H., Lecomte, D., Ladevie, B., & Sablayrolles, C. (2009). Monitoring of pathogenic microorganisms contamination during heat drying process of sewage sludge. Process Safety and Environmental Protection, 87(6), 377–386.

Yen-Phi, V. T., Rechenburg, A., Vinneras, B., Clemens, J., & Kistemann, T. (2010). Pathogens in septage in Vietnam. Science of the Total Environment, 408(9), 2050–2053.

Jönsson, H., Stintzing, A. R., Vinnerås, B., & Salomon, E. (2004). Guidelines on the use of urine and faeces in crop production. EcoSanRes Programme.

Vincent, J., Molle, P., Wisniewski, C., & Liénard, A. (2011). Sludge drying reed beds for septage treatment: Towards design and operation recommendations. Bioresource Technology, 102(17), 8327–8330.

Lin, C. Y., Chang, F. Y., & Chang, C. H. (2000). Co-digestion of leachate with septage using a UASB reactor. Bioresource Technology, 73(2), 175–178.

Lin, C. Y., & Chou, J. (1998). Aerobic digestion of septage. Bioresource Technology, 64(3), 219–224.

Sanguinetti, G. S., Tortul, C., Garcia, M. C., Ferrer, V., Montangero, A., & Strauss, M. (2005). Investigating helminth eggs and Salmonella sp. in stabilization ponds treating septage. Water Science and Technology, 51(12), 239–247.

Koottatep, T., Polprasert, C., Oanh, N. T. K., Heinss, U., Montangero, A., & Strauss, M. (2001). Potentials of vertical-flow constructed wetlands for septage treatment in tropical regions. Advances in water and wastewater treatment technology (pp. 315–323).

Tsalkatidou, M., Gratziou, M., & Kotsovinos, N. (2013). Septage treatment using a combined waste stabilization ponds—Vertical flow constructed wetland system. Desalination and Water Treatment, 51(13–15), 3011–3017.

Ingallinella, A. M., Sanguinetti, G., Koottatep, T., Montangero, A., & Strauss, M. (2002). The challenge of faecal sludge management in urban areas-strategies, regulations and treatment options. Water Science and Technology, 46(10), 285–294.

Cofie, O., Kone, D., Rothenberger, S., Moser, D., & Zubruegg, C. (2009). Co-composting of faecal sludge and organic solid waste for agriculture: Process dynamics. Water Research, 43, 4665–4675.

Heinss, U., Larmie, S.A., & Strauss, M. (1998). Solid separation and pond systems for the treatment of faecal sludges in the tropics: Lessons learnt and recommendations for preliminary design. SANDEC Report No. 05/98. EAWAG/SANDEC, Duebendorf, Switzerland.

Koné, D., & Strauss, M. (2004). Low-cost options for treating faecal sludges (FS) in developing countries–Challenges and performance. In 9th International IWA Specialist Group Conference on Wetlands Systems for Water Pollution Control and to the 6th International IWA Specialist Group Conference on Waste Stabilisation Ponds, Avignon, France (Vol. 27).

Strauss, M., Larmie, S. A., Heinss, U., & Montangero, A. (2000). Treating faecal sludges in ponds. Water Science and Technology, 42(10), 283–290.

USEPA. (1994). Guide to septage treatment and disposal guide to septage treatment disposal (September).

APHA (American Public Health Association). (1995). Standard methods for the examination of water and wastewater (17th ed.). Washington, DC: APHA.

Tiquia, S. M., & Tam, N. F. Y. (2000). Fate of nitrogen during composting of chicken litter. Environmental Pollution, 110(3), 535–541.

Puyuelo, B., Ponsá, S., Gea, T., & Sánchez, A. (2011). Determining C/N ratios for typical organic wastes using biodegradable fractions. Chemosphere, 85, 653–659.

Nayak, A. K., & Kalamdhad, A. S. (2013). Composting of sewage sludge based on different C/N ratios. Journal of Chemical, Biological and Physical Sciences, 3(3), 2251–2268.

Malińska, K. R. Y. S. T. Y. N. A., & Zabochnicka-Świątek, M. A. G. D. A. L. E. N. A. (2013). Selection of bulking agents for composting of sewage sludge. Environment Protection Engineering, 39(2).

Prabhu, S. R., & Thomas, G. V. (2002). Bioconversion of coir pith into value added organic resource and its application in agrihorticulture: Current status, prospects and perspective. Journal of Plantation Crops, 30, 1–17.

Thomas, A. R., Krithika, D., Gomathy, R. I., Kranert, M., & Philip, L. (2016). Optimization of bulking material for co-composting of septage. In Proceedings of IndoGerman Conference on Sustainability, Chennai, India, pp. 25–27.

Rynk, R., van de Kamp, M., Willson, G. B., Singley, M. E., & Richard, T. L., et al. (1992). On-farm composting handbook (p. 186). New York: Northeast Regional Agricultural Engineering Service.

Haug, R. T. (1993). The practical handbook of composting engineering. USA: CRC Press.

Mohee, R., & Mudhoo, A. (2005). Analysis of the physical properties of an in-vessel compostingmatrix. Powder Technology, 155(1), 92–99.

Kalamdhad, A. S., & Kazmi, A. A. (2009). Effects of turning frequency on compost stability and some chemical characteristics in a rotary drum composter. Chemosphere, 74, 1327–1334.

Jiang, J., Huang, Y., Liu, X., & Huang, H. (2014). The effects of apple pomace, bentonite and calcium superphosphate on swine manure aerobic composting. Waste Management, 34(9), 1595–1602.

Lopez, R. J., & Foster, M. (1985). Plant pathogen survival during the composting of agricultural wastes. In Composting of agriculture and other wastes. London: Elsevier Applied Science Publishers.

Liao, P. H., Jones, L., Lau, A. K., Walkemeyer, S., Egan, B., & Holbek, N. (1997). Composting of fish wastes in a full-scale in-vessel system. Bioresource Technology, 59(2–3), 163–168.

Graves. (2000). Environmental engineering national engineering handbook. http://www.wcc.nrcs.usda.gov/ftpref/wntsc/AWM/neh637c2.pdf.

Varma, V. S., Mayur, C., & Kalamdhad, A. (2014). Effects of bulking agent in composting of vegetable waste and leachate control using rotary drum composter. Sustainable Environment Research, 24(4).

Huang, G. F., Wong, J. W. C., We, Q. T., & Nagar, B. B. (2004). Effect of C/N on composting of pig manure with sawdust. Waste Management, 24, 805–813.

Wong, J. W. C., Li, S. W. Y., & Wong, M. H. (1995). Coal fly ash as a composting material for sewage sludge: Effects on microbial activities. Environmental Technology, 16, 527–537.

Vuorinen, A. H., & Saharinen, M. H. (1997). Evolution of microbiological and chemical parameters during manure and straw co-composting in a drum composting system. Agriculture, Ecosystems & Environment, 66, 19–29.

Varma, V. S., & Kalamdhad, A. S. (2013). Composting of municipal solid waste (MSW) mixed with cattle manure. International Journal of Environmental Sciences, 3(6), 2068.

Hirai, M. F., Chamyasak, V., & Kubota, H. (1983). Standard measurement for compost maturity. BioCycle: Journal of Waste Recycling, 24(6), 54–56.

Zucconi, F., Forte, M., Monac, A., & De Bertoldi, M. (1981). Evaluating toxicity of immature compost. Biocycle, 22, 54–57.

Kalamdhad, A. S., & Kazmi, A. A. (2007). Rotary drum composting of mixed organic waste based on different C/N ratios. In Proceedings of the International Conference on Sustainable Solid Waste Management, Chennai, India (pp. 258–265).

Zucconi, F., Monaco, A., Forte, M., & de Bertoldi, M. (1985). Phytotoxins during the stabilization of organic matter. In J. K. R. Grasser (Ed.), Composting of Agricultural and Other Wastes. Amsterdam, Netherlands: Elsevier Science.

Shiralipour, A., McConnell, D. B., & Smith, W. H. (1992). Physical and chemical properties of soils as affected by municipal solid waste compost application. Biomass and Bioenergy, 3, 261–266.

Kim, J.-D., Park, J.-S., In, B.-H., Kim, D., & Namkoong, W. (2008). Evaluation of pilot-scale in-vessel composting for food waste treatment. Journal of Hazardous Materials, 154, 272–277.

van Heerden, I., Cronje, C., Swart, S. H., & Kotze, J. M. (2002). Microbial, chemical and physical aspects of citrus waste composting. Bioresource Technol., 81(1), 71–76.

Acknowledgements

The authors express gratitude towards DST-IGCS for funding this project. The authors also express sincere gratitude towards DST-INSPIRE for the financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Thomas, A.R., Praveen Rosario, A., Philip, L., Kranert, M. (2019). Performance Evaluation of In-vessel System for Co-composting of Septage. In: Ghosh, S. (eds) Waste Management and Resource Efficiency. Springer, Singapore. https://doi.org/10.1007/978-981-10-7290-1_43

Download citation

DOI: https://doi.org/10.1007/978-981-10-7290-1_43

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7289-5

Online ISBN: 978-981-10-7290-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)