Abstract

Severe environmental impact of manufacturing has led to highly unsustainable condition by consuming natural resources at faster pace, Green House Gases (GHG) emissions, massive landfills, etc. It is the right time to wake up and adopt green manufacturing (GM) so that resources can be consumed at minimum possible rate and climate change issue can be addressed optimally. GM requires huge efforts in terms of financial and human resources. The facilitation of the industry for GM implementation by investigating the enablers would prove to be helpful for faster implementation. In this paper, 15 enablers are identified through a survey of literature and discussion with experts in industry, academia and research. An application of MOORA method is utilized to assess the most important and high-impact enablers. This study concluded that the most important six enablers are: energy and resource crisis, competitiveness, financial and human resources, strategic management commitment, green supplier management, and information technology management. This research is expected to throw light on understanding of GM implementation in manufacturing industry such as aerospace, nuclear, and power plants more smoothly and gradually.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Green manufacturing (GM) is generically defined as ‘the process of redefining the processes in order to reduce or minimize the waste’ [1]. GM is a relatively new concept that can be viewed as a product of the 1990s. It is defined as an economically driven, system-wide, and integrated approach to the reduction and elimination of all waste streams associated with the design, manufacture, use and/or disposal of products and materials [2]. Several other jargons such as end-of-line management, sustainable manufacturing, and environmentally conscious manufacturing mean the same thing [3]. The common observation of recent trends in manufacturing technology reveals that every organization is taking their problem solving method to an advanced level by adopting different techniques and solutions. GM is one such solution which could enhance the scope of problem solving by taking part in each and every activity untaken by the organization. Such solutions lead us to reduced cost by reducing material handling and reducing effluents and other wastes. All such efforts are applications of GM. This manufacturing concept not only addresses the environmental issues, but also reduces redundancy and improves ergonomics and cost too. Nowadays, cheaper production at faster pace is not the only criterion which is followed by manufacturers, but the type of material used, the processes involved, and the futuristic fate of the product is taken into consideration. So, in order to make our system fully eligible for such criteria, green manufacturing systems need to be adopted.

The GM paradigm is an outcome of technological and market motivations. People are getting more and more aware about the environmental risks, and thus, they support the shaping of a new system which meets their demands without affecting other aspects as well. This is achieved through new eco-friendly product designs which will actually realize the objectives of green manufacturing systems [4]. In recent years, the GM proved to be a very important edge for its implementation in corporate sector to become competitive. However, there were certain complications which arose because of the initial investments which are huge and irreversible. Thus, the managers had to take into account all the factors before the implementation of GM. The accuracy of the decision to adopt GM is very crucial as it should fulfill the objectives of the company and the world. In reality, manufacturing organizations directly impact the environment, and it is sometimes overshadowed by the economic aspects [5]. Manufacturing firms not only generate harmful wastes, but also consume a huge portion of available energy. Thus, we need to foresee the effects related to the environment as well as on the economic aspects. As the adoption of GM requires many major decisions such as disruption of routine production, huge initial investment, and fear of success [6], so it is required to make this change very smooth and gradual. It is realized that the analysis of the factors which enables this change needs to be investigated so that government can act as strong catalyst to facilitate the change without much negative impact.

Section 2 presents literature survey followed by enablers of green manufacturing in Sect. 3. Section 4 provides methodology, results, and discussions. The study is concluded in Sect. 5 followed by acknowledgements and references.

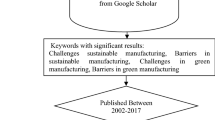

2 Literature Review

The ‘Industrial Revolution’ came into picture in late 1700s and has been through several phases [7]. The real challenge begun when different new manufacturing systems were adopted and the sustainability issues came later on. The major issues such as cost and the environmental aspects such as reduction of greenhouse gases forced developed economies such as USA, Canada, Great Britain, and European countries to shift their manufacturing base to China and India. The problem needs a solution based on the facts related to the cost optimization as well as environmental safety. One possible solution to this problem is the adoption of GM [3]. GM is defined as total elimination of wastage and redefining existing process to minimize the carbon emissions during each process without increasing cost and affecting production targets [1, 8]. Nowadays, it is unescapable situation for the companies to think of a system which do not respond to environmental consequences. So, it is necessity for the companies to consider GM system as a solution for environmental safety and for optimize the cost of the products [9, 10].

GM is not only limited to production stages of the manufacturing system, but also includes the design development and management aspects as well [11]. It also emphasizes the reverse engineering in the manufacturing processes for implementation of closed-loop system like recycling and reconsidered the waste product with an aim to reduce the wastage produced by the industries [12, 13]. GM is not only limited to environmental aspects, but also includes the best use of available resources in the industry. It helps the company in long run to compete in global market scenario and able to increase the production quality, produce the product at optimum cost, and increase the efficiency of the company [14]. Adoption of GM gives various benefits to the company in term of brand enhancement with customers, long-term cost savings, etc.

Studies on GM can be divided into two groups, first, the studies that dealt with the overall theoretical concept of GM and second, the studies that provided various analytical tools and models to realize GM at different levels [4]. Various researchers have done lot of work on both types of studies separately. In today’s competitive scenario, there is need to combine these two types of research together so that a comprehensive GM model can be framed which includes the total concepts of GM. There exists a lot of literature on drivers for GM in different countries including India, European, and American. Similarly, many studies were conducted on barriers to GM. These studies discussed a set of influencing factors affecting the implementation in either way and suggested various solutions relevant to different countries, different industry sizes, different industry sectors, etc. The research studies are very limited that discussed the GM enablers which is very important for GM implementation in the industry. This is clearly evident from the literature that GM adoption in the industry is not possible without mitigating the barriers to GM which is not possible without investigating the GM enablers. This study aims to identify the GM enablers through literature survey and brain storming with various researchers in the field of industry and academia. At the end, most effective and high-impact enablers are proposed, so that GM systems can easily implement in the industry more effectively and efficiently.

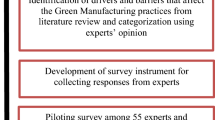

3 Enablers of Green Manufacturing

Any new change in the existing manufacturing systems requires some motivations and facilitation for implementation. Similarly, the adoption of GM in the industry needs enablement in addition to motivations for implementation. Hence, fifteen enablers which can facilitate the implementation of GM in the industry are identified through a review of literature and opinion of experts from industry and academia (see Table 1). Additionally, 6 assessment criteria were identified which can be used to find the most important, high-impact and influential enablers for faster implementation of GM.

Assessment Criteria’s for GM Enablers

-

1.

Green Reputation: Green reputation describes the image of the company in the market. High reputation leads to the alignment of customers. Here, we will see the effect of each enabler on these criteria and how much is the effect of this factor in deciding the application of GM in that particular firm.

-

2.

Profit: Each and every firm enters into the market with an aim to earn profit. The technology application and each criteria is oriented at increasing the profit. So, these criteria hold the upper hand over all the other criteria’s. A firm will prefer only that very technological perspective in which they need not to compromise with their profit.

-

3.

Productivity: A firm needs to see that if it is meeting the customer demands at the right time. So, productivity plays an important role. High productivity leads to high sustainability and prevents the stock outs. We will assess as to what effect these enablers bring on the productivity of the firm.

-

4.

Recurring Cost: It defines the overall cost of production including the investment cost. Efforts are being made to minimize this cost as it provides the edge of competition in the market. Lower recurring cost leads to lower unit price, which in turn attracts the customers.

-

5.

Time Period: A firm need to spend some time to implement GM. That consumes valuable time of the company which can further influence the routine production and finance. So, the time required for the change is important criteria for assessment of enablers.

-

6.

Human Resources: The implementation of any new system requires skilled human resources which can install, operate, use, and maintain the new technology. The availability and cost of such human resources is an important criterion in the present case.

4 Methodology, Results, and Discussion

Fifteen enablers are identified through the review of literature and perception of researchers, academicians, and industry executives. The application of MOORA method as explained in the methodology section is done using six assessment criteria i.e., green reputation, profits, productivity, recurring cost, time period, and human resources. The first three criteria evaluates/assesses the green manufacturing on the basis of output after implementation of GM in industry i.e., green reputation, profits, and productivity. The second three criteria evaluates/assesses the green manufacturing on the basis of input required (say consumables) for implementation of GM in industry i.e., recurring cost, time period, and human resources. These criteria are decided while a rigorous reference to the existing literature, in-depth discussion among 10 researchers of our research group, and consultation with 3 industry executives working at the top management level of manufacturing companies. As the impact of all six criteria is different so the weightage of each criteria is decided in such a way in consultation with all involved in this research that the total weightage is 100% (or 1). The rating of each enabler on a Likert’s scale of 1–5 is done by the same group of people who decided the criteria weights.

Multi-objective optimization on the basis of Ratio Analysis (MOORA) is also known as multi-criteria or multi-attribute optimization. It is the process of simultaneous optimization of two or more conflicting attributes (objectives) subject to certain constraints. The MOORA method, first introduced by Brauers and Zavadskas [15] is a multi-objective optimization technique that can be successfully applied to solve various types of complex decision making problems in the manufacturing environment by providing weightage to each and every analysis. This method is observed to be simple and computationally easy which helps the decision makers to eliminate the unsuitable alternatives while selecting the most appropriate alternative to strengthen the existing selection procedures [16].

Advantages of the MOORA method in comparison with other MCDM method are: easy to understand as comparison to other MCDM techniques; less time require for mathematical calculation work; and no extra assumed parameters required such as ‘v’ in VIKOR method and ‘n’ in GTA method [17].

This methodology has been successfully used by various researchers for different production life cycle such as stages selection, flexible manufacturing system selection, welding process selection, supplier selection [17], material selection [18], optimizing milling process [19, 20], and privatization in a transition economy [21]. The various steps used by Brauers and Zavadskas [15] in MOORA method as follows:

Step 1: Identification of enablers, criteria, and criteria weightage

Table 1 presents the identified 15 enablers of GM and then finalized 6 assessment criteria for evaluating each enabler i.e., green reputation, profits, productivity, recurring cost, time period, and human resources.

Step 2: Allocation of ranking to enablers with respect to all six criteria

Ranking to each enabler on Likert’s scale of 1–5 with respect to outcome and input of GM as shown in Table 2. Criteria weightage and ranking to each enabler decides after the discussion with experts from industry and academia.

Step 3: Normalization of matrix

Normalization of enablers can be done by different methods such as total ratio, Schärlig ratio, Weitendorf ratio, Jüttler ratio, Stop ratio, and Körth ratio suggested by Brauers and Zavadskas [15] in MOORA method. However, it is recommended that for this case, total ratio method is suggested. This ratio can be expressed as follows:

Normalized matrix is generated with the help of Eq. 1 from columns 2–7 as shown in Table 3.

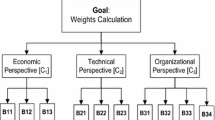

Step 4: Weightage Calculation (Y i )

In case of multiple goals, normalized value added for all beneficial goals (case of maximization) and subtract for all non-beneficial goals (case of minimization). Then, final equation is for Y i is

where g is the number of beneficial goals, (n − g) is the number of non-beneficial goals, and Y i is the normalized assessment value for ith enabler. In some cases, it is often observed that some goals are more important than the others. In order to give more importance to a goal, it could be multiplied with its corresponding weight (significance coefficient) (Brauers et al. 2009). When these goal weights are taken into consideration then new equation for Yi is

where Wj is the weight of jth goal. Values of Y i are calculated for each enabler with the help of Eqs. 2 and 3 in column 8 as shown in Table 3.

Step 5: Final Ranking of Enablers

The Y i value can be positive or negative depending of the totals of its beneficial goals and non-beneficial goals in the Table 3. An ordinal ranking of Y i shows the final preference. Thus, the best enabler has the highest Y i value, while the least effective enabler has the lowest Y i value. Values of Y i and ranking for each enabler are calculated in column 9 as shown in Table 3.

Graph between the values of Y i and enablers are represented as shown in Fig. 1. The middle line (where Y i = 0) represents that the criteria input of the enabler is equal to criteria output of the same enabler. This graph represents enablers 3, 5, 6, 10, 12, and 13 lie above the middle line means (Y i ≥ 0). It means all these enablers have higher output comparison to input given. Other enablers 1, 2, 4, 7, 8, 9, 11, 14, and 15 (Y i ≤ 0) mean that they require more input value for getting output value. The enabler 13 (Y i = 0.003) and enablers 11, 14, and 15 (Y i = −0.003) lie very near to the middle line, and little variation in the criteria values may change the enabler location from positive value of Yi to negative value of Yi and vice versa.

5 Conclusions

The application of 5 step methodology yielded the ranking of the GM enablers. The objective of the research is to identify the most important and high-impact enablers which can greatly enable or facilitate the GM implementation in industry. The research came with six most important enablers, viz. energy and resources crisis; competitiveness; financial and human resources; strategic management commitment; green supplier management; and information technology management.

The enabler 10 (energy and resource crisis) has got highest Yi value (i.e., 0.024) which means it enables the GM implementation more as comparison to other enablers. Waste management system (enabler 1) has got the minimum Yi (i.e., −0.014) which means that it enables the system by consuming more inputs in term of recurring cost, time period, and human resources and achieves less outputs. So, management needs to have primary focus on the three top enablers i.e., energy and resource crisis, competitiveness, and financial and human resources, because it will enable the GM implementation in industry more as comparison to other enablers.

The natural resources are limited in nature, so their cost is increasing with time so it puts extra financial burden on the manufacturing systems which motivate the companies to use these resources in efficient manner while adopting various material recovery strategies like recycling to reduce the use of virgin material for production. It also includes various energy resources which are backbone of any manufacturing system. The cost of energy is increasing worldwide and significantly contributes to the cost of production. The industry works for profits, so energy and resources impact the manufacturing and hence the most important enabler for GM implementation.

The world market is open for all companies, so competitiveness is the primary factor which governs the survival of manufacturing units in the market. The companies have limited scope of reducing their profit margins, so the only way to be competitiveness is by reducing the cost of production which can be achieved by implementation of GM. The adoption of newer technology is not possible without capital investment and human resources which can implement, maintain, and operate the newer technology. The newer initiatives require the commitment among the top management which will allocate funds and direct the organization in the direction of implementation of GM.

The companies are dependent to many other vendors and suppliers for supply of various sub-assemblies, parts and consumable and if all such suppliers and vendors are having active green initiatives that would enable the companies to implement GM. Lastly, the information technology plays a vital role in adoption of newer technology like GM. It helps in operations of newer systems by providing support in data storage, analysis, simulations, interpretations, etc.

This research utilized MOORA method which is one of the multi-criteria decision making (MCDM) method to evaluate the importance of enablers of GM. Various other MCDM methods can be applied such as TOPSIS and AHP for assessment of the enablers by taking inputs from different group of stakeholders for evaluation of enablers from different perspectives. A structural model of enablers using interpretive structural modeling or structural equation modeling like techniques will put more light on the impact, relationship, and hierarchy of the enablers to understand the GM implementation process better.

References

Balan K (2008) Introduction to green manufacturing. Shot Peener 22(3):4–6

Handfield RB, Walton SV, Seegers LK, Melnyk SA (1997) Green’ value chain practices in the furniture industry. J Oper Manage 15(4):293–315

Sangwan KS, Mittal VK (2015) A bibliometric analysis of green manufacturing and similar frameworks. Manage Environ Qual Int J 26(4):566–587

Deif AM (2011) A system model for green manufacturing. J Clean Prod 19(14):1553–1559

Vachon S, Klassen RD (2008) Environmental management and manufacturing performance: the role of collaboration in the supply chain. Int J Prod Econ 111(2):299–315

Mittal VK, Sangwan KS (2014) Prioritizing drivers for green manufacturing: environmental, social and economic perspectives. Proc CIRP 15:135–140

Lofrano G, Brown J (2010) Wastewater management through the ages: a history of mankind. Sci Total Environ 408(22):5254–5264

Azzone G, Noci G (1998) Identifying effective PMSs for the deployment of “green” manufacturing strategies. Int J Oper Prod Manage 18(4):308–335

Atasu A, Sarvary M, Van Wassenhove LN (2008) Remanufacturing as a marketing strategy. Manage Sci 54(10):1731–1746

Kleindorfer PR, Singhal K, Wassenhove LN (2005) Sustainable operations management. Prod Oper Manage 14(4):482–492

Lai KH, Wong CW (2012) Green logistics management and performance: some empirical evidence from Chinese manufacturing exporters. Omega 40(3):267–282

Ferguson ME, Toktay LB (2006) The effect of competition on recovery strategies. Prod Oper Manage 15(3):351–368

Rogers DS, Tibben-Lembke R (2001) An examination of reverse logistics practices. J Bus Logist 22(2):129–148

Fullerton D, Leicester A, Smith S (2008) Environmental taxes, NBER working paper no 14197, issued in July 2008

Brauers WKM, Zavadskas EK (2006) The MOORA method and its application to privatization in a transition economy. Control Cybern 35(2):445–469

Brauers WKM, Zavadskas EK, Peldschus F, Turskis Z (2008) Multi-objective decision making for road design. Transport 23(3):183–193

Attri R, Grover S (2013) Decision making over the production system life cycle: MOORA method. Int J Syst Assur Eng Manage 5(3):320–328

Karande P, Chakraborty S (2012) Application of multi-objective optimization on the basis of ratio analysis (MOORA) method for materials selection. Mater Des 37:317–324

Gadakh VS (2011) Application of MOORA method for parametric optimization of milling process. Int J Appl Eng Res 1(4):743–758

Shihab SK, Chanda AK (2015) Multi response optimization of milling process parameters using Moora method. Int J Mech Prod Eng 3(4):67–71

Brauers WK (2013) Optimization methods for a stakeholder society: a revolution in economic thinking by multi-objective optimization, vol 73. Springer

Bhattacharya A, Jain R, Choudhary A (2011) Green manufacturing: energy, products and processes. The Green manufacturing report by The Boston Consultancy Group for Confederation of Indian Industry

Bhateja AK, Babbar R, Singh S, Sachdeva A (2011) Study of green supply chain management in indian manufacturing industries: a literature review cum an analytical approach for the measurement of performance. Int J Comput Eng Manage 13:84–99

Jhadav JR, Mantha SS, Rane SB (2013) Practice bundles for integrated green-lean manufacturing systems. In: IJCA proceedings on international conference on green computing and technology ICGCT, October 2013

Kumar S, Kumar S, Gahlot P, Haleem A (2013) Analysis of interdependence among the enablers of green concept implementation In Indian automobile supply chain. J Eng Res Stud 4(2):05–11

Sushil, Vrat P (1989) Waste management policy analysis and growth monitoring: an integrated approach to perspective planning. Int J Syst Sci 20(6):907–926

Yamakawa H, Ueta K (2002) Waste reduction through variable charging programs: its sustainability and contributing factors. J Mater Cycles Waste Manage 4(2):77–86

Luthra S, Kumar V, Kumar S, Haleem A (2011) Barriers to implement green supply chain management in automobile industry using interpretive structural modelling technique: an Indian perspective. J Ind Eng Manag 4(2):231–257

Mittal VK, Sindhwani R, Kapur P. K (2016) Two-way assessment of barriers to lean–green manufacturing system: insights from India. Int J Syst Assur Eng Manage 1–8. https://doi.org/10.1007/s13198-016-0461-z

Zhu Q, Sarkis J, Geng Y (2005) Green supply chain management in China: pressures, practices and performance. Int J Oper Prod Manage 25(5):449–468

Khan RWA, Khan N, Chaudhary MA (2011) Green supply chain management—global opportunities and challenges: a case study. In: Business innovation and technology management (APBITM), IEEE international summer conference of Asia Pacific, pp 5–9

Srivastava SK (2007) Green supply chain management: a state-of-the-art literature review. Int J Manage Rev 9(1):53–80

Tsoulfas GT, Pappis CP (2006) Environmental principles applicable to supply chains design and operation. J Clean Prod 14(18):1593–1602

Zhu Q, Sarkis J, Cordeiro JJ, Lai K (2008) Firm-level correlates of emergent green supply chain management practices in the Chinese context. Omega 36(4):577–591

Delmas M, Montiel I (2009) Greening the supply chain: when is customer pressure effective. J Econ Manage Strategy 18(1):171–201

Dubey R, Bag S, Ali SS (2014) Green supply chain practices and its impact on organizational performance: an insight from Indian rubber industry. Int J Logist Syst Manage 19(1):20–42

Field JM, Sroufe RP (2007) The use of recycled materials in manufacturing: Implications for supply chain management and operations strategy. Int J Prod Res 45(18–19):4439–4463

Singh LP, Singh S, Bhardwaj A (2011) Role of logistics and transportation in green supply chain management: an exploratory study of courier service industry in India. Int J Adv Eng Technol 2(1):260–269

Vachon S (2007) green supply chain practices and the selection of environmental technologies. Int J Prod Res 45(18–19):4357–4379

Min H, Galle WP (2001) Green purchasing purchases of US firms. Int J Oper Prod Manage 21(9):1222–1238

Simpson D, Power D, Samson D (2007) Greening the automotive supply chain: a relationship perspective. Int J Oper Prod Manage 27(1):28–48

Sundarakani B, Souza R, Goh M, Wagner SM, Manikandan S (2010) Modeling carbon footprint across supply chains. Int J Prod Econ 128:43–50

Lee C (2010) The effect of environmental regulation with green technology innovation using supply chain integration. Int J Sustain Econ 2(1):92–112

Soler C, Bergstrom K, Shanahan H (2010) Green supply chains and the missing link between environmental information and practice. Bus Strategy Environ 19(1):14–25

Berns M, Townend A, Khayat Z, Balagopal B, Reeves M, Hopkins MS, Kruschwitz N (2009) The business of sustainability: what it means to managers now. MITSloan Manage Rev 51(1):20–26

Ninlawan C, Seksan P, Tossapol K, Pilada W (2010) The implementation of green supply chain management practices in electronics industry. In: Proceeding of international multi conference of engineers and computer scientists, IMECS 2010, vol 3, March 17–19, 2010, pp 17–19

Simpson D, Samson D (2008) Developing strategies for green supply chain management. Decis Line 39(4):12–15

Zhu Q, Sarkis J (2007) The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int J Prod Res 45(18–19):4333–4355

Hosseini A (2007) Identification of green management of system’s factors—a conceptualized model. Int J Manage Sci Eng Manage 2(3):221–228

Hsu CW, Hu AH (2008) Green supply chain management in the electronic industry. Int J Sci Technol 5(2):205–216

Zhu Q, Sarkis J (2006) An inter-sectoral comparison of green supply chain management in China: drivers and practices. J Clean Prod 14(5):472–486

Nidumolu R, Prahalad CK, Rangaswami MR (2009) Why sustainability is now the key driver of innovation. Harvard Bus Rev 87(9):56–64

Diabat A, Govindan K (2011) An analysis of the drivers affecting the implementation of green supply chain management. Resour Conserv Recycl 55(6):659–667

Golinska P, Romano CA (2012) Environmental issues in supply chain management: new trends and applications, Eco production: environmental issues in logistics and manufacturing. Springer, Heidelberg

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mittal, V.K., Sindhwani, R., Lata Singh, P., Kalsariya, V., Salroo, F. (2018). Evaluating Significance of Green Manufacturing Enablers Using MOORA Method for Indian Manufacturing Sector. In: Singh, S., Raj, P., Tambe, S. (eds) Proceedings of the International Conference on Modern Research in Aerospace Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-5849-3_30

Download citation

DOI: https://doi.org/10.1007/978-981-10-5849-3_30

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-5848-6

Online ISBN: 978-981-10-5849-3

eBook Packages: EngineeringEngineering (R0)