Abstract

To develop high-efficient biofertilizer, a chemical fertilizer stress-tolerant feldspar-solubilizing Bacillus subtilis Xue-113168 was isolated from soil, and breed, with resistance against multiple environmental stresses, including 20–50 °C temperature, 4–10 pH range, 0–12.5% (w/v) K2O and 0–0.5 M phosphate. The Bacillus subtilis Xue-113168 was used to convert food waste and feldspar to a potassium biofertilizer through a solid fermentation (SSF) process. After fermentation of 7 days, spore density can be increased to 2 × 109 CFU/g. The control of pH and temperature humidity effectively lead to the formation of spore and potassium dissolving rate of 41.53%. Results confirmed that solid state fermentation presents considerable advantages compared to the complex process (solid-state and bioleach).Compound Microbial Fertilizer (CMF) formulated with humic acid, K2HPO4, and biofertilizer have the advantage of a quick and long-lasting effect. Provisional registration certificate of CMF is No. 3878 by Ministry of Agriculture of the People’s Republic of China in March 15, 2017. CMF promote the sustainable development of the agriculture industry.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the exhaustion of non-renewable resources like coal and peat, the advancing of technology also prompt the development of new sustainable sources of humic products (e.g. organic wastes) [1]. Biofertilizer without chemical fertilizer has a slow effect on crops, Compound Microbial Fertilizer (CMF) with stress-tolerant microorganisms combine the advantages of both biofertilizer and chemical fertilizer.

Microbial fertilizers promote biological fertility of soil, maintain and slow the release of chemical fertilizer, reduce the amount of nitrate nitrogen, heavy metals, and pesticides in crops, and reduce the occurrence of crop diseases [2]. Biofertilizers could mitigate crisis, e.g., the energy crisis, scarcity of resources, and environmental pollution [3]. Plant growth-promoting rhizosphere (PGPR) raises the resistance to pathogen by producing antibiotics and System resistance, etc. The CMF can palliate Jujube and Selenium-enriched Jujube from rust and anthracnose. Solid state fermentation using waste is a popular way of biofertilizer manufacturing. Low water activity in solid state fermentation (SSF) medium facilitates spore forming on the solid substrate. Unlike in submerged fermentation (SMF) processes, humidity is an important parameter of SSF. Microbial releases of potassium from K-bearing minerals have two steps, fermentation and bioleach [4]. The solubilization of potassium-bearing rock powder by Aspergillus niger in submerged fermentation lasted for 35-day period [5]. This study achieves it in one process for 7 days, saving production cycle and enhancing robustness. The imbalance of soil nutrients in China is the consequence of available potassium deficiency in the soil and shortages of potassium fertilizer, although K-bearing minerals in soil and mine, such as K-feldspar is rich, the amount of potassium dissolved by bacteria in soil is limited.

Keldspar can be dissolved by silicate bacteria such as B. mucilaginosus, B. edaphicus, B. circulans, B. subtilis which are part of the PGPR [6, 7]. Humus and Humic acids, which exist in spent mushroom substrates and biofertilizer, can complex with the potassium released from K-feldspar to improve its dissolving efficiency. Conversion of food waste and feldspar into biofertilizer using a stress-tolerant keldspar-solubilizing Bacillus subtilis Xue-113168 make the best use of agricultural and mineral resources, enhance crop yields and play an important role in the sustainable development.

2 Materials and Methods

2.1 Food Waste and Feldspar for SSF

In an SSF process, the solid substrate not only supplies anchorage for the cells, but also nutrients and air channel. A number of cheaply available raw substrates have been screened for the SSF. Shrimp shell, spent mushroom substrate (SMS) and corn bran of 0.1 mm, are all support material for ventilation in SSF. Chitin in shrimp shell and SMS can induce chitinase. K-feldspar containing 10.0% total potassium and insoluble potassium, was purchased from Lingshou County, Hebei, P.R. China. The shrimp shell was from Whiteleg. SMS of Pleurotus ostreatus, constitute of 4.45% organic matter, 1.58% total N, C/N ratio 28/1, water absorption rate 78–80%, humic acid content 20–30%, obtained from a local market. Corn bran constitute of 11.8% protein, 32% glucose, 1% cellulose, purchased from the North China Pharmaceutic Corporation, Hebei, P.R. China.

2.2 Potassium Dissolving Microorganism (KSM)

KSM are isolated from medium containing feldspar as the only potassium source (Hutchens et al. 2003). Medium’s ingredients are as follows (g/L): starch, 5.0; yeast extract, 1.0; MgSO4 · 7H2O, 0.5; CaCO3, 0.1; FeCl36H2O, 5 mg, feldspar 10, pH 7.5. After 1-day incubation at 30 °C, the transparent colonies, which resemble half round glass bead, were picked and purified by growth of K-feldspar medium.

Stress-tolerance induction was carried out by semi-continuous culture in 50-ml shaking flasks at 30 °C on a reciprocal shaker (150 rpm). The cells were transferred to the induction solution which contains KCl, monosodium glutamate 4.27 mg%. Concentration of k is increasing at a rate of about 2.5% per circulation, from 2.5 to 15%.

This isolates were originally named Bacillus circulans, later identified as Bacillus subtilis by culturing characteristics and morphological observation, physiological and biochemical characteristics and identification of genetic characterization by Institute of Microbiology, Chinese Academy of Sciences in December 2016. The potassium dissolving rate was determined as = (St–Sc)/It*100%, where “St” and “Sc” are the water-soluble potassium in the treatment and matrix, respectively, and “It” = the total potassium in the treatment.

For UV’s convenience and efficacy, breeding a high potassium dissolving rate B. subtilis strain had been performed using UV mutagenesis, screen in a fermentation broth using the potassium tetraphenylborate spectrophotometric method. After a series of mutation steps (Fig. 1), B. subtilis Xue-113168 has been obtained, which have chitinase and dissolving potassium function, preserved as patent strain in the Chinese General Microbiological Culture Collection Center (CGMCC) with the accession number 5155 [8].

2.3 CMF Preparation by Solid-State Fermentation (SSF)

The biofertilizer was made from SMS, shrimp shell, corn bran and feldspars using a simultaneously dissolving K-feldspar and SSF. Besides solid material, flour and feldspar were used as substrates at 10 and 2% (w/v), respectively, medium are sterilized in 121 °C, 0.1 MPa, for 30 min. An initial moisture content is 60–65%, and culture temperature is 30 °C. The SSF was stirred every 48 h for 7 days. The pH was nature during the fermentation of the SSF with B. subtilis Xue-113168. After 168 h of fermentation, the spore number and dissolving K rate are tested.

2.4 Testing the Quality Index of the CMF

The amount of viable B. subtilis Xue-113168 in the CMF was calculated by counting colonies of the medium: (g/L) sucrose (5.0), MgSO4 (1.0), FeCl3 (0.2), yeast extract (0.2), (NH4)2SO4 (0.5), KH2PO4 (1), pH 7.0. The moisture content was measured using the vacuum oven method. PH of Solid-water suspension (1:1) was determined using a pH meter. Reagent of digested CMF is H2SO4–H2O2. The total N K2O P2O5 content was determined by the Kjeldahl method, potassium tetraphenylborate gravimetric method, molybdenum antimony anti-colorimetry respectively. The organic matter was digested and tested with H2SO4–K2Cr2O7 method.

2.5 Statistical Analysis

Variance (ANOVA) of experimental data was analysed by a significance value of p < 0.05 and to Duncan’s multiple range test (Duncan’s) using SPSS 18.

3 Results and Discussion

3.1 Isolation and Breeding of Bacillus Subtilis Xue-113168

Bacillus subtilis Xue-113168 was isolated from a corn rhizosphere and breed by UV, UV+LiCl, natural selection, breed genealogy is showed in Fig. 1. Sieved by feldspar as the only source of potassium and colloid chitin for carbon. We use monosodium glutamate as osmotic protection, culture the stress-tolerance bacteria with a stepwise increase of KCl concentration, which are different from sorbitol [9], NaCl, glycerol and glucose as osmotic protection [10]. The biofertilizer are manufactured by B. subtilis Xue-113168 for dissolve potassium mineral substance in soil. Potassium dissolving microorganisms (KSM) is able to solubilize ‘unavailable’ forms of K-bearing minerals, such as micas, illite and keldspar, by excreting organic acids that either directly dissolves rock K or chelate silicon ions to bring the K into solution [11].

B. subtilis Xue-113168 has a high potassium dissolving rate (41%), also produces chitinase. Due to superiority alive in 8% K2O of Bacillus subtilis Xue-113168, CMF had the combining advantage of both chemical fertilizer and biological fertilizer.

B. subtilis Xue-113168 colon morphology changes into opaque, B. subtilis Xue-10311 still transparent and B. subtilis Xue-103116 stay thickness and viscous (Fig. 2). The changes of colon morphology indicate the potential increase of stress-tolerant capacity.

Morphology of B. subtilis Xue-113168 is Gram-positive, rod shape showed in Fig. 3.

3.2 Formulation of the Biofertilizer Produced by the SSF

The component of formulation is a key factor of the SSF and influences the overall cost significantly.

The formulation of SSF could be similar to that of a submerged fermentation (SMF) [12]. But sucrose was replaced with wheat flour for the SSF in this study and the spore formation rate of SSF is higher than SMF because these two processes have state and component of substance. The combination of corn bran, shrimp shell, and spent mushroom substrate was the best medium for the SSF. The K-dissolving rate (43.00%) and spore formation rate (83.18%) achieved were the best among all the groups, and the live bacteria amount of 9.16 lg (CFU) was second only to the spent mushroom substrate group (10.08 lg(CFU)).

The fermentation formulation for obtain a higher concentration of spores and potassium dissolving capacity for B. subtilis Xue-113168 was initially determined through a single factor experiment, then further through an orthogonal experiment. The range of (NH4)2SO4 concentrations was the most important variable, suggesting that in the B. subtilis Xue-113168 culture, the effects of the three factors of the potassium dissolving ratio were (NH4)2SO4 content > MgSO4 content > wheat flour content by range analysis. The above three factors have evident effects on potassium dissolving ratio (P < 0.05) and the optimal conditions were: wheat flour content, 0.75%; (NH4)2SO4 content, 0.1%; and MgSO4 content, 0.2%.

As for the spore concentration, it can be concluded that the ranges of (NH4)2SO4 and wheat flour concentrations were larger compared to the MgSO4 concentration. Thus, the effects of the three factors of the spore concentration were (NH4)2SO4 content > wheat flour content > MgSO4 content, MgSO4 is not significant factor for spore concentration (p > 0.05). Optimal conditions were: wheat flour content, 0.75; (NH4)2SO4 content, 0.1%; and MgSO4 content, 0.2%. The effect of ingredient composition and concentration in medium for spore formation is the same with potassium dissolving condition. The K-dissolving rates are different between the SMS and Corn bran + Shrimp shell + SMS in the SSF. The humic acids in the SMS can also dissolve the K-feldspar, which is complementary to the effect of B. subtilis Xue-113168.

Organic matter is 250 g kg−1 for the B. subtilis Xue-113168 high decompose performance to food waste. Organic matter reach 532 g kg−1 by adding humic acid.

3.3 Process Index of SSF

We observed some changes in pH in the reactor with different medium during the experiment. The pH decreased from 7.0 to 5.0 during the first day, recovered to 5.0–6.0 in a few days and then increased and maintained around 7.6 to the end of the experiment.

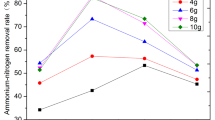

The Spore formation was affected by varietal spectrum of humidity and temperature. Controlling the moisture content of the SSF process was performed as follows: Initially the moisture content was adjusted to approximately 60–65%, at the end of the fermentation, the moisture content was 40–50%. The moisture content was controlled by environmental moisture and also by controlling the temperature in three phrases. During the prophase, the temperature was 33–35 °C, whereas, at the metaphase, the temperature dropped to 30–33 °C. Finally, it increased to 33–35 °C during the anaphase.

The fermentation time was also an important parameter. By the time that the rate of spores is 80%, the processes had typically ended. An appropriate temperature and humidity ensured the formation of the spores. When the fermentation last for 4 days, the potassium dissolving rate was 24.09%. After the fermentation time was extended to 7 days, the potassium dissolving rate increased to 41.53%.

The process of potassium dissolving from feldspar is a synthesized multifaceted result. There is no single gene that encodes for a potassium dissolving ability in bacteria, which is similar to the process of dissolving phosphate. It is well known that there are many differences between SSF and SMF in physiology, such as Aw (water activity) and metabolite. The pH range for B. subtilis Xue-113168 is between 5 and 9, and the temperature range is 28–37 °C. Moreover, the indispensable moisture required for SSF was low. All the characteristics described above make B. subtilis Xue-113168 suitable for SSF. Sheng demonstrated that the potassium dissolving rate of Bacillus edaphicus is low, which also has been proven to have a low potential for commercial use [13]. Tan reported that 9–28% of the potassium that they measured was released by humic acids [14]. It has been hinted that the potassium dissolving rate (41.53%) of B. subtilis Xue-113168 may include dissolved potassium from K-feldspar through the action of humic acids. Consistent and sustained product of SSF can be achieved in different growing media as long as the following variables are being controlled: consistency of the parent organic material, moisture content, carbon to nitrogen ratio, and process parameters.

During SSF with feldspar, spore concentrations can reach 2 × 109 cfu/g and soluble potassium content is 1%, B. subtilis Xue-113168 ferments and dissolves K simultaneously. B. subtilis Xue-113168 displayed the highest K-solubilizing activity, as high as 41.53% after 7d in culture with K-feldspar powder. This cycle is shorter than Lian and Ciceri [4, 15], who performed SSF and SMF for 15 and 35 d respectively. Bioleaching combined with SSF is more advantageous, more economical and more timesaving. Stephanie. K gets mutant bacteria for a high efficient bioleaching also [16].

3.4 Quality Index of the CMF

The quality index plays a vital role in measuring the efficiency of a fertilizer. The indexes are consistent with the Compound Microbial Fertilizer Standard (NY/T 798-2015, China): N + P2O5 + K2O ≥ 80–250 g kg−1, number of viable cells is 0.2 (one hundred million/g) [17]. Compound Microbial Fertilizer (CMF), formulated by humic acid and K2HPO4 with biofertilizer, have a quick and long-lasting effect. The stress-tolerance towards K2HPO4 of B. subtilis Xue-113168 is a key factor, the humic acid’s chelating functions also lessens the damage to bacteria done by K2HPO4. Product Quality index of the CMF were examined by Quality supervision, inspection and Testing Center for microbial products of Ministry of Agriculture in WuHan in December 2016. Provisional registration certificate of CMF is No. 3878 by Ministry of Agriculture of the People’s Republic of China in March 15, 2017. Product Quality index of the CMF is different from the that of pilot sample showed in Table 1, such as content of P2O5, inferring phosphorus as massive element in cell is less harmful to microorganism. Function of PGPR dependent on the clone in zone of root [18]. Organic matter in CMF offer nutrient, shelter to adverse situation for PGPR in field.

4 Conclusions

This CMF is formulated by humic acid, K2HPO4, and biofertilizer which is SSF by chemical fertilizer-tolerant feldspar-solubilizing B. subtilis Xue-113168. Provisional registration certificate of CMF is No. 3878 by Ministry of Agriculture of the People’s Republic of China in March 15, 2017.

Bacillus subtilis Xue-113168 converts K-feldspar, corn bran, shrimp shell, and spent mushroom substrate to a biofertilizer that have a 41% potassium dissolving rate. The CMF used in this study can enhance the efficiency of fertilizers and utilize recycled waste resource. It also promotes a sustainable agriculture industry, complex formulations and process of the SFF are suitable for factory, especially farmer uses in the fields.

Abbreviations

- CMF:

-

Compound Microbial Fertilizer

- PGPR:

-

Plant growth-promoting rhizosphere

- SSF:

-

Solid-state fermentation

- SMF:

-

Submerged fermentation

- SMS:

-

spent mushroom substrate

- KSM:

-

Potassium dissolving microorganism

- LiCl:

-

Lithium chloride

- KCl:

-

Kalium chloratum

References

Placido J, Capareda S, Karthikeyan R (2016) Production of humic substances from cotton stalks biochar by fungal treatment with ceriporiopsis subvermispora. Sustain Energy Technol Assess 13:31–37

Dilfuza E, Elsayed FAA, Jaime A. Teixeira da S (2016) Microbially Assisted Phytoremediation of Heavy Metal–Contaminated Soils. In: Ahmad P (ed) Plant metal interaction. 1st. Elsevier Inc.

Reddy KG, Madhavi GB, Reddy ASR, Yellareddygari SK, Reddy MS, Reddy MS et al (2011) Current status of biofertilizers development, farmers acceptance, utilization and future perspective in Andhra Pradesh, india. Appl Acoust 63(12):1301–1313

Lian B, Wang B, Pan M et al (2008) Microbial release of potassium from K-bearing minerals by thermophilic fungus Aspergillus fumigates. Geochim Cosmochim Ac 1:87–98

Lopes-Assad ML, Avansini SH, Rosa MM, de Carvalho JR, Ceccato-Antonini SR (2010) The solubilization of potassium-bearing rock powder by aspergillus niger in small-scale batch fermentations. Can J Microbiol 56(56):598–605

Esitken A, Yildiz HE, Ercisli S, Donmez MF, Turan M (2010) Effects of plant growth promoting bacteria (PGPB) on yield, growth and nutrient contents of organically grown strawberry. Sci Hortic 124:62–66

Adesemoye AO, Kloepper JW (2009) Plant-microbe interaction in improving fertilizer use efficiency. Appl Microbiol Biotechnol 1:1–12

Xue S (2011) Biological compound potash fertilizer and preparation method. China. Patent 201,110,256,623.1

Ikeuchi T, Ishida A, Tajifi M, Nagata S (2003) Induction of salt tolerance in bacillus subtilis ifo 3025. J Biosci Bioeng 96(2):184–186

Palazzini JM, Ramirez ML, Alberione EJ, Torres AM, Chulze SN (2009) Osmotic stress adaptation, compatible solutes accumulation and biocontrol efficacy of two potential biocontrol agents on fusarium head blight in wheat. Biol Control 51(3):370–376

Sheng X (2005) Growth promotion and increased potassium uptake of cotton and rape by a potassium releasing strain of Bacillus edaphicus. Soil Biol Biochem 37:1918–1922

Tan KH (1978) Effects of humic and fulvic acids on release of fixed potassium. Geoderma 21(1):67–74

Barrios-González J (2012) Solid-state fermentation: physiology of solid medium, its molecular basis and applications. Process Biochem 47:175–185

Vaneeckhaute C, Janda J, Vanrolleghem PA, Tack FMG, Meers E (2016) Phosphorus use efficiency of bio-based fertilizers: bioavailability and fractionation. Pedosphere 26(3):310–325

Ciceri D, Allanore A (2015) Microfluidic leaching of soil minerals: release of k+ from k feldspar. PLoS One 10(10):1–10

Kraft S, Obst U, Schwartz T (2011) Immunological detection of uv induced cyclobutane pyrimidine dimers and (6–4) photoproducts in dna from reference bacteria and natural aquatic populations. J Microbiol Methods 84(3):435–441

Ministry of Agriculture of China (2015) Compound microbial fertilizer standard NY/T 798-2015. Standard Press

Dutta S, Podile AR (2010) Plant growth promoting rhizobacteria (PGPR): the bugs to debug the root zone. Crit Rev Microbiol 36(3):232–244

Acknowledgements

This work was supported by the Ministry of Science, People’s Republic of China under Grant [number 2008GA620020]; Hebei Province natural fund under Grant [number C2015207019]. Hebei University of Economics and Business fund under Grant [number 2016kyz01]. Hebei Provincial department of education under grant [number ZD2017229].

Thanks to professor Yu Li, Wenhang Wang, Guorong He, Yingjie Pan for review the paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Xue, S., Miao, L., Xue, J., Yan, H., Li, G. (2018). Conversion of Food Waste and Feldspar into Biofertilizer Using a Stress-Tolerant Keldspar-Solubilizing Bacillus Subtilis Xue-113168. In: Liu, H., Song, C., Ram, A. (eds) Advances in Applied Biotechnology. ICAB 2016. Lecture Notes in Electrical Engineering, vol 444. Springer, Singapore. https://doi.org/10.1007/978-981-10-4801-2_53

Download citation

DOI: https://doi.org/10.1007/978-981-10-4801-2_53

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4800-5

Online ISBN: 978-981-10-4801-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)