Abstract

Considerable amount of fruits and vegetables have been wasted due to non-availability of appropriate processing facilities in farmers field, in spite of high production in India with second rank in the world. A little of total fruit and vegetable productions in the country have been processed in industries. It has been noted that food crisis in most parts of the world is due to non-availability of processing and preserving facility rather than due to low production. Spoilage of fruits and vegetables can be reduced by drying and preserving them by suitable solar devices. Keeping in mind this requirement, a simple solar dryer has been fabricated at ICAR-CAZRI, Jodhpur. The dryer comprises a drying tray (0.75 m × 0.53 m) made of wooden frame and SS wire mesh and a glass sheet (4 mm thick) fitted on a wooden frame and a couple of hinges with opening and closing arrangements. Suitable openings for entry of ambient air and exit of water vapour have also been provided. The cost of the dryer is about Rs. 800. The drying tray serves dual purpose of solar collector and drying chamber. The maximum stagnation temperature observed inside the drying chamber was 63 °C on loading of 3 kg ber (Ziziphus sp.). It was 49 °C, when the outside ambient temperature was 27 °C on a clear sunny day (from 10 am to 4 pm) in the month of December–January. For drying of 3 kg ber fruits to a final weight of 1 kg using the developed dryer, it took about 7–8 days. It has been observed that the drying time for Ziziphus (ber) decreased by 50% in comparison to open sun drying. The developed dryer was also successfully tested to dry spinach (Spinacia oleracea), grated aonla (Phyllanthus emblica) and beetroot (Beta vulgaris). This solar dryer would be very useful for small and marginal farmers.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

India stands second in the world in producing fruits and vegetables, which are 12.6 and 14.0%, respectively. Nearly 76% of fruits and vegetables are consumed in fresh form of the total production and post-harvest losses are up to 20–22%. Only 2–4% of vegetable and fruit production are processed and preserved by industries. It was observed that food crisis in most of the countries is due to lack of ability to preserve food production rather than solely due to low production. In India, still 70% people are depending on agricultural practices and of this most people are not well off to afford advanced technologies and it is a major obstacle.

Drying produce in the open sun is still a practice in many countries. This method is very cheap but it creates a number of problems of contamination by foreign materials, which include dust, dirt, unwanted materials, infection due to insects and non-uniform drying. In the monsoon season, it becomes difficult to achieve optimum moisture content for safe storage and there are chances of materials also getting wet. India is endowed with abundant insolation. The arid western parts of India receive maximum irradiance, i.e. 7600–8000 MJ m−2 per annum, followed by semi-arid parts receiving 7200–7600 MJ m−2 per annum and least on hilly areas where solar irradiance is still appreciable, i.e. 6000 MJ m−2 per annum. Therefore, solar dryers can replace sun drying method. The produce dried in a solar dryer is not only economically viable but also of good quality and can return the cost incurred on solar dryer in one or two years. Therefore, small-sized solar dryers can be developed for cash crops and highly perishable products [1]. Some low-cost solar dryers were developed for entrepreneurs and marginal rural farmers as reported by Sharma et al. [2] and Fudholi et al. [3].

With this in view, ICAR-CAZRI, Jodhpur has developed a number of solar dryer of different designs during past three decades [4,5,6,7,8,9,10]. One major drawback behind wide-scale adoption of these previously developed solar dryers by farmers is the cost, which is not affordable by most of farming community. In order to make the dryer more economical, we have designed and developed a simple and small-sized solar dryer at ICAR-CAZRI, Jodhpur, India. The dryer that we have developed is a simple box-type solar dryer where the heat is provided by solar collector which also acts as drying chamber. Here the atmospheric air enters through inlet portion of the solar collector at the bottom end and the moist air gets exhausted through the outlet portion. The target stakeholders of the developed dryer are marginalized and poor farmers who cannot afford hi-tech facilities and equipment for preserving agricultural products, thus eliminating the unwanted and unpredictable food spoilage.

2 Design of Solar Dryer

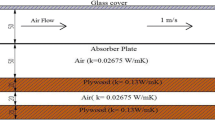

The solar dryer is based on greenhouse effect wherein the solar irradiance enters into the chamber through top glass sheet which is trapped inside the drying chamber and thus increases the stagnation temperature. The experimental solar dryer comprises a drying tray (0.75 m × 0.53 m) made of wooden frame and SS wire mesh. A glass top made of clear window glass (4 mm thick) fitted on a wooden frame and a couple of hinges with opening and closing arrangements. Suitable openings for entry of ambient air and exit of water vapour have also been provided. The drying material can be put on the perforated SS wire mesh by opening the top wooden frame fitted with glass. The cost of the dryer is about Rs. 800. The drying tray serves the dual purpose of solar heat collector and drying chamber (Fig. 1).

3 Experimental Details and Results

In this dryer, the drying of Ziziphus (ber) was carried out during clear sky condition as on month of January 2016. About 3 kg of fresh ber was put inside the dryer with 80% moisture content on wet basis. Hourly values of total solar irradiance on the horizontal surface were measured by pyranometer coupled with integrator. The air temperature inside the dryer and ambient temperature were measured hourly from 10.00 to 17.00 h during the drying trials. The detailed results of the drying experiment of Ziziphus (ber) are given in Table 1.

From Table 1, it is clear that during the drying trials, maximum stagnation temperature observed inside the drying chamber was 63 °C and on loading 3 kg of ber the maximum temperature reduced to 49 °C, when the outside ambient temperature was 27 °C on a clear sunny day (from 10.00 to 17.00 h) in the month of January 2016. The moisture content of the ber decreased from 85 to 15% in 6 days and the rate of drying decreased rapidly for moisture content below 65%.

The efficiency of solar dryer (ratio of evaporative moisture to the solar irradiance on horizontal surface) is given by the relation given below:

where

- A :

-

Absorber area, m2

- H T :

-

Solar radiation on horizontal plane, J m−2 h−1

- L :

-

Latent heat of vaporisation, J kg−1

- M :

-

Mass of moisture removed from the product, kg

- θ :

-

Test duration, h

- η :

-

Efficiency of the solar dryer.

The efficiency of the developed solar dryer was found about 16%. The developed dryer will be very useful for the people of rural areas. As there is an abundance of solar energy in our country, the rural people can use solar dryer for drying fruits and vegetables when this is a glut in the market and earn money by selling them.

3.1 Cost

The developed solar dryer comprises wooden flank, glass sheet (4 mm thick), and wire mesh. These materials are easily available and a village carpenter can fabricate this solar dryer. The cost of solar dryer is as low as Rs. 800/-.

4 Conclusion

The developed solar dryer could be very useful at the domestic level. Due to its low cost (Rs. 800/unit), it is very affordable. It can dry vegetable and fruits which can be packaged for use in off season. It can be used to dry fruits such as ber, aonla, beat root, leafy vegetables, spinach, coriander, chilies, fenugreek and other vegetables such as onion, garlic, carrot, etc. The use of such dryers at domestic level can go a long way in reducing postharvest losses.

References

P. Purohit, A. Kumar, T.C. Kandpal, Solar drying vs. open sun drying: a framework for financial evaluation. Sol. Energy 80, 1568–1579 (2006)

A. Sharma, C.R. Chen, N. Vu Lan, Solar-energy drying systems: a review. Renew. Sustain. Energy Rev. 13, 1185–1210 (2009)

A. Fudholi, K. Sopian, M.H. Ruslan, M.A. Alghoul, M.Y. Sulaiman, Review of solar dryers for agricultural and marine products. Renew. Sustain. Energy Rev. 14, 1–30 (2010)

H.P. Garg, A. Krishnan, Solar drying of chillies in a solar cabinet dryer. Ann. Arid Zone 13(4), 285–292 (1974)

H.P. Garg, K.P. Thanvi, Year round performance studies on a solar cabinet dryer at Jodhpur, in Proceedings of 7th Meeting of All India Solar energy working group and Conference on the utilization of solar energy, Ludhiana, pp. 142–145 (1975)

P.C. Pande, Performance studies on an improvised solar cabinet dryer, in Proceedings of National Solar Energy Convention, India. Allied Pub., India, pp. 1–5 (1980)

P.C. Pande, K.P. Thanvi, A solar dryer for maximum energy capture, in Proceedings of National Solar Energy Convention, IIT Delhi, India, pp. 4.009–4.0012 (1982)

P.C. Pande, K.P. Thanvi, Design and development of solar dryer cum water heater. Energy Convers. Manag. 31(5), 419–424 (1991)

K.P. Thanvi, P.C. Pande, Development of a low cost solar agricultural dryer for arid regions of India. Energy Agric. 6, 35–40 (1987)

K.P. Thanvi, P.C. Pande, Performance evaluation of solar dryers developed at CAZRI, Jodhpur, in Solar Drying, ed. by A.N. Mathur, Y. Ali, R.C. Maheshwari (Himanshu Publication, Udaipur, 1989), pp. 159–164

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Poonia, S., Singh, A.K., Santra, P., Mishra, D. (2018). Design, Development and Performance Evolution of a Low-Cost Solar Dryer. In: Chandra, L., Dixit, A. (eds) Concentrated Solar Thermal Energy Technologies. Springer Proceedings in Energy. Springer, Singapore. https://doi.org/10.1007/978-981-10-4576-9_20

Download citation

DOI: https://doi.org/10.1007/978-981-10-4576-9_20

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4575-2

Online ISBN: 978-981-10-4576-9

eBook Packages: EnergyEnergy (R0)