Abstract

Gluonic acid is a platform chemical that can be derived from biomass for making plastics and food additives, while glucaric acid is expected to be a sustainable precursor for producing adipic acid. This chapter provides an overview of the chemical processes for the production of gluconic acid and glucaric acid from mono-saccharides and poly-saccharides with a focus on heterogeneous catalysts. Because catalytic conversions of biomass are usually in aqueous solutions, the solid catalysts must be water tolerant. The oxidation of glucose into gluconic acid has been well-investigated using supported noble metals, such as Pt, Pd, and Au catalysts and those bimetallic catalysts, such as PdAu and PtBi. For the heterogeneous catalytic oxidation of glucose in aqueous solutions, three hypotheses can be used to explain catalyst deactivation: (i) poisoning of the catalyst by oxygen or hydrogen, (ii) poisoning of the catalyst by products, and (iii) metal sintering and metal leaching. Bimetallic catalysts with appropriate compositions have higher activity than those of monometallic catalysts to inhibit poisoning of oxygen, hydrogen, and acidic products. Supported Au catalyst also shows high yields of gluconic acid in aqueous solutions even without pH control. On the other hand, compared with oxidation of glucose to gluconic acid, oxidation into glucaric acid is a challenging reaction because an oxidation step from gluconic acid to glucaric acid is slow. Among tested catalysts, supported Pt and PtCu catalysts show relatively high glucaric acid yields. Direct production of gluconic acid from polysaccharides using bifunctional catalysts is also discussed. Bifunctional catalysts, such as sulfonated activated-carbon supported platinum, have acidic active sites and redox actives sites that can provide efficient conversion of gluconic acid and glucaric acid from polysaccharides.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Gluconic acid

- Glucaric acid

- Catalytic hydrothermal process

- Heterogeneous catalyst

- Bifunctional catalyst

- Sugar

- Polysaccharide

1 Production of Gluconic Acid from Glucose Over Heterogeneous Catalysts

Biomass is a promising sustainable chemical resource [1, 2]. Gluconic acid and glucaric acid, as high value-added chemical compounds, are mainly obtained from selective oxidation of glucose (Scheme 7.1). Gluconic acid is a carboxylic aldose and an important industrial product in the food and pharmaceutical industries or as water -soluble cleansing agent [3]. Many methods, including biochemical , heterogeneously catalytic, chemical and electrochemical procedures have been proposed to effectively oxidize glucose into gluconic acid. At present, gluconic acid is mainly produced by fermentation processes and enzymatic processes using glucose oxidase and glucose dehydrogenase [3, 4]. However, biochemical methods have some disadvantages, such as slow reaction rate, low space time efficiency , and difficulty in the separation of the enzyme from the product. To overcome these issues, inorganic heterogeneous catalysts, such as supported noble metal catalysts for oxidizing monosaccharides with oxygen or air have been proposed [5,6,7,8,9,10,11,12]. Here, some reported chemical processes using heterogeneous catalysts are introduced. The oxidation of glucose to gluconic acid has been investigated using supported Pt , Pd, and Au catalysts [13,14,15,16] or their bimetallic catalysts , such as PtPd, PdAu, PtPdBi, PtAu, PtBi, and PdTe [17,18,19,20,21,22,23,24].

1.1 Pd and Pt Monometallic Catalysts

In aqueous solutions, oxidation of D-glucose to D-gluconic acid was carried out by oxygen or air at atmospheric pressure of monometallic, such as Pd and Pt, catalysts at 30–80 °C [5]. Abbadi et al. reported results using 5% Pt/C catalyst at 50 °C as shown in Fig. 7.1 and Table 7.1 [9]. Glucose was converted under 0.2 atm of oxygen partial pressure and the main product was gluconic acid with initial rates being almost independent of pH control. However, in reaction without pH control, conversion of glucose and yield of gluconic acid plateaued to be under 25% and 15%, respectively. The pH in reaction media decreased to about 2.6 because of production of gluconic acid . On the other hand, when the pH of reaction media was controlled by adding KOH, conversion of glucose and yield of gluconic acid increased with increasing of the pH. Below pH = 7, poisoning of the catalyst was markedly observed. The catalytic performance of Pt/C catalyst in the oxidation of glucose into gluconic acid showed a strong dependence on the pH of the reaction media . Product distribution was hardly affected by the pH control. The selectivity of the catalyst for the oxidation of D-glucose toward D-gluconic acid was reasonably good and ranged from 80% in acidic conditions to almost 90% in alkaline conditions. The by-products , 2-keto-D-gluconic acid and oxalic acid were formed and those authors speculated that the termination of the reaction without pH control was caused by strong adsorption of the reaction products on catalysts. Besson et al. [25, 26] examined the effect of palladium particle size on the gluconic acid yield in the glucose oxidation over Pd/C catalyst. The catalyst with Pd particles larger than 3 nm converted almost 100% of glucose, whereas Pd/C catalyst with Pd particles smaller than 2 nm gave about 60% of maximum conversion. This could indicate particle size dependence on the catalytic stability for oxygen poisoning in the oxidation as the smaller particles probably have stronger affinity for oxygen. For the heterogeneously catalytic oxidation of glucose in aqueous solution, three hypotheses to explain the deactivation of catalysts are suggested.

-

(i)

Deactivation of the catalyst by poisoning due to oxygen or hydrogen adsorption . Noble metals have high stability for the oxidation, but even Pd and Pt are chemisorbed by oxygen, which can cause deactivation. Chemisorption of hydrogen is also often a cause of the deactivation of Pd and Pt catalysts. In the case of Pd and Pt, the phenomenon is reversible in the sense that the catalyst can be reactivated by hydrogen (or oxygen) and another reducing (or oxidizing) agent , such as glucose. When the reduced Pt/C catalyst is contacted with the substrate before the introduction of O2 gas, Pt/C catalyst show much higher catalytic activity than for catalysts contacted with substrate after introduction of O2 gas. Therefore, catalytic activity seems to depend on O2 adsorption on the catalysts [27].

-

(ii)

Deactivation of the catalyst by poisoning due to adsorption of products formed such as gluconate species . The active sites are at the surface of the Pd and Pt particles and the chemisorption of products formed can cause deactivation. In the case of chemisorption of gluconate species, the phenomenon can be reversible in the sense that the catalyst can be reactivated by alkaline treatment. Therefore, in Fig. 7.1, higher pH results in higher glucose conversion.

-

(iii)

Deactivation of catalyst due to metal sintering and metal leaching . In aqueous solvent systems , metal leaching is a serious problem. Both Pt and Pd have relatively high stability for sintering and leaching under aqueous conditions, even when the solution is hot and acidic. However, it has been reported [28] that in solutions of D-ribose and D-xylose , both platinum and aluminum from Pt/Al2O3 catalysts undergo leaching with Pt leaching being much larger than Al for the reaction of D-ribose, since D-ribose is favorable for metal complexing. Sintering of metal particles also causes a decrease in catalytic activity . The support materials and preparation methods are important for inhibiting the growth of metal particle sizes during reaction and pretreatment [26, 29].

Effects of pH on the oxidation of D-glucose to D-gluconic acid. □ No pH control, ○ pH = 5, ◇ pH = 7, △ pH = 9. Reaction conditions: 0.05 mol·L−1 glucose aqueous solution 80 mL, 5%Pt/C catalyst 40 mg, reaction temperature 50 °C, total pressure 1.0 atm (P(O2) = 0.2 atm) (Reprinted from Ref. [9], Copyright © 1995, with permission from Elsevier)

1.2 Pd-M and Pt-M Bimetallic Catalysts

Alloy and bimetallic catalysts have been examined since the 1950s, and both alloys and bimetallic catalysts have been investigated for scientific interest in terms that the electronic and ensemble effects have on the catalytic activity and selectivity.

Many important catalytic processes that use bimetallic catalysts have been developed. The Pt–Re, Pt–Ir, and Pt–Sn catalysts are very important in petroleum reforming [30, 31], however, at present, their improved catalytic activities or product selectivity compared with monometallic catalysts is still not well understood.

For the heterogeneous catalytic oxidation of glucose in aqueous solution, the catalytic activities and selectivities of supported monometallic palladium catalysts in the oxidation processes increase by addition of metals such as Bi, Tl, Co, Sn, and Pb [21, 24, 26]. Karski et al. studied the influence of added heavy metals on palladium supported catalysts regarding their selectivity for glucose oxidation [23]. The highest selectivity for the reaction of liquid phase oxidation of glucose was achieved with bismuth .

Fig. 7.2 shows the oxidation of glucose over Pd/C and Pd-Bi/C catalyst [26]. The rate of glucose oxidation was about 20 times larger on Pd-Bi/C than on Pd/C. The selectivity to D-gluconate was also improved to be 99.8% at a conversion of 99.6%. In recycling of the catalyst, there was no bismuth leaching and the activity and selectivity were almost constant. Besson et al. suggested the mechanism of glucose oxidation over Pd-Bi/C catalyst and interpreted the results in terms of bismuth playing the role of protecting palladium from over-oxidation because Bi has a stronger affinity for oxygen than Pd, which was evident from calorimetric measurements [33]. Furthermore, oxygen bonded to Bi easily reacts with hydrogen bonded to Pd, which would maintain the catalytic activity of Pd0, as shown in Scheme 7.2.

Glucose conversion as a function of time for a catalytic ratio [glucose]/[Pd] = 3150. Reaction conditions: 0.05 mol L−1 glucose aqueous solution 80 mL, 5%Pd/C (a) and Pd-Bi/C (b) catalyst 40 mg, reaction temperature 50 °C, total pressure 1.0 atm (P (O2) = 0.2 atm) (Reprinted from Ref. [26], Copyright © 1995, with permission from Elsevier)

The mechanism of glucose oxidation into gluconate on Pd-Bi catalyst (Reprinted from Ref. [26], Copyright © 1995, with permission from Elsevier)

1.3 Supported Au Catalysts

For the oxidation of glucose, supported gold catalysts are interesting because of their high activity and stability under low pH conditions. Biella et al. reported that the oxidation of D-glucose into D-gluconic acid occurred using 1%Au/C catalyst [6]. As shown in Fig. 7.3, the catalytic activity of gold catalyst depends on pH for both Pt/C and Pd-Bi/C catalysts. The Au/C catalyst showed much higher activity than Pt/C and Pd-Bi catalysts, and its selectivity was comparable with Pd-Bi/C bimetallic catalysts . Moreover, Au/C catalyst gave 100% conversion of glucose under uncontrolled pH conditions and supported gold catalyst are active at pH as low as 2.5 as shown in Fig. 7.4 [6]. In recycling, gold is more stable towards deactivation than platinum and palladium catalysts. However, even for Au/C catalysts, in the case of uncontrolled pH, ICP analysis shows that 10% of the metal is lost after two runs and about the 70% of metal is lost after six runs.

Glucose oxidation over 1%Au/C (•), 5%Pt/C (△), 5% Pd-5%Bi/C (■), and 1%Pt-4%Pd-5%Bi/C (◆) catalysts under pH-controlled conditions by NaOH. Reaction conditions: glucose 4 wt%; glucose/M = 1000; O2 flow = 20 ml/min; T = 50 °C: (a) the pH was maintained at 9.5; (b) the pH was maintained at 8; (c) the pH was maintained at 7 (Reprinted from Ref. [6], Copyright © 2002, with permission from Elsevier)

Glucose oxidation at uncontrolled pH conditions using 1%Au/C catalyst. Reaction conditions: glucose 4 wt%; glucose/M = 1000; pO2 = 300 kPa; T = 100 °C (Reprinted from Ref. [6], Copyright © 2002, with permission from Elsevier)

Comotti et al. compared the results of monometallic catalysts Au, Pt, Pd and Rh, and bimetallic catalysts in the aerobic oxidation of D-glucose into D-gluconic acid [32, 34]. Experiments of the catalytic reactions were performed under 300 kPa of O2 partial pressure and at 50–90 °C using supported catalysts having average particle sizes of metals as 3–5 nm. Table 7.2 summarizes the catalytic activities of supported monometallic and bimetallic catalysts under uncontrolled pH experiments. Comparing activities of mono-metal catalysts, Au and Pt catalysts show much higher activity than Rh and Pd catalysts. On the other hand, the activity of bimetallic Au particles combined with Pd and Pt show higher activity than monometallic Au, Pd, and Pt catalysts. However, Au-Rh catalysts have lower activity than monometallic Au catalyst. As shown in Table 7.3, in the presence of alkali at a controlled pH of 9.5, the catalytic activity of Au for oxidation of glucose to gluconate is higher than activities of Pd and Pt, whereas Au-Pt and Au-Pd bimetallic catalystic activities improved over that of monometallic gold .

As mentioned above, Au has catalytic activity so that there are many reports for the oxidation of glucose over supported gold catalysts [33]. However, one problem for Au-containing catalysts is the sintering of Au particles , because many metals become soluble in hot water under specific conditions. For example, unsupported gold particles without a protecting agent were initially as active as Au/C catalysts at 30 °C in basic solution, but the as-is particles became sintered and their particle sizes changed from 3.6 to 10 nm. To circumvent this problem, mesoporous materials with about 5 nm channels are effective as supports. Gold particles supported onto mesoporous materials remain unchanged [19, 32]. Metal–oxides (Al2O3, ZrO2, TiO2, CeO2) are also suitable supports for Au particles in which catalytic activity increases as particle size decreases [8].

Another effective method to prepare stable Au particles is to encapsulate them with polymers . Au particles protected by polymers show good product selectivity, but they are often less active than an Au/TiO2 catalyst prepared by a deposition -precipitation method [34]. To increase their catalytic activity, a series of not supported but PVP polymer-protected Au alloy nanoparticles have been synthesized: Ag–Au, Au–Pd, Au–Pt, and Au–Pt–Ag [12]. Trimetallic Au–Pt–Ag (70:20:10) particles with an average diameter of about 2 nm were several times more active than monometallic and bimetallic particles having nearly the same size.

Hydrogen peroxide (H2O2) has higher activity than molecular oxygen or air for the oxidation of glucose over Au/Al2O3 catalyst [35]. Microwave-assisted oxidation of sugars , such as glucose , galactose , mannose , maltose , and cellobiose is effective with hydrogen peroxide over Au/Al2O3 and Au/CeO2 catalysts [36]. Although oxidation with H2O2 can lead over-oxidation, the conversion and selectivity of glucose to gluconate exceeds 99% using 1 equivalent of H2O2 per unit of glucose even in aqueous solutions with high glucose concentrations (ca. 50 wt%) at 40 °C. Even at room temperature around 25 °C, glucose oxidation with H2O2 at pH 9 using a suspended Au/SiO2 catalyst showed an 85% selectivity to gluconate at 100% conversion with ultrasound [37].

2 Production of Glucaric Acid Over Heterogeneous Catalysts

Glucaric acid is one of the value-added chemicals that can be obtained from biomass, and it is a promising raw material for the production of biodegradable polymers [38]. It can be an important precursor of adipic acid , which is conventionally produced from fossil resources (Scheme 7.3). However, production of glucaric acid from glucose has many challenges.

Current synthesis methods of glucaric acid are far from satisfactory. For example, chemical oxidation using strong oxidants such as nitric acid to oxidize glucose are non-selective and expensive [39]. Moreover, processes that use nitric acid as oxidant result in NOx emissions [39]. In other methods, production of glucaric acid is through electrochemical means or by stoichiometric oxidation using additives . Significant amounts of additives and formation of toxic by-products and inorganic salts are the major issues in terms of the sustainability and environmental compatibility of these methods. The use of environmentally-friendly oxidants such as air, molecular O2 or dilute H2O2 and solid catalysts are advantageous. Recently, 2, 2, 6, 6-tetramethyl-1-piperidinyloxy (TEMPO) as catalyst for selective oxidation of primary alcohols of glucose to glucaric acid has been studied attracted for which the yield of glucaric acid was over 85% for the oxidation of glucose [40]. However, high cost and difficulty in recycling TEMPO are issues preventing this method from reaching industrial scale. To overcome these issues, inorganic heterogeneous catalysts, such as supported noble metal catalysts and bimetallic catalysts , are expected to be effective for oxidizing monosaccharides into glucaric acid with oxygen or air [41,42,43,44].

2.1 Productions of Glucaric Acid Using Solid Catalysts

In 1981, Dirkx et al. reported that glucaric acid could be formed from glucose with carbon-supported platinum catalysts [27]. Experiments were performed using 5%Pt/C catalyst in aqueous solutions of gluconic acid and glucaric acid at 55 °C and at a pH of 10 controlled by adding NaOH. In the oxidation, glucose rapidly disappeared within 30 min and the yield of gluconic acid was about 60% in 15 min. In contrast, the formation rate of glucaric acid from gluconic acid was slower than that of gluconic acid. The yield of glucaric acid was about 50% in 120 min, and it almost remained unchanged up to 300 min reaction time. Their results indicated that the oxidation of gluconic acid to glucaric acid is apparently a slow step and it is not easy to obtain high yields of glucaric acid. In addition, they suggested that most of the by-products formed were from gluconic acid in the production of glucaric acid from glucose, and that L-guluronic acid was one of the by-products [27]. In consequence, the oxidation step of the intermediate gluconic acid into glucaric acid is slow and low selective is obtained in the glucaric acid production from glucose.

Lee et al. reported the oxidation of glucose into glucaric acid using supported 5 wt% platinum catalysts [45]. Under 6.2 bar O2 partial pressure, glucose was immediately converted into gluconic acid and then glucaric acid was slowly produced as shown in Fig. 7.5. The highest yield of glucaric acid was 74% under 14 bar O2 gas partial pressure. The Pt/C catalyst was stable after five cycles without leaching of Pt.

Glucose conversion and product selectivity for glucose oxidation in water on a Pt/C catalyst as a function of reaction time (□ glucose conversion; ▲ gluconic acid selectivity; ● glucaric acid selectivity). Reaction conditions: 10 wt% glucose solution 20 mL, 80 °C, 6.2 bar O2, glucose/Pt (mol/mol) = 54 (Reprinted from Ref. [45], Copyright © 2016, with permission from Royal Society of Chemistry)

The product selectivity depended markedly on not only partial pressure of O2 gas, but also on the support materials and pH. Pressurized oxygen can enhance the catalytic activity for the oxidation of intermediate gluconic acid, and support materials and pH can increase selectivity into glucaric acid by improving desorption of glucaric acid and inhibit formation of by-products . As shown in Table 7.4, glucaric acid yield under 14 bar O2 gas partial pressure was clearly higher than yields obtained under 6 bar and 3 bar O2 partial pressure which indicates that high pressure oxygen promotes oxidation of gluconic acid into glucaric acid. Pt/C catalyst in acidic aqueous medium using H2SO4 gave gluconic acid as a major product, while in basic solutions using NaOH, it gave significant amounts of low carbon chain carboxylic acids as by-products, such as dicarboxylic acids , tartronic acid and oxalic acid. When pH was not controlled, glucaric acid yield was higher than other acids in the solution controlled by NaOH and H2SO4. In addition, as shown in Fig. 7.6, carbon was an effective support in the oxidation of glucose, and Pt/C catalyst showed higher catalytic activity and glucaric acid yield than Pt/Al2O3 and Pt/SiO2 catalysts, which might be due to the adsorption ability for substrates .

Gluconic and glucaric acid yields over three catalysts. Reaction conditions: 10 wt% glucose solution 20 mL, 80 °C, 6.2 bar O2, glucose/Pt (mol/mol) = 54. TOFs were calculated at 20% conversion (Reprinted from Ref. [45], Copyright © 2016, with permission from Royal Society of Chemistry)

Bimetallic catalysts , such as MnPt, CoPt, FePt, AuPt, and PtCu, are reported as effective catalysts for oxidation of glucose into glucaric acid as shown in Table 7.4 [43,44,45,46,47]. Jin et al. reported highly catalytic performance of bimetallic PtCu supported on titania for oxidation of glucose into glucaric acid with 1 bar of oxygen gas in alkali media [43]. Table 7.5 shows the conversion and glucaric acid selectivity for oxidation of gluconate over Pt, Pd, Cu, Co, and bimetallic catalysts . The major products formed from gluconate oxidation were glucaric acid, tartronic acid , and oxalic acid, and monocarboxylic acids such as glyceric acid, lactic acid , glycolic acid, and formic acid. The product selectivity was almost the same for all catalysts. Pt and Pd catalysts showed markedly higher catalytic activity than Cu and Co catalysts. For bimetallic catalysts , PtCu showed higher catalytic activity than PtPd and PtCo catalysts. The catalyst support also affected the catalytic properties as well as the glucose oxidation . TiO2 showed better promotional effect for the oxidation into glucaric acid than CeO2.

Colmenares et al. reported on the photo-oxidation of glucose to glucaric acid in the presence of TiO2 as catalyst [48]. Experiments were performed typically as follows: 150 mL of a mixed solution of H2O:acetonitrile = 10:90, 150 mg of TiO2 catalyst, and 0.42 mmol of glucose were added into a batch reactor at 30 °C for 10 min UV irradiation time. The conversion and selectivity depended significantly on the nature of TiO2 catalysts and the ratio of H2O to acetonitrile. In 100% H2O solvent, conversions of glucose were relatively high, but the selectivities of glucaric acid and gluconic acid were almost zero. In contrast, in a mixed-solvent system of H2O:acetonitrile = 10:90, TiO2 catalyst prepared by the sol-gel method gave 13% selectivity of glucaric acid and 14% selectivity of gluconic acid at 32% conversion of glucose. Although decarboxylation proceeded readily during photocatalytic oxidation , significant amounts of gluconic acid and glucaric acid were observed by the photocatalytic oxidation of glucose. The glucaric acid yield was low, but improvements of the photocatalytic method can be expected, as well as those of the conventional oxidation methods.

2.2 Oxidation of Uronic Acid Using Solid Catalysts

Uronic acids, such as glucuronic and galacturonic shown in Scheme 7.4, can be obtained from hemicelluloses and pectin . Uronic acids have a carboxyl group at the C6 carbon site similar to glucose and galactose . So, it is expected to be easier to prepare glucaric acid from uronic acid than from aldose sugars. Rautiainen et al. reported that uronic acid could be used as raw material for the synthesis of aldaric acids over Au/Al2O3 catalysts [49]. Commercially available D-gluconic acid and D-galacturonic acid were used as reactants. Typically, they added 50 mL of H2O, 25 mg of Au/Al2O3 catalyst, 2.58 mmol of uronic acid (glucuronic acid and galacturonic acid), and 100 mL min−1 of flowing O2 into a batch reactor . The reaction temperature and pH were 25–60 °C and 8–10, respectively. As shown in Table 7.6, the pH had a significant effect on the initial reaction rate. At pH 10 at 60 °C, a TOF value close to 8000 h−1 was measured for glucuronic acid oxidation. The reaction rate was comparable with those of the oxidation of glucose and galactose into gluconic acid and galactonic acid . When the pH was 8 or 9 at 60 °C, the TOF was about 3000 h−1 or 6000 h−1, respectively. The TOF decreased with decreasing the pH. The apparent activation energy for glucuronic acid oxidation was dependent on pH which can be attributed to the higher energy barrier for desorption of acids at lower pH.

3 Bifunctional Catalysts for Direct Production of Gluconic Acid

Heterogeneous catalytic processes for oxidation of monosaccharides with oxygen or air into sugar acids have been developed using Pd-Bi/C and Au/C catalysts as described previously. However, polysaccharides represent the largest sources of organic compounds in nature. Therefore, direct production of sugar acids from polysaccharides is of great significance as necessary for sustainable society. Development of bifunctional catalysts for the hydrolysis of polysaccharides into monosaccharides and the oxidation of monosaccharides into sugar acids can be anticipated. As known examples of bifunctional catalysts, noble metal supported solid acid catalysts, such as Pt/zeolites and Pt/sulfated-zirconia , have been reported to be effective for the dehydroisomerization of butane into isobutene and the isomerization of alkanes in gas-solid catalytic reactions [57,58,59,60]. On the other hand, for polysaccharide conversions in hot water , these bifunctional catalysts are easily destroyed or dissolved into water at low pH that is attributed to the production of organic acids . The selective hydrolysis of cellulose with a sulfonated carbon catalyst and a sulfonated activated-carbon (AC-SO3H) catalyst and polyoxometalate catalysts have been reported [50,51,52,53,54,55,56, 61]. Carbon materials and POM complexes are highly stable in hot and acidic water. In this section, some bifunctional catalysts , such as acidic carbon materials and polyoxometalate catalysts supported noble metal catalysts are introduced as being effective for direct conversion of polysaccharides into gluconic acid (Scheme 7.5) [62].

3.1 Bifunctional Sulfonated Activated-Carbon Supported Platinum Catalyst

Gluconic acid can be produced from polysaccharides , such as starch and cellobiose , at relatively mild reaction conditions at 120 °C under 1 bar of air by a one-pot process using a bifunctional sulfonated activated-carbon supported platinum (Pt/AC-SO3H) catalyst. Pt/AC-SO3H was made by a two-step method that firstly prepared Pt/AC by impregnation , and sulfonation of the Pt/AC that was carried out under concentrated sulfuric acid . Then, the material was hydrothermally treated at 200 °C. The obtained Pt/AC-SO3H catalyst had strong acidic sulfo groups, platinum fine particles , and high surface area of 226 m2 g−1 and it was highly water-tolerant even under hot acidic water. The loading amounts of platinum was 4 wt%. As shown in Fig. 7.7, XRD patterns indicated the metallic state of the bulk of platinum particles and the platinum particle sizes were 4.7 nm for Pt/AC-SO3H catalyst as estimated by the diffraction peaks of XRD.

3.2 Conversion of Starch

As shown in Fig. 7.8, activated carbon (AC) catalyst with carboxylic acid groups gave very low amounts of glucose and 68 C-% of the remaining fractions were adsorbed onto AC. In contrast, sulfonated activated-carbon (AC-SO3H) catalyst gave glucose in 69 C-% yields and oligo-saccharides in 29 C-% yields. Glucose yields increased with increasing reaction time over the AC-SO3H catalyst, and the glucose yield reached values over 90% (Fig. 7.9a).

On the other hand, as shown in Fig. 7.8, the Pt/AC-SO3H catalyst gave gluconic acid in 40 C-% yields. The active sites for the glucose oxidation into gluconic acid are the platinum particles , because the catalysts without platinum gave no amounts of gluconic acid. After reaction, the loading amounts of platinum was 4.0 wt% determined by ICP and the average platinum particle size was estimated to be 4.5 nm by XRD, which were almost the same values as the fresh catalyst. This means that the platinum particles on sulfonated activated-carbon were mostly neither leached nor sintered during the reaction. Fig. 7.9b shows changes in product yields in starch hydrolysis over Pt/AC-SO3H catalyst. The yields of oligosaccharides , glucose, and gluconic acid increased linearly with an increase in reaction time up to 9 h. Then, gluconic acid was produced and became the main product at 24 h. Molar ratios of gluconic acid to total S atoms and total Pt atoms in the catalyst were about 8 and 9, respectively, which indicates that the sulfo groups and platinum particles catalytically accelerated the hydrolysis of starch into glucose and the oxidation of glucose into gluconic acid. The pH values before and after the starch reaction over the Pt/AC-SO3H catalyst were, nearly neutral (pH = 6) and acidic (pH about 3), respectively. The decrease in pH value was mainly due to the production of gluconic acid , because there was almost no sulfuric ions detected an ion chromatography . The catalyst was separated by filtration, and then it was used repeatedly. Furthermore, as shown in Fig. 7.9b, the yield of gluconic acid increased to about 60 C-% by adding fresh air into the reactor. These results show that the Pt/AC-SO3H catalyst remained mostly active under the reaction conditions. As a consequence, the catalytic active sites , such as Pt nano particles and sulfo acidic groups, were stable and effective for direct conversion of starch into gluconic acid in aqueous solutions at 120 °C.

3.3 Conversion of Various Polysaccharides

As shown in Fig. 7.10, conversion of pullulan, which is a polysaccharide of glucose with α-glycoside bonds and is easily soluble in water at room temperature , was accelerated by Pt/AC-SO3H catalyst, as well as starch. Product yields from cellobiose were almost same as those from maltose. These results show that Pt/AC-SO3H catalyst has bifunctional catalytic properties for direct production of gluconic acid from hydrothermally soluble poly- and di-saccharides even when they have a β-1,4 glycoside bond.

3.4 Comparison of Pt/AC-SO3 H Catalyst to Mixed Catalyst of AC-SO3H with Pt/AC

To consider the catalytic properties of Pt/AC-SO3H, AC-SO3H catalyst and Pt/AC catalyst were mixed and used as catalyst for starch conversion under air. As shown in Fig. 7.8, hydrolysis products with the mixed catalyst were in significantly smaller amounts than those with the Pt/AC-SO3H catalyst. The mixed catalyst gave glucose in 43 C-% yield and gluconic acid in 11 C-% yield and large amounts of adsorption of about 30 C-%, whereas, the Pt/AC-SO3H catalyst gave gluconic acid in 40 C-% and relatively small amounts of adsorption of about 10 C-% under the same reaction conditions. It can be suggested that the location of platinum nano-particles on acidic support is effective for direct production of gluconic acid from polysaccharides and to inhibit strong adsorption of polysaccharides onto neutral carbon supports as well as to promote desorption of gluconate from the platinum particles .

As a consequence of Sect. 7.3.1, a new bifunctional Pt/AC-SO3H catalyst was prepared by the impregnation and sulfonation method . The catalyst was highly water-tolerant and showed catalytic properties for the hydrolysis of polysaccharides and sequentially the air-oxidation into gluconic acid in a one pot process with hot water. Au/AC-SO3H catalyst showed an increased yield of gluconic acid from starch and cellobiose , and the results are being prepared as an original paper.

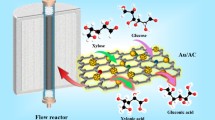

3.5 Cellobiose Conversion into Gluconic Acid Over Various Gold Catalysts

Gold nanoparticles have highly catalytic performance for the oxidation of glucose into gluconic acid as mentioned in Sect. 7.1. Some researchers have reported on the catalytic properties of supported gold catalysts for production of gluconic acid from cellobiose at 145 °C under pressurized oxygen . Because cellobiose is easily hydrolyzed under hydrothermal conditions at 145 °C, various kinds of support materials can be used. Specific surface area and concentration of gold nanoparticles and catalytic properties of support materials are important for selective production of gluconic acid from cellobiose.

Tan et al. reported on the selective oxidation of cellobiose to gluconic acid with carbon supported Au nanoparticles in the presence of oxygen in water [18]. Table 7.7 shows a summary of the conversion of cellobiose over Au fine particles on carbon materials and zeolites , at 145 °C under 5 bar of oxygen. The catalytic activity and selectivity markedly depended on the type of the support. Au/CNT catalysts showed the highest yields of gluconic acid . The CNT was a carbon nanotube treated with concentrated HNO3. Au catalysts using the other carbon supports, such as AC, graphite , and XC-72, showed lower cellobiose conversions and gluconic acid selectivities, although they gave high selectivity for the hydrolysis products of glucose and gluconic acid. The CNT support might play a role not only to hydrolyze cellobiose, but also to improve the oxidation catalytic activity of Au particles catalysts.

In contrast, Au/Al2O3, Au/MgO and Au/MCM-41, MCM-41 are mesoporous materials of silica that had high catalytic activity , but gave high yields of by-products , which would be formed due to catalytic properties of the supports. Au/H-ZSM-5 catalyst showed relatively high catalytic activity and selectivity as well as carbon supported Au catalysts , which would be due to the acidic property of H-ZSM -5.

The same group reported on the catalytic behavior of new bifunctional catalysts that were protonated polyoxometalate supported gold [63]. The reaction conditions were almost the same as ref. [18] in water at 145 °C under 5 bar of O2, except for loading amounts of gold. TEM observation clarified that the mean-sizes of the Au nanoparticles were in the range 2.5–3 nm for all samples . Au/Cs1.2H0.8PW12O40 catalyst exhibited an excellent gluconic acid yield of 97%. A further increase in Cs content to x = 2.2 and 3.0 decreased the selectivity from 99% of x = 1.2 to 95% of x = 2.2 and 85% of x = 3.0 although conversions of cellobiose hardly depended on the Cs content (x). Au/Cs3.0PW12O40 catalyst is not protonated and has no strong acidity, but it gave high yields (81%) of hydrolysis products, which suggests that the strong acidity of the support materials is not effective for hydrolysis of cellobiose. The results are unexpected and may be due to the high reaction temperature (145 °C). In addition, in Table 7.7 the supports with basic sites, such as MgO and Al2O3, gave large amounts of by-products , which would indicate that protonating treatment of the support enhances the selectivity of gluconic acid to inhibit production of by-products. Compared with 1% Au/CNT catalyst reported in ref. [63] and 0.5% Au/CNT catalyst reported in ref. [18] (Table 7.7), 1% Au/CNT catalyst gave significantly higher gluconic acid selectivity (86%) and yield (72%) than 0.5% Au/CNT catalyst. These results show that by-product would be produced over the support, but not over the gold particles . As shown in Table 7.7, Au/Cs3-xHxPW12O40 catalysts with the larger surface area had the higher selectivity of gluconic acid and Au/CNT catalysts with the larger loading amounts of gold exhibited the higher selectivity of gluconic acid, which might indicate that the concentration of gold particles is important for gluconic acid selectivity from cellobiose. Eblagon et al. [64] reported on the cellobiose conversion into gluconic acid using carbon supported Au catalyst under almost the same reaction conditions as those of Wang’s group [63]. They showed that oxidized carbon supported Au catalysts with the higher concentrations of functional groups, such as phenolic groups, had higher selectivity of gluconic acid. It can be considered that the effect of the functional group on the selectivity is due to not only adsorption ability mentioned by Eblagon et al. [64], but also due to surface acidity that inhibits production of by-products as suggested by the overview given in this chapter.

Amaniampong et al. reported the catalytic behavior of new bimetallic Au-Cu catalysts [65]. As shown in Table 7.7, Au/TiO2 catalysts allow high gluconic acid yields comparable with those of the Au/CNT catalyst and bimetallic AuCu/TiO2 catalyst increased the selectivity and yield of gluconic acid . Bimetallic AuCu particles might have higher catalytic properties than monometallic ` Au particle in the glucose oxidation . Although there needs to be attention given to the leaching of Cu species, the results are interesting for future development of this reaction system .

4 Conclusions and Future Outlook

Gluonic acid and glucaric acid can be expected to become platform chemicals for making useful products, such as plastics and food additives from biomass. Especially, glucaric acid can be a promising sustainably-produced chemical as a route to production of adipic acid . The highly selective oxidation of glucose using monometallic and bimetallic catalysts , such as Au, PtPd, PdAu, and, PtBi supported on carbon, has been studied by many researchers. Supported Au catalyst is one of the appropriate catalysts for glucose oxidation into gluconic acid, because Au is highly water tolerant and has suitable catalytic activity for the oxidation. For supports of Au catalysts, carbon materials with acidic functional groups, such as phenol groups, are generally appropriate for the oxidation of sugars. Titania is also an appropriate material as support. However, the development of the production of glucaric acid from glucose is still not sufficient. A practical process will require progress in new oxidation catalysts that have high activity for the selective oxidation of both a primary alcohol group and an aldehyde group into carboxyl groups in the chemical structures of sugars. On the other hand, the direct conversions of natural polysaccharides are still challenging processes. Practical processes will require progress in new bifunctional catalysts with oxidation active sites , acidic active sites, and they must have water tolerant properties.

References

Huber GW, Iborra S, Corma A. Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem Rev. 2006;106:4044–98.

Chheda JN, Huber GW, Dumesic JA. Liquid-phase catalytic processing of biomass-derived oxygenated hydrocarbons to fuels and chemicals. Angew Chem Int Ed. 2007;46:7164–83.

Ramachandran S, Fontanille P, Pandey A, Larroche C. Gluconic acid: properties, applications and microbial production. Food Technol Biotechnol. 2006;44:185–95.

Godjevargova T, Dayal R, Turmanova S. Gluconic acid production in bioreactor with immobilized glucose oxidase plus catalase on polymer membrane adjacent to anion-exchange membrane. Macromol Biosci. 2004;4:950–6.

Besson M, Gallezot P. Selective oxidation of alcohols and aldehydes on metal catalysts. Catal Today. 2000;7:127–41.

Biella S, Prati L, Rossi M. Selective oxidation of D-glucose on gold catalyst. J Catal. 2002;206:242–7.

Mirescu A, Prüße U. Selective glucose oxidation on gold colloids. Catal Commun. 2006;7:11–7.

Ishida T, Kinoshita N, Okatsu H, Akita T, Takei T, Haruta M. Influence of the support and the size of gold clusters on catalytic activity for glucose oxidation. Angew Chem Int Ed. 2008;47:9405–8.

Abbadi A, van Bekkum H. Effect of pH in the Pt-catalyzed oxidation of D-glucose to D-gluconic acid. J Mol Catal A. 1995;97:111–8.

Onda A, Ochi T, Kajiyoshi K, Yanagisawa K. A new chemical process for catalytic conversion of D-glucose into lactic acid and gluconic acid. Appl Catal A. 2008a;343:49–54.

Abbadi A, Gotlieb KF, van Bekkum H. Study on solid acid catalyzed hydrolysis of maltose and related polysaccharides. Starch. 1998;50:23–8.

Zhang H, Toshima N. Glucose oxidation using Au-containing bimetallic and trimetallic nanoparticles. Cat Sci Technol. 2013;3:268–78.

Dirkx JMH, van der Baan HS, van den Broen JMAJJ. Preparation of D-glucaric acid by oxidation of D-gluconic acid-catalyzed by platinum on carbon. Carbohydr Res. 1977;59:63–72.

Banu M, Venuvanalingam P, Shanmugam R, Viswanathan B, Sivasanker S. Sorbitol hydrogenolysis over Ni, Pt and Ru supported on NaY. Top Catal. 2012;55:897–907.

Abbadi A, Makkee M, Visscher W, van Veen JAR, van Bekkum H. Effect of pH in the Pd-catalyzed oxidation of D-glucose to D-gluconic acid. J Carbohydr Chem. 1993;12:573–87.

Onal Y, Schimpf S, Claus P. Structure sensitivity and kinetics of D-glucose oxidation to D-gluconic acid over carbon-supported gold catalysts. J Catal. 2004;223:122–33.

Liang X, Liu CJ, Kuai P. Selective oxidation of glucose to gluconic acid over argon plasma reduced Pd/Al2O3. Green Chem. 2008;10:1318–22.

Tan XS, Deng WP, Liu M, Zhang QH, Wang Y. Carbon nanotube-supported gold nanoparticles as efficient catalysts for selective oxidation of cellobiose into gluconic acid in aqueous medium. Chem Commun. 2009;46:7179–81.

Ma CY, Xue WJ, Li JJ, Xing W, Hao ZP. Mesoporous carbon-confined Au catalysts with superior activity for selective oxidation of glucose to gluconic acid. Green Chem. 2013;15:1035–41.

Worz N, Brandner A, Claus P. Platinum–Bismuth-catalyzed oxidation of glycerol: kinetics and the origin of selective deactivation. J Phys Chem C. 2010;114:1164–72.

Wenkin M, Touillaux R, Ruiz P, Delmon B, Devillers M. Influence of metallic precursors on the properties of carbon-supported bismuth-promoted palladium catalysts for the selective oxidation of glucose to gluconic acid. Appl Catal A. 1996;148:181–99.

Wenkin M, Renard C, Ruiz P, Delmon B, Devillers M. Promoting effects of bismuth in carbon-supported bimetallic Pd–Bi catalysts for the selective oxidation of glucose to gluconic acid. Stud Surf Sci Catal. 1997;110:517–26.

Karski S, Paryjczak T, Witonska I. Selective oxidation of glucose to gluconic acid over bimetallic Pd-Me catalysts (Me = Bi, Tl, Sn, Co). Kinet Catal. 2003;44:618–22.

Witonska I, Karski S, Frajtak M. Supported Pd–Te catalysts for selective oxidation of glucose to gluconic acid in liquid phase. Przem Chem. 2011;90:475–80.

Besson M, Gallezot P, Lahmer E, Fleche G, Fuertes P, Kosak JR. In: Johnson TA, editor. Catalysis of organic reactions, vol. 53. New York: Marcel Dekker; 1993. p. 169–80.

Besson M, Gallezot P, Lahmer E, Flbche G, Fuertes P. Catalytic oxidation of glucose on bismuth-promoted palladium catalysts. J Catal. 1995;152:116–21.

Dirkx JMH, van der Baan HS. The oxidation of gluconic acid with platinum on carbon as catalyst. J Catal. 1981;67:14–20.

Venema ER, Peters JA, van Bekkum H. Platinum-catalyzed oxidation of aldopentoses to aldaric acids. J Mol Catal. 1992;77:75–85.

Gallezot P, de Mésanstourne R, Christidist Y, Mattioda G, Schouteeten A. Catalytic oxidation of glyoxal to glyoxylic acid on platinum metals. J Catal. 1992;133:479–85.

Botman MJP, de Vreugd K, Zandbergen HW, de Block R, Ponec V. The effect of alloying Pt with Re on the intermediates in hydrocarbon reactions: reactions of 2,2-dimethylbutane. J Catal. 1989;116:469–79.

Betizeau C, Leclercq G, Maurel R, Bolivar C, Charcosset H, Frety R, Tournayan L. Platinum-rhenium-alumina catalysts: III catalytic properties. J Catal. 1976;45:179–88.

Comotti M, Pina CD, Rossi M. Mono- and bimetallic catalysts for glucose oxidation. J Mol Catal A. 2006;251:89–92.

Besson M, Gallezot P, Pinel C. Conversion of biomass into chemicals over metal catalysts. Chem Rev. 2014;114:1827–70.

Mirescu A, Berndt H, Martin A, Prüsse U. Long-term stability of a 0.45% Au/TiO2 catalyst in the selective oxidation of glucose at optimized reaction conditions. Appl Catal A. 2007;317:204–9.

Saliger R, Decker N, Prüsse U. D-Glucose oxidation with H2O2 on an Au/Al2O3 catalyst. Appl Catal B. 2011;102:584–9.

Omri M, Pourceau G, Becuwe M, Wadouachi A. Improvement of gold -catalyzed oxidation of free carbohydrates to corresponding aldonates using microwaves. ACS Sustain Chem Eng. 2016;4:2432–8.

Bujak P, Bartczak P, Polanski JJ. Highly efficient room-temperature oxidation of cyclohexene and d-glucose over nano gold Au/SiO2 in water. J Catal. 2012;295:15–21.

Kiely DE, Chen L, Lin T. Hydroxylated nylons based on unprotected esterified D-glucaric acid by simple condensation reactions. J Am Chem Soc. 1994;116:571–8.

Smith TN, Hash K, Davey CL, Mills H, Williams H, Kiely DE. Modifications in the nitric acid oxidation of D-glucose. Carbohydr Res. 2012;350:6–13.

Merbouh N, Bobbit JM, Bruckner C. 4-AcNH-tempo-catalyzed oxidation of aldoses to aldaric acids using chlorine or bromine as terminal oxidants. J Carbohydr Chem. 2001;21:65–77.

Ibert M, Fuertès P, Merbouh N, Fiol-Petit C, Feasson C, Marsai F. Improved preparative electrochemical oxidation of D-glucose to D-glucaric acid. Electrochim Acta. 2010;55:3589–94.

Bin D, Wang H, Lia J, Wang H, Yin Z, Kang J, He B, Li Z. Controllable oxidation of glucose to gluconic acid and glucaric acid using an electrocatalytic reactor. Electrochim Acta. 2014;130:170–8.

Jin X, Zhao M, Shen J, Yan W, He L, Thapa PS, Ren S, Subramaniam B, Chaudhari RV. Exceptional performance of bimetallic Pt1Cu3/TiO2 nanocatalysts for oxidation of gluconic acid and glucose with O2 to glucaric acid. J Catal. 2015;330:323–9.

Ibert M, Fuertès P, Merbouh N, Feasson C, Marsai F. Evidence of benzilic rearrangement during the electrochemical oxidation of D-glucose to D-glucaric acid. Carbohydr Res. 2011;346:512–8.

Lee J, Saha B, Vlachos DG. Pt catalysts for efficient aerobic oxidation of glucose to glucaric acid in water. Green Chem. 2016;18:3815–22.

Murphy VJ, Shoemaker J, Zhu G, Archer R, Salem F, Dias EL. US Patent. 2011. 2011/0306790A1.

Boussie TR, Dias EL, Fresco ZM, Murphy VJ, Shoemaker J, Archer R, Jiang H. US Patent. 2010. 2010/0317823A1.

Colmenares JC, Magdziarz A, Bielejewska A. High-value chemicals obtained from selective photo-oxidation of glucose in the presence of nanostructured titanium photocatalysts. Bioresour Technol. 2011;102:11254–7.

Rautiainen S, Lehtinen P, Chen J, Vehkamaki M, Niemela K, Leskela M, Repo T. Selective oxidation of uronic acids into aldaric acids over gold catalyst. RSC Adv. 2015;5:19502–7.

Dhepe PL, Ohashi M, Inagaki S, Ichikawa M, Fukuoka A. Hydrolysis of sugars catalyzed by water-tolerant sulfonated mesoporous silicas. Catal Lett. 2005;102:163–9.

Takagaki A, Tagusagawa C, Domen K. Glucose production from saccharides using layered transition metal oxide and exfoliated nanosheets as a water-tolerant solid acid catalyst. Chem Commun. 2008;14:5363–5.

Onda A, Ochi T, Yanagaisawa K. Selective hydrolysis of cellulose into glucose over solid acid catalysts. Green Chem. 2008b;10:1033–7.

Onda A, Ochi T, Yanagaisawa K. Hydrolysis of cellulose selectively into glucose over sulfonated activated-carbon catalyst under hydrothermal conditions. Top Catal. 2009;52:801–7.

Suganuma S, Nakajima K, Kitano M, Yamaguchi D, Kato H, Hayashi S, Hara M. Hydrolysis of cellulose by amorphous carbon bearing SO3H, COOH, and OH groups. J Am Chem Soc. 2008;135:12757–93.

Kobayashi H, Komanoya T, Hara K, Fukuoka A. Water-tolerant mesoporous-carbon-supported ruthenium catalysts for the hydrolysis of cellulose to glucose. ChemSusChem. 2010;3:440–3.

Shimizu K, Furukawa H, Kobayashi N, Itaya Y, Satsuma A. Effects of Brønsted and Lewis acidities on activity and selectivity of heteropoly acid-based catalysts for hydrolysis of cellobiose and cellulose. Green Chem. 2009;11:1627–32.

Pirngruber GD, Seshan K, Lercher JA. Dehydroisomerization of n-butane over Pt–ZSM5 (I): effect of the metal loading and acid site concentration. J Catal. 1999;186:188–200.

Komatsu T, Ikenaga H. Dehydroisomerization of butane into isobutene on Pt–Sn intermetallic compounds supported on H-SAPO-11. J Catal. 2006;241:426–34.

Ebitani K, Konishi J, Hattori H. Skeletal isomerization of hydrocarbons over zirconium oxide promoted by platinum and sulfate ion. J Catal. 1991;130:257–67.

Iglesia E, Soled ST, Kramer GM. Isomerization of alkanes on sulfated zirconia: promotion by Pt and by adamantyl hydride transfer species. J Catal. 1993;144:238–53.

Deng W, Zhang Q, Wang Y. Polyoxometalates as efficient catalysts for transformations of cellulose into platform chemicals. Dalton Trans. 2012;41:9817–31.

Onda A, Ochi T, Yanagaisawa K. New direct production of gluconic acid from polysaccharides using a bifunctional catalyst in hot water. Catal Comm. 2011;12:421–5.

An D, Ye A, Deng W, Zhang Q, Wang Y. Selective conversion of cellobiose and cellulose into gluconic acid in water in the presence of oxygen, catalyzed by polyoxometalate-supported gold nanoparticles. Chem Eur J. 2012;J18:2938–47.

Eblagon K, Pereira M, Figueiredo J. One-pot oxidation of cellobiose to gluconic acid. Unprecedented high selectivity on bifunctional gold catalysts over mesoporous carbon by integrated texture and surface chemistry optimization. Appl Catal B. 2016;184:381–96.

Amaniampong P, Booshehri A, Jia X, Dai Y, Wang B, Mushrif S, Borgna A, Yang Y. High-temperature reduction improves the activity of rutile TiO2 nanowires-supported gold-copper bimetallic nanoparticles for cellobiose to gluconic acid conversion. Appl Catal A. 2015;505:16–27.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Onda, A. (2017). Production of Glucaric/Gluconic Acid from Biomass by Chemical Processes Using Heterogeneous Catalysts. In: Fang, Z., Smith, Jr., R., Qi, X. (eds) Production of Platform Chemicals from Sustainable Resources. Biofuels and Biorefineries. Springer, Singapore. https://doi.org/10.1007/978-981-10-4172-3_7

Download citation

DOI: https://doi.org/10.1007/978-981-10-4172-3_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4171-6

Online ISBN: 978-981-10-4172-3

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)