Abstract

This chapter describes a knowledge-based system (KBS) developed for design of deep drawing die for axisymmetric parts. The production rule-based KBS approach of artificial intelligence (AI) is utilized for development of the proposed system. The overall system is organized in 4 subsystems and 27 modules. System modules are coded in AutoLISP language and user interface is created using Visual Basic 6.0 and interface with AutoCAD software. The proposed system is capable to automate all major activities of design of deep drawing die such as process planning, design of strip-layout, selection of die components, and modeling of die components and die assembly. The system is user interactive, flexible, and has low cost of implementation.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

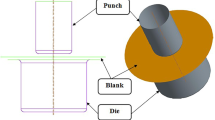

Deep drawing operation is one of the widely used sheet metal forming processes due to ease of forming complex shapes, high strength to weight ratio, short production time, etc. It is popular because of its rapid press cycle to produce complex axisymmetric geometries (Kalpakjian and Schmid 2009). Deep drawn parts are used in subassemblies of automobile, food processing, beverage, pharmaceuticals, computers, medical, refrigerators, kitchen utensils, electrical, micro-electronics, and telecommunication equipments. In context with production of axisymmetric deep drawn parts using mechanical presses, variety of processing methods like single action die, double action die, combination dies, transfer die, etc., are being used. Figure 1 shows a schematic of deep drawing process for producing an axisymmetric part.

Deep drawing process (Kaushish 2010)

One of the important tasks in the production of deep drawn sheet metal parts is the design of deep drawing dies to suit the product features. One of the important aspects for successful production of defect free production of deep drawn parts depends on quality of die design. The process of design of deep drawing die involves a number of activities such as calculation of blank size, process planning, design/selection of die components, and modeling of die components and die assembly. Traditionally these tasks are carried out manually by highly experienced die designers and process planners. Various problems in traditional die design process are (i) scarcity of experienced die designers worldwide, (ii) it is complex, time consuming, trial and error process, (iii) quality of sheet metal parts are not consistent, and (iv) frequent mobility of experienced die designers and process planers.

Since early 1970s, a number of commercial softwares have been developed to assist die designers to perform the task of die design. These CAD/CAM softwares provide some aid to die designers and process planners to perform simple calculation, storage and retrieval of data, visualization of part geometry and drafting of die. These packages have shown their capability through increase in productivity of die designers to some extent. Nowadays, there are number of commercial CAD/CAM systems available for sheet metal industries. But most of these CAD/CAM systems provide the solution for specific die design tasks for very simple sheet metal parts. Also multiple software packages are required to perform various activities of die design process and small scale industries (especially in developing countries) are not able to afford these commercial softwares because of their high installation cost. Further trained competent persons are required to operate and interpret the results of these commercial software packages.

Therefore, there is a need of development of a KBS for automatic design of deep drawing dies. The system must be capable to automate all major activities of traditional die design process including process planning, strip-layout design, selection of die components and die modeling. In this chapter, a KBS developed for automatic design of deep drawing die for axisymmetric parts is described. The production rule-based approach of AI is utilized for development of this system. Capability of the developed system is tested on various types of industrial deep drawn parts.

The next section describes the literature review in the domains of computer-aided process planning (CAPP), computer-aided die design, and KBS for deep drawing die design.

2 Literature Review

2.1 Computer-Aided Process Planning

Several researchers applied efforts in developing computer-aided process planning (CAPP) systems for deep drawn parts using various AI techniques. For example, Karima and Richardson (1987) pioneered the idea of applying KBS in sheet metal forming. The system consists of manipulating the knowledge as facts, procedures, judgment, and controls which can be acquired from relevant sources. This system advices the user what action to be taken to achieve the desired goal keeping in perspective various design constraints. Later on Karima (1989) presented a hybrid system for process planning in sheet metal forming. System takes the overview of stamping engineering from micro and macro perspectives. The role of computer modeling is also examined with emphasis on applicability of different computer tools and need for a broad methodology to support application of computer tools. Sitaraman et al. (1991) developed a hybrid computer-aided engineering (CAE) system for automatic process sequence design for manufacturing of axisymmetric deep drawn parts. They integrated expert system module and a process modeling analysis module for handling symbolic and numeric information. Tisza (1995) from University of Miskolc, Hungary developed a Metal Forming Expert (METEX) system for sheet metal forming applications. The system used AutoCAD and AutoLISP to generate possible solutions for deeply formed shapes. An expert system namely ASFEX (Axisymmetric Sequence Forming Expert System) was developed by the Engineering Research Centre for Net Shape Manufacturing (ERC/NSM) (Esche et al. 1996). This system used design rules to generate process sequences for multistage drawing of round cups and tool geometry for each station of the sequence. In process sequence design, both geometry and formability based decisions are taken. The process is then analyzed by finite element simulation to check the feasibility of the production. Sing and Rao (1997) constructed a knowledge-based CAPP system using decision tables for axisymmetrical deep drawn cup. Researchers from Center for Net Shape and Die Manufacturing, Pusan University, South Korea (Park et al. 1998) developed a rule-based CAPP design system namely Pro_Deep for generation of process sequence with intermediate object geometry and also to determine process parameters. Knowledge is represented in ‘IF-THEN’ type of production rules. Similarly a compact and practical CAD/CAM system for the blanking or piercing of irregular shaped sheet metal products was developed by Choi et al. (2000). The program for the system was written in AutoLISP language for strip and die layout of stator and rotor parts with bending and piercing operations. Choi et al. (2002) used case-based reasoning (CBR) approach to develop a modular design support system for production of circular cup. System suggests various possible process sequences for circular cup. Kang and Park (2002) constructed a rule-based expert system for process planning of multistage non-axisymmetric deep drawn parts having elliptical cross-sectional shape. System includes 3-D modeling, blank size calculation, and process planning module. Shi et al. (2002) proposed prototype knowledge-based process planning system for auto panel. The system consists of process planning and forming analysis modules. Case-based and rule-based reasoning approach is used and supported with the CAD tool Unigraphics (UG)-II. Park and Prasad (2004, 2005) developed a surface area calculating system (SACS) and CAPP system for non-axisymmetric deep drawn parts with elliptical shape. Researchers Wifi et al. (2004, 2005) from Cairo University, Egypt reported to develop a CAPP system using rule-based technique for complex axisymmetric circular and rectangular deep drawn parts. This system is coded using Visual Basic (VB) and interfaced with AutoCAD software. George-Christophe et al. (2005) used logic programming for process planning of sheet metal forming with progressive dies. Zhang et al. (2006) developed a CAPP system for multistage, non-axisymmetric deep drawn parts using CBR approach. It is implemented in a C language integrated production system (CLIPS) and interfaced with the Solid Edge CAD system. Abbassi and Zghal (2007) proposed a CAPP system based on the experimental results and empirical knowledge of experts for axisymmetric deep drawn parts. Outputs of the system are in the form of stamping process parameters and geometrical modeling of tool. Potocnik et al. (2011) developed an intelligent system for automatic calculation of stamping process parameters for design of stamping die for manufacturing of circular cup with flange. Further they also reported to develop a KBS for modeling of the reinforcement of a press plate (Potocnik et al. 2012). This system is based on the implemented knowledge of experts in the execution of design, material selection, and numerical analysis based on FEM. Fazli et al. (2014) developed a computer-aided design (CAD) system for automatic process design and finite element (FE) modeling of axisymmetric deep drawn components using the theoretical and experimental rules.

2.2 Computer-Aided Die Design

From early 1970s to mid-1980s, the first generation CAD systems for die design were developed to reduce time, cost and to minimize trial and error adjustments in die design process. Schaffer (1971) was probably the pioneers in use of computer in die design. The system namely PDDC (Progressive Die Design by Computer) was developed to identify projections of the part which may subject the die to undue stresses during cutting operation. Later on (Fogg and Jaimeson 1975) proposed an improved PDDC system by considering other factors which influence the die design. The system has different modules to perform various tasks for die designer such as strip-layout, die layout, etc. But it takes long design time due to its semi-automatic nature. Later on number of researcher including Nakahara (1978), Adachi et al. (1983), Shirai and Murakami (1985), Altan (1987), Bergstrom et al. (1988), Prasad and Somasundaram (1992), Nee (1994), Choudhary and Allada (1999) developed CAD/CAM system for automation of progressive die design.

Very few researchers applied their efforts to develop CAD system to automate design of deep drawing die. For example, Park (1999) proposed a prototype CAD/CAM system for axisymmetric deep drawing processes in simple action press. The system was written in User Programming Language (UPL) and developed under the environment of Personal Designer CAD/CAM software. The system needs expert designer’s assistance for analysis of final results. A fully integrated CAD/CAM/CAE system was developed by Lin and Kuo (2008) for stamping dies of automotive sheet metal parts. The system operates using high end softwares like CATIA for layout diagram design and die structure analysis, STRIM software for die face design, DYNAFORM for formability analysis and CADCEUS for tooling path generation and simulation. Lin and Kuo (2011) presented a method to explore multi-objective optimization in the structural design of ribs for drawing dies by combining Finite Element Analysis (FEA) and the fuzzy based taguchi method.

The foregoing literature review reveals that only few research efforts are found in the area of CAD of deep drawing die. Most of the reported systems are semi-automatic, dedicated to specific type of application, and need experienced die designers to operate the system.

2.3 Knowledge-Based Deep Drawing Die Design

Eshel et al. (1986) developed a rule-based expert system for generation of process plan for axisymmetric and monotone parts produced by deep drawing process. They suggested G & TR (Generate & Test and Rectify) strategy for the process planning of axisymmetric deep drawing products. Xiao et al. (1990) proposed an expert system using a set of production rules and frames for designing process sequence of strip-layout design of progressive drawing of simple axisymmetric parts. Tisza (1995) from University of Miskolc, Hungary developed a Metal Forming Expert (METEX) system for sheet metal forming applications. The system used AutoCAD and AutoLISP to generate possible solutions for deeply formed shapes. An expert system namely ASFEX (Axisymmetric Sequence Forming Expert System) was developed by the Engineering Research Centre for Net Shape Manufacturing (ERC/NSM) (Esche et al. 1996). This system used design rules to generate process sequences for multistage drawing of round cups and tool geometry for each station of the sequence. A compact and practical CAD/CAM system for design of die for irregular shaped stator and rotor parts with bending and piercing operations was developed by Choi et al. (2000). Researchers at Indian Institute of Technology, Bombay, Mumbai, India (Pilani et al. 2000) proposed a neural network and knowledge-based approach to design a hybrid intelligent system for generating an optimal die face for forming dies. Researchers from Department of Mechanical and Automation Engineering, National Kaohsiung First University of Science and Technology, China (Lin and Hsu 2008a; Lin et al. 2008a, c) developed a knowledge-based parametric design system to automate the design of main components of drawing die (Lin 2008a). Similarly they also developed another automated die design system using prebuilt design knowledge-base and database on the platform of CATIA software (Lin 2008b). Further, researchers also developed an integrated CAD/CAM/CAE system for design of an automobile stamping die using concurrent engineering approach (Lin 2008c). Some researchers (Lin et al. 1989; Cheok et al. 1994; Huang et al. 1996; Ismail et al. 1995, 1996; Singh and Sekhon 1996, 1998; Kim et al. 2002; Chu et al. 2004, 2008; Tor et al. 2005; George-Christophe et al. 2005; Kumar and Singh 2007a, b, c, 2008, 2011; Hussein et al. 2008; Giannakakis and George-Christopher 2008; Ghatrehnaby and Arezoo 2009; Tsai et al. 2010) developed KBSs for design of single operation dies (shearing, blanking, bending, etc.) and progressive dies.

The reviewed literature on CAPP, computer-aided die design, and knowledge-based deep drawing die design systems reveals the growing interests of worldwide researchers and technocrats in the area of automation of sheet metal die design process using various CAD systems and AI techniques. Limited research efforts are found in the area of automation of deep drawing die design. Even these reported systems are not capable to automate all activities of traditional die design process. Further these systems need considerable interactive inputs from experienced die designers and finally to take appropriate decisions at various stages of die design process planning, strip-layout design, selection of type and size of die components; and die modeling.

3 Considerations for Design of Deep Drawing Die

3.1 Process Planning

During process planning of deep drawing, the die designer or process planner has to determine various process parameters such as limiting draw ratio, die radius, punch radius, clearance between punch and die, punch velocity, type of lubricant etc. (Naranje and Kumar 2013a). These process parameters depend on sheet material, sheet thickness, type of die, accuracy requirement and complexity of part geometry, etc. Generally the limiting draw ratio (blank diameter to cup diameter) is taken as 1.8 for aluminum; 1.9 for steel and 2.0 for stainless steel sheet material. Die radius should be four to six times of material thickness for steel and five to ten times for stainless steel and aluminum. Punch radius should be at least four to eight times of material thickness for steel, and eight to ten times for aluminum sheet material. Generally it is recommended that punch-die clearance should be at least 1.10 times of sheet thickness. Experienced process planners recommend that punch velocity should be 0.4 m/s for deep drawing of steel and 0.15–0.2 m/s for stainless steel and aluminum alloys. Lubricants must be checked for compatibility with sheet material.

3.2 Strip-Layout Design

For the design of strip-layout, die designer has to identify the operations required and their sequence; and determine the details of each operation for production of defect free deep drawn parts (Naranje and Kumar 2013b). Design features of different part types should be produced at separate stations. If there is a hole inside the deep drawing shape, then it should be worked after the deep drawing operation. When two stages are used to lance the strip, there should be minimum 3.0 mm distance between two lance operations. Sequence of operations should be in such a way that all features and tolerances can be controlled. Once the sequence of operations is established, idle stations can be inserted if necessary. Idle stations are included to strengthen a die and to incorporate future design modifications. The strip width and feed distance depend on the sheet thickness, dimensions of blank, direction of sharp edge of sheet, and number of stations. Where deep tapered shells are required with a height to diameter ratio of greater than one half, a stepped shell with vertical walls should be first produced and then redrawn to produce the final shape.

3.3 Selection of Die Components

Selection of type and size of die components is a vital step in the design process of a deep drawing die. A deep drawing die consists of several components including die block, die gages, strippers, stripper plate, punch plate, back plate, die-set, and fasteners. The size of die block depends on sheet thickness, sheet material, direction of sharp edge of strip, strip size, and die material. Dimensions of die gages mainly depend on size of stock strip. It is necessary to maintain a minimum gap of about 5–10 times of sheet thickness between fixed stripper plates and die plate. The size of stripper plate corresponds to the size of die block. Stationary strippers are provided with a milled channel in its bottom surface to accommodate and guide the strip material. The width of channel in the stripper should be equal to the strip width plus adequate clearance to allow for variations in strip width. The height of the channel should be at least equal to 1.5 times of sheet thickness. The stripping force depends on several factors such as type and thickness of strip, lubrication, any galling or metal pickup on the punch, and sharpness of punch and die. The thickness of punch plate depends on punch diameter. Length and width of punch plate are usually same as that of die block. Backup plates are hardened and normally interposed between small perforator punches and punch holder. The backup plate is generally about 10–12 mm thick.

A die-set is a unit component constituted of punch holder, die holder, guide post, and guide bush. Open die-set is generally used to manufacture simple parts in small quantities and where loose tolerances are required. Pillar die-set is used where greater accuracy is required. Dimensions of die-set depend on part quantity, dimensional tolerance of the component, clearance between punch and die, and clearance between guide posts and bushings. Type of die-set is selected by considering size of the press opening, requirements for strength and stability of the tool, amount of downtime and cost to regrinding, ease in maintenance and repairs and for assembly as well. Die shoe forms the base of the die-set and in majority of die-sets the guide posts are mounted on it. The die shoe thickness is based on how much force can be expected during cutting and forming operations. The length of guideposts should be sufficient so that it never come out of their bushings during the press operation (Smith 1990). The guide pins should be 6.5 mm shorter than the shut height of the die. For selection of die-set, die designer needs to determine the type and size of die-set (Waller 1978). Selection of the type of die-set depends on the type of sheet metal operation, part quantity, and job accuracy. Dimensions of the die-set depend upon the length and width of the die and its placement in the die-set. The primary purpose of fasteners is to clamp together all the die components in a safe and secure manner. Whenever possible hex-socket head cap type screws should be used. For die-sets of greater weight, an additional socket cap screw should be inserted through the upper die shoe to the underside of the ram. Screw head holes must be counter-bored in the die section and screw threads must enter into die components at least 1.5 times of its diameter. To achieve the precise alignment at least two dowels per block are essential and must be press-fitted. The number and size of screws are determined by estimating the space available and the load to be resisted. Generally four Allen bolts are used at the four corners of die block.

3.4 Modeling of Die Components and Die Assembly

Modeling of plate elements of a die requires the dimensional data of die block, die gages, stripper plate, punch plate and back plate. For automatic 2-dimensional (2-D) modeling of plate elements of deep drawing die, drawing commands of AutoCAD such as LINE, PLINE, CIRCLE, FILLET, LAYER, etc., can be invoked. Similarly, for 3-dimensional (3-D) modeling of die components and die assembly in the drawing editor of AutoCAD software, AutoCAD commands such as ORBIT, EXTRUDE, UNION, SUBTRACT, REVOLVES, SWEEPS, etc., can be invoked (Naranje and Kumar 2013c).

Based on the above considerations, a KBS, namely, INTDDD (Intelligent Design of Deep Drawing Dies) is developed for intelligent design of deep drawing dies.

4 Intelligent Design System: INTDDD

4.1 Methodology for Development of Proposed System

Various steps involved in development of proposed system are knowledge acquisition, framing of production rules, verifications of production rules, selection of knowledge representing language, identification of hardware, development of knowledge base, and construction of user interface (Kumar and Singh 2004; Kumar et al. 2006). Domain knowledge for development of the proposed system is essentially collected by online and off line discussion with experience die designers, process planners, design consultants, and shop floor engineers of different stamping industries, and reviewing published research articles, industry catalogs and manuals. Heuristics knowledge acquired for each module of the proposed system was framed into the production rules of IF (condition)-THEN (action) variety. These production rules framed for each module were cross-checked from other teams of die design experts by presenting them IF-condition of the production rule of IF-THEN variety. The system overall comprises of more than 1000 production rules of IF-THEN variety. A sample of production rules so framed, verified and thereafter incorporated in various modules of the proposed systems is given in Table 1 (Naranje and Kumar 2012, 2013a, b, 2014a, b). The sequencing of production rules is unstructured as this arrangement allows insertion of new production rules even by a relatively less-experienced knowledge engineer. Knowledge base of the proposed system is constructed by coding of production rules using AutoLISP language. The user inputs’ information provides guidance to the inference engine as to what ‘IF-THEN’ rules to fire and which process of information are needed from the knowledge base. In the proposed system forward chaining search strategy is used for searching the solution. User interface of the system is developed using Visual Basic 6 and interfaced with AutoCAD software and AutoLISP language. User receives recommendations or outputs though user interface either on AutoCAD screen or VB forms. The user is also guided in a friendly manner throughout the consultation on how to proceed further after execution of each module. The proposed system is implemented on PC (Pentium 4 CPU, 2.0 GHz, 2 GB RAM) with Autodesk AutoCAD software.

4.2 Organization of the Proposed System

The proposed system labeled as INTDDD has been organized into various subsystems and modules. Organization of the system is shown in Fig. 2 (Naranje and Kumar 2014a). Execution of the various subsystems and modules are briefly described as under.

4.2.1 Subsystem PPDDP

The subsystem namely PPDDP is developed for process planning of axisymmetric deep drawn parts (Naranje and Kumar 2013a, 2014b). The system consists of three modules namely BLDIA, PROCPAR and DRWSEQ. The system PPDDP assists the process planers and die designers of stamping industries for calculation of blank diameter, selection of process parameters, and development of process sequence for axisymmetric deep drawn sheet metal parts.

For development of module BLDIA, a feature library of axisymmetric deep drawn parts is constructed for part modeling and blank size calculation. It consists of various primitives shapes such as ring, cylinder, taper, convex, concave, disk, etc. Various shapes of part features and the mathematical formulas for calculation of their surface area stored in this feature library are listed in Table 2. A trim allowance is also considered to compensate the thinning and thickening of material during deformation. Production rules incorporated in the module are coded in AutoLISP language. Execution of the module BLDIA is depicted in Fig. 3. On loading the module through a graphical user interface (GUI), drawing editor window of AutoCAD displays feature library on AutoCAD screen. The module invites the user to select the primitives required to model the part geometry and then to enter the dimensions of selected primitives. The dimensions of selected primitives are stored in a data file labeled as PARTDIM.DAT. After selection of all the required primitives from feature library, the module models the part geometry in the drawing editor of AutoCAD and calculates its surface area and blank diameter. The calculated blank diameter with/without trimming allowance is stored in a data file namely BLDIA.DAT and part drawing is stored in a drawing file labeled as PARTMOD.DWG.

The module PROCPAR is developed to determine the appropriate values of various process parameters. Module displays the output in the form of appropriate values of drawing force, blank holding force, draw measures, clearance, type of lubricant, draw speed, air vent size, etc., which are automatically stored in an output data file PROCPAR.DAT.

The module DRWSEQ is developed to assist die designers and process planners for the determination of suitable draw sequence for manufacturing of deep drawn parts. This module generates a sequence plan on the basis of geometric profile characteristics of the parts and formability of sheet material. The module is designed to take required inputs such as production requirement and tolerance on the part automatically from the part data file PART.DAT and various process parameters from PROCPAR.DAT. The user is also invited to enter other required inputs such as type of press, diameter of upper cylindrical section, height of lower cylindrical section, length of taper section, etc., through graphic user interface (GUI). As soon as the user enters all required inputs, the module generates the process sequence on AutoCAD screen which is stored automatically in a drawing file DRWSEQ.DWG. The data related to draw sequence at each stage of deep drawing is stored in a data file namely DRWSEQ.DAT.

4.2.2 Subsystem ISDSL

The subsystem ISDSL is developed for design of strip-layout for production of axisymmetric deep drawn parts (Naranje and Kumar 2013b, 2014b). The proposed system has seven modules namely, (i) module IDOPR for identification of operations, (ii) module SEQOPR for sequencing of operations, (iii) module SELPLT for selection of piloting scheme, (iv) module OPSTG for staging of operation, (v) module SLWS for selection of strip size, (vi) module BLOUT for modeling of blank layout and (vii) module MSLYT for modeling of strip-layout in the drawing editor of AutoCAD. The execution of proposed system is shown in Fig. 4.

4.2.3 Subsystem DDCOMP

The subsystem DDCOMP is developed for selection of major components of deep drawing die. The system is structured in form of eight modules, namely (i) module DBLCK for selection of size of die block, (ii) module DGAGE for selection of size of die gages, (iii) module STRP for selection of stripper, stripper plate, (iv) module PUNSEL for selection of punch details, (v) module PBPLT for selection of size of punch plate and backup plate, (vi) module BHOLD for selection of size of blankholder, (vii) module DSS for selection of type and size of die-set, and (vii) module FSTN for selection of fasteners.

The execution of proposed system is shown in Fig. 5 (Naranje and Kumar 2012, 2014a).

4.2.4 Subsystem AUTODDMOD

The subsystem AUTODDMOD is developed for automatic modeling (2-D and 3-D) of deep drawing die components and die assembly in the drawing editor of AutoCAD (Naranje and Kumar 2013c, 2014a). The proposed system consists of nine modules namely, (i) module DBLCKMOD for modeling of die block, (ii) module STRPMOD for modeling of stripper plate, (iii) module BPLTMOD for modeling of back plate, (iv) module PPLTMOD for modeling of punch plate, (v) module BLNKHMOD for modeling of blank holder, (vi) module BBDSMOD for modeling of bottom bolster of die-set, (vii) module TBDSMOD for modeling of top bolster of die-set, (viii) module DBAMOD for modeling of die bottom assembly, and (ix) module DTAMOD for modeling of top assembly of deep drawing die.

The outputs of various modules developed for selection of die components are recalled automatically during execution of the proposed subsystem. Execution of the proposed subsystem is depicted in Fig. 6. The first module namely DBLCKMOD takes required inputs in form of type and size of die block and fasteners from output data files generated during the execution of modules developed earlier for selection of design of die block and selection of fasteners. This module also recalls the drawing file of strip-layout labeled as MSLYT.DWG generated during execution of strip-layout module. The module is capable to generate 2-D and 3-D drawings of die block automatically in the drawing editor of AutoCAD software. The module is designed to save the top and front views of die block automatically as a global block, namely, WDBLCKMOD for its further use in modeling of die assembly. The module namely STRPMOD is constructed for automatic modeling of stripper plate. Inputs in form of size of stripper plate and fasteners are read automatically from the data files namely STRP.DAT and FSTN.DAT, generated during the execution of module developed earlier respectively for selection of stripper and selection of fasteners. The output of this module is in the form of 2-D and 3-D drawings of stripper plate is automatically stored in output global block, namely, WSTRPMOD in ‘.DWG’ format. The next module namely BPLTMOD is developed to model top and front views of back plate of deep drawing die. The module takes its input in form of dimensions of back plate from the data file PBPLT.DAT and fastener data from the data file FSTN.DAT. Output of this module includes orthographic and 3-D view of back plate and are automatically saved as a global block namely WBPLTMOD. The module labeled as PPLTMOD is developed to model punch plate automatically in the drawing editor of AutoCAD.

Similar to previous module, this module also takes inputs directly from output data file PBPLT.DAT and FSTN.DAT. The outputs of the module in the form of orthographic and 3-D view of punch plate are automatically saved as a global block namely WPPLTMOD. The next module namely BHOLDMOD of the system has been designed to model blank holder of deep drawing die. It recalls the data file BLHOLD.DAT to read size of blank holder. The outputs of this module in the form of orthographic and 3-D view of blank holder are automatically saved as a global block namely WBHOLDMOD. The modules labeled as BBDMOD and TBDMOD are developed, respectively, for automatic modeling of bottom bolster and top bolster of die-set of deep drawing die. These modules recall data files namely DST.DAT, DIMDS.DAT, and FSTN.DAT to take inputs in the form of type of die-set, its dimensions and size of fasteners.

The drawings of bottom bolster and top bolster generated by these modules are automatically saved as global blocks, respectively, labeled as WBBDSMOD and WTBDSMOD. These can be recalled during the modeling of die assembly. The next module namely DBAMOD is developed for automatic modeling of bottom assembly of deep drawing die. The bottom assembly consists of bottom bolster, die block, and stripper plate. The module reads the data from data files DST.DAT and DIMDS.DAT. On the basis of type of die-set, it computes the reference point on die-set for inserting global blocks of die block and stripper plate. Next, it inserts the global blocks of die block and stripper plate generated during execution of previous modules relative to the bottom bolster on the calculated reference point. The complete dimensioned orthographic views of bottom die assembly are automatically saved as a drawing file namely DBAMOD.DWG. The last module namely DTAMOD of the proposed system is developed for automatic modeling of the top assembly of deep drawing die. The module recalls the data files DSS.DAT and DIMDS.DAT to read type of die-set and their dimensional details. Next, it recalls the global block of top bolster of die-set and inserts the global blocks of back plate and punch plate on the calculated reference point. The 2-D and 3-D views of top die assembly are automatically saved as DTAMOD.DWG.

5 Validation of the System INTDDD

The developed system INTDDD has been tested for various types of industrial deep drawn sheet metal parts for design of deep drawing die. A sample run of the system modules for one typical deep drawn part (Fig. 7) is depicted in Figs. 8, 9, 10, 11, 12 and 13. The outputs of various system modules are found to be reasonable and very similar to those actually practiced by domain experts in industry (namely M/s GEC Private Limited, Pune, India) for the example part. The proposed system has also been tested successfully in other sheet metal industries including M/s Shrys Tool Makers, Pune, M/s Hindustan pressings Pvt. Ltd., Pune, M/s Allwin press tools, Pune, M/s G & G Engineering, Pune, and M/s Nirmiti Stampings Pvt. Ltd. Pune, India for various types of axisymmetric deep drawn sheet metal parts. The outputs generated by the proposed system for various types of axisymmetric deep drawn parts were found very similar to that developed by the domain experts in these industries. The proposed system is capable to execute the design task of deep drawing die in less than 45 min. Also notable feature of the proposed system is its low cost of implementation because it can be implemented on a PC having AutoCAD software. Further, knowledge base of the system is flexible enough to accommodate new knowledge or editing of existing knowledge easily due to advancement in sheet metal technology in the future (Fig. 14).

6 Conclusion

This chapter is focused on automatic design of deep drawing die for axisymmetric parts. Problems in traditional process of die designs are highlighted and then R&D efforts applied by worldwide researchers in this domain are discussed. A knowledge-based system developed by authors for design of deep drawing dies for axisymmetric parts is described. The developed system consists of more than 1000 production rules of ‘IF-THEN’ variety. To construct the knowledge base of proposed system, these rules are coded in AutoLISP language and user interface is created using Visual Basic 6.0 on AutoCAD platform. The system has been tested for various types of industrial axisymmetric deep drawn parts. Recommendations imparted by the system modules for process planning, strip-layout design, selection of die components, and the drawings generated by the system were found to be reasonable and very similar to those actually practiced in stamping industries. The developed system is capable to execute the whole task of deep drawing die design in less than an hour. The system can be implemented on a PC having AutoCAD software and therefore its low cost of implementation makes it affordable by small and medium scale sheet metal industries. Further, the system is flexible enough as its knowledge base can be extended or modified easily on the advancement of technology in sheet metal industries.

References

Abbassi F, Zghal A (2007) A CAPP system for axisymmetrical deep drawing parts. Int J Autom Control 1:118–132

Adachi M, Inoue K, Funayama T (1983) Integrated CAD system for progressive dies. Fujitsu Scient Tech J 19(2):133–148

Altan T (1987) Design and manufacture of dies and molds. CIRP Ann 36:455–462

Bergstrom K, Kivivuori S, Osenius S, Korhonen A (1988) Computer aided design of progressive die. In: Chersot Int JL, Ohate E (eds) Modeling of metal forming process. Kluwer Academic Publishers, NY, pp 155–162

Cheok BT, Foong KY, Nee AYC, Teng CH (1994) Some aspects of a knowledge-based approach for automating progressive metal stamping die design. Comput Ind 24:81–96

Choi JC, Kim C, Choi Y, Kim JH, Park JH (2000) An integrated design system for deep drawing or blanking products. Int J Adv Manuf Technol 16(11):803–813

Choi TH, Choi S, Naa KH, Baeb HS, Chung WJ (2002) Application of intelligent design support system for multi-step deep drawing process. J Mater Process Technol 20:76–88

Choudhary S, Allada V (1999) Integrated manufacturing System for precision Press Tooling. Int J Adv Manuf Technol 15:356–365

Chu CY, Tor SB, Britton GA (2004) A graph theoretic approach for stamping operations sequencing. Proc Instit Mech Eng Part B J Eng Manuf 218:467–471

Chu CY, Tor SB, Britton GA (2008) Theoretic algorithm for automatic operation sequencing for progressive die design. Int J Prod Res 46:2965–2988

Esche S, Khamitkar S, Kinzel G, Altan T (1996) Process and die design for multi-step forming of round parts from sheet metal. J Mater Process Technol 25:24–33

Eshel G, Barash M, Chang TC (1986) Rule-based system for automatic generation of deep drawing process outlines. Comp Aided Intell Process Plan 1:1–115

Fazli A, Arezoo B, Hasanniya M (2014) An automated process sequence design and finite element simulation of axisymmetric deep drawn components. J Manuf Sci Eng 136:031005–031005-9

Fogg B, Jaimeson S (1975) The influencing factors in optimizing press tool die layouts and a solution using computer aids. CIRP Ann 24:429–434

George-Christophe V, Segredou I, Giannakakis T (2005) Logic programming for process planning in the domain of sheet metal forming with progressive dies. J Intel Manuf 16:479–497

Ghatrehnaby M, Arezoo B (2009) A fully automated nesting and piloting system for progressive dies. J Mater Process Technol 209:525–535

Giannakakis T, George-Christopher V (2008) Sheet metal cutting and piercing operations planning and tools configuration by an expert system. Int J Adv Manuf Technol 36:658–670

Huang K, Ismail HS, Hon KKB (1996) Automated design of progressive dies. Proc Inst Mech Eng Part B J Eng Manuf 210:367–376

Hussein HMA, Abdeltif LA, Etman MI, Barakat AF (2008) An approach to construct an intelligent system in sheet metal cutting die design. In: Proceedings of 9th Cairo university international conference on mechanical design & production (MDP-9), Cairo, Egypt, January 8–10, pp 61–70

Ismail HS, Chen ST, Hon KKB (1996) Feature-based design of progressive press tools. Int J Mach Tools Manuf 36:367–378

Ismail HS, Hon KKB, Huang K (1995) An intelligent object-oriented approach to the design and assembly of press tools. CIRP Ann 44:91–96

Kalpakjian S, Schmid S (2009) Manufacturing processes for engineering materials, Dorling Kinderly (India) Pvt. Ltd. New Delhi

Kang SS, Park DH (2002) Application of computer-aided process planning system for non-axisymmetric deep drawing products. J Mater Process Technol 124:36–48

Karima M (1989) On the micro and macro perspectives of stamping engineering. J Mater Shaping Technol 7:213–227

Karima M, Richardson J (1987) A knowledge based system framework for computer-aided technology in metal forming. J Mech Work Technol 15:253–273

Kaushish JP (2010) Manufacturing Processes, 2nd edn. PHI Learning Pvt. Ltd., New Delhi, India

Kim C, Park YS, Kim JH, Choi JC (2002) A study on the development of computer-aided process planning system for electric product with bending and piercing operations. J Mater Process Technol 130–131:626–631

Kumar S, Singh R (2004) A low cost knowledge base system framework for progressive die design. J Mater Process Technol 153–154:958–964

Kumar S, Singh R (2007a) Knowledge-based system for selection of progressive die components. J Achievements in Mater and Manuf Eng 20:475–479

Kumar S, Singh R (2007b) A short note on an intelligent system for selection of materials for progressive die components. J Mater Process Technol 182:456–461

Kumar S, Singh R (2007c) An intelligent system for automatic modeling of progressive die. J Mater Process Technol 194:176–183

Kumar S, Singh R (2008) Automation of strip layout design for sheet metal work on progressive die. J Mater Process Technol 195:94–100

Kumar S, Singh R (2011) An automated design system for progressive die. Expert Syst Appl 38:4482–4489

Kumar S, Singh R, Sekhon GS (2006) CCKBS: a component check knowledge base system for accessing manufacturability of sheet metal parts. J Mater Process Technol 172:64–69

Lin BT, Hsu SH (2008a) Automated Design system for drawing die. Expert Syst with App 34:1586–1598

Lin BT, Kuo CC (2008) Application of an integrated CAD/CAM/CAE system for stamping dies for automobiles. Int J Adv Manuf Technol 35(9–10):1000–1013

Lin BT, Kuo CC (2011) Application of the fuzzy based taguchi method for the structural design of drawing dies. Int J Adv Manuf Technol 55:83–93

Lin BT, Chang M, Huang HL, Liu CU (2008a) Computer-aided structural design of drawing dies for stamping processes based on functional features. Int J Adv Manuf Technol 23:1670–1677

Lin BT, Chan CK, Wang JC (2008c) A knowledge based parametric design system for drawing dies. Int J Adv Manuf Techno 36:671–680

Lin ZC, Hsu CY, Yao KH (1989) Planning and building an integrated design software of blanking and piercing dies (ESSCP) with a micro expert system as a main structure. J Chin Soc Mech Eng 10:101–120

Nakahara S, Toshio K, Tamura K, Asuke F, Soda C, Nakamura, T (1978) Computer aided progressive die design. In: Proceedings of the 19th machine tool design research conference, 1978, London, pp 171–176

Naranje V, Kumar S (2012) A knowledge based system for selection of components of deep drawing die. Am J Intell Syst 2(2):1–11

Naranje V, Kumar S (2013a) A knowledge based system for process planning of axisymmetric parts. Key Eng Mater 549:239–246

Naranje V, Kumar S (2013b) A knowledge-based system for design of strip-layout for progressive deep drawing dies. Int. J Comp Appl in Technol 48(3):222–234

Naranje V, Kumar S (2013c) An intelligent CAD system for automatic modeling of deep drawing die. Int J Comp Appl in Technol 48(4):330–344

Naranje V, Kumar S (2014a) A knowledge based system for automated design of deep drawing die for axisymmetric parts. Expert Syst Appl 41(4):1419–1431

Naranje V, Kumar S (2014b) An expert system for selection of process parameters and strip layout design for production of deep drawn sheet metal parts. Int J Internet Manuf Serv 3(3):263–278

Nee AYC (1994) Some aspects of knowledge based approach for automating progressive metal stamping die design. Comput Ind 24:55–70

Park DH, Prasad KDVY (2004) Computer aided process planning for non-axisymmetric deep drawing products. In: Proceedings of the 8th international conference on numerical methods in industrial forming processes, June 13–17, 2004, Columbus, Ohio, USA, pp 1985–1988

Park DH, Prasad KDVY (2005) Industrial application of surface area calculating system (SACS) in non-axisymmetric deep drawing process. J Mater Process Technol 164–165:1578–1583

Park SB (1999) An expert system of progressive die design for electron gun grid parts. J Mater Process Technol 88:216–221

Park SB, Choi Y, Kim BM, Choi JC (1998) A study on the computer-aided process design system of axisymmetric deep drawing products. J Mater Process Technol 75:17–26

Pilani R, Narasimhan K, Maiti SK, Singh UP, Date PP (2000) A hybrid intelligent systems approach for die design in sheet metal forming. Int J Adv Manuf Technol 16:370–375

Potocnik D, Pesan B, Balic J, Ulbin M (2011) Intelligent system for the automatic calculation of stamping parameters. Adv Prod Eng Manag 6:129–137

Potocnik D, Ulbin M, Dolsak B (2012) Knowledge based system for supporting the design of a plate-press. J Comput Inform Sci Eng 12:1–5

Prasad YKDV, Somasundaram S (1992) CADDS: An automated die design system for sheet metal blanking. Comput Control Eng J 3:185–191

Schaffer G (1971) Computer designs progressive dies. Am Machinist 22:73–75

Shi X, Chen J, Peng Y, Ruan X (2002) Development of a knowledge based process planning system for an auto panel. Int J of Adv Manuf Technol 19:898–904

Shirai K, Murakami H (1985) Development of a CAD/CAM System for progressive dies. CIRP Ann 34:187–190

Sing WM, Rao KP (1997) Knowledge-based process layout system for axisymmetrical deep drawing using decision tables. Comput Ind Eng 32:299–319

Singh R, Sekhon GS (1998) An expert system for optimal selection of a press for a sheet metal operation. J Mater Process Technol 86:131–138

Singh R, Sekhon GS (1996) A computerized diagraph and matrix approach for evaluation of metal stamping layouts. J Mater Process Technol 59:285–293

Sitaraman SK, Kinzel GL, Altan T (1991) A knowledge base system for process sequence design in axisymmetric sheet metal forming. J Mater Process Technol 25:247–271

Smith DA (1990) Die Design Handbook, 3rd edn. Society of Manufacturing Engineers, New York

Tisza M (1995) Expert systems for metal forming. J Mater Process Technol 53:423–432

Tor SB, Britton GA, Zhang WY (2005) Development of an object-oriented blackboard model for stamping process planning in progressive die design. J Intel Manuf 16:499–513

Tsai YL, You CF, Lin JY, Liu KY (2010) Knowledge-based engineering for process planning and die design for automotive panels. Comput Aided Des Appl 7:75–87

Waller J (1978) Press tool and press Working. Portcullis press, Bristol, Great Britain

Wifi AS, Gomaa AH, Abdel-Magied RKS (2004) Deep drawing process design and CAPP system for axisyemmetric complex shells. In: Proceeding of Cairo university conference on mechanical design and production, Jan 4–6, 2004, Cairo, Egypt, pp 1–12

Wifi AS, Gomaa AH, Abdel-Magied RKS (2005) Deep drawing process design and CAPP system for box shaped parts. In: Proceeding of tehran international congress on manufacturing engineering (TICME2005) Dec 12–15, 2005, Tehran, Iran, pp 1–9

Xiao X, Chen S, Wang G, Xiao J (1990) An expert system for process planning for drawing. Adv Plastic Technol 23:545–549

Zhang WY, Tor SB, Britton GA (2006) Indexing and retrieval in case based process planning for multi-stage non-axisymmetric deep drawing. Int J Adv Manuf Technol 28:12–22

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Naranje, V., Kumar, S. (2017). Knowledge-Based System for Design of Deep Drawing Die for Axisymmetric Parts. In: Kumar, S., Hussein, H. (eds) AI Applications in Sheet Metal Forming. Topics in Mining, Metallurgy and Materials Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-2251-7_5

Download citation

DOI: https://doi.org/10.1007/978-981-10-2251-7_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-2250-0

Online ISBN: 978-981-10-2251-7

eBook Packages: EngineeringEngineering (R0)