Abstract

In sheet metal industries, blanking dies are considered as basic types of stamping dies. Die design is a highly experience-based task. There is no computer-aided system available for automation of design of blanking dies. This chapter describes a knowledge-based system for design of sheet metal blanking dies. The developed system can be used to analyze different die design techniques and complete the design task base on an optimum design configuration. A knowledge base for the selection of a most suitable design from 14 different designs has been constructed. The developed system uses parametric design approach for design and finally engineering drawings in 2-dimensions (2-D) and 3-dimensions (3-D) can be generated automatically. The system is tested through sample runs. The system was built on the AutoCAD platform with Visual Basic, AutoLISP programming languages and MS-Access for the database.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

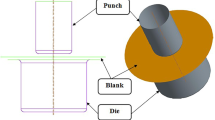

Blanking die is a single station cutting die which deals with regular-and irregular-shaped sheet metal parts. It is usually used in the first operation for cutting off the blank when the sheet metal part is manufactured in a serious of stamping operations. This makes blanking dies (design and manufacturing) an important tool in sheet metal industries. Although blanking dies seem to be a simple type of die, yet its design process is complex and requires highly experienced persons. There is a variety of shapes of blanking dies to produce different types of sheet metal parts with different sizes, shapes, thicknesses, designs, and material types. Classification and coding of sheet metal blanking dies can be a good step for knowing the relation between die part shapes and die shapes. In this chapter, a new classification is proposed. Blanking die types are classified into two main groups—fixed and movable stripper types. Each group can be further classified, according to its size (i.e. small, small–medium, medium, medium large, large, and extra-large sizes). Each size has its own design characteristics based on the added or removed components in its classification skeleton. In fact, optimum design is a tool for finding out the most suitable size of die.

Computer-aided selection of type of blanking dies that directs to optimum solution, has not been reported so far in the available literature. It may be the first time herein to study this idea. This type of research can result in a fully automated die design system using knowledge-based approach and artificial intelligence (AI). The computer-aided design and drafting of sheet metal blanking die involves two main tasks. The first one is the development of the knowledge-base (KB) for die design; and the second is the parametric design functions.

Research efforts made in the area of computer-aided die design mainly concentrated on describing a specific size of blanking dies. For example, Ruan et al. (1987) developed a blanking CAD system called “SBDS.” Prasad and Somasundaram (1991, 1992) proposed two systems “CASNS” for sheet metal nesting, and “CADDS” for sheet metal blanking dies. The proposed systems were for progressive die. Wong (1992) described a system called BECAM which is suitable for medium sized dies. Huang et al. (1993) constructed a Computer-Aided Press-Tool Design “CAPTD.” It deals with small blanking dies. Choi et al. (1998) discussed a compact CAD/CAM system for blanking die. Nye (1999) proposed a technique for sheet metal nesting for blanking dies. Hussein et al. (1999) constructed JUPITER’99 which is used only for medium-large size blanking dies. Pacanowski (2000) discussed a computer-aided design of the lower shedders used in blanking dies. Singh and Sekhon (2003) reported a special package called AUDIEDR which is suitable for small–medium type blanking dies. Also, Gürün et al. (2006) proposed two systems for strip layout and die design using Visual Lisp and VBA. Shaikh and Desai (2006) used Inventor as platform for blanking dies. Researchers Zamzam et al. (1988) and Bedewy et al. (1993), from Egypt have also contributed in the domain of blanking die design. In the domain of KBS/expert System for blanking die design, Akira (1982) described many shapes and classifications in blanking die designs. Lin et al. (1989) developed a system namely “ESSCP” for design of a simple blanking die shape. Zhao et al. (2001) discussed application of hybrid expert system in blanking process. Cheung (2001) reported a simple blanking die CAD using knowledge-based design. Recently, Sun and Song (2014) developed a KBS for blanking dies.

In fact, there is no system available till now to deal with all types and sizes of blanking dies. Rather, the existing systems are suited only for specific shape and size of blanked part. Therefore, it is meaningful to develop a computer-aided system for automated design of blanking dies for all types of stampings.

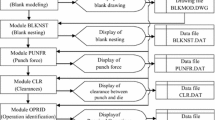

In this chapter, the functions of the KBS for designing blanking dies are first introduced. The sheet metal parts are analyzed by using methodologies, such as rule-based reasoning (RBR), which is the most widely used for solving such type of problems. The input parameters for the sheet metal part are thickness, diameter, length, width, contour length, area, the degree of accuracy, and quantity of parts to be produced per month. The output of KBS is in form of a digital number that gives an optimum design code. The system includes 60 case studies which are taken from actual and practical die design data base of reputed automotive manufacturers. The construction of the proposed system depends on three main programs—AutoCAD for solid modeling, MS-Access as a database for storing part data, and visual basic used as a design interface controller. The parametric functions control all the dimensions of die components with each other. It must be noted that the AutoCAD software does not support parametric technique, just like CATIA, Pro-Engineer, Inventor, SolidWorks, and the other recent CAD systems. In the present study, the parametric techniques under AutoCAD are customized as a tailor-made for blanking die design. The main purpose of using this technique is to automate design of blanking die.

2 Knowledge-Based Design Rules for Blanking Dies

In this section, the parameters of sheet metal parts are described for optimum designs of the sizes of the sheet metal blanking dies. The parts may have holes or bends but these design features are not considered in the present study.

2.1 Strip Thickness

Strip thickness is considered as the first parameter to be checked. It decides the main construction of die based on the type of the stripper. Listed in Table 1 are two rules for the classification of die type based on strip thickness.

2.2 Contour Length

The second parameter, contour length leads to the optimum size of die-block shape. Die block is the main component of a blanking die. The problem is that the contour length cannot alone lead to the correct die-block shape. For one specific contour length there can be numerous shapes. Those different part shapes (the same contour length with different dimensions) will determine the shape of the die block. To simplify this problem, there is a need to merge the parameters of part dimensions and contour length, in order to select the optimum design of the die block.

2.3 Main Part Dimension (Length/Width/Diameter)

Since sheet metal parts may have different shapes but approximately the same perimeter, the contour length itself will not lead to the optimum die block shape. Figure 1 shows four parts with different external shapes having approximately the same perimeter. Therefore, for each part shape, different die block is to be designed. The part dimensions alongside with the perimeter will lead to the selection of an optimum die block shape.

To simplify this problem, the contour length of blank part shape is converted into a diameter by dividing it by \( \pi \). The empirical relationship between the diameter and the corresponding die block shape is given in Tables 2 and 3. The die sizes are classified into 14 different sizes, 7 sizes with fixed stripper and the other 7 sizes with movable stripper. For both the groups, dies are coded as follows.

-

(i)

Small-size die with fixed stripper—D01,

-

(ii)

Small–medium die size with fixed stripper—D02, and so on.

-

(iii)

Medium size with fixed stripper—D03,

-

(iv)

Medium-large size with fixed stripper—D04,

-

(v)

Large size with fixed stripper—D05,

-

(vi)

Extra-large size with fixed stripper—D06,

-

(vii)

Medium-large size with ejector—D07

-

(viii)

Small-size die with movable stripper—D08

-

(ix)

Small–medium die size with movable stripper—D09, and so on.

-

(x)

Medium size with movable stripper—D10,

-

(xi)

Medium-large size with movable stripper—D11,

-

(xii)

Large size with movable stripper—D12,

-

(xiii)

Extra-large size with movable stripper—D13,

-

(xiv)

Medium-large size with ejector—D14.

Each die size of the 14 die shapes has its own die components. Table 4 shows some of the 7 die sizes with the fixed stripper.

3 Parametric Design in 2D

In the following sections, the parametric functions are discussed for 2D of fixed stripper medium-large size blanking die “D04” as it is the most popular die blanking size.

3.1 Blank Layout

Strip layout is generally done for the purpose of optimizing of the material utilization in blanking die design because averagely, the material cost takes 75 % of the entire cost of a stamped part. The resulting layout is determined by the nesting of two blanks to achieve the optimum material utilization.

Numerous studies have been carried out in blank nesting and a number of techniques have been developed and adopted, such as the Minkowski sum approach (Nye 1999), and the incremental rotation algorithm (Chow 1979; Nee 1984; Prasad et al. 1995; Lin and Hsu 1996).

In this system, we adopted the incremental rotation algorithm. When a blank, which can be a single one or a compound one consisting of more than one blank, is selected, the paired one is duplicated alongside of the initial one on its right side with a distance equal to the minimum bridge width between the blanks. At each rotation, the pitch is determined, the strip width is calculated with the minimum bridge width is added on both the top and the bottom of the blanks, and the material utilization is computed by

where \( \eta \) is the computed material utilization, n the number of blanks in the compound blank, W the strip width, and P the pitch of the layout.

A list of the data is generated for all the incremental rotational angles. The rotational angle corresponding to the maximum utilization may be adopted by the user or any other rotational angle may be chosen for engineering reasons. The material utilization data can be viewed graphically on in the dialog box, or in a data file, see Fig. 2.

It is logic to start blanking die design with the sheet metal nesting, as it is the process planning of the blanking die. Optimum and economical design of blanking die depends on the good laying of the blank on the strip. For this reason, taking blank layout into consideration for the design of blanking die is seen as a knowledge-based design parameter.

For the new economical layout position of the blank part, the system records this new position to be the start position for blank part in blanking die design process. Extreme coordinates of blank part are taken while the part lies in its new position.

For the blank (part) shown in Fig. 2, the optimum layout of the strip is shown in Fig. 3, which shows the material utilization report for the blank part in its proposed position. The system stores the blank part in its optimum position/orientation to control the punch position/orientation inside the die.

3.2 Die Block Boundary

The first parametric relation to be considered in the blanking die design is shown in Fig. 4. The blank part is surrounded by 4 points which represent the extreme points of the part. The points are the extreme upper point, the extreme right point, the extreme lowest right point, and the extreme lowest left point. These extreme points may fall on three different elements, (points, lines, or arcs). If the point falls on any of these elements, then a specific equation must be applied. The determination of coordinates of extreme points for the blank part contour shape is important in case of margin estimation between blank part and boundary of die. Figure 4 shows an example of determination of extreme points for the blank part shape and the die block allowable margins.

To determine the parametric relationship of the fixed stripper medium-large size blanking die, we must note the following.

The first 12 points extracted from the blank part shape are used as the base for the other 114 parametric points which are required to accomplish the whole blanking die design. As the first 12 points are a function of the die block thickness “H” (Hussein 1999), therefore the cutting force which is determined from a formula as given below must be set first. So the die block thickness “H” which is function of cutting force can be determined.

where:

- Ϭ:

-

Material of Sheet Metal

- FS:

-

Safety Factor

- ST:

-

Strip Thickness

- CL:

-

Contour Length (mm.)

- Wup =:

-

1.2H(Case of Arc), 1.5H(Case of Line), 2H(Case of Point)

- Wlp =:

-

1.2H(Case of Arc), 1.5H(Case of Line), 2H(Case of Point)

- Wmlp =:

-

1.2H(Case of Arc), 1.5H(Case of Line), 2H(Case of Point)

- Wmrp =:

-

1.2H(Case of Arc), 1.5H(Case of Line), 2H(Case of Point)

It should be mentioned here that P1, P2 to P7, P8 as in Fig. 4 are the extreme points of the blank part, while P9, P10 to P11, P12 are the left and right intersection points of the blank part boundary with the horizontal axis passing through the center of pressure. The allowable margins are taken such that:

where, H is the die block thickness.

Figure 4 shows the fore-mentioned stated relationship between blank part shape and both of strip layout and die block dimension. The present methodology in this proposed die block design is dependent on P, which is the X coordinate of the upper point, will remain the same for the die block, and the P2, which is the Y coordinate of the upper point, will change to be P17 which equals to P2 + Wup. The most right point on the die block boundary P3, P4. P3 which is the X coordinate of the right point of the blank part, will be changed to P45 on the die block boundary, i.e., P45 = P3 + Wmrp. The P4 which is the Y coordinate of the blank part, will be the same on the die block. P5 which is the X coordinate on the lower point of the blank part will be the same on the die block boundary. P6 which is the Y-Coordinate of the lower point of the blank part, will changed to P24, which equals to P6—Wlp. P7 which is the X coordinate of the most left point on the blank part will be changed to P44, which equals to P7-Wmlp. Finally, P8 which is the Y coordinates of the blank part will be the same on the die block boundary.

3.3 Die Block Parametres

The whole die block boundary is determined as a function of the blank part extreme point coordinates or variables, and the die block margin as illustrated in the following formulas:

- P17 =:

-

Y Coordinate of the Upper point − Die Block boundary = P2 + Wup

- P24 =:

-

Y Coordinate of the Lower point − Die Block boundary = P6 − Wlp

- P44 =:

-

X Coordinate of the max. Left point − Die Block boundary = P7 − Wmlp

- P45 =:

-

X Coordinate of the max. Right point − Die Block boundary = P3 + Wmrp

By this method, the die block boundary could be determined as a merging point between the four outermost points. For example, the upper right corner is determined as a merging point between the (Y-Coordinate) upper point and the (X-Coordinate) most right point. The point is determined by taking the Y-coordinate from the upper point with the X-coordinate from the most right point.

The new created point is P45(X-Coordinate) and P17 (Y-Coordinate). Figure 5 shows the method of determining the die block boundary points.

3.4 Fasteners and Dowel Pin Position

Figure 6 illustrates some parametric relations (Akira 1982) to determine the fasteners position. This position is controlled between the die opening [a3 = 1d] and the outside edges of die block [a1 = 1.13d], and then the dowel pin position determined as [a2 = 1d] and measured from the fastener position. It must be noted that d is the fastener hole and value equal to [1.1d]. Moreover, Table 5 shows the recommended fasteners sizes for the designer to select as related to the die block thickness H (Akira 1982).

The fastener and dowel pin position inside the die block (Akira 1982)

In Fig. 6, the parameters of the whole die block design in 2D are shown. The fastener position could be determined by adding new vertices P18, P23, P35, and P39. The vertices of the new parameters could be determined by applying the following parametric formulas:

Moreover, die opening can be determined by adding 1 mm to the blank part extreme points as follows:

3.5 Strip Boundary

The strip boundary is also a function of the sheet metal blank part extreme points and strip thickness. The resulted dimensions of the strip boundaries become the base of the guide rails boundary dimensions and spacing. Figure 7 shows the relationship between the part extreme points and the strip boundary.

To determine the strip layout boundary, the following parameters are considered.

- Nup =:

-

the distance between the part upper point and the strip boundary

- Nmlp =:

-

the distance between the part most left point and the strip boundary

- Nlp =:

-

the distance between the blank most left point and strip boundary

Nup, Nmlp, and Nlp are taken as (1.5 X Strip Thickness), where -

- Nup =:

-

the upper edge of the strip boundary

- Nmlp =:

-

the most left point of the strip boundary

- Nlp =:

-

The lower edge of the strip boundary

Then, the new point vertices are created to determine the boundary of the strip layout.

- P20 =:

-

Y Coordinate of the Upper point—Strip Boundary = P2 + Nup

- 220:

-

is taken as the value of the max right point of the strip boundary

- P43 =:

-

X Coordinate of the Max Left point—Strip Boundary,

= P7—Nmlp

- P22 =:

-

Y Coordinate of the Lower point—Strip Boundary,

= P6—Nlp

3.6 Parametric Relation of Die Holder Plate

In this section, the parametric relation of die holder plate is discussed as shown in Fig. 8. To get the die holder boundary, four more coordinates are added which are P27, P14, P32, and P42.

- P42 =:

-

X Coordinate for the Upper-left corner-Die Holder Boundary = P44 − 24

- P14 =:

-

Y Coordinate for the Upper-left corner-Die Holder Boundary = P17 + 24

- P32 =:

-

X Coordinate for the Lower-Right corner-Die Holder Boundary = P45 + 24

- P27 =:

-

Y Coordinate for the Lower-Right corner-Die Holder Boundary = P24 − 24

To get the Die Holder Opening, four more coordinates are added which are P46, P47, P36, and P21.

- P46 =:

-

X Coordinate for the Upper-left corner-Die Holder Opening = P7 – 1

- P47 =:

-

Y Coordinate for the Upper-left corner-Die Holder Opening = P2 + 1

- P36 =:

-

X Coordinate for the Lower-Right corner-Die Holder Opening = P3 + 1

- P21 =:

-

Y Coordinate for the Lower-Right corner-Die Holder Opening = P6 – 1

To get the fasteners and dowel pin positions for the die holder the following parameter formulas are considered:

- P40 =:

-

X Coordinate of the Die-Holder left bolt position, = P42 + 1.13 × D

- P38 =:

-

X Coordinate of the Die-Holder left pin position, = P40 + 1.3 × D

- P37 =:

-

X Coordinate of the Die-Holder right pin position, = P34 − 1.3 × D

- P34 =:

-

X Coordinate of the Die-Holder right bolt position, = P32 − 1.13 × D

- P16 =:

-

Y Coordinate of the Die-Holder upper row fasteners = (P14 + P17)/2

- P25 =:

-

Y Coordinate of the Die-Holder lower row fasteners = (P24 + P27)/2

To get the position of the stop pin position, the following formula can be applied:

- P41 =:

-

P44 − 12.5

3.7 Parametric Relation Between Die Holder Dimension and Die-Set Selection

The proposed system database includes seven different sizes of die-set which are used in an industry. To select the suitable die-set, the program checks the length and width of the die holder, and then checks which of company’s die-set is suitable to include this die holder. Figure 9 shows the schematic drawing of die-sets. The main dimensions of die-set are presented in Fig. 10 in which the shadow area shows the available area to include the die holder. If the die holder dimensions exceeded the shadow area, the program starts automatically and parametrically to design a new die-set (Hussein 2006). Moreover, Table 6 shows the decision table of die-sets for the products manufactured by the company provided with necessary dimensions.

To select the optimum die-set type and to define the position of the shank, a knowledge-based system is developed. The sample of rules incorporated in the proposed system is given in Table 7.

If condition is within the required range, then the result will be as follows: The selected die-set drawing will insert automatically in its position in the AutoCAD drawing file with respect to the other items of the blanking die. The factor k will take a value. The value of k is responsible of the insertion point of the shank in the AutoCAD drawing file. The shank must be inserted in its position in the upper plate of the die-set. Databases of shanks are added for this reason to the system as shown in Fig. 11. Another k factors k1 and k2 are taken into consideration to decrease the number of parameters required for design and drafting of the blanking die.

The full sketch of the parametric blanking die design in 2D is illustrated in Fig. 12. It must be noted that the whole structure of the blanking die can be achieved by 114 variables. Those 114 variables are determined after a significant simplification of the drafting arrangement as illustrated in Fig. 12. The traditional drafting arrangement will cause a large number of variables which will be necessary for blanking die construction. The problem in 3D parametric designs is easier, since the computer deals with every component as package and the number of variables decreases significantly.

4 Parametric Design in 3D

The parametric design in 3D is slightly different from the previous one. Figure 13 is a schematic drawing shows seven different parametric relations, which describe the main design idea or the proposed die codes. Each of the proposed die code has its own features which are suitable for producing the optimum blanking die design. The results of the suggested parametric relations as described in Fig. 13 are illustrated in Table 4. The knowledge base concerned with this table is discussed in Hussein et al. (2008). The parametric relations translated into variables by using the visual basic program. It is very difficult to define all those variables for the different 14 subprogram into the visual basic.

As a progressive step, a nested parametric relationship is suggested as shown in Fig. 14. The nested technique decreases the number of variables from about 350 different variables to about 30 variables only. Table 8 shows the nested parametric formulas suggested for constructing all 14 die codes in 3D Blanking Die Design.

This progressive step–nesting in die code parametric relationships has led to another progress which is the nested program modules. Table 9 shows how the nested program module simplifies the suggested die code paths which are suggested in Table 4. Moreover, the nested modules include the sub nested modules. As example, the die opening is a separate module runs from inside the die block module. The die opening module is illustrated in Fig. 15. Moreover, Fig. 16 shows the assembly and the disassembly of a 3D blanking die design resulted from the system. A Case study for selecting of AutoCAD version, selection of the optimum die code, and finally constructing 3D die design are shown in Figs. 17, 18, and 19 respectively

5 Conclusion

Parametric design of the sheet metal blanking die in both 2D and 3D is discussed. The parametric formulas for each component in both 2D and 3D are described in details. A list of 14 different shapes of the blanking die is also described, in both of fixed stripper type and movable stripper type. An innovation of nesting the 14 shapes into similar modules is also shown in this chapter. The proposed system can be foundation for development of a knowledge-based system for automated design of all types of sheet metal dies.

References

Akira O (1982) Die structure and design-illustrated. NAGOYA International Training Center, JAPAN International Cooperation Agency, JAPAN

Bedewy MK, Abdin M, Nassef G (1993) Bowing and spring-back in progressive piercing blanking of sheet metals. In: Proceedings of the 4th international conference of production and design for development, Ein–Shams University, Cairo, Egypt, 27–29

Choi J, Kim B, Cho H, Kim C (1998) A compact and practical CAD system for blanking or piercing of irregular-shaped sheet metal products and stator and rotor parts. Int J Mach Tools Manuf 38(8):931–963

Cheung K (2001) A knowledge based CAD system for the blanking of sheet metal product. Master Thesis, Department of Manufacturing Engineering and Engineering Management, City University of Hong Kong

Chow WW (1979) Nesting of a single shape on a strip. Int J Prod Res 17:305–322

Gürün H, Nalbant M, Dilipak H, Ozdemir A (2006) Computer aided design of the sequential piercing and cutting dies. J Fac Eng Arch Gazi Univ l 21(2):205–213

Huang K, Ismail H, Hon K (1993) CAPTD: a low-cost integrated computer aided design system for press-tool design. Proc. Instn. Mech. Engrs. Part B J Eng Manuf 207:117–127

Hussein HMA, Shebl MG, Ghobrial MI, Hassan NF (1999) Computer aided design and drafting of sheet metal blanking dies. Jupiter’99, Ain Shams Univ Sci Bull 34(4):611–624

Hussein HMA (2006) Computer aided design and selection of the die-set for sheet metal punching and blanking dies. In: International conference on manufacturing science and technology, (ICOMAST-2006), Melaka, Malaysia, pp 303–306

Hussein H, Abdeltif L, Barakat A, Etman M (2008) An approach to construct an intelligent system in sheet metal cutting die design. In: 9th Cairo university international conference on mechanical design & production (mdp-9) Cairo, Egypt, Jan 8–10

Lin ZC, Hsu CY (1996) An investigation of an expert system for shearing cut progressive die design. Int J Adv Manuf Technol 11:1–11

Lin Z, Hsu C, Yas K (1989) Planning and building an integrated design software of blanking and piercing dies (ESSCP) with a micro expert systems as a main structure. J Chin Soc Mech Eng 10(2):101–120

Nye TJ (1999) Optimal blanking die design for arbitrary blanks. Technical Papers of the NAMRI, Berkeley CA 19–24

Nee AYC (1984) A heuristic algorithm for optimum layout of metal stamping blanks. Annals of the CIRP 33:317–320

Prasad YKDV, Somasundaram S (1991) CASNS: a heuristic algorithm for nesting of irregular shaped sheet metal blanks. Comput Aided Eng J 8(2):69–73

Prasad YKDV, Somasundaram S (1992) CADDS: an automated die design system for sheet metal blanking. Comput Control Eng J 3(4):185–191

Prasad YKDV, Somasundaram S, Rao KP (1995) A sliding algorithm for optimal nesting of arbitrarily shaped sheet metal blanks. Int J Prod Res 33:1505–1520

Pacanowski J (2000) Computer aided designing of the lower shedders used in the blanking die. Metall Foundry Eng 26(1):41–48

Ruan X, Zhang Z, Lu W, Tin L (1987) A blanking die cad system on microcomputers. Adv Technol Plast 1:139–143

Singh R, Sekhon GS (2003) Design and application of hybrid software for modeling die components and die assembly. Proc Inst Mech Eng Part B: J Eng Manuf 217:235–250

Shaikh A, Desai C (2006) Design of blanking die by integration of CAD modeling package and microsoft excel. In: National conference on design of product life (DPLC2006), Paper DPLC-MA&FP-08

Sun BF, Song Y (2014) Research and development of a knowledge-based system for blanking die. Appl Mech Mater 599–601:396–400

Wong K (1992) A CAD/CAM system for sheet metal blanking dies. Master Thesis University of Hong Kong

Zhao Z, Peng Y, Chi X, Haojun M (2001) Research on hybrid expert system application to blanking technology. J Mater Process Technol 116:95–100

Zamzam M, Ahmed A, Chaaban M (1988) Design of blanking and piercing dies using computers. Ain Shams Bulliton, Mech Eng 64–75

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Hussein, H.M.A., Barakat, A.F., Fengyin, W., Kumar, S. (2017). Knowledge-Based System for Design of Blanking Dies. In: Kumar, S., Hussein, H. (eds) AI Applications in Sheet Metal Forming. Topics in Mining, Metallurgy and Materials Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-2251-7_4

Download citation

DOI: https://doi.org/10.1007/978-981-10-2251-7_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-2250-0

Online ISBN: 978-981-10-2251-7

eBook Packages: EngineeringEngineering (R0)