Abstract

Lately, fish oils are being given importance due to the presence of n−3 polyunsaturated fatty acids (n−3 PUFA). Since n−3 PUFA are known to have many health benefits, researchers are focusing on the methods to concentrate them from various fish oils. In an attempt to enrich n−3 PUFA in the present study, Indian Sardine oil was hydrolyzed with Candida rugosa lipase. Lipase activity was optimized for the reaction parameters such as pH, temperature, water concentration, solvent amount and time. The optimal pH, temperature, water- oil ratio, solvent- oil ratio and time were pH 6.5, 35 °C, 1:10 (w/v), 1:1 (w/v) and 30 min respectively. Under these conditions, the iodine value of the oil was found to have increased from 145.45 to 162.29 which indicate an enhancement of n−3 PUFA in the oil. This study shows an improvement in the quality of oil in terms of n−3 PUFA content that has a potential for use in nutraceuticals.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- n−3 polyunsaturated fatty acids

- Candida rugosa lipase

- Hydrolysis

- Indian sardine oil

- Iodine value

- Activity

1 Introduction

The demand for healthy food and nutrition are becoming a need for everyone to build up the immunity for different types of diseases. Therefore, there is a search for the production of compounds which prevent these diseases. Many reports have studied the beneficial properties of n−3 PUFA namely Eicosapentaenoic acid (EPA) and Docosahexaenoic acid (DHA). Researches over the last decades have shown positive effects of fish oils on the cognitive development and vision enhancement in the newborns (Colombo et al. 2004). The long chain fatty acids like EPA and DHA have been shown to reduce certain types of cancers, diabetes, mental health disorders and asthma (Alasalvar et al. 2002; Nettleton and Katz 2005). The presence of large quantities of these two long chain polyunsaturated fatty acids (PUFA) in Sardine oil (Pike and Jackson 2010) has induced immense interest in researchers to look for methods to concentrate n−3 PUFA from sardine oil. In response to this demand, pharmaceutical industries used various techniques, namely, chromatographic separation, fractional distillation, low temperature crystallization, supercritical fluid extraction, and urea complexation. However, most of these methods produce PUFA in the form of free fatty acids (FFA) or alkyl esters which are nutritionally unfavorable and are known to occur at high temperatures. Since n−3 PUFA are sensitive to heat and oxidation, a hunt for mild conditions which leads to the concentration of EPA and DHA have become essential. Several papers describing the use of lipase for hydrolyzing the glycerides in fish oil are available. Wanasundara and Shahidi (1998) have reported the use of Candida cylindracea lipase for the enrichment of n−3 PUFA in seal blubber oil. The n−3 PUFA content increased from 28.0 % (w/v) to 43.5 % after 70 h enzymatic treatment. Hoshino et al. (1990) have claimed twofold increase in n−3 PUFA after Candida cylindracea lipase treatment in the case of refined Sardine oil. Shimada et al. (1994) have reported that Geotrichum candidum lipase increased the n−3 PUFA content to 48.7 % in tuna oil. However, no literature has studied the hydrolysis of Indian Sardine oil. In this study, maximum activity of Candida rugosa lipase (CRL) was found by optimizing the various operation parameters. The Indian Sardine fish oil was subjected to hydrolysis by this CRL to concentrate the n−3 PUFA content.

2 Materials and Methods

2.1 Materials

Crude Indian sardine oil was obtained from Mukka fish oil industries, Mukka, which was obtained by a conventional pressing method. The refined oil was achieved through degumming, neutralization, bleaching and deodorization according to Cmolik and Pokorny (2000). Refined oil was stored under nitrogen at −20 °C in dark container until use. CRL was obtained from Sigma Aldrich, India. All other chemicals and solvents were of reagent grade and were used without further purification.

2.2 Methods

The optimal activity of the CRL was obtained by studying the parameters like pH, temperature, water- oil ratio, solvent- oil ratio and time. The reaction mixture containing 1 g of oil and 0.325 mg/mL of CRL was subjected to pH ranging from (5.5, 6, 6.5, 7, 7.5, 8), temperature (25, 30, 35, 40, 45 °C), oil to water ratio (1:1, 1:4, 1:8, 1:10, 1:12), oil to solvent ratio (1:0.5, 1:1, 1:1.5, 1:2) and time (10, 20, 30, 40, 50, 60 min) by shaking at 500 rpm at room temperature. Enzymatic activity was obtained by the determination of the liberated FFA through titration with 0.1 N KOH using phenolphthalein as the end point indicator. The activity of CRL was calculated according to the official method of American Oil Chemists’ Society (AOCS) (2009) methodologies, (Cd 3d-63). The hydrolysis was performed under the optimized reaction conditions of CRL for 30 min and the reaction was stopped by addition of 10 mL ethanol. The hydrolyzed oil was subjected to solvent extraction using methanol in the ratio 1:1 oil to methanol (w/w) in order to remove the FFA released during the hydrolysis reaction. The solvent extracted oil was studied for its iodine value (AOCS (Cd 1c-85) 2009) which was compared with the iodine value of the refined oil measured before hydrolysis.

3 Results and Discussion

Stability of the lipase was checked at different pH, temperatures, time, water concentration and solvent amount. This study is important since the information it reveals about the optimum processing conditions is for the efficient hydrolysis of sardine oil.

3.1 Effect of pH on Activity of CRL

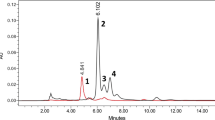

The activity of CRL was studied at room temperature by dissolving it in the phosphate buffer ranging in pH from 5.5 to 8 as given in Fig. 1.

As seen in the Fig. 1, lipase showed the maximum activity of 90.9 mg KOH/g of oil at pH 7. This is because they generally contain residues of amino acids at the active site which bind efficiently to the substrate at neutral pH. CRL was unstable in alkaline and extremely acidic pH because of the structural changes in the proteins due to the pH variation. In alkaline solutions (pH > 8.0), the partial damage of cysteine residues caused by β-elimination could result in the reduced activity of CRL and in acidic solutions (pH < 4.0) the labile peptide bonds sometimes found next to aspartic acid residues may be hydrolyzed (Akova and Ustun 2000). Besides, at acidic pH, the enzyme may form high molecular weight aggregates due to the unspecific associations with other proteins because of its hydrophobic nature (Montero et al. 1993). The result of this study was similar with that of Montero et al. (1993), where the soluble CRL was active between pH 6.2 and 7.7. Another study by Fadologlu and Soylemez (1997) stated the optimum pH for the soluble CRL as 7.0.

3.2 Effect of Temperature on the Activity of CRL

Tests to decide the effect of temperature on lipase activity were done at a temperature range of 25–45 °C, and it was taken in that CRL showed a maximum activity of 88.7 mg KOH/g of oil at a temperature of 35 °C in pH 7.0 phosphate buffer. However, 9.4 and 26.35 % of the activity was lost at 40 °C and 45 °C, respectively (Fig. 2). This is due to the denaturation of the enzyme structure at these temperatures. Several researchers have reported the optimum temperature of soluble CRL at 37 °C (Montero et al. 1993; Xu et al. 1995). Also, Montero et al. (1993) found that treatment at higher temperatures led to the inactivation of the enzyme. According to Fadologlu (1996), CRL exhibits its maximal activity at 40 °C. In this study, enzyme showed considerable activity in a temperature of 35 °C.

3.3 Effect of Oil to Water Ratio

CRL catalyse the splitting of the ester bonds of triglycerides with the consumption of water molecules. Hence it gets significant to consider the quantity of water required for hydrolysis as it increases the functionality of the enzyme at the interphase in the biphasic solvent system. From Fig. 3, it is clearly seen that the hydrolytic activity was highest (88.5 mg KOH/g of oil) at the oil to water ratio of 1:10 (w/v). The ratios less than 1:10 (w/v) and above 1:10 (w/v) showed lesser activities which could be because the lesser quantity of water leads to the reduced rate of conversion, whereas higher quantity of water leads to a thicker water layer around the CRL which increases the flexibility of CRL to interact with the solvents,causing denaturation. (Aditi et al. 2014). Han and Rhee (1986) stated similar reaction conditions for the hydrolysis of olive oil catalyzed by CRL enzyme in the range of pH 6.5–7.1, temperature 30–35 °C and 0.72–9.78 (v/v) oil to water ratio.

3.4 Effect of Oil to Solvent Ratio

The enzyme displayed a maximum activity of 86.7 mg KOH/g of oil at 1:1 (w/v) oil to solvent ratio, as is shown in the Fig. 4. The isooctane due to its non polarity, acts as an organic phase and completely dissolves the non polar triglycerides formed during hydrolysis and separates them with great ease (Yadav and Devi 2004). The enzyme activity is found to decrease beyond 1:1 (w/v) oil to solvent ratio due to the excess amount of iso octane which reduces the availability of the active site of enzyme to the oil. (Aditi et al. 2014). The presence of iso octane results in an increased interfacial area of the oil water system due to the reduced effect of viscosity of the oil.(Aditi et al. 2014). The non polarity of iso octane reduce the enzyme inhibition without stripping off the essential water from CRL during hydrolysis and helps in maintaining a monolayer of water around the CRL (Klibanov 1989).

3.5 Effect of Time

Figure 5 shows the time course of hydrolysis where the CRL was shown to give maximum product formation at 30 min equivalent to 85.4 mg of KOH/g of oil. It is clear from the trend observed in Fig. 5, that with the initial increase in time the product formation was increased up to 30 min and a further increase in time up to 1.5 h did not lead to any improvement in the product formation. The progress of biocatalytic reactions is almost never linear and is given to slow down with time due to the decrease in oil concentration, the increase in product concentration or the inactivation of the biocatalyst (Gardossi et al. 2010).

Thus, the most suitable reaction conditions for hydrolysis of sardine fish oil with CRL in solvent system were obtained at pH 7.0, temperature 35 °C, and oil to water ratio of 1:10 (w/v), oil to solvent ratio of 1:1 (w/v), and time 30 min. The activity of lipase for optimized parameters was found to be 85.4 for CRL in µmoles of FFAs/ml.

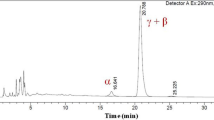

3.6 Enhancement of n−3 PUFA in Oil

The iodine value of oil before hydrolysis was found to be 145.45 and after hydrolysis it was 162.29. This significant increase in iodine value number indicates the enhancement of unsaturated fatty acids in the oil. The increase in the unsaturation is probably due to the enhancement of nutritionally important n−3 PUFA like EPA and DHA. This is because CRL has fatty acid chain length specificity showing an increased discrimination against the long chain PUFA like C18–C22. CRL hydrolyses the short chain fatty acids, saturated fatty acids and mono unsaturated fatty acids because of the reduced steric hinderances when linked to the glycerol backbone acids leading to the protection and concentration of EPA and DHA (Okada and Morrissey 2006).

4 Conclusions

In this study, the optimal activity of CRL was found after which the hydrolysis of oil with CRL in the optimized conditions was carried out followed by FFA removal which resulted in an enhancement of n−3 PUFA in Indian sardine oil. It should be noted that the hydrolysis of oil for 30 min resulted in a significant increase in n−3 PUFA after which there was not much increase observed. For commercial purposes, 30 min might be an optimum reaction time for producing n−3 PUFA concentrates. Hence lipase catalysed hydrolysis was considered to be a beneficial and feasible method for the enhancement of n−3 PUFAs from Indian sardine oil for the use in nutraceuticals and other products.

References

Aditi, S., Chaurasia, S.P., Dalai, A.K.: Non-selective hydrolysis of tuna fish oil for producing free fatty acids containing docosahexaenoic acid. Can. J. Chem. Eng. 92, 344–354 (2014)

Akova, A., Ustun, G.: Activity and adsorption of lipase from Nigella sativa seeds on celite at different pH values. Biotechnol. Lett. 22, 355–359 (2000)

Alasalvar, C., Shahidi, F., Quantick, P.: Food and health applications of marine nutraceuticals: a review. Seafoods Qual. Technol. Nutraceutical Appl. 175–195 (2002)

AOCS: Official methods and recommended practices of the American oil chemists. Soc. Sampling Anal. Fats Oils (2009)

Cmolik, J., Pokorny, J.: Physical refining of edible oils. Eur. J. Lipid Sci. Technol. 102, 472–486 (2000)

Colombo, J., Shaddy, D.J., Anderson, C.J., Blaga, O.M., Kannass, K.N., Kundurthi, S.: Maternal DHA and the development of attention in infancy and toddlerhood. Child Dev. 75(4), 1254–1267 (2004)

Fadologlu, S.: Kinetics of olive oil hydrolysis by free and immobilised Candida rugosa lipase. Ph.D thesis, University of Gaziantep (1996)

Fadologlu, S., Soylemez, Z.: Kinetics of lipase catalyzed hydrolysis of olive oil. Food Res. Int. 30, 171–175 (1997)

Gardossi, L., Poulsen, P.B., Ballesteros, A., Hult, K., Svedas, V.K., Vasic-Racki, D., Carrea, G., Magnusson, A., Schmid, A., Wohlgemuth, R., Halling, P.J.: Guidelines for reporting of biocatalytic reactions. Trends Biotechnol. 28, 171–180 (2010)

Han, D., Rhee, J.S.: Lipase-catalyzed hydrolysis of milk fat in lecithin reverse micelles. Biotechnol. Bioeng. 28, 1250–1255 (1986)

Hoshino, T., Yamane, T., Shimazu, S.: Selective hydrolysis of fish oil by lipase to concentrate n−3 polyunsaturated fatty acids. Agric. Biol. Chem. 54, 1459–1467 (1990)

Klibanov, M.A: Enzymatic catalysis in anhydrous organic solvents. Trends Biochem Sci. 14(4), 141–144 (1989)

Montero, S., Blanco, A., Virto, M., Ladenta, L.C., Agud, I., Solozabal, R., Lascaray, J.M., Renobales, M., Llama, M.J., Serra, J.L.: Immobilization of Candida rugosa lipase and some properties of the immobilized enzyme. Enzyme Microb. Technol. 15, 239–247 (1993)

Nettleton, J.A., Katz, R.: n−3 long-chain polyunsaturated fatty acids in type 2 diabetes: a review. J. Am. Diet. Assoc. 105(3), 428–440 (2005)

Okada, T., Morrissey, M.T.: Production of n−3 polyunsaturated fatty acid concentrate from sardine oil by lipase-catalyzed hydrolysis. Food Chem. 103, 1411–1419 (2006)

Pike, I.H., Jackson, A.: Fish oil: production and use now and in the future. Lipid Technol. 22(3), 59–61 (2010)

Shimada, Y., et al.: Enrichment of polyunsaturated fatty acids with Geotrichum candidum lipase. J. Am. Oil Chemist’s Soc. 71(9), 951–954 (1994)

Wanasundara, U.N., Shahidi, F.: Lipase-assisted concentration of n−3 polyunsaturated fatty acids in acylglycerols from marine oils. J. Am. Oil Chemist’s Soc. 75(8), 945–951 (1998)

Xu, H., Li, M., He, B.: Immobilization of Candida cylindracea lipase on methyl acrylate-divinyl benzene copolymer and its derivatives. Enzyme Microb. Technol. 17, 194–199 (1995)

Yadav, G.D., Devi, K.M.: Kinetics of hydrolysis of tetrahydrofurfuryl butyrate in a three phase system containing immobilized lipase from Candida antarctica. J. Biochem. Eng. 17, 57–63 (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Sampath, C., Anita, N., Prasanna, B.D., Regupathi, I. (2016). Enzymatic Concentration of n−3 Polyunsaturated Fatty Acids from Indian Sardine Oil. In: B. D., P., Gummadi, S., Vadlani, P. (eds) Biotechnology and Biochemical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-1920-3_15

Download citation

DOI: https://doi.org/10.1007/978-981-10-1920-3_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1919-7

Online ISBN: 978-981-10-1920-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)