Abstract

In the emerging business environment, the organizations must promote alternative uses of resources that may be cost-effective and eco-friendly by extending products’ routine life cycles. In this perspective, an efficient management of product returns through reverse logistics operating channels is a strategic issue. Business organizations including those of automobile manufacturing industries would like to focus on their core competency areas and there is need of making outsourcing decisions of their reverse logistics operating channels. There are five operating channels of reverse logistics; Supplier Operation, Manufacturer Operation, Distributor Operation, Third Party Operation and Joint Operation. The objective of this work is to develop the multi-criteria group decision support system to assist the top management of the company in selection of reverse logistics operating channels through integration of analytical hierarchy process (AHP) and technique for order preference by similarity to ideal solution (TOPSIS) under fuzzy environment. An illustrative case is included to validate the proposed method. The key findings and managerial insights of present study also enables the logistics managers to better understand the complex relationships of the main attributes in the decision making environment and subsequently improve the reliability of the decision making process.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the past, supply chain process flow happens in the one way or forward direction only. Nowadays, industries are encountering the issues of return flow of the products in the supply chain for a variety of reasons like product recalls, warranty failure, guarantee failure, service failure, commercial returns, non-commercial returns, manufacturing returns, end-of-life and end-of-use returns. Reverse logistics is the process of return product handling mechanism in forward supply chain. Due to the growing environmental legislations, more attention is given to Reverse Logistics. Reverse Logistics (RL) is the process of planning, implementing and controlling the efficient, cost effective flow of raw materials, in process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value, or proper disposal [10].

The research of reverse logistics is in exploration stage. In Addition, cost minimization is possible in reverse logistics. A reverse logistics defines a supply chain that is redesigned to efficient manage the flow of products or parts designed for remanufacturing, recycling or disposal and to effectively utilize resources [11]. The various functions executed through RL activities include gate-keeping, compacting disposition cycle times, remanufacturing and refurbishment, asset recovery, negotiation, outsourcing and customer service [8].

In addition to disposition and transportation, value added services such as JIT, quick response and program solutions are also important functions in reverse logistics. Recovery of products for remanufacturing, repair and recycling can create profitable business opportunities. For managing the returns, the companies can reuse them, resell or destroy them. Retailers may return the goods due to seasonality, expiry or because of transit damage. Customers may return the goods due to poor quality. Managing the product returns increases the customer service level and retention level. Each activity from procurement to distribution generates waste and reduction of this waste is a major goal of environmentally conscious business practices [16]. Manufactures see reverse logistics as a process of recovering defective products or reusable containers back from the user. In the e-commerce since buyers need assurance for refund, reverse logistics is an important issue. Owing to R approach, this area present an opportunity for research. A conceptual framework for managing retail reverse logistics operation is presented in [12].

In the case study conducted by [1], three companies were visited and identified reverse logistics process flow and the strategic issues a firm may use for competitive advantage. An integrated forward logistics multi echelon distribution inventory supply chain model and closed loop multi echelon distribution for the built to order environment was designed using genetic algorithm and particle swarm optimization. A model for green supply chain management with incomplete information was developed [3]. Reverse logistics was suggested as an area for future research and the advantages of soft computing is its capability to tolerate imprecision, uncertainty [2]. A mathematical model for the design of Reverse Logistics network design was proposed [6, 9, 19] considering the location and allocation of facilities. A dynamic model was constructed and validated the same using the data collected from the computer company [18]. A distribution system which uses a combination of manufacturing and remanufacturing was proposed and the models were compared with respect to the various prices.

From the above references, studies have been done for the RL network design and the selection of third party logistics provider. But AHP and Fuzzy TOPSIS has not been used by any researcher for selection of RL operating channels selection. The companies can choose five operating channels for performing the RL activities (1) Supplier Operation collecting the raw material-Supplier Operation (2) Manufacturer collecting the used products-Manufacturer Operation (MO). (3) The distributor should control human resources, information systems and related equipment. (4) Outsourcing to third party-Third Party Operation (TPO). (e) Retailer will collect the used products- Joint Operation (JO). Remanufacturing costs may be reduced by third party. Since the third party logistics is using his latest technology and resource sharing advantages, uncertainty of recovery may be reduced. By outsourcing reverse logistics activities, the organizations can concentrate on their core business operation, but customer satisfaction and delivery performance may be improved. Third party reverse logistics provider will compete with each other in specific areas like price, quality and credit. Logistics costs will be reduced and order fill rate will be improved. Each channel has its distinct characters and suitable for companies with their sole service requirements. Evaluating and selecting reverse logistics channels is regarded as fuzzy multi criteria group decision making (FMCGDM) process in which a decision maker chooses the best option among the existing alternatives.

The rest of this paper is structured as follows. Following the introduction, in Sect. 92.2, the key problem for the automotive industry with different kinds of attributes in a reverse logistics under uncertain environment is described. The formulation of a fuzzy (MCGDM) model for selecting reverse logistics operating channels in a supply chain and its conversion into a crisp value can be explained in Sect. 92.3. In Sect. 92.4, a practical case study is presented to demonstrate the applicability of the proposed model. In the final section, the conclusions and directions for future research are discussed.

2 Problem Statement

In this problem, we classified the RL operating channels into five types based on the newly introduced attributes and as well as through literature review. Nowadays, profitable reuse and remanufacturing of automotive parts must meet the challenges of turbulent business environment which may includes continuous change in design pattern, frequent price fluctuations of new car models, disassembly of unfriendly designs, short life cycles, and prohibiting transport, labor and machining costs in high-wage countries. In current business environment, the remanufacturing of expensive, long-living investment machine/equipments, e.g., jet fans, machine tools, defense equipment or automobile engines, is extended to a large number of consumer goods with short life cycles and relatively low values. Reuse is an alternative to material recycling to comply with recovery rates and quantities as well as special treatment requirements.

Reverse Logistics can be applied to wide variety of industries like pharmaceutical, electronic, chemical, automobile and computer manufacturers. Automobile companies recover the end of life auto parts. Automotive products that contain hazardous materials are disposed. Reverse Logistics may take place through Supplier Operations (SO), Manufacturer Operation (MO), Distributor Operation (DO), Third Party Operation (TPO), and Joint Operation (JO). The criteria for the selection of RL operating channels have been found through literature review and experts discussions. The detailed classification of attributes is structured in Fig. 92.1.

3 Formulating a Fuzzy MAGDM Model for Selecting RL Operating Channels

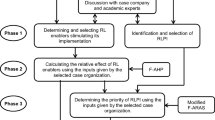

This section proposes a methodology for selecting RL operating channels in the automotive sector. The methodology consists of three main stages as given in Fig. 92.2. The first step requires the firm to come up with a comprehensive hierarchy of all the criterion which may affect the firm. This is done by thoroughly studying the considered chain and identifying potential loopholes. These are then analyzed for overlaps and categorized using similar characteristics. This exercise should be repeated whenever a major change is made in the chain. The second step in the process involves assigning weights to the attribute according to their importance. Fuzzy AHP is used for this purpose and expert views are taken as input. The third step involves determining the scores of different criterion by analyzing them under five different attribute; namely logistics, financial, environmental, capacity, and alliances. In the fourth step fuzzy TOPSIS approach is employed to evaluate the organization’s readiness of selecting RL operating channels [4]. Finally, comparison of results and managerial implications has been discussed.

3.1 Fuzzy Hierarchical Approach for Selecting RL Operating Channels

In this section, an integrated fuzzy AHP-TOPSIS methodology is employed for selecting RL operating channels. In fuzzy AHP, fuzzy ratio scales are used to indicate the relative strength of the factors in the corresponding attribute. Therefore, a fuzzy judgment matrix can be constructed. The final scores of alternatives are also represented by fuzzy numbers. The optimum alternative is obtained by ranking the fuzzy numbers using special algebraic operators. In this methodology, all elements in the judgment matrix and weight vectors are represented by triangular fuzzy numbers.

Using fuzzy numbers to indicate the relative importance of one type over the other, a fuzzy judgment vector is then obtained for each criterion. These judgment vectors form part of the fuzzy pairwise comparison matrix which is then used to determine the weight of each criterion. Table 92.1 shows the meaning of linguistic expressions in the form of fuzzy numbers and Table 92.2 shows the random consistency index to calculate the consistency ratio (CR). Figure 92.3 represents the fuzzy membership function for linguistic expressions for attribute and sub-attribute. Experts are asked to give their assessment in the form of these linguistic expressions which are then converted and analyzed to finally get the weights. Chang’s extent analysis method has been used for determining weights from pairwise comparisons (Table 92.3).

For evaluating and ranking the alternatives, the fuzzy TOPSIS method is very suitable for solving real life application problems under a fuzzy environment. TOPSIS one of the classical multi-attribute decision making methods was developed by Hwang and Yoon [4]. Table 92.2 gives the linguistic scale for evaluation of the alternatives. Assuming that a decision group has K people, the ratings of alternatives with respect to each criterion can be calculated as Eq. (92.1).

where \(\tilde{x}_{ij}^{k}\) is the rating of the \(K^{th}\) decision maker for \(i^{th}\) alternative with respect to \(j^{th}\) criterion. Obtaining weights of the attribute and fuzzy ratings of alternatives with respect to each criterion, the fuzzy multi-attribute decision-making problem can be expressed in matrix format as

where \(\tilde{x}_{ij}\) is the rating of the alternative \(A_{i}\) with respect to criterion j (i.e. \(C_{j}\)) and \(w_{j}\) denotes the importance weight of \(C_{j}\). These linguistic variables can be described by triangular fuzzy numbers: \(\tilde{x}_{ij}=a_{ij},b_{ij},c_{ij}\). To avoid the complicated normalization formula used in classical TOPSIS, the linear scale transformation is used here to transform the various attribute scales into a comparable scale. Therefore, we can obtain the normalized fuzzy decision matrix denoted by \(\tilde{R}\)

where B and C are the set of benefit attribute and cost attribute, respectively, and

The normalization method mentioned above is to preserve the property that the ranges of normalized triangular fuzzy numbers belong to [0, 1].

Considering the different importance of each criterion, we can construct the weighted normalized fuzzy decision matrix as

where

According to the weighted normalized fuzzy decision matrix, we know that the elements \(\tilde{v}_{ij}\forall , j\) are normalized positive triangular fuzzy numbers and their ranges belong to the closed interval [0, 1]. Then, we can define the fuzzy positive-ideal solution \((\text {FPIS}, A^{*})\) and fuzzy negative-ideal solution \((\text {FNIS}, A^{-})\) as

where

The distance of each alternative from \(A^{*}\) and \(A^{-}\) can be currently called as

where d(.) is the distance measurement between two fuzzy numbers calculating with the following formula:

Obviously, an alternative \(A_{i}\) is closer to the (FPIS, \(A^{*}\)) and farther from (FNIS, \(A^{-}\)) as \(CC_{i}\) approaches to 1. Therefore, according to the closeness coefficient, we can determine the ranking order of all alternatives and select the best one from among a set of feasible alternatives.

4 Practical Application

The proposed model is developed to sort the solutions for selecting RL operating channels to deal its attributes. Based on the previous section, the practical application can be explained with numerical results as following.

4.1 Presentation of the Problem

A fuzzy multi-criteria group decision making (FMCGDM) model is applied to a real problem in industry. An electronics industry located in the western part of Pakistan is selected. The industry wanted a systematic way to implement the reverse logistics operations. Reverse Logistics brings significant improvements in the manufacturing process and the correct decisions made brings the industry competitive advantage. Therefore selecting the most important operating channels is of great importance for the industry. To collect the used auto spare parts and automobiles from the customers, the industry may choose Supplier Operation (SO), Manufacturer Operation (MO), Distributor Operation (DO), Third Party Operation (TPO) and Joint Operation (JO).

Nowadays, companies in Pakistan realize that physical distribution and reverse logistics management play a vital role in organization success and that selecting RL operating channels in supply chain is becoming an important activity. Only a few companies have adopted reverse logistics practices in integration with supply chain. But the success ratio is very low due to barriers selecting channels in supply chain. To improve the success rate it is essential to assess the attributes and solutions to overcome them. It is difficult to implement all attributes at the same time. Therefore, it is important and necessary to highlight these solutions of selecting RL operating channels, hence, Pakistani firms can focus on the prioritize solutions and implement them in a procedural way.

4.2 Case Solution

Phase 1. Identification of attributes and selection of RL operating channels

The decision group is composed of the 3 expert panel which comprising planning manager, production manager and logistics manager. In this study, through the panel discussion, the detailed sub-attribute under five main attribute (logistics, financial, environmental, capacity and alliances) were identified. The results are illustrated in Fig. 92.1, in which the hierarchy is descended from the general attribute in the second level to more detailed sub-attribute.

The overall objective of decision process determined as for selecting RL operating channels is in the first level of hierarchy. The main attribute on the second level, the sub-attribute at third level and alternative operating channels solutions in the fourth level of hierarchy See Fig. 92.1.

Phase 2. Calculation of the attribute weight by using fuzzy AHP

The committee members are asked to construct pair wise comparisons of five major attributes and 24 sub attributes by employing linguistic variables by using Tables 92.1 and 92.2. Through the arithmetic mean the pairwise comparison matrixes of attribute and sub attribute are established and given in Tables 92.4, 92.5, 92.6, 92.7, 92.8 and 92.9. The computational results got from the computations based on pairwise comparison matrixes provided in Tables 92.4, 92.5, 92.6, 92.7, 92.8 and 92.9, are shown in Table 92.10. Consistency ration values of all the matrices are less than 0.1, therefore, these matrices are sufficiently consistent.

Phase 3. Evaluation of the solutions of RL operating channels

The decision makers constructed a fuzzy evaluation matrix by taking linguistic variables shown in Table 92.3. It is constructed by comparing solutions under each of the attributes separately (See Table 92.11). Then transformed linguistic expressions into triangular fuzzy numbers and established the fuzzy evaluation matrix (See Table 92.12). Aggregate fuzzy weights of the alternatives are computed using Eq. (92.2) and presented in Table 92.13. In this study all the attribute are the barriers of selecting reverse logistics operating channels in supply chain, as per the goal minimization of these barriers is required. Hence, all the barriers are termed as cost attribute and normalization performed by Eq. (92.6) and for further detail (See Table 92.14). Next step is to obtain a fuzzy weighted evaluation matrix. Using the attribute weight calculated by fuzzy AHP (See Table 92.10), the weighted evaluation matrix is established using the Eq. (92.7) which is shown in Table 92.15.

Phase 4. Determination of final rank by fuzzy TOPSIS

In this study all the sub-attributes are the cost criteria. Hence, fuzzy positive-ideal solution (\(\text {FPIS}, A^{*}\)) and fuzzy negative-ideal solution (\(\text {FNIS}, A^{-}\)) as \({\tilde{v}^*} = \left( {0,0,0} \right) \) and \({\tilde{v}^-} = \left( {1,1,1} \right) \) for all these sub-criterion. Then compute the distance d of each alternative form FPIS and FNIS using the Eqs. (92.10) and (92.11). For example the distance \({d_v}\left( {{A_1},{A^*}} \right) \) and \({d_v}\left( {{A_1},{A^-}} \right) \) for alternative \(A_{1}\) and sub-criteria \(M_{1}\) from FPIS and FNIS, are calculated as follows.

Similarly, calculations are done for other sub-criterion for solutions of alternative \(A_{1}\) and computed the cumulative distances of \(d^{+}_{i}\) and \(d^{-}_{i}\) as \(d^{+}_{i}\)= 0.4725 and \(d^{-}_{i} = 23.6246\). By using the Eq. (92.12), the closeness coefficient (\(CC_{i}\)) of alternative \(A_{1}\) computed as follows.

The same procedure can be adopted to compute the distances and (\(CC_{i}\)) values of remaining alternatives. The final results are summarized in Table 92.16. Based on (\(CC_{i}\)) values rank the alternatives in descending order.

4.3 Case Analysis

In this section, the results derived for the proposed hybrid AHP-TOPSIS framework depict that \(A_{3}\) has the highest coefficient closeness value, therefore selection of reverse logistics operating channels among the five alternative operating channels should be recommended. Therefore, based on the (\(CC_{i}\)) values, the ranking of alternatives in descending order are \(A_{3}\), \(A_{1}\), \(A_{5}\), \(A_{2}\) and \(A_{4}\).

5 Conclusion

The evaluation and selection of the RL operating channels for automobile industry segment is a strategic management level decision. The e-waste is terribly increasing and it has become menace to community and green supply chain burden. Although financial and operational attributes are involved, the applicability of reverse logistics RL may be a dangerous activity for the industry. However growing environmental/green supply chain concerns have stimulate the industries to opt for reverse logistics operating channels. Nowadays the core agenda is by which channel the industries will be able to collect the required returned product.

The proposed methodology based on hybrid fuzzy AHP-TOPSIS is used for the selection of RL operating channels. The problem addressed in this research has been described as a fuzzy multi-criteria group decision making method under uncertainty, prompting the need for the method to handle imprecise judgments from experts.

Future research includes incorporating a two phase methodology combining fuzzy AHP-VIKOR and slightly carrying out sensitivity analysis to confirm the robustness in the relevant industries.

References

Amin M, Zahora Nasharuddin S (2013) Hospital service quality and its effects on patient satisfaction and behavioural intention. Clin Govern Int J 18(3):238–254

Andaleeb SS, Kara A (2014) The structure and measures of service quality perceptions for multiple-encounter services: a study of hospitals in bangladesh. Int J Healthc Manag 7(2):92–102

Bagozzi RP, Yi Y (1988) On the evaluation of structural equation models. J Acad Mark Sci 16(1):74–94

Bollen KA (2014) Structural equations with latent variables. Wiley, New York

Bollen KA, Long JS (1993) Testing structural equation models, vol 154. Sage

Breckler SJ (1990) Applications of covariance structure modeling in psychology: cause for concern? Psychol Bull 107(2):260

Cheng EW (2001) Sem being more effective than multiple regression in parsimonious model testing for management development research. J Manag Dev 20(7):650–667

EzPATH SJ (1989) A Supplementary Module for SYSTAT and SYSGRAPH (computer program). SYSTAT

Fornell C, Johnson MD et al (1996) The american customer satisfaction index: nature, purpose, and findings. J Mark, pp 7–18

Lt Hu, Bentler PM (1999) Cutoff criteria for fit indexes in covariance structure analysis: conventional criteria versus new alternatives. Struct Eq Model Multidiscip J 6(1):1–55

Jöreskog KG (1970) A general method for analysis of covariance structures. Biometrika 57(2):239–251

Kazemi N, Ehsani P et al (2013a) Measuring hospital service quality and its influence on patient satisfaction: an empirical study using structural equation modeling. Manag Sci Lett 3(7):2125–2136

Lei P, Jolibert A (2012) A three-model comparison of the relationship between quality, satisfaction and loyalty: an empirical study of the Chinese healthcare system. BMC Health Serv Res 12(1):1

ML W (2011) Questionnaire statistical analysis and practicełSPSS operation and application. Chongqing University Press, Chongqing

Oliver RL (1980) A cognitive model of the antecedents and consequences of satisfaction decisions. J Mark Res, 460–469

Ping Jr RA (2015) A note on estimating second-order interactions and quadratics in latent variables. In: Assessing the different roles of marketing theory and practice in the jaws of economic uncertainty, pp 304–304. Springer, Heidelberg

Qin H, Prybutok VR et al (2014) UCPERF: An urgent care patient satisfaction instrument. Qual Manag J 21(3):11

Huo YB (2004) CSI model building and the GME comprehensive estimation research of its parameters. Master’s thesis, Doctoral Dissertation of Nanjing University of Science and Engineering

Liu ZH (2015) Literature review of domestic and international research on patient satisfaction. Chin J Health Policy 8(4):60–66

Acknowledgments

The authors wish to thank the anonymous referees for their helpful and constructive comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this paper

Cite this paper

Nazam, M., Hashim, M., Ahmad, J., Ahmad, W., Tahir, M. (2017). Selection of Reverse Logistics Operating Channels Through Integration of Fuzzy AHP and Fuzzy TOPSIS: A Pakistani Case. In: Xu, J., Hajiyev, A., Nickel, S., Gen, M. (eds) Proceedings of the Tenth International Conference on Management Science and Engineering Management. Advances in Intelligent Systems and Computing, vol 502. Springer, Singapore. https://doi.org/10.1007/978-981-10-1837-4_92

Download citation

DOI: https://doi.org/10.1007/978-981-10-1837-4_92

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1836-7

Online ISBN: 978-981-10-1837-4

eBook Packages: EngineeringEngineering (R0)