Abstract

Bacteria with the abilities to degrade crude oil were isolated from soil, activated sludge and biological treatment lagoon of the local petrochemical industries. For the biodegradation process, n-alkanes, of varying carbon chain length, C16–C38, were used. Out of the 12 cultures of bacteria isolated, 3 of the best oil degraders were partially identified via biochemical tests; 2 of which were Acinetobactor spp while another one belonged to Proteus sp. Degradation of the n-alkanes in crude oil was monitored under agitated and non-agitated condition using gas chromatography technique. Generally, non-agitated cultures showed higher degradation rates. One of the Acinetobacter sp. showed the highest degradation rate, in which 80–100 % of the alkanes (C16–C38) in crude oil was degraded without any addition of organic nitrogen and phosphorus. It is of interest to highlight another of the Acinetobacter sp. which showed the ability to degrade longer chain alkanes more rapidly than shorter ones; C36 and C38 were fully degraded in 2 days. Only one bacterium, Proteus sp showed increased rates of degradation under agitated condition.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Crude oil degrading bacteria

- Degradation rates

- Petrochemical wastewater

- n-Alkanes

- C16–C38

- Gas chromatography

1 Introduction

The biodegradation of petroleum or its alteration by bacteria has long been discovered and it is a widespread phenomenon in nature (Leahy and Colwell 1990). The interest in the research on hydrocarbon-utilizing microorganisms never ceased since the 1940s when the interactions of microorganisms and petroleum were first reported (Zobell 1946). The research in petroleum microbiology kept evolving through the years, where each decade is marked by intense interest in a different aspect of this field (Brito et al. 2015; Shibulal et al. 2014; Voordouw 2011; Atlas 1981, 1995).

Although interactions of microorganisms and petroleum has been intensively researched for decades in many advanced countries, such as United States and United Kingdom (Venosa et al. 2001), it is a relatively a new field of research in countries such as Malaysia (Othman et al. 2011). For the oil-degrading microbes to be applied in local environments, it is essential to isolate microorganisms that are adapted to the local climatic condition prior to the optimisation process. Comparatively it is more expensive to import the technology from other countries than to tailor-make our own technology for our own needs.

Crude oils in general can vary greatly in composition, viscosity, density, and flammability consisting of organic compounds ranging from methane to extremely heavy hydrocarbon molecules with up to 80 carbon atoms (Leahy and Colwell 1990). Among them, alkanes constitute the major fraction. Alkanes can constitute up to 50 % of crude oil, depending on the oil source, but are also produced by many living organisms such as plants, green algae, bacteria or animals. As alkanes are polar molecules that are chemically very inert (Labinger and Bercaw 2002), their metabolism by microorganisms poses challenges related to their low water solubility, their tendency to accumulate in cell membranes, and the energy needed to activate the molecule. However, several microorganisms, both aerobic and anaerobic, can use diverse alkanes as their source of carbon and energy. Several reviews have covered different aspects of the physiology, enzymes and pathways responsible for the degradation of alkanes (Watkinson and Morgan 1990; Ashraf et al. 1994; van Beilen et al. 2003; van Hamme et al. 2003; Coon 2005; van Beilen and Funhoff 2007; Wentzel et al. 2007). The chemical composition of crude oils may vary between regions and even within the same geologic formations (Head et al. 2006; Harayama et al. 2004, Margerin et al. 2003).

In view of the diverse microbial metabolism and adaptation mechanisms, the success of biodegradation of crude oil is very much dependent on the selection of microbes that are adapted to the local climatic condition. Hence this study focused on the isolation of local bacterial species able to degrade crude oil. These bacteria were partially characterised via biochemical tests and the profiles of n-alkane degradation by the selected bacteria are presented.

2 Materials and Methods

2.1 Chemicals Reagents

All chemicals reagents used for medium preparation, crude oil extraction and various biochemical tests were of analytical grade, except solvents used for gas chromatography analyses which were of HPLC-grade.

2.2 Crude Oil Samples

The crude oil samples were obtained from local petrochemical industries. The crude oil was autoclaved at 121 °C for 15 min prior to use.

2.3 Source of Microorganisms

Twelve bacteria that were isolated and taken from various sampling points within the vicinity of the petrochemical industries and their ability to biodegrade crude oil was investigated in this research. Bacterial sources were activated sludge, soil sludge farm, influent flotation tank, biological treatment lagoon effluent, aeration basin wastewater and treatment lagoon. These samples were serially diluted and inoculated into enrichment media (Sect. 2.5) and were incubated at 37 °C, 250 rpm in a shaking incubator overnight or until the culture medium became turbid. The bacteria were then isolated using the dilution streak method until pure colonies were obtained.

2.4 Subculturing and Storage of Microorganisms

All isolated microorganisms were subcultured directly from the stock culture on slant agar and plated on fresh nutrient agar (NA). Overnight cultures of the 12 isolates were transferred to nutrient agar slants complemented with 0.5 mL paraffin oil for storage at 5 °C. Bead cultures were also prepared for selected strains for long-term storage. Overnight cultures were centrifuged at 5000 rpm at 4 °C for 30 min and the cell pellet obtained was resuspended in nutrient broth. The cell suspension was then transferred to the bead culture system and stored at −70 °C.

2.5 Enrichment Medium

The bacteria were grown in an enrichment medium based on basal salts medium consisting of the inorganic salts 0.5 g/L KH2PO4, 1.0 g/L NH4Cl, 2.0 g/L Na2SO4, 2.0 g/L KNO3, 0.001 g/L CaCl2·6H2O, 1.0 g/L MgSO4·7H2O and FeSO4 as a trace element. The salts were dissolved in a total volume of 1000 mL distilled water and autoclaved at 121 °C for 15 min. Crude oil, 2–3 % (v/v) was added to the medium in addition to 5 mM of glucose. The glucose solution was prepared as a 50 mM stock solution and was autoclaved separately under the same condition.

2.6 Experimental Design

The experiments were carried out under both agitated and non-agitated condition in 250 mL flasks to determine which condition was more favourable for the microbial degradation of crude oil. One loop-full of stock cultures were first inoculated into the enrichment medium and incubated overnight at 37 °C. Then, 10 % (v/v) of the overnight cultures were transferred to the same enrichment medium and cultured under agitation at 250 rpm and non-agitated conditions. Control experiments in the absence of the microorganisms were also carried out. Growth was monitored throughout the process. Samples were collected after 2 and 6 days of cultivation and solvent extraction of the organic compounds (Sect. 2.8) prior to gas chromatographic analysis was performed.

2.6.1 Degradation of Crude Oil Under Agitated Condition

The inoculum was prepared by inoculating a loop-full of fresh overnight cultures plated on nutrient agar into 10 mL of the basal salts medium in a 25 mL universal bottle supplemented with 5 mM glucose and 2 % (v/v) of crude oil. The cultures were incubated at 37 °C in a shaking incubator at 250 rpm for 24 h prior to inoculation.

10 % (v/v) of inoculum was added to 250 mL Erlenmeyer flask containing 87 mL of basal salts medium supplemented with 5 mM glucose and 3 % (v/v) crude oil to a final culture volume of 100 mL. Cultures of each isolate were incubated in a shaking incubator at 30 °C, 250 rpm for 6 days.

2.6.2 Degradation of Crude Oil Under Non-agitated Condition

An inoculum of the overnight suspension culture (l mL; 4 % (v/v)) was transferred into a universal bottle containing 23.5 mL basal salts medium supplemented with 5 mM glucose and 2 % (v/v) of crude oil. This was to minimize air in the head space. The cultures were incubated at 37 °C without any agitation for 6 days.

The universal bottles used for the non-agitated culture were sealed using the rubber stopper. They were positioned upside down to ensure the seal was fitted properly. A hole was inserted in the lid of the universal bottles using the syringe needle for sampling. All universal bottles were autoclaved before use.

2.7 Growth Determination

Growth of the cultures was monitored using a UV–Vis spectrophotometer at 550 nm.

2.8 Crude Oil Extraction

Samples of the agitated and non-agitated cultures were collected at regular time intervals after inoculation with the isolated bacterial strains. Residual crude oil was extracted by adding approximately 2 mL of n-pentane to the sample. The mixture was shaken briefly and filtered using a Whatman silicon-treated filter paper that held the aqueous portion while allowing hydrophobic compounds to pass through. The filtrate was collected in a 1.7 mL sample bottle and was vacuum-evaporated to dryness using a BUCHI B-169 vacuum system. The residual crude oil was recovered by using 1 mL of toluene and stored at 0 °C prior to gas chromatography (GC) analysis.

2.9 Gas Chromatography

The separation and determination of n-saturated alkanes was achieved by GC using a Hewlet-Packard (HP) 6890 gas chromatograph equipped with a flame ionization detector and a 25 m (0.2 mm inner diameter) Ultra-1 capillary column containing cross-linked methyl siloxane. The operating temperature of the detector was 320 °C and that of the injector was 300 °C. The column temperature was set at 50 °C for the first minute, then increased to 310 °C at a rate of 6 °C/min and the final temperature was maintained for 5 min.

Alkanes varying in length from Cl6 to C38 (Alltech Associates Inc.) were used as standards. The un-inoculated control and the hydrocarbons standards with chain length varying from CWC38 were first analysed by gas chromatography and results obtained were compared. The resultant chromatograms showed the presence of all the standard compounds in the crude oil extracted from the un-inoculated control with retention times between 20 and 50 min. Peaks with differences in retention time of ±0.5 min compared to the standards were assumed as similar compounds or having the same carbon number.

Degradation was calculated by difference in percentage area of the peaks between un-inoculated control and experimental culture extracts.

2.10 Biochemical Tests

Strains selected on the basis of best oil-degradation were subjected to further biochemical characterization. The bacteria were partially identified according to the Bergey’s Manual of Bacteriology.

3 Results and Discussion

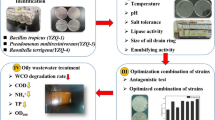

3.1 Screening for Potential Crude Oil Degrading Microorganisms

Mineralization or complete biodegradation of a hydrocarbon compound can occur under either aerobic or non aerobic conditions using agitated and non-agitated system. As we aimed to identify potential crude oil degrading microorganisms, both systems were used for the screening process.

Twelve bacteria isolated from two petrochemical industries were screened for their abilities to degrade crude oil under both agitated and non-agitated conditions (Table 1). Bacteria showing high biodegradation rates of crude oil, under agitated and non-agitated culture was selected for further work.

The outcomes on performance of non-agitated and agitated systems for the biodegradation of crude oil are presented in Table 2. Non-agitated biodegradation showed better degradation rates compared to the agitated cultures. All 12 isolates showed abilities to degrade C16–C38 within 2–6 days under non-agitated conditions.

Some isolates were able to degrade long chain carbon completely after day 2 and 6 of incubation in non-agitated systems. Isolate BTL (+g)-Cr7 was able to degrade long chain C30–C36 completely after 2 days of incubation at 37 °C. Another isolate showing ability to degrade C34–C38 was RETL-Cr3. Isolate STL-Cr7 and STL (-g)-Cr8 consistently degraded C16–C38 up to 100 % after 6 days in non-agitated system. Strain STL-(-g)-Cr8 had the highest biodegradation rates achieving 79.7 % biodegradation after 2 days of incubation. Although RETL-Cr3 and STL-Cr7 also achieved 80 % of biodegradation after 6 days of incubation, the initial biodegradation rate was slower compared to STL-(-g)-Cr8. Hence STL-(-g)-Cr8 was selected as the best crude oil-degrader among the 12 isolates and were partially characterised via biochemical tests. Alongside STL-(-g)-Cr8, bacteria coded as BTL-(+g)-Cr7 were also selected because of its ability to utilize longer chain alkanes.

Most of the petroleum biodegradation studies show that agitation significantly increased biodegradation of crude oils (Foster 1962; Gibson and Subramaniam 1984; Watkinson 1980; Britton 1984). Conversely, this situation was not observed in this study. Screening of potential degrading microorganisms using agitated system showed contradicting results compared with non-agitated system. Most of the agitated cultures showed poor performance for the degradation of C16–C38 as compared to cultures in non-agitated condition. The only bacterium that showed high biodegradation rates for short chain alkanes under agitated condition was RSSF-Cr1. None of the isolates were able to degrade long chain alkanes by more than 50 % after 6 days of incubation. This might be due to the origin of the microorganisms. Almost all of the microorganisms used in this research were from petroleum wastes, which were covered by oily substances preventing the diffusion of oxygen. The high degree of aeration provided might be toxic to these microorganisms (Madigan et al. 1997). Another other possibility is that agitation subjected the isolates to high shear stress (Morgan and Watkinson 1990). Some of the specific enzymes responsible for catalysing degradation of crude oil components are very sensitive to oxygen. While enzymes are synthesised inside the cell, their secretion is important for the initiation of the degradation of extracellular macromolecules, which must be broken down into smaller subunits prior to uptake (Rojo 2009; Ajisebutu et al., 2001; Maier et al. 1999).

The reduction of the crude oil in the cultures was established for most isolates after a few days of incubation in the agitated system (Fig. 1a, b). Some problems occurred prevented sampling processing of a few bacteria, RAS-Crl, BSSF-Crl, RFTA-02 and BAS-Crl. Formation of slimy and foam-like oil clumps was observed after a few hours to 2 days of cultivation (Fig. 1a, b), making it was difficult to obtain homogenous aliquots of the cultures. The oil clumps remained in clusters or aggregates and smaller clusters could not be obtained despite of vigorous shaking of the flasks.

Besides the formation of oil clumps by a few strains, most of the cultures showed signs of emulsification (Fig. 2a, b). This emulsification of the crude oil into tiny oil droplets could be observed within hours of shaking at 250 rpm for RSSF-Crl, RETL-Crl, STL-Cr7, STL-(-g)-Cr8 and MFTA-Wl. This observation is very common in most petroleum biodegradation and biosurfactant studies (Shibulal et al. 2014; Bryant 1987; Cooper 1982). The results provided the evidence for the production of biosurfactants by these microorganisms. Biosurfactants and extracellular enzymes are important agents in the degradation of aliphatic macromolecules (Robert and Philip 2012; Maier et al. 1999).

Complete biodegradation or mineralization involves the oxidation of the parent compound to form carbon dioxide and water, a process that provides both carbon and energy for growth and reproduction of cells (Rojo 2009; Maier et al. 1999,). Low degradation in all agitated culture might be due to lack of internal or extracellular enzymes. Lack of appropriate biodegrading enzymes is one of the common reasons for persistence of organic contaminants, particularly those with unusual chemical structures that existing enzymes do not recognize.

3.2 Characterization of Selected Bacteria

The 3 strains that were selected for biochemical testing were STL-(-g)-Cr8, RSSF-Cr1 and BTL-(+g)-Cr7. Twelve different biochemical tests had to be carried out to characterize the 3 selected isolates, and the results are shown in Table 3.

All three isolates were Gram-negative. RSSF-Crl was rod shape, while STL-(-g)-Cr8 and BTL-(+g)-Cr7 were cocci, with fresh cultures, however, appearing to be short rods. Coccobacilli are often short rods becoming spherical in stationary phase of growth. Based on the results of the biochemical tests and their cellular morphologies, RSSF-Crl was identified as Proteus sp., while STL-(-g)-Cr8 and BTL-(+g)-Cr7 were identified as the genus Acinetobacter.

Strain STL-(-g)-Cr8 and BTL-(+g)-Cr7 were rod shaped Acinetobacter bacteria with 0.9–1.6 µm in diameter and 1.5–2.5 µm in length becoming spherical in stationary phase of growth [4]. They commonly occur in pairs and also in chains of variable length. Cells do not form spores. Cells are Gram-negative. Swimming motility does not occur, but the cells display “twitching motility” when observed under the microscope, presumably because of the presence of polar fimbriae (Baltimore 1994). They grow well on non-selective media such as nutrient agar. They are oxidase negative and catalase positive. Most bacteria grow well in defined media (as in this case was basal salts medium) containing a single carbon and energy source; they use ammonium or nitrate salts as the source of nitrogen and display no growth factor requirement (Baltimore 1994). Species of this genus occur naturally in soil, water and sewage (Baltimore 1994). In this study, both STL-(-g)-Cr8 and BTL-(+g)-Cr7 were from a treatment lagoon at a petroleum refinery. Acinetobacter sp. is also one of the genera commonly reported to be encountered in hydrocarbon-contaminating soils (Kampher and Steiof 1991; Scott and Finerty 1976).

RSSF-CrI bacteria were straight rods with 0.4–0.8 µm in diameter and 1–3 µm in length (Baltimore 1994). The bacterium was motile when observed by light microscope, which is one of the characteristics of the genus Proteus. The bacteria spread in a uniform film over moist surfaces of nutrient media solidified with agar. Proteus bacteria have both a respiratory and a fermentative type of metabolism (Baltimore 1994). The Proteus sp. isolated was oxidase-negative and catalase-positive, and was capable of reducing nitrates. Species of this genus commonly occur in the intestines of humans and a wide variety of animals; they also occur in manure, soil and polluted waters (Baltimore 1994). As for RSSF-Crl, it originated from a soil-sludge farm. Proteus sp. has rarely been used in studies as an oil-degrading strain (Shaw et al. 1985; Kalish et al. 1964).

3.3 Biodegradation of Crude Oil by Selected Bacteria

This section described the biodegradation potential of the selected bacteria in greater details. STL-(-g)-Cr8 showed the highest biodegradation rate among all isolates; RSSF-Crl, was the best n-alkanes degrader under agitated conditions, and BTL-(+g)-Cr7 exhibited ability to degrade higher molecular weight n-alkanes.

Figure 3a–c shows the crude oil biodegradation by STL-(-g)-Cr8 (Acinetobacter sp.) under non-agitated condition. The chromatograms of the control (a) and the partially degraded crude oil by STL-(-g)-Cr8 (b) were used as comparison. In general, there was a significant decrease in all hydrocarbon peaks after day-2 (Fig. 3b) and day-6 (Fig. 3c) of cultivation as compared to the control (Fig. 3a). The short chain alkanes below C10 were not detected in the chromatogram because they are generally lost by evaporation or by dissolution in water (Brown 1987). The performance of STL-(-g)-Cr8 in non-agitated system is presented in Table 4. The percentage biodegradation of each standard compound (C16–C38 alkanes) after days 2 and 6 of incubation were more than 30 % degraded on day 2. Biodegradation of alkanes below C34 was achieved above 80 % and C34–C38 alkanes were fully degraded after days 6. Published reports show biodegradation of up to 90.6 % on day 10 by Oscillatoria salina (Raghukumar et al. 2001). However, the results could not be compared directly since the parameters and conditions were different. Further optimization of the conditions and parameters might improve the biodegradation process.

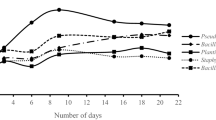

The change of the peaks of respective alkanes is presented in Fig. 4. The shorter length alkanes decrease more rapidly as compared to the longer ones. This finding is in a good agreement with most published research (Brown 1987; Blasig et al. 1988). It is commonly known that the greater the chain length and amount of branching, the more resistant compounds are to microbial attack. It is possible that shorter alkanes are metabolised preferentially, since less energy is required in breaking down simple compounds (Blasig et al. 1988; Maier et al. 1999). The rate of biodegradation of crude oil by strain STL-(-g)-Cr8 was calculated as 0.65–1.15 % h−1. Figure 5 shows the profile of crude oil degradation by BTL-(+g)-Cr7. BTL-(+g)-Cr7 showed a preference for metabolising longer chain n-alkanes. C36 and C38 compounds were first fully degraded within 2 days while by C30–C34 were fully degraded after 6 days. The degradation rate varied from 1.05 to 2.08 % h−1 which is 2 times higher than for STL-(-g)-Cr8.

However, all other compounds were degraded less than 70 % after days 6 of incubation, except for C26 and C28 in which 74.75 and 82.84 % were degraded, respectively. The profiles of crude oil biodegradation observed were the opposite to other published data (Brown 1987). This may be explained by the conditions of the original habitat from which the strain was isolated which are dominated by long chain alkanes. Results suggest that degradation of shorter alkanes could be enhanced using mixed cultures, that is, combining potential oil-degrading strains, which will complement each other’s role.

The potential biodegradation of crude oil by RSSF-Crl (Proteus sp.) under agitated condition was studied. Generally, agitated conditions showed no major improvement to the biodegradation process. Only the bacteria coded as RSSF-Crl performed better under agitated condition. During the biodegradation process under non-agitated condition, RSSF-Crl degraded C20 alkanes at 0.93 % h−1, while the rate increased to 1.30 % h−1 when agitation was provided, which means the rate of biodegradation had increased by 39.7 %. Other studies on certain bacteria had shown a higher increase in biodegradation rate, ranging from 50–60 % when agitation was provided (Blasig et al. 1988; Okoh et al. 2001; Raghukumar et al. 2001). Figure 6 shows the comparison of biodegradation of crude oil by RSSF-Crl under non-agitated and agitated conditions. All compounds showed increase in biodegradation under agitated condition. The differences in the biodegradation on shorter chain alkanes were more significant than for the longer ones, implying aeration was required for the better degradation of shorter chain alkanes.

4 Conclusions

In this study, 12 cultures of bacteria with potential ability to degrade n-alkanes were successfully isolated. Three of the best n-alkanes degraders were partially identified via biochemical tests; two were Acinetobactor spp while the other belonged to Proteus sp. STL-(-g)-Cr8, identified as Acinetobacter sp. yielded the highest biodegradation rate, in which 80–100 % of the standard alkanes were degraded within 6 days at varying rates, ranging from 0.65 to 1.51 % h−1. It was able to degrade most of the n-alkanes (C16–C38) present in crude oil without any addition of organic nitrogen and phosphorus source. Overall, the biodegradation rate of non-agitated cultures was nearly 39.7 % higher than in agitated cultures. The only bacteria that showed improvement in biodegradation under agitated condition was RSSF-Cr1 (Proteus sp.). RSSF-Crl biodegradation rate on C20 was higher than non-agitated cultures. BTL-(+g)-Cr7, an Acinetobacter sp. had an ability to degrade longer chain alkanes more rapidly than shorter ones. C36 and C38 were fully degraded within 2 days at a rate varying from 1.05 to 2.08 % h−1.

References

Ajisebutu S, Babalola G, Trejo-Hernandez MR (2001) Potential of Burkholderia cepacia RQ1 in the biodegradation of heavy crude oil. Int Microbiol 4:83–87

Al-Wasify RS, Hamed SR (2014) Bacterial biodegradation of crude oil using local isolates. Int J Bacteriol 1–8

Ashraf W, Mihdhir A, Murrell JC (1994) Bacterialoxidation of propane. FEMS Microbiol Lett 122:1–6

Atlas RM (1981) Microbial degradation of petroleum hydrocarbons: an environmental perspective. Microbiol Rev 45(1):180–209

Atlas RM (1995) Bioremediation of petroleum pollutants. Int Biodeterior Biodegradation 35(1–3):317–327

Baltimore M (1994) Bergey’s manual of determinative bacteriology, 9th edn. Williams & Wilkins, Baltimore

Blasig R, Mauersberger S, Riege P, Schunck W-H, Jockisch W, Franke P, Muller H-G (1988) Degradation of long-chain n-alkanes by the yeast Candida maltosa II. Osidation of n-alkanes and intermediate using microsomal membrane fractions. Appl Microbiol Biotechnol 28:589–597

Brito EM, De la Cruz Barron M, Caretta CA, Goni-Urriza M, Andrade LH, Cuevas-Rodriguez G, Malm O, Torres JP, Simon M, Guyoneaud R (2015) Impact of hydrocarbon, PCBs and heavy metals on bacterial communities in Lerma River, Salamanca, Mexico: investigation of hydrocarbon degradation potential. Sci Total Environ 521–522:1–10

Britton LN (1984) Microbial degradation of aliphatic hydrocarbons. In: Gibson DT (ed) Microbial degradation of organic compounds. Marcel Dekker, New York, pp 89–129

Brown LR (1987) Oil degrading microorganisms. Chem Eng Prog October 35–40

Bryant RS (1987) Potential uses of microorganisms in petroleum recovery technology. Proc Okla Acad Sci 67:97–104

Coon MJ (2005) Omega oxygenases: nonheme-iron enzymes and P450 cytochromes. Biochem Biophys Res Commun 338:378–385

Cooper DG (1982) Biosurfactant and enhanced oil recovery. Proc Int Conf Microbial Enhanced Oil Recovery. Afton, Oklahoma, pp 112–113

Das N, Chandran Okoh P (2011) Microbial degradation of petroleum hydrocarbon contaminants: an overview – SAGE Hindawi. Biotechnol Res Int 1–13

Foster JW (1962) Hydrocarbons as substrate for microorganisms. Anton van Leuwenhooke Microbiol Serol 28:241–274

Gibson DT, Subramaniam V (1984) Microbial degradation of aromatic hydrocarbons. In: Gibson ET (ed) Microbial degradation of organic compounds. Marcel Dekker, Inc., New York, pp 181–252

Harayama S, Hara A, Baik A, Shutsubo K, Misawa N, Smits THM, van Beilen JB (2004) Cloning and functional analysis of AlkB genes in Alcanivorax borkumensis SK2. Environ Microbiol 6:191–197

Head IM, Jones DM, Rolly WF (2006) Marine microorganism make a meal of oil. Nat Rev Microbiol 4:173–182

Kalish PJ, Stewart JA, Rogers WF, Bennett EO (1964) The effect of bacteria on sandstone permeability. J Petrol Technol 16(7):805–814

Kampher P, Steiof M (1991) Microbiological characterization of a fuel-oil contaminated site including numerical identification of heterotrophic water and soil bacteria. Microbial Ecol 21:227–251

Labinger JA, Bercaw JE (2002) Understanding and exploiting C–H bond activation. Nature 417:507–514

Leahy JG, Colwell RR (1990) Microbial degradation of hydrocarbons in the environment. Microbiol Rev 54(3):305–315

Madigan MT, Martinko JM, Parker J (1997) Brock biology of microorganisms. Prentice Hall, Englewood Cliffs, pp 473–531

Maier RM, Pepper IL, Gerba CP (1999) Environmental microbiology. Academic Press, London, pp 365–402

Morgan P, Watkinson RJ (1990) Physiology of aliphatic hydrocarbon-degrading microorganisms. In: Ratledge C (ed) Physiology of biodegradative microorganisms. Kluwer, Dordrecht, pp 79–92

Okoh, Ajisebutu S, Babalola G, Trejo-Hernandez M (2001) Potential of Burkholderia cepacia RQ1 in the biodegradation of heavy crude oil. Int Microbiol 4(2):83–87

Othman N, Irwan JM, Hussain N, Abdul-Talib S (2011) Bioremediation a potential approach for soil contaminated with polycyclic aromatic hydrocarbon: an overview. Int J Sustain Construct Eng Technol 2(2):48–53

Raghukumar C, Vipparty V, David JJ, Chandramohan D (2001) Degradation of crude oil by marine cyanobacteria. Appl Microbiol Biotechnol 57:433–436

Robert JW, Philip M (2012) Physiology of aliphatic hydrocarbon-degrading microorganisms. In: Colin R (ed) Physiology of biodegradative microorganism, 2nd edn. Springer, Heidelberg, pp 79–92

Rojo F (2009) Minireview: degradation of alkanes by bacteria. Environ Microbiol 11(10):2477–2490

Scott CCL, Finerty WR (1976) Characterization of intra cytoplasmic hydrocarbon inclusions from the hydrocarbon-oxidizing Acinobacter sp. HO1-N. J Bacteriol 127:481–489

Shaw JC, Bramhill B, Wardlaw NC, Costerton JW (1985) Bacterial fouling in a model core system. Appl Environ Microbiol 49(3):693–701

Shibulal B, Al-Bahry SN, Al-Wahaibi YM, Elshafie AE, Al-Bemani AS, Joshi SJ (2014) Microbial enhanced heavy oil recovery by the aid of inhabitant spore-forming bacteria: an insight review. Sci World J 1–12

van Beilen JB, Funhoff EG (2007) Alkane hydroxylases involved in microbial alkane degradation. Appl Microbiol Biotechnol 74:13–21

van Beilen JB, Li Z, Duetz WA, Smits THM, Witholt B (2003) Diversity of alkane hydroxylase systems in the environment. Oil Gas Sci Technol 58:427–440

van Hamme JD, Singh A, Ward OP (2003) Recent advances in petroleum microbiology. Microbiol Mol Biol Rev 67:503–549

Venosa AD, Zhu X, Suidan MT, Lee K (2001) Guidelines for the bioremediation of marine shorelines and freshwater wetlands. U.S. Environmental Protection Agency, National Risk Management Research Laboratory Cincinnati, Ohio

Voordouw G (2011) Production-related petroleum microbiology: progress and prospects. Curr Opin Biotechnol 22:1–5

Watkinson RJ (1980) Interaction of microorganisms with hydrocarbons. In: Harrison DEF, Higgins IJ, Watkinson RJ (eds) Hydrocarbons in biotechnology. Heyden, London, pp 1–24

Watkinson RJ, Morgan P (1990) Physiology of aliphatic hydrocarbon-degrading microorganisms. Biodegradation 1:79–92

Wentzel A, Ellingsen TE, Kotlar HK, Zotchev SB, Throne-Holst M (2007) Bacterial metabolism of long-chain n-alkanes. Appl Microbiol Biotechnol 76:1209–1221

Zobell CE (1946) Action of microorganisms on hydrocarbons. Bacteriological Rev 10:1–49

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Heng, C.Y., Salleh, M.M., Yahya, A., Ibrahim, Z., Hussin, H. (2017). HC-0C-07: Isolation and Characterisation of Crude Oil Degrading Microorganisms from Petrochemical Wastewater. In: Heimann, K., Karthikeyan, O., Muthu, S. (eds) Biodegradation and Bioconversion of Hydrocarbons. Environmental Footprints and Eco-design of Products and Processes. Springer, Singapore. https://doi.org/10.1007/978-981-10-0201-4_11

Download citation

DOI: https://doi.org/10.1007/978-981-10-0201-4_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0199-4

Online ISBN: 978-981-10-0201-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)