Abstract

As the world’s largest developing country, China creates considerable quantities of municipal solid waste (MSW) every day, which is one of the most serious urban pollution sources. Waste to energy can not only reduce greenhouse gas emission from simple piling of solid waste, but also can generate energy to cope with the increasing demand on fossil fuel. So far, landfill gas-fired power generation, MSW incineration and anaerobic digestion are the primary waste to energy technologies successfully applied in China. In recent years, MSW incineration power generation technologies have undergone rapid development with the demand for a low carbon economy and the encouragement of national policies. The distribution and operation status of various waste to energy facilities built in China are assessed. Meanwhile, the limitations and potential development trend of landfill, incineration and anaerobic digestion are discussed. In addition, a series of preferential policies and regulations to encourage the expansion of MSW to energy is presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Anaerobic digestion

- Incineration

- Landfill gas-fired power generation

- Municipal solid waste

- Waste to energy

- Solid waste management

1 Introduction

As the largest developing country in the world, China creates considerable quantities of municipal solid waste (MSW), which is one of the most serious urban pollution sources. China is faced with serious environmental and administrative challenges caused by MSW management. MSW to energy is a novel eco-friendly renewable energy resource and has attracted the attention of both national and local governments with various preferential policies. Not only can MSW to energy contribute to a significant reduction in greenhouse gas emissions caused by storeyards and landfills, but it can also generate clean energy to offset the increasing energy requirements. Waste-to-energy (WTE) incineration recovers energy from MSW and produces electricity and/or steam for heating, which is recognized as a renewable source of energy and is playing an increasingly important role in MSW management in China. Anaerobic digestion is a method engineered to decompose organic matter by a variety of anaerobic microorganisms under oxygen-free conditions. The end product of anaerobic digestion includes biogas (60–70 % methane) and an organic residue rich in nitrogen. This technology has been successfully implemented in the treatment of agricultural wastes, food wastes, and wastewater sludge due to its capability of reducing chemical oxygen demand (COD) and biological oxygen demand (BOD) from waste streams and producing renewable energy (Chen et al. 2008).

China’s MSW to energy development has the characteristics of late starting, large scale and rapid growth, so it urgently needs to present and analyze the development status and challenges of MSW to energy technologies in China in view of latest situations. In recent years, central and local governments have made great efforts to improve MSW management in China. New regulations and policies have been issued, urban infrastructure has been improved, and commercialization and international cooperation have been encouraged. Nevertheless, China still falls behind developed countries in MSW technologies. Therefore, more efforts on developing efficient MSW disposal technologies are in demand based on the assessment of MSW management. In this chapter, the distribution and operation status of various waste to energy facilities (i.e., landfill, incineration and anaerobic digestion) in China will be assessed, as well as their limitations and potential development trend. In addition, a series of preferential policies and regulations to encourage the expansion of MSW to energy is presented.

2 Current Status of MSW Production and Management in China

2.1 MSW Generation and Characteristics

The sustained growth of the Chinese economy, with its rapid urbanisation and improved living standards, has generated a large amount of MSW and a significant rise in total energy consumption. From 1980s to 2000s, MSW production in China was expanding rapidly (Huang et al. 2006). The quantity of MSW collected and transported in 1981 was 26.1 million tons; in 2002, 136.5 million tons of MSW was handled, which was 3.2 times more than 1981. Nevertheless, the growth rate was slowing down in recent ten years, with annual waste production growing less than 10 % per year, resulting 172.4 million tons of MSW being handled in 2013. Figure 1 shows the situation of MSW management in China from 2004 to 2013 (China 2003–2014).

MSW management is a systematic project that includes collection, transportation, transferring, treating and recycling. Chinese MSW management began in the late 1980s; prior to the adoption of this management, MSW was placed in open dumps. While the disposal rate of MSW was less than 2 % before 1990, the level of MSW disposal was gradually improved in the 1990s. By 1999, there were 696 MSW disposal plants with the disposal rate of 63.4 %, and less than 200 harmless treatment plants with a harmless treatment rate of 20.3 % in 668 Chinese cities.

In China, the MSW is generally divided into organic matter, inorganic matter, paper, fiber, timber bamboo, plastic, rubber, glass and metal (Li et al. 2001). The respective composition of MSW after entering the municipal recycling system is shown in Fig. 2. Characteristics of waste generation from several OECD countries are listed in Table 1. It can be seen that the the proportion of organic waste reaches as high as 59 %, which leads to the high moisture content of MSW, typically around 20–30 % in the U.S. and European countries (Cheng et al. 2007; Hu and Cheng 2013).

The characteristic of MSW in China 2008, in dry weight, % (China 2014)

The composition of MSW is influenced mainly by the city size, geography circumstance, habit and living standard of the residence and fuel type people use. The quantity of paper, plastics, and glass is relatively small when compared with western countries, because most of the recyclable paper and glass are collected before entering the MSW management system. The calorific values (3000–6700 kJ/kg) of Chinese MSW are typically less than those of the developed countries (8400–17,000 kJ/kg), which are mainly composed of sorted organic wastes (Cheng and Hu 2010; Thipse et al. 2001). The low calorific value of the mix collected MSW is mainly caused by food remnants, resulting in incineration difficulties and applicable landfill sites. Nevertheless, the proportion of plastics is increasing, which is related to the increased use of plastic package materials (Huang et al. 2006).

2.2 Source-Separated Collection and Transportation of MSW

Utilizing source-separated collection is one of the key steps in MSW management. Source-separated collection begins at the source of MSW and involves the whole process of collection, transportation, disposal and recycling. The source-separated collection enables better waste minimization, resource utilization and hazardous waste disposal.

The principle underlying MSW source-separated collection requires that large volume wastes and hazardous wastes are first separated, and then the remaining MSW are classified in detail. The classification method of MSW applied in the collection system of eight megacities are presented in Table 2. As can be seen, all cities have followed relevant national standards. Although several differences existed among these cites, most of the cities share a similar philosophy: recyclables should be separated beforehand, while hazardous waste such as batteries and light tubes should be separated during the collection. Residents in Beijing, Xiamen, Shenzhen and Hangzhou are encouraged to classify waste as kitchen waste, recyclables, hazardous waste and other waste; while Shanghai is encouraging the use of a four-category classification: recyclables, hazardous waste, wet waste and dry waste.

It is worth pointing out that during the past years, Chinese cities have been consistently adjusting and refining the classification according to their different city conditions. For example, at the end of 20th century, sanitary landfill was the primary MSW disposal method in Shanghai, thus the separation of hazardous waste, such as battery and old lamp tube, from the buried waste is necessary. After that, the development of incineration increased rapidly; because the fused glass would impose a hazardous effect on the incinerator, and the private sectors are not willing to recycle glass due to the low economic profit, Shanghai started to separate the glass from the household scraps. Thus for the service area of incineration, the MSW is classified as combustible materials, glass and hazardous waste; while in other service areas, waste is classified as organic waste, inorganic waste and hazardous waste. In 2014, Shanghai started to implement the “Method for MSW Classification and Reduction” and adopted a four-category classification: recyclables, hazardous waste, wet waste and dry waste.

3 Overview of Waste to Energy Technologies Status in China

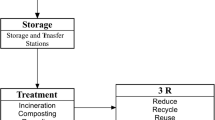

Traditional integrated MSW management plans have focused on decreasing the amount of material that must be disposed of via incineration or landfilling. More recently, “zero waste” strategies have come to the fore, emphasizing prevention and materials recovery but also sharpening the focus on energy recovery as an approach for securing additional environmental benefits, including reductions in land use and emissions. Figure 3 displays an integrated sustainable solid waste management hierarchy, with environmental efficacy declining from top to bottom. The hierarchy of waste management advocates that the best approach to waste management is to first and foremost try to reduce waste generation and separate potential recyclables at source to improve the quality of materials for reuse, including organics for composting or anaerobic digestion. The waste hierarchy leads to reduced quantities requiring transfer and disposal; extends landfill lifetimes; reduces Greenhouse Gas generation; provides valuable recovered resources (e.g., methane gas and compost).

Environmental hierarchy for solid waste management, revised from Themelis (2013)

In fact, waste-to-energy (WTE) technologies come in different forms, offer a variety of outputs, and are in various stages of development, but they have two common objectives: to both manage waste and generate energy. Digestion-based waste-to-energy technology can be deployed to extract useful energy from biodegradable organic materials and from landfill gas that is captured to reduce pollutant and greenhouse gas emissions (Kaufman et al. 2010). Incineration and advanced thermal conversion of the residual waste after recycling and composting represent environmentally sound MSW management options. Conventional combustion-based processes transform solid wastes into heat for direct use or further conversion into steam and electricity, while advanced conversion processes convert solids into gaseous or liquid fuels offering broader utility.

3.1 Landfill Gas-Fired Power Generation

3.1.1 Status of MSW Landfill in China

Landfill, incineration and composting are the three primary MSW disposal methods (Wang et al. 2009; Tian et al. 2013). In the late 20th century, landfill was recommended as the only option for waste management, because landfill is cost effective and easy to implement. However, it may lead to secondary pollution problems such as water and air pollution and soil contamination. Nowadays because of the change in the characteristics of waste, and the implementation of the 3R principle of waste management, i.e., waste reduction, reuse and recycle, composting and sanitary landfill are common and more suitable management practices (Tinmaz and Demir 2006). Nevertheless, waste disposal at landfill is still widely applied in many cities in China, handling almost over 70 % of the total waste as shown in Fig. 4. Composting accounts for less than 10 %, which is classified into sub-type of “others” in Fig. 4. Composting, costly to implement and maintain, has become an unpopular method. Furthermore, the fertiliser, being of low nutrient contents and containing certain heavy metals, can only be used as a soil modifier.

Different proportions of MSW treatment modes in the perspective of administrative division in the year of 2013 (China 2014)

As presented in Figs. 4 and 5, most of the Organization for Economic Cooperation and Development (OECD) countries tend to decrease the ratio of MSW disposed in landfill. Especially for Germany, all landfill sites were shut down in 2005. Other developed countries with limited land resource, i.e., Austria, Belgium and Sweden etc., are also vigorously decreasing MSW disposal capacity and looking for a more sustainable way, such as waste to energy development. Although China has vast territory, the arable land per capita in China is no more than 1.33 m2, which is less than 1/2 of the global average (Zheng et al. 2014). Due to the infinite land capacity for sustainable development, landfill should be the last alternative considered for China. In recent years, China was encouraging the development of landfill, leading to the proportion of MSW treated in landfill decreased from 89 % in 2001 to 68 % in 2013 of the total MSW disposed.

3.1.2 Landfill Scenarios

As presented previously, the fraction of organic materials in MSW is relatively high. Poor management of organic waste (such as kitchen waste) is usually related to leachate percolation, causing serious sanitary and environmental problems such as unpleasant odors, the risk of explosion in landfill areas, as well as groundwater contamination (Mor et al. 2006). Necessary measures are required to cut down the emission of landfill gas (LFG) and leachate so as to prevent pollutions (MOHURD 2004, 2010). Larger sanitary landfill can reduce the cost of land requirement and environmental assessments, and can also be equipped with better pollution control facilities. Every sanitary landfill has designed carefully considered pollution prevention systems, such as leachate collection and treatment systems, gas collection and treatment systems, flood control systems and permeation prevention systems. For example, the Laogang Landfill Site in Shanghai has a daily capacity of 4900 tons, with an estimated service period of 45 years, which is equipped with leachate treatment and LFG collection facilities.

Yang et al. (2013) has summarized the landfilling technologies used in China into four scenarios. A brief overview of their main technical differences and the existing landfill situations in China, are summarized in Table 3. The open dump (Scenario 1) represents a dump site with no measures to control leachate or gas (e.g., lining and cover systems) and no regular landfilling operation processes (e.g., Waste compaction). Such sites mainly exist in remote, under-developed regions. Since the isolation of waste from the environment is not well managed, residual oxygen within the waste body may induce considerable aerobic degradation of the waste. In a sanitary landfill with LFG collection (Scenario 2), liner and cover systems have been introduced as well as leachate collection and treatment systems, but there is no LFG extraction system. In such a system, the LFG can migrate through the top cover layer. This type of landfill exists in most small Chinese cities. Compared with Scenario 2, the sanitary landfill (Scenario 3) has an LFG collection and flare system. According to the current Chinese standard of landfill management (MOHURD 2004), LFG must be collected effectively and be flared if it cannot be utilized for energy recovery. Hence, Scenario 3 may be a favorable replacement for Scenarios 1 and 2 in the near future. The sanitary landfill with LFG utilization (Scenario 4) represents the most advanced landfilling technology presently used in China. In this case, LFG is collected and used for energy recovery (usually for electricity production) with all the other measures being the same as those described for Scenario 2. Scenario 4 has now been applied to a number of big cities.

3.1.3 Use of Combined Heat and Power (CHP) Systems

Depending on the fuel and power generation option, extensive pretreatment may be required to remove siloxane, hydrogen sulfide, and other constituents with potential to cause corrosion, erosion, environmental control, and odor problems. Further cleaning and purification are necessary to achieve the quality required for injection of pipeline-quality renewable fuel in natural gas delivery systems.

Alternatively, combined heat and power (CHP) system can realize in situ utilization of LFG by converting it to electricity and heat. CHP is commonly used in European countries as it can increase the energy recovery efficiency of LFG. Fueled by electric industry deregulation, environmental concerns, unease over energy security, and many other factors, interest in CHP cogeneration technologies for distributed heat and power generation has been growing. Methane can replace natural gas as the fuel source in CHP systems. However, such facilities need to be strategically placed at or near customer facilities to efficiently supply the heating needs.

3.2 MSW Incineration

3.2.1 Potential of MSW as Biofuel

As a fuel, MSW poses a number of challenges. It is produced on a distributed basis, and its composition is highly variable, including a mix of organic and inorganic constituents. Hazardous and toxic waste stream components pose health and safety risks. Low energy density and high moisture, chlorine, and ash content lead to handling, combustion, slagging and fouling, corrosion, and byproduct management issues (Cheng and Hu 2010). Incineration of materials with heating capacities less than 3344 kJ/kg is probably not economical.

Lightly processed, post-recycling MSW received at mass-burn WTE plants has a heating value in the range of 10,000–12,500 kJ/kg; while high-intensity processing refuse derived fuel (RDF) is more amenable to firing in fluidized-bed combustor (FBC) units and advanced thermal conversion systems, with heating values roughly ranging from 12,500 to 15,000 kJ/kg, offers the potential for high-rate co-firing in pulverized coal plants. Mechanical, magnetic, thermal, biological, and other techniques may be applied to isolate and process combustible fractions. A typical system configuration of the MSW presorting process is illustrated in Fig. 6, which consists of three major units: shredding, air classification, and screening (Chang et al. 1998). After screening, the lightest portion in the MSW with the size greater than 100 mm can be exactly identified as the fluff-RDF; while the outputs with particle size larger than 100 mm and between 25 and 100 mm can be used as alternative fuels in the incineration facilities.

Representative system of the MSW presorting process (Chang et al. 1998)

After adding certain amount of combustion-supporting agent, sulfur fixing agent and antiseptic, RDF made from MSW can be packed as cubes or pellets for easy storage and transportation (Wei et al. 2009). It is not only convenient for storage and transportation, and can significantly improve the fuel performance, control pollution (Hernandez-Atonal et al. 2007; Jiang et al. 2008), has received widespread attention in waste energy reuse. Of course, installing and operating fuel-processing systems at the plant site imposes energy and cost penalties. Centralized manufacturing of higher-grade fuels offers potential economies of scale, while source-based production creates opportunities to reduce hauling costs and facilitate long-distance trade.

3.2.2 Incinerator Types and Process

The incinerator is the core of MSW incineration process, which cost accounts for approximately 50 % of the MSW incineration power plant. The technologies of its craft and design have a direct influence on MSW disposal effects and economic benefits, as well as a direct impact on the subsequent treatment of flue gases. There are various incinerators such as stoke grate incinerators, fluidised bed incinerators, rotary kiln furnaces and pyrolysis gasification furnaces.

Figure 7 shows the comparison of different MSW incinerators in China (CAEPI 2011). Stoke grate incinerators and fluidised bed incinerators predominate, while pyrolysis furnaces and rotary kiln furnaces are only adopted on a small scale. At present, most incineration facilities adopting mechanical stoke grate technologies are located in the more economically developed cities of eastern coastal areas, especially in the provincial capital and the sub-provincial cities. By contrast, incineration facilities using fluidised bed technologies are predominantly located in small and medium cities, as well as the large cities in the middle and western regions of China that are economically less developed. Comparatively, the cost of investment and operation of fluidised beds are relatively low. Furthermore, coal as the auxiliary fuel for fluidised beds, is abundant in central and western China. The facility costs for stoke grate incinerators vary between US$98 million and US$164 million per thousand tonnes daily of treatment capacity; while the costs for fluidised beds are merely half of that (CAEPI 2014). The operation and maintenance of stoke grate incinerators and fluidised beds are both costly.

It must be pointed out that the market share of stoke grate becomes increasingly higher than that of the fluidised bed. Total incineration capacity and total power generation capacity of stoke grate incinerator are 26.2, 31.5 and 32.6 % respectively from 2011 to 2013, while counterparts of fluidised bed incinerator are 11.3, 11.1 and 14.0 % respectively. There are 21 plants adopting stoke grate among the 28 newly built MSW incinerators in the year of 2013. The reason for this tendency is that the technology of fluidised bed is not as mature and stable as stoke grate; therefore, all advantages, such as complete combustion of native MSW through mixed unsorted collection, less dioxin emission, and no additional investment in sewage treatment etc., are not as good as expected. Due to this reason, the Chinese government is prone to support promotion of stoke grate at present, which is best illustrated by the first selection of “3A Selection of MSW Incineration Plants” in China lasting a whole year from March, 2012 to March, 2013. All of the MSW incineration plants adopting fluidised bed technology were unconditionally excluded for the selection, which represented the government’s attitude and hindered the development of fluidised bed technology to a certain extent.

A MSW incineration power system generates electricity by driving turbines with high temperature steam produced by the incineration of MSW, as shown in Fig. 8. After transportation in closed trucks, MSWs were poured into a storage pool to ferment for approximately three days. The characteristics of MSW in China are unsorted coupled with low calorific values (3000–5000 kJ/kg) and high moisture rates (45–65 %), which organic ingredients account for 40–60 % of dry weight. This fermentation procedure could reduce the materials’ humidity and increase their heating values. MSWs were then burned in incineration boilers to heat water to generate steam, which is the driving force of turbine generators. The flue gases and solid residues generated during the MSW incineration process should be treated accordingly to avoid secondary environmental pollution, especially the flue gases which contain significant amounts of dioxins, particulate matters, heavy metals, sulfur dioxide, and hydrochloric acid. The flue gases are first sent into a flue gas scrubber to remove acidic material, after which bag filters are used to remove dust particles so that the gas can meet the final emission standards. Fly ash, one of the flue gas residues, is a hazardous substance and should be dealt with in accordance with hazardous material waste laws.

Schematic diagram of MSW incineration and power generation process (Zheng et al. 2014)

3.2.3 Current Status and Development Trend of Waste Incineration in China

-

(1)

Rapid development of large scale waste incineration projects

Although MSW incineration power generation in China is a recent development, the MSW incineration power generation technologies have undergone rapid development with the demand for a low carbon economy and the encouragement of national policies. Since the inception of the first incineration power plant in 1988, the number of MSW incineration plants has increased to 166 by the end of 2013, and the MSW incineration capacity has increased to 158488 tonnes/day. Figure 9 shows the daily processing capacity and the number of MSW incineration plants from 2003 to 2012 (China 2014).

Fig. 9 In China, the development of MSW incineration power generation project tends to be large scale. Some significant MSW incineration power plants are shown in Table 4. In 2013, the Lujiashan incineration plant (Asia’s largest MSW incineration power generation project) underwent trial operation and eventually supplied 320 million kWh of electricity to the grid per year. The first driving factor is the difficulty in selection a proper site for incineration plant, due to the “Not-In-My-Back-Yard” effect. Thus it is reasonable to build a large scale plant once the location is determined, which treatment capacity is up to 2000–3000 tonnes, sometimes even high up to 5000 tonnes. In addition, because MSW incineration requires massive funding and complex technologies, scale economy could ensure enterprises to obtain better economic benefits. More importantly, a larger scale MSW incineration tends to use more advanced technologies and will ultimately be better for the environment. Therefore, the Chinese government is vigorously promoting the construction of large incineration plants (Fig. 10).

Table 4 MSW incineration power plants of significance in China (Zheng et al. 2014) Fig. 10 As shown in Fig. 4, more MSW is treated by incineration in the eastern coastal areas of China, such as the provinces of Shanghai, Jiangsu, Fujian and Guangdong. Actually, more than 2/3 of the incineration power plants are concentrated in the Yangtze and Pearl River Delta regions; the rest are located in the middle and western provincial capital cities. Obviously, we can conclude that MSW incineration facilities currently operating in China are primarily located in cities that are economically developed and densely populated.

-

(2)

Disputes on waste incineration technology tend to be more rational

“Whether a white cat or black cat, a good cat catches mice”. In recent years, controversy over waste incineration technology has never stopped, one of the focus of the debate is entangled in the selection of stoke grate or fluidized bed. As knowledge developed and practice experience accumulated, a rationale is gradually emerging for the selection of these two technologies.

Stoke grate has been developed for nearly a hundred years, which is more mature and stable than fluidised bed, thus currently dominating the Chinese market. In contrast, fluidised bed is being developed by domestic independent research with independent intellectual property rights to the technology, which gradually matures as improvement of more than ten years has been informed by practical experience. It is characterized by more fully and completely combustion, thus has good adaptability for the region acceptable to sludge and solid waste of low heat value.

-

(3)

Standards continue to improve

In recent years, it is not rare to find that MSW incineration plants discharge pollutants beyond pollution limits. As the requirement of developing waste incineration technology and pollution control increased, the previous “Standard for pollution control on the municipal solid waste incineration (GWKB3-2001)” has been difficult to adapt to the new requirements. Revisions has been made and drafted to “Standard for pollution control on the municipal solid waste incineration (GB 18485-20)”, which started to be implemented in July 2014. Furthermore, the provinces such as Beijing, Shanghai, Guangzhou have laid out local standards, which are stricter than the national standard. As per update of new pollution standards, some of the existing incinerators need to carry out technical renovation to improve the performance of end flue gas treatment facilities. In the long-term, it will be favorable for the development of the incineration industry in China.

3.3 Anaerobic Digestion

3.3.1 Advantages of Anaerobic Digestion Technology for MSW

With the increasing quantities of MSW, limited landfill areas and increased environmental impact awareness, alternative methods are being sought to treat municipal solid waste. Anaerobic digestion is attractive because it contributes to the solution of several important problems in China. Anaerobic digestion provides an environmentally friendly method for treating municipal solid waste. Landfills are currently the most common MSW disposal method in China (Fig. 4). In 2000, about 25 million m3 of landfill leachate contaminated adjoining land and water sources while 17.6 million tons of undesirable CH4 gas (Wang et al. 2001), which is a strong greenhouse gas, were produced by bio-waste deposited in landfills. In modern landfills, although improved liner and cover systems have been applied, some leakage is inevitable due to non-standard operation, leading to the releases of methane, volatile organic compounds, hazardous air pollutants, and leachate. Worldwide, societies are realizing that bio-waste needs to be disposed of in more environmentally friendly ways, such as waste digestion and methane gas recycling.

Anaerobic digestion will reduce land requirements for MSW disposal. 134.7 million tons of municipal solid waste was produced in China in 2001, and required about 500 million m2 of land for disposal. With the increased urbanization in China, the cost of constructing and operating landfills will rapidly increase. Anaerobic digestion can substantially reduce the waste load on landfills. Meanwhile, anaerobic digestion can also produce useful fertilizer. An attractive option for treating the organic fraction of these wastes by anaerobic digestion is to compost the digestion sludge and then apply the stabilized residue on the soil as a fertilizer. Therefore, anaerobic digestion is the best technology for bio-waste disposal.

3.3.2 Status and Potential Assessment of Anaerobic Digestion Technology Development for MSW in China

Considerable success in using anaerobic technology for processing bio-waste is being reported by several recently constructed facilities in Europe. Although anaerobic digestion has been used in China for over 100 years, it is usually used to treat human and animal manure along with agricultural by-products. Compared with the large advanced anaerobic digestion plants in Europe, China still has a long way to go in developing effective bio-waste processing systems.

Introduction of Anaerobic Digestion Processes for MSW in China

Most anaerobic digestion plants used around the world can be divided into single phase, two-phase, and batch style plants. Batch reactors have economic advantages in developing countries, but their organic load rate is much lower than continuous feed systems and the reactors take up a larger area. Two-phase anaerobic digestion reactors have good shock load tolerance for the separation of acidification and methanation processes, but the technique is complex and relatively expensive. Single-phase reactors provide an acceptable result at less cost. Therefore, most recently built plants use single phase reactors. As listed in Table 5, most of the existing large-scale anaerobic digestion plants in China adopted single-phase digester. However, some plants setup one additional hydrothermal hydrolysis tank to facilitate efficient decomposition of biomass, such as the Suzhou Food Waste Treatment Plant (Jiangsu Province), Changchun Food Waste Treatment Plant (Jilin Province), and Shenzhen Municipal Organic Waste Treatment Plant.

New plants using high solid anaerobic digestion (with a total solid fraction of above 20 % compared to low solid plants with 4–8 % solid fraction) can improve energy production somewhat due to their high digestion efficiency and the process residues can be more easily dehydrated, which saves a great amount of water. Valorga and Dranco mode high solid anaerobic digestion plants have reactor volumes of less than 3300 m3 and heights usually less than 25 m. However, high organic load rates and high salt and fat concentrations make high solid anaerobic digestion systems difficult to operate, so suitable control systems are needed for Chinese plants. Wet fermentation is the mainstream of the anaerobic treatment on MSW in biogas production currently with the advantage of high speed of fermentation, mature technology to construct and manage, and convenient input and output for the material.

Utilizing biogas to generate electricity via CHP system has become the major efficient way to use biogas. There is a large scale anaerobic digestion plant in Anyang, Henan designed to utilize biogas as vehicle fuel instead of electricity.

Factors Affecting MSW Digestion Efficiency

For anaerobic digestion technologies, the digestion process relies on anaerobic bacteria that break down organic materials into sugars, acids, and then gases, leaving behind liquid and solid residues. Decomposition occurs over years to decades in landfills and days to weeks in purpose-built digesters. However, the digestion efficiency is affected and limited by the characteristics of substrate.

There are great variations in the composition of MSW between developed countries and China. The disposal and treatment rates in China are much lower than those in developed countries. In China, organic matters in MSW is not sorted before disposal, typically, in landfills or in incineration plants, so most biogas plants are based on the digestion of animal manure and are built in the countryside using low efficiency and locally developed technology. Waste separation and collection are being developed in some big cities such as Beijing, Shanghai, and Shenzhen to enable the conversion of bio-waste into biogas containing methane and the separation of solid materials from anaerobic digestion processes for use as fertilizers. Furthermore, with the popularization of central heating and gas-fired heating systems, the proportion of coal residue in the MSW has decreased gradually while the proportion of organic waste has increased. Figure 1 shows that the main component of Chinese MSW is bio-degradable organic matters which includes kitchen waste, hotel and restaurant waste, vegetable market waste, and garden waste (Jiang et al. 2007).

Since MSW includes many components, the ratio of carbon to nitrogen of the waste may not be suitable for anaerobic digestion, which will hinder efficient operation of the anaerobic digestion plant. Therefore, the various components in the waste stream must be collected separately so that the ratio of carbon to nitrogen can be adjusted to a suitable range by mixing the waste from different sources. In addition, the use of food residues as direct feedstuff is being limited by new regulations and transportation concerns in Chinese cities. Therefore, regulations are needed to facilitate separate collection systems for bio-waste with appropriate disposal technologies. If a bio-waste collection system can be set up and made compatible with existing collection systems, anaerobic digestion technologies for bio-waste disposal can be standardized. Since there are not yet any anaerobic digestion plants operating in any cities, an efficient design would be widely used throughout China.

Limitations to the Spread of Anaerobic Digestion Technology

-

(1)

The capital investment for energy production systems may be somewhat higher for anaerobic digestion systems than for conventional systems, and electricity is fairly inexpensive in China, unlike in many other countries. As such, the development of anaerobic digestion technologies is currently limited.

-

(2)

The costs of anaerobic digestion systems depend greatly on the local circumstances, including construction and labor costs, treatment capacity, the possibility of energy recovery, energy price, market, and taxes as well as the energy purchase tariff, land prices, and the worth of the digested material. Although the equipment for high solid anaerobic digestion plants is expensive, the operating costs are relatively low considering their smaller sizes, higher digestion efficiencies and water savings.

With costs increasing for landfills and energy taxes on fossil fuels, anaerobic digestion should be encouraged as a renewable energy source. Anaerobic digestion will be a highly competitive alternative for the treatment of MSW in the near future.

4 The Prospects of MSW to Energy Technologies in China

Globally, more than 1 billion tons of post-recycling MSW continues to be disposed of in landfills each year, including more than 130 million tons in the U.S, while European, Asian, and other nations move forward with strong commitments to energy recovery. Global adoption of integrated resource management strategies could dramatically increase deployment of incinerators and advanced conversion technologies. This development would reduce landfilling and associated emissions of methane, while expanded landfill gas capture and energy production could further reduce the carbon footprint of waste management practices.

In recent years, China has issued a series of polices to promote the harmless treatment of MSW, including the development of WTE. The foremost influential policies are as follows,

-

(1)

National 12th Five Year Plan (2011–2015)

-

Reform garbage fee collection methods, appropriate increase garbage fee standards and the level of financial subsidies;

-

Speed up the development of rural waste centralized treatment;

-

Improve the recycling system of renewable resources; establish and improve waste separation and recovery system;

-

Promote the resource utilization and harmless treatment of kitchen waste and other waste;

-

In 2015, the rate of MSW harmless treatment in all cities rose to 80 %. It is clearly put forward that incineration technologies will be employed to handle more than 30 % of MSW, a huge increase over current practice (Fig. 11).

-

-

(2)

Cleaner Production Law 2002

The Renewable Energy Law 2006. On February 28, 2005, the fourteenth conference of the National People’s Congress (NPC) passed the “Renewable Energy Law of the People’s Republic of China”, effective on January 1, 2006, which is the first and only legislation providing strong legal protection, as well as phased support, for the development of renewable energy sources. As the cornerstone of the development of renewable energy, it boosted the proportion of renewable energy in the energy structure dramatically, particularly wind and photovoltaic energy. However, some imperfections in this law gradually appeared during the expansion of wind and solar energy. In order to provide better legal protection, it was amended on December 26, 2009 and the amendments affecting seven articles took effect on April 1, 2010. Owing to the prosperity later than wind and solar energy, MSW to energy could benefit more from the amendments, which ensure its benign development and avoid analogous problems occurring during the development of wind and solar energy. There are some amendments closely related to MSW to energy that should be pointed out. Firstly, the amendments reiterate purchase obligation (grid companies should purchase all the electricity generated by the MSW to energy generating entities), but put it within the overall framework of the national plan, suggesting that MSW to energy is viewed as an integral part of the total national energy resource. The amendments also established a renewable energy development fund financed by budgetary allocations from the central government and the collection of renewable energy fees charged throughout China, in which the amounts accumulated are slated for use as compensation to grid companies for the additional expenses they incur in purchasing renewable energy (as opposed to conventional energy), and for grid connection costs to facilitate the use of renewable energy, etc. (Renewable Energy Law of the People’s Republic of China). Overall, the release of the law provides a broad path for the development of MSW to energy.

The economics of WTE incineration plants are extremely site-specific, depending on tipping fees, MSW characteristics, environmental regulations, byproduct management practices, and many other factors. WTE incineration installations often benefit from the investment and production tax credits granted to renewable energy sources. The economic viability of anaerobic digestion to energy (ADTE) installations is strongly influenced by policy drivers. Policies requiring control of air pollutant and greenhouse gas emissions from landfills, agricultural operations, and wastewater treatment plants improve economics by reducing the incremental cost of adding generating capacity. Depending on site-specific circumstances, these projects may also yield revenue streams in the form of marketable renewable energy certificates and carbon credits.

Market mechanisms are playing an increasingly prominent role in the Chinese economic system, and are also starting to be utilized to address certain environmental protection problems. In the area of MSW management, a handful of enterprises have entered the field; in late 1999, for example two private MSW enterprises were founded in Beijing. But generally speaking, outside of a few cities, the harnessing of market mechanisms is still not a significant part of MSW management in China, leaving local governments nationwide with the responsibility for and burden of MSW management. Typically, collection and transportation capability, as well as treatment plants, are paid for through direct government investment, and MSW management operations consistently draw on government subsidies. This leaves public sector MSW management entities without any profit incentive to rationalize operations and management.

China’s economy is still underdeveloped, and in this context China must search for a least-cost path to achieve optimized MSW management through the promotion of a more sustainable municipal ecological model, and the use of economic incentives to improve MSW management. The primary method for resolving the growing MSW problem is to use the tools of environmental economics to design a rationalized system of MSW generation, collection, transportation, treatment and final disposal.

References

Chang Y-H, Chen WC, Chang N-B (1998) Comparative evaluation of RDF and MSW incineration. J Hazard Mater 58(1–3):33–45

Chen Y, Cheng J, Creamer K (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064

Cheng H, Hu Y (2010) Municipal solid waste (MSW) as a renewable source of energy: current and future practices in China. Bioresour Technol 101(11):3816–3824

Cheng H, Zhang Y, Meng A, Li Q (2007) Municipal solid waste fueled power generation in China: a case study of waste-to-energy in Changchun city. Environ Sci Technol 41(21):7509–7515

China, NBSO (2003–2014). In: NBSO China (ed) China statistical year book 2003–2014, China Statistical Press, Beijing

China Association of Environmental Protection Industry (CAEPI). China development report on urban domestic refuse treatment industry in 2011–2013. China Environmental Protection Industry, 2012–2014

Hernandez-Atonal FD, Ryu C, Sharifi VN, Swithenbank J (2007) Combustion of refuse-derived fuel in a fluidised bed. Chem Eng Sci 62(1–2):627–635

Hu Y, Cheng H (2013) Development and Bottlenecks of renewable electricity generation in China: a critical review. Environ Sci Technol 47(7):3044–3056

Huang Q, Wang Q, Dong L, Xi B, Zhou B (2006) The current situation of solid waste management in China. J Mater Cycles Waste Manage 8(1):63–69

Jiang J, Sui J, Wu S, Yang Y, Wang L (2007) Prospects of anaerobic digestion technology in China. Tsinghua Sci Technol 12(4):435–440

Jiang C, Huang L-W, Zhang X-M (2008) Pyrolysis analysis of RDF by TG-FTIR techniques. Environ Sci Technol 1:7

Kaufman SM, Krishnan N, Themelis NJ (2010) A screening life cycle metric to benchmark the environmental sustainability of waste management systems. Environ Sci Technol 44(15):5949–5955

MOHURD (Ministry of Housing and Urban-Rural Development of China) (2004). Technical Code for Municipal Waste Sanitary Landfill (CJJ 17-2004)

MOHURD (Ministry of Housing and Urban-Rural Development of China) (2010). Technical Code for Leachate Treatment of Municipal Solid Waste (CJJ 150-2010)

Mor S, Ravindra K, De Visscher A, Dahiya R, Chandra A (2006) Municipal solid waste characterization and its assessment for potential methane generation: a case study. Sci Total Environ 371(1):1–10

OECD library, Retrived on August 2015 from http://www.oecd-ilibrary.org/environment/data/oecd-environment-statistics/municipal-waste_data-00601-en

Tai J, Zhang W, Che Y, Feng D (2011) Municipal solid waste source-separated collection in China: a comparative analysis. Waste Manag 31(8):1673–1682

Themelis NJ (2013) Waste-to-Energy, Introduction. In: Kaltschmitt M, Themelis NJ, Bronicki LY, Söder L, Vega LA (eds) Renewable energy systems. Springer New York, New York

Thipse SS, Sheng C, Booty MR, Magee RS, Dreizin EL (2001) Synthetic fuel for imitation of municipal solid waste in experimental studies of waste incineration. Chemosphere 44(5):1071–1077

Tian H, Gao J, Hao J, Lu L, Zhu C, Qiu P (2013) Atmospheric pollution problems and control proposals associated with solid waste management in China: a review. J Hazard Mater 252–253:142–154

Tınmaz E, Demir I (2006) Research on solid waste management system: to improve existing situation in Corlu town of Turkey. Waste Manag 26(3):307–314

Wang W, Han F (2001) Study on methane generation from landfills in China. China Biogas, 19(2):20–24. (in Chinese)

Wang L, Pen T, Huang C, Yuan H (2009) Management of municipal solid waste in the three Gorges region. Waste Manag 29(7):2203–2208

Wei X, Wang Y, Liu D, Sheng H, Tian W, Xiao Y (2009) Release of sulfur and chlorine during cofiring RDF and coal in an internally circulating fluidized bed. Energy Fuels 23(3):1390–1397

World Bank, Waste management in China: issues and recommendations, 2005. Retrieved on August 2015 from http://siteresources.worldbank.org/

Yang N, Zhang H, Shao LM, Lü F, He PJ (2013) Greenhouse gas emissions during MSW landfilling in China: influence of waste characteristics and LFG treatment measures. J Environ Manage 129:510–521

Zheng L, Song J, Li C, Gao Y, Geng P, Qu B, Lin L (2014) Preferential policies promote municipal solid waste (MSW) to energy in China: current status and prospects. Renew Sustain Energy Rev 36:135–148

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Xu, S., He, H., Luo, L. (2016). Status and Prospects of Municipal Solid Waste to Energy Technologies in China. In: Karthikeyan, O., Heimann, K., Muthu, S. (eds) Recycling of Solid Waste for Biofuels and Bio-chemicals. Environmental Footprints and Eco-design of Products and Processes. Springer, Singapore. https://doi.org/10.1007/978-981-10-0150-5_2

Download citation

DOI: https://doi.org/10.1007/978-981-10-0150-5_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0148-2

Online ISBN: 978-981-10-0150-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)