Abstract

“R&D” is today’s buzzword in the technological world, where these two activities are construed as inseparable. What I intend articulating herein are my thoughts on this fondly debated topic today, engulfed by my experiences in the emerging areas of Composite Materials Science and Technologies that I pursued, in a highly demanding Aerospace Engineering Environment. It is a recall of what exactly these two terms meant to me, when I had to handle them in parallel (riding two horses at the same time), when I faced a dilemma (not a confusion) when to do the research and when to do the development.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

“R&D” is today’s buzzword in the technological world, where these two activities are construed as inseparable. What I intend articulating herein, are my thoughts on this fondly debated topic today, engulfed by my experiences in the emerging areas of Composite Materials Science and Technologies that I pursued, in a highly demanding Aerospace Engineering Environment. It is a recall of what exactly these two terms meant to me, when I had to handle them in parallel (riding two horses at the same time), when I faced a dilemma (not a confusion) when to do the Research and when to do the Development. I also tried to figure out, what type of Research I was in, falling in between the Fundamental (postulative/hypothetical) and the frontier (Emerging/Futuristic). There I realized that, what I did could be most aptly termed the “Concurrent Research or Research Development Driven—RDD,” running in parallel with the project objectives that I was mandated to meet for what I was hired and paid for. Implication was that we will deliver more than what was expected of us, for all that freedom and security we were blessed with. What resulted therein were a host of Scientifically Substantiated and externally funded Application Specific Indigenous Products, using Home-Grown Technologies. Publications, Patents, Academic Guidance, and Technical Training to Technology Transfer (TOT) were the by-products that came out in an “Engineering Sciences Laboratory,” established under the prestigious CSIR Umbrella. Being a Chemical Engineer basically seems to have provided me the much needed “Multifunctional Character of an Interfacial Engineer,” destined to work in a Multidisciplinary, if not an alien Environment. This article is dedicated to late Prof. R.B. Damania also a pilot, who initiated at NAL, the Program on “All Composite HANSA,” the country’s first DGCA-Certified two-seater light aircraft, for ab initio training of aspirant pilots. This program gave us the nuances of Polymer Matrix Composites for high-end applications also paving the way for many a subsequent nationally crucial programs such as Radomes and many.

Passion and Purpose—The Two Horses

As I was trying to get over the R&D Syndrome, two questions stared at me with implicit answers, “Is Research for Research Sake?” With a “No,” and is Development at the cost of Research? With a “Not at all.” What dawned onto me was that these are like two horses one can ride with pride, when handled with both a passion to do so and a purpose in doing so, by walking that extra mile. Soon, it turned out that these two are in a way inseparable (when the deliverable was a visible Hardware, to be scientifically substantiated), but not interchangeable or synonymous (a gross misnomer, when this combo term is used casually/routinely). As a “Scientist Designate” in a Premier National Laboratory, mandated to take the Engineering Sciences to Industrial Applications, it then appeared a daunting task in a situation wherein the primary responsibility was to deliver the externally funded hardware, rather than pursuing a Passionate Scientific Research. And my conscience all the while haunted me, “Lo, you are the Scientist First.” So, there was a conflict between “Science and Conscience.”

Research—Different Shades

“Research” as such is variously viewed as Pure/Fundamental/Basic, Applied/Application Oriented, the Forward Looking/Futuristic, or the Frontier, leading to Cutting Edge Technologies. So, where does one stand in this galaxy of terminologies? If “Research” was to mean mere exploration or a quest into the fundamentals of Pure Science (postulations/hypotheses for instance), the outcome remains dormant, but not necessarily meaning that it has no societal bearing. The immediate best it can do is to inspire many who venerate and value Research in its pristine form. The Researcher pursues what he enjoys passionately. It is for others to reap the benefits out of the resulting publications/seminal lectures, academic guidance, talks, celebrations, and so on, the hallmarks of his achievements. Also, it may have emerged out of curiosity to know why, as a cure for boredom. “There is no cure for curiosity” it is quipped. Such research can often lead to path breaking results of a Nobel Class. The best example of this that hogged the limelight in recent times is the discovery of “The God Particle or Higgs Bosons that form very foundation of atoms,” claimed to have taken us closer to the understanding of the origins of the physical universe, postulated in 1964 by Peter Higgs, a young physics teacher at Edinburgh and later Professor Emeritus after retirement (1996). Chance has it that in November 2013 (half a century later), Higgs an elusive professor who turned 84 learnt that he was awarded the “Nobel Prize in Physics,” thanks to the Large Hadron Collider (LHC) experiments at CERN that confirmed existence of a particle consistent with Higgs Bosons. Happy and relieved at it, Higgs found “this Nobel fame a bit of nuisance too.” This passionate Higgs story (1964–1996–2013) can be likened to “Nishkama Karma” or “Disinterested Endeavor”—an anglicized term I picked up from my elder brother Prof. R.M.V. Raghavendra Rao, a litterateur par excellence and who directed my destiny toward an engineering profession. There are more parallels to Higgs discovery, as examples of “frontier turned fundamental research.”

The Applied Research with an implied end use has a different connotation in that the pursuer has an inherent interest in “Research,” to apply his results remaining a driving force. This may even result in a Forward Looking Research (fanciful or purposeful again). The Researcher here has a priory a hope that someday down the line his results could be put to practical use. His research outputs are either widely published with adequate “Experimental Data” for posterity or patented for commercial exploitation (as in a Corporate R&D). This may even turn out to be a Frontier Research, for the future. Coming next is the Research Application Oriented, wherein the Researcher has clearly a process/product in mind, awaiting development, but delayed for want of decision makers and supporters (Minds and Funds typically with a phase lag). Here, when pursed with limited or no funds, his results will be “Relevant” in developing a Product with a purpose. In a way, this is a vision, since such a research output does form a precursor of the Product yet to be borne (akin to a ready to use composite prepreg), saving on effort, time, and associated costs (like a straight line with an intercept). Often, an in-house pre-project funding (PPF), however small it can be, provides well ahead, certain crucial inputs to an “Impending Sponsored Project,” also providing continuity to the researcher’s penchant. The best example of this in the author’s experience is the Development of the Large DWR-Radomes (Mark I/Mark II) for ISRO/IMD (more on this later). Thanks to the foresight/support from the then Director Dr. T.S. Prahlad, who while admiring researchers/publications, set the bottom line that scientists should not ignore laboratory’s major sponsored programs, to be executed in a la “Mission Mode.” “Concurrent Research” (Research Development Driven—RDD) presents the case when a commitment is made to a funded project to develop and deliver a product, to be scientifically substantiated with well-identified/defined performance specifications, quality, timelines, and budgets (deadlines) hanging over the R&D Head like a Damocles Sword, with no room for excuses for delays”. In a way, the promised deliverable sets the fixed boundary conditions (like in an unrealistic idealized linear analysis model). Thus, a passionate researcher has to put the Product above the Paper. By contrast, the so-called Sponsored Research, again from Government bodies, may not invariably have resulted in an end product.

Of all the shades of the research, the RDD showed the quick returns on balanced investments (intellectual and infrastructural), in typical government backed/run laboratories, as it is linked all the way, to an end product. Doing such RDD under the CSIR charter clearly demonstrated that “Research here is not open-ended, but ends with a product.” Here, the R&D appears on the same sheet (if not on the same page).

R&D Performance—Yardsticks

Doing the “R for R sake (Publications) and the D for D sake (Products)” is a thing with no ambiguities and misgivings. A genuine R&D in a Scientific and Industrial Establishment can be understood only through certain yardstick/performance indices, when it comes to evaluating one’s performance. These constitute publications, presentations, patents, invited talks, seminar lectures, and academic guidance for the R-Component; while the Product—delivered with attendant progress reviews/deadlines, and compulsions of certification and acceptance from the sponsor’s end—constitutes those of the D-Component. Then, how much the R&D Scientist needs to score on both these counts is a mute question. This turns out to be a gray area, governed by both subjectivity and objectivity, with no exact formula in sight yet. Different perceptions naturally emerge here. For some, it is difficult to publish because of the classified nature of their work, patenting becoming even more difficult when the sponsor’s endorsement/clearances become an issue, thereby deterring them from doing enough in terms of meeting the yardsticks of the R&D put together. Also, time being a constraint in developing the hardware in return to the price tag attached to it, taking time off to “indulge in publishing,” of what they can and what they cannot. This is much like having variables more than the equations. But, for one, immensely smitten by the feeling that being a scientist with an innate obsession for research/publications (not for publicity sake, but for placing in public domain his experiences for posterity), riding these proverbial two horses becomes inescapable. Else, such a scientist can end up with a tendency of tilting toward an industrial type of activity, losing his moorings with Science or blunting his Scientific Temper, when he has one.

When an R&D Organization leans gradually toward Hardware Development, for whatever justifiable reasons, the evaluation of a Scientist Designate often if not invariably tends to be governed by what one delivers against External Cash Flow—ECF (another new buzzword). But for those, not in a position to bring in ECF by the very nature of their specialization in roping in the funds, the R-Component yardsticks come handy, but the question one must face is “At whose cost the Research is done.” In case of Hardware development, the ECF can take the precedence, for reasons obvious. But, for one whose conscience resonates between the R&D, it is walking on a sword’s edge with the risk of doing neither or sacrificing one for the other, even to the extent of permanently missing returns/rewards for his efforts. That is a price he must be prepared to pay without losing passion (heart), for doing the R&D in parallel.

R&D Management—Its Culture

Well, typically in public-funded scientific institutions, the R&D Managers evolve from within the organization. It is to be recognized that Passionate R&D Professionals are usually born, but not created or made overnight. In extreme cases, the criteria of how a R&D personnel is assessed can resonate in between, by what he develops and delivers against ECF and what research he does resulting in publications/patents, books, and so on. Here, two distinct classes of people emerge, by default, viz. the Researchers and the Developers, analogous to Thinkers and Doers (a once hotly debated issue in one of Country’s Premier Organization, bogged down in a dilemma as to who should head and lead it?). Often, there can be little or inadequate overlap of the perceptions and philosophies driving respective activities within the same organization; the passions, commitments, and outputs however, and remaining undoubtedly visible in their own way. Herein crops up the issue regarding the Manifesto or Charter of an R&D Organization (meant to bridge the gap between Academy and Industry), as expounded in letter and spirit by its Founders, bringing into picture its attitude and environment it creates and provides for these two classes of people. The Managers should be the higher-order R&D professionals, having reached the level, meant to visualize and draw the Road Maps for the immediate, near, and far futuristic programs, in order to sustain the organization in a challenging and rapidly changing “Techno-Scientific Environment.”

The role of an R&D Manager in such an Organization has got to be versatile and unique, unlike what exists in an Industrial R&D (Return on Investments). He has to lead from the Front/Rear, Plead when needed (generating funding), and bleed often (in a situation of do or die), having committed to deliver a visible end product to the sponsor. It is a different matter that it is the organization which is ultimately accountable to the sponsor, no matter who stays and who leaves (in the spirit of Dr. S.R Valluri’s statement, more on this later). The Manager has to take along all concerned at all levels in synergizing their Strengths and normalizing the Weaknesses. Building and Maintaining the “Research Reserves” are like keeping the over head (OH) storage tank full all the while (with a liquid level controller, if needed), in order that the taps do not go dry, one day. This analogy came off my hat over a decade ago much to the amusement of the expert committee members, when I was surprisingly invited for a “Discussion” for the highest position of my laboratory and the question close to my heart put to me was, “How do you address the downward trends in publications in your organization?” Well, it is a different matter that I suggested setting up a Hypersonic Wind Tunnel Facility at my laboratory (a dream I fancied in my mind, ever since I visited the NAL-Japan way back). In this case, the question refers to what unique contribution I could make sans composites, if I were to be selected. “Thank God,” nothing of the sort happened.

The role of the Captains of the R&D Organization is vital as the watchdog all the time, in facilitating right outputs from groups of diversified disciplines, much like in a result oriented sport. But, what is missed out often is how to functionalize, align, and attach the research minded to the development savvy (like with the CNTs—Carbon Nanotubes) to get the best of them, as one cannot afford to have in an R&D, either of them exclusively. Both the R&D groups have to work together and share the Fruits of the R&D Success, for an inclusive growth of the organization. The Binding Matrix undoubtedly is the R&D Manager, but the Captains are the Eye in the Sky. Often it is a testing time for the Manager, especially when he on his own volition or under compulsion accepts the R&D responsibility of leading a well-groomed group of individuals with diversified potentials, disciplines, and attitudes. Here, he should willfully become an interface among his team members with different inclinations, rather than being preferential to some and not being so to some. Hierarchy and ranks should not come in the way when it comes to giving due credit if not undue elevation. However, if some outperform in promoting Academics despite direct project responsibilities/pressures, the organization should not miss spotting them and reward them, by giving them independent responsibilities and empower them (recall Dr. T.S. Prahalad’s vision here). As regards the technical staff (under employed, in particular) who acquires higher academics while contributing enormously to the sponsored programs, the organization should automatically upgrade them to suitable scientific cadres. If the system has limitations, it should “Effect Bold Institutional Reforms,” to reward in time and retrain them. Preserving them ensures a Leadership-Bank for the health of the organization in the long run. Regretfully, not much has been done in this direction yet.

Often, he (the Manager) may need to even learn where it is not his domain or of no interest to him inherently. But having “accepted the responsibility” for whatever reasons, he has to Lead, Plead, and Bleed. Once he likes doing it, the results are fantastic, but first, the “EGO must GO.” A Bottom-up Top-Down approach (willingness to learn even from below when needed with humility and managing the Equals and Superiors at the top with courage) enables the Manager rise like a Phoenix, pledging his long experience, maturity, wisdom, and foresight. Often, the Ombudsmen of the R&D Organization may need to help the Captains wake up and make up with mid-course corrections, if need be, to ensure smooth running of the R&D Band Wagon. If this is not done, it will lead to depletion of the Research Reservoir in the long run. At the National Scientific R&D Institutions, we are the Custodians of the Public Trust and should ask ourselves what we give back to the country and not what we get from it (oft repeated by Dr. S.R. Valluri, the legendary former Director NAL, and later the Founder and First DG of ADA, and the visionary of the LCA program: thanks to Sri. G.N. Vittal, Chief Controller of Administartion, for timely reminding me on this patriotic statement of Dr. Valluri). Respecting and Nurturing the High Science and High-technology Areas in contemporary and fast emerging fields is the prime responsibility of such Institutions. They should have strong Research Inclinations side by side the Product Indigenization Goals and Responsibilities, at the same time be the Beacon, or a hope for the Country’s NEXGEN (e.g., the have-nots from the educational sector).

Concurrent Research (the RDD)

The Concurrent Research or the Research Development Driven (RDD) is need based and carried out mostly in parallel and occasionally in tandem with the Development programs, committed with the Sponsor’s funding, timeline, and specifications clearly identified right from the beginning. The RDD thus is “conjoint with a product” from the beginning like in a mission mode, but not in Toto. Again, the task of the R&D Manager is to deliver what was promised, standing under a Damocles Sword, rather than sitting pretty on a high pedestal.

This is a very challenging situation, since the “Research here is Application linked” and Contemporary, to be carried out on well-defined and directed project relevant topics not necessarily linked to one’s fancies or passions, with the expected results to feed into the end product, continuously. And, it is time bound since it has to run Peggy Back with on the development. But, such research should not be coterminus with the product delivery, paving the way to forward looking or the futuristic R&D Road Maps. That is when the R&D represent two sides of the genuinely coined term “R&D,” since the research results have to be compulsively fed into the Product under development, making it scientifically substantiated and technically sound. Yet it is a kind of Business and a win-win situation, both for the Donor (of challenge) and the Receptor (of opportunity). Here, while the deliverable is most often a visible hardware (a product), it can be a software too, if demonstrated/installed on an application platform (Control Law for a combat air vehicle—a priceless contribution by present Director Sri. Shyam Chatty and team). In a true R&D setup, the bottom line is that the research component is unambiguously visible, side by side the deliverable developed. Once this is done with least or no dependence on external sources, one can see a “Made in India” insignia, on every product made in India and used elsewhere too. It is a charm, ultimately to do this kind of research feeding its results into an end product, and the Researcher is at no one’s mercy for funding, only rider being, “Are you willing to ride two horses, and walk that extra mile”? In this case, there is nothing like, someone questioning for accountability, the promised and delivered (promised version) speaking for itself.

Once again, it is worth recognizing here that R&D in its true sense is an outcome of “intellectual and infrastructural synergy.” Comprehensive Project Documentation covers technical and scientific reviews, prototype development processes, sponsor’s acceptance/satisfaction indices, publications in open literature, patents, TOT records, and all stand as a testimony to the R&D prowess of the Organization as a whole. It is important to note that both these activities are inherently dissimilar in nature, resonating in between those of a “Research Passionate Scientist” and a “Hard Core Development Engineer.” That brings us into the concept of doing both the R&D, in a hardware development-dominated (HDD) environment. In this case, it leaves no room for an attitude, “I did my job, it is for you to do what you want to do with that.” But then, these two horses need to be tamed and harnessed with both courage and commitment. Though this is a challenging and conflicting situation for a Research Obsessed Scientist, it is a win-win situation, as the Scientist gets the funding support (big or small) and the sponsor gets his end product (small or big)—sort of you can have the cake and bite it too. Question is how many wish to bite the bullet, taking them as Thrills in Chills and Charms in Challenges, with a will to put their neck on the anvil.

Thrill, Chills, Charms, and Challenges—Some Case Studies

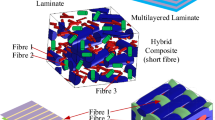

The best example here is the development of an end product, with novel/new materials, new processes, and acceptance methods specific to the novelty (first time done, and none else can do). That was when my mind wandered in a wonder world called the “Composite Materials,” especially when the products to be developed were as diversified as a 2-seater all-composite aircraft-HANSA (for pilot-training), and “Radomes” (Radar Domes for protecting ground-based Radars for disaster warning/management in coastal regions and for flight vehicles), both having a very close bearing on societal development and needs. These called for interdisciplinary participation (Materials, Processes, Technologies, Manufacturing, Mechanical Design/Structural Analysis, Fluid Dynamics and Flight Experiments, and Electromagnetics, including customized Engineering Services).

In essence, the HANSA demanded formulation and execution of Applied Research Programs on customized composite material formulations, their characterization, multilevel testing (coupon to component) till their certification/qualification and acceptance, concurrently with the development of inexpensive indigenous processes/fabrication techniques (Appropriate Technologies). Here, the emphasis was on very modest budget and easy absorption by a small-scale private sector for mass production, bringing together “Basics of Polymer Science and different disciplines of Engineering and Engineered Materials and their Sciences.” This culminated in realization of a certificated light trainer aircraft of world class with a stringent weight budget (All Up Weight-AUW within 750 kg, vide the JARVLA regulations—not a gram exceeded, reminding the Act from The Quality of Mercy of the Shakespearian Drama, the Merchant of Venice). Many who worked in the program either lost or maintained their body mass indices (BMIs) in the process, even as there was some skepticism about the feasibility of such a weight budgeted aircraft. The indomitable courage and confidence imbibed in the “TEAM HANSA” by Dr. Siva Kumara Swamy, Program Director, and Dr. S.S. Desai, the CTFD Head and the Chief Quality Control Manager (CQCM-HANSA), in this regard were tremendous.

Coming to the Radomes, The “DWR-RADOME” provided yet another case of a challenging R&D venture, standing up against imports prevalent at that time to indigenously build the next-generation (NEXGEN) product for protecting the Doppler Weather Radars (the ground installed DWRs of ISRO) used for coastal disaster management and many AirBorne Radomes, in particular the ones for the Fire Control Radars on JAGUAR Maritime upgrades (of HAL/IAF) and the Weather Radars on NAL’s-SARAS. Though a Radome is very complex confluence of multidisciplinary subjects and human interactions, the subject electromagnetics turned out to be a crucial design driver, and the last word, (Glorious tributes to Late Dr. Rakesh Mohan Jha, the EM-Emperor), for the final acceptance of the product by the sponsor/user.

The Bearer of the R&D Mantel

Here emerges the main question, how and who, should find the time or scope to do the Research in parallel with the Hardware realization. This is here that a passion of a Scientist (the Author) gave the clue that led to identification of myriads of project specific topics “for short-term, medium–term, and long-term research opportunities,” in training directly and indirectly, countless number of students/scholars/faculty both from within and outside the Organization. Everyone in the project teams was engrossed in the technoscientific significance of the product underdevelopment. Here, the policy of Prof. R. Narasimha FRS, the then Director of NAL, is that “the laboratory should also involve and benefit the young students and academic-aspirants liberally in its R&D pursuits reinforced by documentation of achievements,” which gave a big Phillip and a new turn to the organization’s Scientific Culture that persisted. Superimposed on all these are the stringent certification mandates imposed by the regulatory agencies such as the ISO, the DGCA (for the civil aircraft-HANSA), and the CEMILAC (for LRUs on the military Aircraft), as well as the continuous reviews by respective sponsors of these products—a situation not at all comfortable (most scary if at all), for a Scientist, wishing to be left alone as an independent Researcher, if there was a choice.

Project “HANSA” gave an impetus to a gamut of technical, scientific, and engineering aspects such as materials, choice, characterization/testing (coupons to component levels, invoking spectroscopic, thermal, mechanical, structural, and electromagnetics analyses), before and after rigorous exposure to application specific service environments, optimization of parameters for material formulation development and composite cure chemistry related to matrices and adhesives, in parallel addressing the scientific topics such as Synthesis and Cure kinetics modeling/optimization. For the first time in our country, the concept of the thermodynamics parameter “Glass Transition Temperature Tg” and its research took firm roots, as a crucial measure of the composite cure as well as a service temperature index for the Aerospace Composites. Throughout the program, Tg took the centre stage of material certification and acceptance. It is not hype if said that at one point of time, this parameter as one of the design drivers was among the most debated, even capturing the curiosity and imagination of the Aerodynamicists, for a change. That was when the Directorate General of Civil Aviation (DGCA) got convinced and certified a humble RT-Cured Epoxy Composite system with an enhanced Tg (by a novel step post cure process scientifically evolved in house) for the airframes. Selection and certification of a Flame-Retardant Resin System for the Engine Cowling and a composite fuel tank, both replacing the conventional Aluminum Alloy, were other excitements (Mr. Burt Routon, the legendary builder and flyer of world’s first wet-winged all-composite experimental aircraft Routon-Voyager, endorsed the composite fuel tank, vide Dr. S.S Desai’s Communications).

Research Studies on “hygrothermal effects” on the composites used (epoxies with glass and carbon reinforcements, adhesive joints, and sandwich panels) played a vital role in this program. This led to extensive studies on Hot-Wet property Degradation trends, to generate the composite material Design Allowables (A Basis/B Basis), for the primary and secondary structures, so crucial inputs for the structural Engineers for their optimum Design and Analysis efforts to evolve a safe design for the composite parts. All these exercises demanded continuous inputs for the structural designers on the top floor and the design compliant process sheets for the fabrication teams on the shop floor. The all-composite (nonmetallic) HANSA using in-house groomed, inexpensive, and customized RTVBM Technology (Room Temperature Vacuum Bag Molding) made its maiden flight with an all up-weight of 750 kg after rigorous weight reduction campaigns, and flight trials made its maiden flight test on 11 May, 1998—The Technology Day, creating a great excitement among all those involved. The CSIR newsletter went viral with HANSA described as the “most-researched aircraft in its class” (Ref: Article of Sri. Hasan Jawaid Khan, its Editor). The certification for series production by DGCA in 2002/03 gave a sigh of relief as the TEAM HANSA dedicated to the project for more than a decade and a half went hysteric. Thus, HANSA provided the best example of a totally indigenous mission undertaken by a National Laboratory up to its certification, demonstration, and deployment in several flying academies. Today, HANSA has a silent and subtle message, “Hey, I am here as a great Made In India fully certified pilot-friendly aircraft, rearing to don the 50 and odd flying schools across the Country and beyond.” Any takers please?

The DWR-Radome was an equally if not a lesser significant example that went beyond its indigenization as it culminated in the TOT to the End User/Sponsor, after about 5 years of efforts and more than 2 years of rigorous EM and Structural Tests on ground, before acceptance for its maiden installation (MARK I Version) at the Satish Dhawan Space Centre-SDSC, Sriharikota for ISRO-the sponsor, in 2003. Soon followed the MARK II version with less number of larger panels, the technology of which was finally transferred to the sponsor identified PSU (BEL). The research issues related to the Radome have been the selection and fine-tuning of a PUF-core and composite skins for the large sandwich panels, the incorporation of the cast in situ foam core in between the composite skins ensuring a strong bond, and the chemistry of foaming/curing to desired densities/pore architecture, for structural properties (strength and modulus) and EM Critical Properties (Epsilon, Tan Delta), to name a few. The Design Allowable established already for the HANSA Composite Air Frames came very handy here. On the EM front, a synergy had to be established between the development of the composite formulations, fabrication processes, and the EM Material Characterization for an optimally EM—designed and structurally integral Radome, to meet the stringent performance specs, on site. This is yet another example of a truly successful nationally important Inter-Institutional Program that literally gave yet another loud call, “No more imports please.” These Radomes demonstrated at few Indian Coasts already, to withstand 250/300 kmph wind speeds, are all set to done the cyclone prone/ravaged Indian coast, replacing our own earlier generation Radomes (protecting the new generation DWRs). This indigenization effort will go a long way in strengthening our early warning capabilities, to ensure safety of vast coastal populations. The need of the hour: mass production of these radomes by PSU Licensee of this technology.” The managerial support of late Dr. B.R. Somashekar and late Dr. S. Nagabhushana, during price negotiations for this program, was invaluable.

Well then, the Indigenization and certification (by CEMILAC) of a flight worthy Nose Radome for the Jaguar Maritime fighter aircraft, closely followed by its TOT to the sponsor (HAL, to be inducted very soon into the Jaguar Air Squadrons), was another example of achieving, “The Mission Impossible.” The success story of this high-temperature resistance composite radome for a high-speed flight vehicle has many twists, excitements, and all the ingredients of a R&D venture, in a filmy style, in its execution in a record time that ultimately established a “Template for Radome Indigenization Programs,” with in the country, to say the fact. Apart from several applied research activities addressing critical material and manufacturing issues, the radome’s EM performance (near and far field) had to be evaluated on ground at LRDE, ISRO, and CAB facilities, including the radar supplier’s facilities at ELTA-in Israel upon insistence. Finally, with the successful in-flight evaluation of the radome on the Jaguar Maritime aircraft platform by ASTE-IAF, ELTA (also our contender for these Radomes), gave a thumps up saying, “NAL Built Radomes are on par with the best available internationally.” Thus, NAL had to get over the conflict of interests, in this program, to craft a strategy and establish its dominance in the development of this class of Radomes too. The solid backing of Dr. B.R. Pai, the then Director in this regard was very timely.

The aforesaid products and many of their predecessors/successors not covered herein for want of brevity were an off shoot of the Applications-Related Research Activities pursued concurrently with the product development encompassing composite materials, processes, and technologies with spin-off benefits. These are briefly different scaled versions of the Carbon Composite Air intake wind tunnel models of LCA-Tejas, the rigid composite Air Combat Simulators (ACS Domes) installed at the Hindon Air Base, the reusable Rocket Launcher Tubes for the MBRL’s of ARDE/DRDO replacing the imported heavy steel tubes, the massive 300- and 500-KW wind turbine blades under a CSIR’s NIMITLI enabled PPP Program, including the earlier porous composite support tubes for the RO-membranes used in water desalination plants (BRNS/BARC funded) and its TOT as well as a first time demonstrated composite Bus Body for the mobile speech and Hearing Unit, funded by All India Institute of Speech and Hearing-AIISH-Mysore. Thus, all these products firsts in the country are capable of positioning Our Nation more self-reliant than ever before, in this field of Composite Technologies, in taking the Chemistry to Component.

After Effects of a Passionate R&D and the Road Map

During my nearly three and half decades of stint at NAL (1973–2007- and 2008 on contract) and later over the past 7 years as a retired/not tired yet scientist from a prestigious National Laboratory, I tried very hard to understand the similarities and disparities between the R&D. I struggled first as a scientist-in-charge of a pilot plant, with a number of unskilled/semiskilled/skilled workforce (masters in their own art), then getting an opportunity to elevate it to an independent Unit and finally to a full-fledged scientific division, which has today highly qualified human-power (technically/scientifically). Thanks to all my peers from within and outside, who gave me the mandates, that provided me and my Team a golden opportunity and maneuverability like that needed for an unstable fighter aircraft. The “FRP-DIVISION” that I was destined to create and groom has today many Doctorate—decorated Scientists including enviable number of Women Scientists and International Publications in its basket. (For once, I could “discover an excuse” that there was “no time” to hit a century, for records sake). All along, it had been my endeavor to strike a judicious balance between the R&D, by interweaving these two in the warp and weft directions (akin to a planar bidirectionally woven fabric of glass or carbon reinforcement used in a polymer matrix of a composite material), and often by stitching them vertically (like in a 3D composite preform), to ensure the “R&D Structural Integrity,” invoking liberally the pressures from peers and demands of sponsors, and kindling passions of the research minded. In the process, a sandwiched I could create intentionally or unintentionally a platform to play my role at will in synergizing these two activities, research outputs supporting the product development, and products developed and delivered for a price, nourishing, and nurturing the former. The Division with the Road Map I left behind in 2008 had made its forays into many frontier fields of the S&T. These included Conducting Polymers/Composites/Nanocomposites, Radome paints, High Tg Polymer Matrices functionally tunable polymers by taking forward the duel-Tg concept, Radiation Cure Processes for rapid/energy-efficient green composites, Resin Infiltration Techniques, and Jip-Pregs (Just in time prepregs by resin film technology). Realizing a Jip-Preg machine after a long wait (2000–2008) was a great valuable addition to NAL infrastructure, thanks to the timely support of the then Director Dr. A.R. Upadhya. These are all set to replace the expensive Prepreg Technologies if only harnessed further. I am glad that even a tiny imported “Research Autoclave” that I revived from its coma state (a UNDP gift received long ago) serves as a humble reference for NAL-Autoclaves and that the wind turbine blades activity continues.

Tail Piece

I got a semblance (Saakshaatkaaram) of what an R&D could be made to look like, thanks to the organization which gave me the freedom to fire my imaginations into frontiers of realities. All said and done, “R&D” continues to remain an “OXYMORON,” when the Research is done with mere Passion as the purpose, and the Development carried out sans Research. One thing I can say for sure is that for a scientist under the CSIR umbrella, “Research should be his soul and substance and Development his bread and butter.” In this article, I tried to summarize my R&D Trials and Tribulations as a scientist, engineer, and technologist. Looking back, I feel it would have been a missed Life Time Opportunity, had I not taken things as they came, willfully with a passion and bowing in all humility. At the end of the day, I have some sense of fulfillment but with disillusionments too (for instance, missing another challenge of indigenizing the most complex Nose Radomes for the deadly IAF-Sukhoi’s, despite our 3-year-long hectic proposals/presentations on request—alas for the simple reason that it was not commercially viable, even as we were ready to negotiate further). I wish better Days are ahead, for the Indigenous R&D.

Further Readings

“Engineering of Science-The Composites Way “, Annals of Ind. Acad. of Egg, Vole IV, April 2007, Raja Manuri Venkata Gopala Krishna Rao.

“Research Pursuits at the Fiber Reinforced Plastics Division, National Aerospace Laboratories (NAL-CSIR) Covering Journal Publications, 1976–2005 (To be updated, still), Special Publication Report SP 0502(2005), RMVGK Rao & Team.

“R&D-Riding Two Horses”, Invited Lecture delivered for the Participants of Working Professionals Learning Project (AICTE Sponsored/TEQIP funded), Organized by NMIT, at Hotel ITC Gardenia, Bangalore on 18–20th Nov, 2013, RMVGK Rao.

NAL Archives (Presentations, Publications, Project Documents, Theses, weekly news pasteboards, etc…., etc……).

Many formal and informal Interactions I had with and inspirations I got from all my Directors.

“Higgs Finds Nobel Fame ‘a bit of a nuisance”, TNN, Times of India, June 2015.

Acknowledgements

Foremost the author thanks INAE, in particular Dr. Baldev Raj, the Hon President, and Dr. Purnendu Ghosh Editor in chief, for inviting me to pen my experiences on a topic of my choice, and (NMIT) Bangalore. I am indebted to my Academic Mentors (Prof. Manas Chanda, Dr. N. Balasubramanian, Prof. George S Springer of the Stanford University, Dr. A.K. Singh, and the late Prof. C.R.L. Murthy) and all my aforementioned Directors and former Director Dr. K.N. Raju for his very positive support. I thank many colleagues from other divisions/disciplines who were partners in my progresses, in particular, Dr. S. Viswanath, Sri. D.V. Venkatasubramanyam, Sri. Ningaiah, Dr. U. Ravindranath Nair, Dr. R.C. Majumdar, Dr. Chakrabborty, Sri. Satish Rohedekar, and Sri. C. Chandrasekhar; and Project Monitoring Heads Sri. S.C. Narayanamurthy, Sri. M.S. Ramachandra, Dr. Ranjan Moodithaya, and Teams. I place on record the invaluable support extended by my own TEAM-FRP, viz. Ms. N. Ankanna, C. Pragalathan, L.R. Chandramohan, Dr. Shylaja Srihari, Sri. T.H. Samiulla, Dr. A. Vanaja Sri. K. Mohan Kumar, Dr. B.S. Sugun, Dr. Sandhya Rao, Dr. L. Srikanth, Dr. Jyotsna Kiran Mathod, Dr. T. Padmavathi Sri. Rajendra Prakash M, Ms. Kavitha, S. Navaneetha, A. Revathi, and Sri. P.S. Sathyanarayana. My grateful acknowledgments to my colleague Sri. M. Subba Rao and his Team, for very valuable interactions I had. I specially acknowledge Dr. S. Bhogle, former Head Information Management Systems, for masterly articulating our achievements, through his Paste-Board. I recollect here the services of Sri. M.R. Narasimha Swamy, our former Head of Technical Secretariat, and his deputy late Sri. Md. Aslam, for their unique contributions in my student training and TOT programs. Last but not the least, I put on record tremendous support I received from my external sponsors/peers, in particular Sri G. Viswanathan, Director ISTRAC/ISRO, and his colleague Sri P. Sambasiva Rao, Prof. P.R Mahapatra, Dr. Acharya, and Prof. K.P. Rao all from IISc, Sri. S.K. Veluswamy from AGM-HAL, Dr. S. Christopher from LRDE/CABS and presently Chief of DRDO, and many from certification agencies. I have no words to quantify the enrichment I got from my timeless interactions with countless students/research scholars/trainees/contract staff. (Missing acknowledging any is purely unintentional).

I remain ever indebted to my Family (my wife Rathna, son Dr. Raja M.V. Pavan, and daughter R.M. Vauhini), for their decades of infinite patience and cooperation, in letting me achieve whatever I presented herein, never complaining of my unavailability to them when they were young and needed me the most. I am very proud of them. Above all, it is the Blessings of my Parents and the Elders of my large family in providing me the pedigree that made me what I am today.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Rao, R.M.V.G.K. (2016). R&D—Another Oxymoron?. In: Ghosh, P., Raj, B. (eds) The Mind of an Engineer. Springer, Singapore. https://doi.org/10.1007/978-981-10-0119-2_44

Download citation

DOI: https://doi.org/10.1007/978-981-10-0119-2_44

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0118-5

Online ISBN: 978-981-10-0119-2

eBook Packages: EngineeringEngineering (R0)