Abstract

Nanocrystals have the potential to address challenges in very different fields like production of computer chips, delivering drugs of low water solubility, cosmetic research and products, biotechnology, catalysis and textile. In this review, we highlight the industrially relevant technologies, milling, high-pressure homogenization and recent advances in the development of these methods for nanocrystal preparation. The paper summarizes the most up-to-date information and developments available for conventional nanocrystal preparation methods such as antisolvent precipitation, supercritical fluid technology, emulsion method, Impinging Jet Crystallization and spray drying. Finally, we also reviewed recent developments in preparing a nanosized particle of drug crystals using patterned self-assembled monolayers, microfluidic devices and nano confinement in nanoporous material. The present article also describes the merits and demerits of these methods, scale up issues and application in drug delivery of nanocrystals prepared by different methods.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Drug nano-crystals

- Nucleation

- Pearl milling

- High-Pressure homogenization

- Controlled flow cavitation

- Impinging jet crystallization

- Patterned SAM

- Controlled pore glass

1 Introduction

Nanocrystal preparation has been an area of significant interest, due to the wide variety of potential applications in cosmetic, computers, semiconductors, pharmaceutical and biomedical area. The applications of nanocrystals can be found in many cosmetic products including moisturisers, deodorants, toothpaste, make up and sunscreen [1]. The nanocrystal products are identified as next generation cosmetic delivery agents that can provide enhanced skin hydration, bioavailability, stability [1]. In the early 1980’s the research into semiconductor nanocrystals, also known as colloidal quantum dots started [2]. Ekimov and Efros discovered and demonstrated that the optical properties of semiconductor crystals were dominated by their size, and these nanocrystals could absorb light at much lower wavelengths than expected [2]. In the pharmaceutical industry, about 60% of drugs in company pipelines are poorly water-soluble [3]. As per the biopharmaceutical classification scheme many of Active Pharmaceutical Ingredients (API’s) are designated class II compound with low solubility and high permeability [4]. For class II compounds the aqueous solubility is the limiting factor regarding bioavailability [4]. There are many ways to solubilize certain poorly soluble drugs for example solid dispersions are one of the most promising strategies to improve the bioavailability of poorly water-soluble drugs. The main disadvantage is the formation of crystalline solid dispersions rather than amorphous solid dispersion, which was more thermodynamically stable and did not release the drug as quickly as amorphous ones. Other methods include grinding or milling techniques, pH adjustment, freeze-drying and cryogenic engineering, supercritical fluid processing and precipitation techniques. The reduction in sizes of crystals increases the surface area, which further increases the dissolution rates and bioavailability. As per the Noyes-Whitney equation the reduction in size leads to an increased surface area, which further increases the dissolution rate. Micro-crystallization is a suitable way to increase dissolution rates by reducing the size, but nanocrystals can increase the dissolution rates more by increasing the surface area further. The nanocrystals could serve as new building blocks for manufacturing of API’s with improved aqueous solubility.

In the case of nano-crystallization, the induction of nucleation needs to be abrupt and homogeneous throughout the growth medium. For many years, the kinetics of the burst nucleation and the growth of nanocrystals have been described by LaMer and Dinegar [5, 6]. As per the classical nucleation theory, from an initial supersaturation, a rapid nucleation of particles would initially occur which is followed by the absorption of building units (monomers) onto these nucleated particles. The resulting reduction in supersaturation strongly depletes the local concentration of building unit (monomers), which lead to a narrow size distribution by decreasing the rate of further nucleation [7, 8]. The Gibbs free energy (Fig. 16.1) is dependent upon the temperature, the supersaturation of the solution S, and its molar volume, v [7, 9] The Gibbs free energy is defined in Eq. 16.1.

Where r is the radius of spherical nucleus, σ is the surface tension and ΔG v is the volume free energy. Nucleation is the competition between the formation of volume and formation of surface area, because of the positive surface free energy and negative volume free energy. According to the classical nucleation theory, the surface free energy destabilizes nuclei and the nucleation cannot take place until the size of the aggregate reaches the critical size, also known as critical radius (r crit ) of the nucleus [9].

This critical radius corresponds to the minimum size at which a particle can survive in solution, and the particle below the minimum size will dissolve. The same is true for the particle’s free energy, where a critical free energy is required to obtain stable particles within solution, Fig. 16.1. Also the critical cluster size at a given supersaturation defines solubility of that size nucleus. The critical free energy is defined in Eq. 16.3 [9].

Nanocrystal preparation methods can be divided into top-down and bottom-up techniques. [10, 11] The size reduction of relatively large particles into smaller particles are known as top-down technique, whereas bottom-up techniques consist of the growth of small particles from individual molecule [4]. The driving force for the growth of a crystal from individual molecules is supersaturation. Bottom up technique is usually a precipitation or crystallization technique and considered as the oldest technique to prepare nanocrystals [12]. In this Review, we first briefly discuss the methods to produce nanosized particles, which include direct crystallization using high supersaturation (bottom up technique), particle breakage (top-down technique) and crystallization in a constrained environments (bottom up technique). Next, we summarize the merits and demerits of these methods, scale up issues and application in drug delivery of nanocrystals prepared by different methods. We highlight advantages of the Bottom up technique and top-down technique.

2 Top-Down Approach: Milling and High-Pressure Homogenization

The top down approach is the most important technique for the production of nanocrystals. Milling and high-pressure homogenization are the two basic top-down techniques for size reduction. Wet milling produces the most nanocrystal products that have reached the market [13]. Wet milling involves mechanical attrition, where particles are wetted by an aqueous solution of surfactants and sheared and grinded by milling balls in a milling container. The particle size is reduced and may reach a few hundred micro-meter, but the conventional milling with modifications can be used for generating nanosized crystals [13]. The preparation process can be carried out in a reproducible manner. The contamination from erosion of metal milling balls or pearls, high energy input, prolonged operation time and decreased crystallinity are the major drawbacks of the technique [13]. The use of polymeric beads may be helpful in minimizing the erosion and contamination.

A new process known as Jet milling to prepare micro-particles without the use of organic solvent was described by Nykamp et al. [14]. The important advantages of solvent free jet milling are the prevention from toxicity due to the absence of organic solvents and very short preparation time [14]. High-pressure homogenization is the process in which two fluid streams of particle suspensions collide under high pressure in a chamber, leading to particle collision and subsequent particle rupture. Nanosized solid particles are produced in Piston-gap homogenizers by forcing a suspension of drug particles with a piston through a thin gap under high pressure [4]. The high shear forces, and turbulent flow fractures the particles and the particle outcome was decided by the power of homogenization, particle hardness, and number of the piston-moving cycles [15]. High-pressure homogenization required high process temperature, high-energy input, required complex equipment and might have possible degradation of the components and may yield less when compared with wet milling and these are the major drawbacks of the technique [15]. The nonexistence of a large-scale production method yielding a product of a quality that is acceptable by the regulatory authorities hampers the introduction of solid nanoparticles to the market [15, 16]. Wet Milling and High-pressure homogenizers are widely used in many industries including the pharmaceutical industry for the production of micro and nano-particles. [15, 16] Hence, Wet milling and High-pressure homogenizer are considered as being industrially the most feasible one for nanocrystal production with no regulatory problem [15, 16].

3 Bottom-Up Techniques

3.1 Control Flow Cavitation (CFC)

CFC creates the optimum process condition for nanocrystal production after controlling the size, location, density, and intensity of implosion of bubbles in the cavitation zone. The controlled energy released by the implosion of micro bubbles and the ability to control the energy of cavitation, the particles can be brought to desired particle size distributions [17, 18] CFC converts destructive force into constructive with high intensity energy force to produce nano and micro structured materials [17, 18] CFC technology has been exploited in many industries with multiple CFC chamber designs customized for hydrodynamic, chemical, biomedical and cleaning applications [18] The CFC is highly scalable and efficient process with excellent process control and outstanding reproducibility [19].

3.2 Spray Drying

Spray Drying is a single-step process for converting solutions, emulsions, suspensions, slurries, and pastes into powders in a continuous manner. It also allows the production of particles with controlled size and morphological aspects [20]. Due to the limited collection efficiency related to cyclone separators, the traditional spray drying process is limited for producing particles of 2–5 μm sizes. A spray dryer with a piezoelectric driven vibrating mesh atomizer and a high-efficiency electrostatic powder collector seems to correct these limitations. A new Nano spray dryer technology B-90, has been developed by Büchi® (Switzerland) and has been applied to perform nano crystallization and drying [21,22,23]. The other new technology includes the dissolution of drug and a polymeric dispersant system in a suitable solvent. After spray drying the resulting solution the powder containing the drug are produced as either the molecularly dispersant system in the polymer matrix to form a solid solution or dispersed as submicron particles to form solid suspension [24]. The spray drying process is very rapid; can be designed to any capacity, adaptable to a fully automated control system that allows continuous preparation, and also wide ranges of spray dryer designs are available in the market. The spray dryer can be used for heat resistant and heat sensitive products and the feedstock can be as a solution, slurry, gel, suspension or melt form. The current advantage of nanotechnology has increased the stress on existing spray dryer systems to produce nanoparticles with high yield and controlled size distribution.

3.3 Supercritical Fluid

Supercritical antisolvent (SAS) processes are lately proposed for the production of micro- and nanosized particles [25, 26]. The solute, solvent, and the supercritical antisolvent are the three important components of SAS. [26]. A very high level of supersaturation was generated due to the high power of supercritical fluids to dissolve the organic solvents as well as by the low solubility of the solute in the SAS. A very fast diffusion and high supersaturation creates precipitation of nanoparticles that are not possible to obtain with antisolvent precipitation or any other techniques [26]. The main advantage is the complete removal of antisolvent by pressure reduction to the gas phase [25]. In case of SAS the solvent power can be obtained by varying pressure and temperature and their diffusivities can be about two orders of magnitude greater than those of liquids [25, 26]. More recently Caputo et al. [26] proposed the use of SAS for the precipitation of sulfathiazole from acetone solution by the use of urea as habit modifier and in the recent past poly(sebacic unhydride) was used by Jarmer et al. as growth inhibitor for griseofulvin using a SAS [26, 27].

3.4 Impinging Jet Crystallization

Current advancement to directly produce small particles include impinging jet crystallization in which jets are used to create impinging fluid jet streams and thereby achieve high intensity micro mixing of the fluids prior to nucleation [28]. Two or more jets and two fluids with different solvent composition can be used to micro mix the solvent and antisolvent for initiating the precipitation of solute from solution [29]. Woo et al. [28] studied the control distribution by combining controlled seeding by impinging jet crystallization with a batch crystallizer operating at a controlled constant growth rate. The goal of their study was to propose control strategies to produce crystals with a target crystal size distribution (CSD), that are combinations of optimal control and an impinging jet crystallizer [28] The barium sulphate nanocrystal precipitations are studied experimentally by Schwarzer and Peukert et al. [30] and the mean particle size of the nanoparticles are also predicted accurately by CFD model. The impinging jet crystallization offers very high-energy dissipation rate, efficient micro mixing and tightly controlled conditions to high product quality [29].

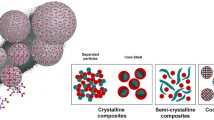

3.5 Emulsion Method

The method of preparation of nanocrystals by microemulsion is gaining a significant interest in both basic research and in different industrial fields [31]. The organic nanocrystal fabrication using the emulsion method is a three-step process (Fig. 16.2) [32]. The first step is the preparation of emulsion by the quick addition of solution of compound in the organic phase to the aqueous phase at high temperatures [28]. High stirring speed and irradiating ultrasound was used to produce the stable emulsion [31]. In the second step the solutes are crystallized by gradually cooling the dispersion to low temperatures. In the third step an antifoaming agent was added to break the emulsion and separate the organic solvent. A nanocrystals were obtained as a stable dispersion in an aqueous phase [32]. Ujiiye-Ishii and co-workers [32] described how to prepare perylene nanocrystals using emulsion and Reprecipitation method. Schulman et al. first described the method in 1959 and prepared macroemulsion and microemulsion of hydrocarbons. [33] A significant feature of this method is its ultralow interfacial tension, large interfacial area, and thermodynamic stability of the resulting nanocrystal dispersions in aqueous media [33].

Schematic model of the organic nanocrystal fabrication using the emulsion method [32]

3.6 Patterned Micro Well and Patterned Gold Islands

The patterned micro wells are well-defined two-dimensional or confined three-dimensional structures that are mainly used as templates to guide the crystal nucleation and growth [34]. The templates can be self-assembled organic monolayers [34, 35], polymeric matrix [36], silica [37], highly ordered graphite or carbon nanotubes [37, 38]. Recently, significant attention has been directed to design protein nanocrystals with uniform shapes for improving bioavailability and providing alternative release route [39] Wang et al. demonstrated that patterned micro wells provide a platform for controlling the crystallization of protein nanocrystals using industry-standard crystallization conditions [39]. Previously, patterned Self-Assembled Monolayers (SAM) were used to crystallize organic molecules such as glycine [10]. The bifunctional SAMs pattern contains hydrophilic islands surround by hydrophobic regions on which small hemispherical droplets are formed when wetted with polar solvents [10]. The nanocrystals of glycine are formed either by slow cooling, slow evaporation or slow diffusion of an antisolvent [10, 34, 40]. Lee et al. showed that the polymorphic outcome of glycine is primarily influenced by the solvent evaporation rate. [40] The slow evaporation results into α-glycine while fast evaporation favours β-glycine due to creation of high supersaturation [40]. The control of the supersaturation during vapour diffusion experiments results into the crystallization of metastable β-glycine polymorphs [10]. The study shows that the organic vapour diffusion was used to obtain the metastable β-glycine, while slow cooling and slow evaporation are used to prepare the α-glycine and γ-glycine polymorphs [10]. By controlling the initial glycine concentration and the rate of diffusion the nanocrystals with a size between 200 nm to 1.2 μm were prepared based on the island size [10]. Kim et al. also calculated the solubility of glycine crystals in methanol using Ostwald-Freundlich eq. [41] and 100 nm crystals displayed two times more solubility then the equilibrium solubility of glycine [10]. The solubility results calculated from the Ostwald-Freundlich equation for α-glycine and β-glycine polymorphs indicates that β-glycine is more stable than α-glycine due to the effect of surface molecules when the crystal size is under 97 nm [42]. The patterned SAMs technique is very simple, with a large variability of molecules and highest density of SAMs and many functional thiols are commercially available. A major limitation is the removal of crystals from the surface while scraping or ultrasound can be used to remove the crystals from the surface [10].

3.7 Microfluidics Devices

A microfluidic system can be used for the continuous production of nanocrystals mainly due to the improved reaction control and performance of mixing, the particle size distribution becomes sharper and the particle size decreases [43, 44]. The microfluidic devices fall into broad categories: capillary- and chip-based systems. In capillary reactors the simple fluidic components can be joined by appropriate lengths of tubing. Chips are precisely tailored and typically fabricated from a plastic, glass or silicon substrate, wet etching or micromachining techniques. Both types of reactor play an important role in nanocrystal synthesis [43, 44]. Single phase or two-phase reactors are two important microfluidic reactors. The single-phase reactors are commonly used reactors, in which miscible streams of reagents are injected into a channel or capillary where they mix and react, making it easy to conduct multistep reactions and produce more complex structures [43]. The undesirable velocity dispersion and fouling on the reactor wall are the two important limitations and can limit the performance of a single phase reactor [43]. In case of two-phase reactors an additional immiscible fluid was injected (which can be a gas or a liquid) into the channel divides and creates a split plug that passes through the reactor at a common speed, eliminating velocity dispersion [44]. The size of the split plugs was proportional to the relative flow rates in the two outlet channels and can be controlled by varying the relative hydrostatic pressures at the two outlets [44]. The microfluidic reactor is still a long way from displacing the conventional reactor for nanocrystal synthesis, which cannot satisfy industrial demand [44].

3.8 Nanocrystal Preparation Using Nanoporous Materials

A novel process to generate nanocrystals of active pharmaceutical ingredients within the nanopores of nanoporous materials is the simplest approach for nanocrystal preparation [11]. Many studies have been performed investigating the potential of carrier materials including metal organic frameworks, mesoporous silica, controlled pore glass, porous polycyclohexyl ethylene and polystyrene and nanostructured lipid carriers [11, 45,46,47,48].

O’Mahony et al. developed a process with the aim of generating nanocrystalline products within the controlled pore glass (GPG), filling the pores of CPG with API solution [11]. The inhibition time was estimated by the Washburn equation in order to facilitate complete filling of the pores of CPG during the process. The Washburn equation (Eq. 16.4) usually predicts the capillary flow of liquids in porous material to describe the migration of this liquid − air interface with time t within a channel [49].

Where t is the time for a liquid of viscosity η and surface tension γ to penetrate a distance L into a fully wettable, porous material whose average pore diameter is D [49] (Fig. 16.3).

Schematic of process design and setup of column process used for the preparation of nanocrystals within the nanoporous channels of controlled pore glass [11]

The surface area to volume ratio can affect the thermotropic properties of very small crystals, which results in substantial melting point depression due to the limitations on crystal size imposed by the pores [50, 51]. The Gibbs-Thomson equation can be used to describe the melting point depression seen in nanocrystals. The Gibbs-Thomson equation for nanocrystals confined to pores is defined as

where T m is the bulk melting temperature, T m (d) is the melting temperature of a confined crystal with diameter d assumed equal to the pore diameter, M is the molecular mass, ρ solid is the density of the solid, γ solid−liquid is the surface free energy of the solid-liquid interface, ΔH fus is the molar enthalpy of fusion, and θ is the contact angle between the wall and crystal. The melting point depression for nanosized crystalline material has been reported for particles confined within nanosized pores for a number of compounds [11, 50, 51].

The important advantage is the sizes of the nanocrystals are limited by the channel diameter, which in turn limits growth of the crystals along the channel length and the melting behaviour is influenced by the matrix material [47]. CPGs have the advantage of being available in a number of different pore diameters, shapes and size [47].

4 Conclusions

Drug nanocrystals are considered as one of the important formulation techniques for poorly water-soluble drugs and can be applied to various routes of administration during the drug delivery of API. The nanocrystal technology offers great benefits that include the increased saturation solubility, and increased dissolution velocity due to increased surface area. We first explained the conventional nanocrystal preparation method and its recent improvements. The Milling and high-pressure homogenization methods are very useful techniques and produced the most nanocrystal products that have reached the market. Supercritical fluid crystallization method, controlled flow cavitation, and impinging jet crystallization methods extend the potential of the re-precipitation method. The key innovations in nanocrystal preparation include microfluidic devices, patterned self-assembled monolayer and generation of nanocrystals within the controlled pore glass. The microfluidic reactor is still a long way from displacing the conventional reactor for nanocrystal synthesis and needs to change before there is a realistic prospect of it. In the future nanocrystal surfaces might be modified to achieve a prolonged or a targeted release that can be the important part of the work for the nanoparticles.

References

Raj S, Jose S, Sumod US, Sabitha M (2012) Nanotechnology in cosmetics: opportunities and challenges. J Pharm Bioallied Sci 4:186–193

Ekimov AI, Efros AL, Onushchenko AA (1985) Quantum size effect in semiconductor microcrystals. Solid State Commun 56:921–924

Tran TT, Tran PH, Khanh TN, Van TV, Lee BJ (2013) Solubilization of poorly water-soluble drugs using solid dispersions. Recent Pat Drug Deliv Formul 7:122–133

Junghanns J-UAH, Müller RH (2008) Nanocrystal technology, drug delivery and clinical applications. Int J Nanomedicine 3:295–310

LaMer VK, Dinegar RH (1950) Theory, production and mechanism of formation of Monodispersed hydrosols. J Am Chem Soc 72:4847–4854

Mer VKL (1952) Nucleation in phase transitions. Ind Eng Chem 44:1270–1277

Mullin JW (2001) 5 - nucleation. In: Mullin JW (ed) Crystallization, 4th edn. Butterworth-Heinemann, Oxford, pp 181–215

Kulkarni SA, Kadam SS, Meekes H, Stankiewicz AI, ter Horst JH (2013) Crystal nucleation kinetics from induction times and metastable zone widths. Cryst Growth Des 13:2435–2440

Myerson A (2002) Handbook of industrial crystallization. Butterworth-Heinemann, Boston

Kim K, Lee I, Centrone A, Hatton TA, Myerson AS (2009) Formation of nanosized organic molecular crystals on engineered surfaces. J Am Chem Soc 131:18212–18213

O’Mahony M, Leung AK, Ferguson S, Trout BL, Myerson AS (2015) A process for the formation of Nanocrystals of active pharmaceutical ingredients with poor aqueous solubility in a nanoporous substrate. Org Process Res Dev 19:1109–1118

Shegokar R, Muller RH (2010) Nanocrystals: industrially feasible multifunctional formulation technology for poorly soluble actives. Int J Pharm 399:129–139

Peltonen L, Hirvonen J (2010) Pharmaceutical nanocrystals by nanomilling: critical process parameters, particle fracturing and stabilization methods. J Pharm Pharmacol 62:1569–1579

Nykamp G, Carstensen U, Müller BW (2002) Jet milling—a new technique for microparticle preparation. Int J Pharm 242:79–86

Wise DL (2000) Handbook of pharmaceutical controlled release technology. CRC Press, Boca Raton

Souto EB, Wissing SA, Barbosa CM, Müller RH (2004) Development of a controlled release formulation based on SLN and NLC for topical clotrimazole delivery. Int J Pharm 278:71–77

Merisko-Liversidge E, Liversidge GG, Cooper ER (2003) Nanosizing: a formulation approach for poorly-water-soluble compounds. Eur J Pharm Sci 18:113–120

Salazar J, ller RH, schwitzer JP (2014) Combinative particle size reduction technologies for the production of drug nanocrystals. J Pharm 2014:14.

Khadka P, Ro J, Kim H, Kim I, Kim JT, Kim H, Cho JM, Yun G, Lee J (2014) Pharmaceutical particle technologies: an approach to improve drug solubility, dissolution and bioavailability. Asian J Phar Sci 9:304–316

Ré M-I (2006) Formulating drug delivery systems by spray drying. Dry Technol 24:433–446

Zgoulli S, Grek V, Barre G, Goffinet G, Thonart P, Zinner S (1999) Microencapsulation of erythromycin and clarithromycin using a spray-drying technique. J Microencapsul 16:565–571

Wan LSC, Heng PWS, Chia CGH (1992) Spray drying as a process for microencapsulation and the effect of different coating polymers. Drug Dev Ind Pharm 18:997–1011

Heng D, Lee SH, Ng WK, Tan RB (2011) The nano spray dryer B-90. Expert Opin Drug Deliv 8:965–972

Huang Y, Dai W-G (2014) Fundamental aspects of solid dispersion technology for poorly soluble drugs. Acta Pharm Sin B 4:18–25

Reverchon E (1999) Supercritical antisolvent precipitation of micro- and nano-particles. J Supercrit Fluids 15:1–21

Caputo G, Adami R, Reverchon E (2008) Supercritical fluid crystallization of adipic acid using urea as habit modifier. Cryst Growth Des 8:2707–2715

Jarmer DJ, Lengsfeld CS, Anseth KS, Randolph TW (2005) Supercritical fluid crystallization of griseofulvin: crystal habit modification with a selective growth inhibitor. J Pharm Sci 94:2688–2702

Woo XY, Tan RBH, Braatz RD (2011) Precise tailoring of the crystal size distribution by controlled growth and continuous seeding from impinging jet crystallizers. Cryst Eng Comm 13:2006–2014

Siddiqui SW, Zhao Y, Kukukova A, Kresta SM (2009) Characteristics of a confined impinging jet reactor: energy dissipation, homogeneous and heterogeneous reaction products, and effect of unequal flow. Ind Eng Chem Res 48:7945–7958

Schwarzer H-C, Peukert W (2004) Combined experimental/numerical study on the precipitation of nanoparticles. AICHE J 50:3234–3247

Malik MA, Wani MY, Hashim MA (2012) Microemulsion method: a novel route to synthesize organic and inorganic nanomaterials: 1st nano update. Arab J Chem 5:397–417

Ujiiye-Ishii K, Kwon E, Kasai H, Nakanishi H, Oikawa H (2008) Methodological features of the emulsion and reprecipitation methods for organic nanocrystal fabrication. Cryst Growth Des 8:369–371

Schulman JH, Stoeckenius W, Prince LM (1959) Mechanism of formation and structure of micro emulsions by electron microscopy. J Phys Chem 63:1677–1680

Lee AY, Lee IS, Dette SS, Boerner J, Myerson AS (2005) Crystallization on confined engineered surfaces: a method to control crystal size and generate different polymorphs. J Am Chem Soc 127:14982–14983

Kulkarni SA, Weber CC, Myerson AS, ter Horst JH (2014) Self-association during heterogeneous nucleation onto well-defined templates. Langmuir 30:12368–12375

Shin K, Leach KA, Goldbach JT, Kim DH, Jho JY, Tuominen M, Hawker CJ, Russell TP (2002) A simple route to metal nanodots and nanoporous metal films. Nano Lett 2:933–936

Fan S, Chapline MG, Franklin NR, Tombler TW, Cassell AM, Dai H (1999) Self-oriented regular arrays of carbon nanotubes and their field emission properties. Science 283:512–514

Han W, Fan S, Li Q, Hu Y (1997) Synthesis of gallium nitride Nanorods through a carbon nanotube-confined reaction. Science 277:1287–1289

Wang L, Barton J, Hughes L, Odom TW (2008) Shape-control of protein crystals in patterned Microwells. J Am Chem Soc 130:2142–2143

Lee AY, Lee IS, Myerson AS (2006) Factors affecting the polymorphic outcome of glycine crystals constrained on patterned substrates. Chem Eng Technol 29:281–285

Mullin JW (2001) 3 – solutions and solubility. In: Mullin JW (ed) Crystallization, 4th edn. Butterworth-Heinemann, Oxford, pp 86–134

Yang X, Myerson AS (2015) Nanocrystal formation and polymorphism of glycine. Cryst Eng Comm 17:723–728

Phillips TW, Lignos IG, Maceiczyk RM, deMello AJ, deMello JC (2014) Nanocrystal synthesis in microfluidic reactors: where next? Lab Chip 14:3172–3180

Song H, Tice JD, Ismagilov RF (2003) A microfluidic system for controlling reaction networks in time. Angew Chem Int Ed 42:768–772

Vallet-Regi M, Rámila A, del Real RP, Pérez-Pariente J (2001) A new property of MCM-41: drug delivery system. Chem Mater 13:308–311

Vallet-Regi M, Balas F, Arcos D (2007) Mesoporous materials for drug delivery. Angew Chem Int Ed Engl 46:7548–7558

Ha JM, Wolf JH, Hillmyer MA, Ward MD (2004) Polymorph selectivity under nanoscopic confinement. J Am Chem Soc 126:3382–3383

Tran TH, Ramasamy T, Truong DH, Choi HG, Yong CS, Kim JO (2014) Preparation and characterization of fenofibrate-loaded nanostructured lipid carriers for oral bioavailability enhancement. AAPS Pharm Sci Tech 15:1509–1515

Fisher L (1999) Physics takes the biscuit. Nature 397:469–469

Ha J-M, Hillmyer MA, Ward MD (2005) Thermotropic properties of organic Nanocrystals embedded in Ultrasmall crystallization chambers. J Phys Chem B 109:1392–1399

Jackson CL, McKenna GB (1990) The melting behavior of organic materials confined in porous solids. J Chem Phys 93:9002–9011

Acknowledgements

Novartis International AG is gratefully acknowledged for funding of this research under the Novartis-MIT Center for Continuous Manufacturing. The authors also thank Dr. Marcus O’Mahony, Dr. Siva Rama Krishna Perala and Leia Dwyer for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media B.V.

About this chapter

Cite this chapter

Kulkarni, S.A., Myerson, A.S. (2017). Methods for Nano-Crystals Preparation. In: Roberts, K., Docherty, R., Tamura, R. (eds) Engineering Crystallography: From Molecule to Crystal to Functional Form. NATO Science for Peace and Security Series A: Chemistry and Biology. Springer, Dordrecht. https://doi.org/10.1007/978-94-024-1117-1_16

Download citation

DOI: https://doi.org/10.1007/978-94-024-1117-1_16

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-024-1115-7

Online ISBN: 978-94-024-1117-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)