Abstract

Innovative composite materials made of continuous fibers embedded in mortar matrices have been recently received attention for externally bonded reinforcement of masonry structures. In this regards, application of natural fibers for strengthening of the repair mortars is attractive due to their low specific weight, sustainability and recyclability. This paper presents experimental characterization of tensile and pull-out behavior of natural fibers embedded in two different mortar-based matrices. A lime-based and a geopolymeric-based mortar are used as sustainable and innovative matrices. The obtained experimental results and observations are presented and discussed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Innovative composite materials made of continuous fibers embedded in mortar matrices have been recently received attention for externally bonded reinforcement of masonry structures. These materials are usually identified as FRM, TRM, or TRC in the literature. Fiber Reinforced Mortars (FRMs) are proposed to overcome or reduce the disadvantages related to the use of FRPs such as durability and compatibility with the masonry substrate (D’Ambrisi et al. 2013; Carozzi et al. 2014; De Felice et al. 2014). Mortar based matrices exhibit a significant heat resistance, allows vapor permeability, can be applied either at low temperatures or on wet surfaces, have a better compatibility with masonry substrates and allow for reversibility. The latter is of great importance in case of strengthening of historical structures.

FRMs are usually constructed with continuous fibers embedded in cementitious mortars for application to concrete structures (Mobasher 2012). Lime-based mortars are however preferable in case of masonry and historical structures as they are more sustainable and compatible with the substrate (De Felice et al. 2014). The fabrics are usually in the form of grids made of multifilament carbon, glass or steel yarns. The use of natural fibers such as flax , hemp and jute has also received recent interest for strengthening of masonry structures (Codispoti 2013). Application of natural fibers in Civil Engineering applications is attractive due to their low specific weight, sustainability and recyclability, although durability of these systems still remains open.

Despite the recent interest on the use of FRMs for strengthening purposes, information regarding their mechanical performance and long-term durability is still lacking. The performance of FRM strengthened masonry elements is strongly dependent on the mechanical properties of FRM, the bond behavior between the fibers and mortar matrix, and the bond behavior between the mortar and the masonry substrate (Sueki et al. 2007; Carozzi and Poggi 2015).

This paper presents preliminary results of an experimental campaign aimed at mechanical characterization of FRMs made of flax natural fibers. The tests include tensile characterization of FRM composite coupons and pull-out tests for characterization of the fiber/mortar bond behavior. A pozzolanic lime-based and a geopolymeric-based mortar were used as two sustainable and innovative matrices. Lime-based mortar was selected as a commercially available mortar usually used for strengthening of masonry structures. On the other hand, it has been shown that natural fibers embedded in lime-based mortars present better performance under aggressive environmental conditions (Olivito et al. 2014). Geopolymeric-based mortar was produced in the laboratory condition as an innovative mortar which has received extensive attention during the last years but their durability and long-term performance are still unknown.

Tensile tests were performed on flax single yarn, flax fabric and flax fabrics embedded in mortar. Six specimens were prepared and tested for each material model. The pull-out tests were performed on flax fabrics embedded in the mortar with 50 and 100 mm bonded lengths. Five specimens were prepared for each mortar type and bonded length resulting in total twenty pull-out tests. The results were presented and discussed critically throughout the paper.

Materials and Specimens

The materials consisted of a commercial pozzolanic lime-based and a geopolymeric-based mortar as the matrix and a commercial bidirectional flax fabric as the reinforcing material. The pozzolanic lime-based mortar was a commercially available mortar selected as a sustainable solution for strengthening of masonry and historical structures. The geopolymeric-based mortar was produced in the laboratory as an innovative and sustainable matrix based on the activation of alkaline materials rich in silica and alumina, whose mechanical properties can be considerably higher than those of conventional binders.

Flax fiber specimens were prepared for mechanical characterization of materials and characterization of bond at fiber/mortar interface. Mechanical characterization tests included compressive and flexural tests on mortar and tensile tests on non-impregnated flax yarn filament and fabric, and fiber reinforced mortar specimens. The specimens were prepared and stored in the laboratory conditions (20 °C and 60 % R.H.) for three months before performing the mechanical tests to assure that the mortar was completely cured. Cylindrical specimens with 50 mm diameter and 100 mm height and prismatic specimens with dimensions of 40 × 40 × 160 mm3 were prepared for mortar compressive and flexural tests, see Fig. 1. The specimens were prepared according to the specifications provided by EN 1015-11 (2007).

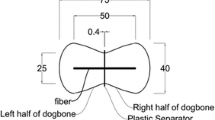

The single yarn and fabric (with 50 mm width) specimens were cut with 250 mm length, Fig. 2. 50 mm aluminum tabs were glued at both ends of the specimens for gripping the specimens during the tests which led to reduction of the specimens’ free length to 150 mm. The fiber reinforced mortar specimens were prepared according to the geometrical details shown in Fig. 3.

The geometrical details of the pull-out tests specimens are shown in Fig. 4. Fiber fabrics with 50 mm width were embedded in the cylindrical mortar specimens with different bonded lengths. Again, aluminum tabs were used at the end of the fabric free end for gripping the specimens. The free length of the fabrics was impregnated with epoxy resin to avoid unfortunate failure during the tests. Two sets of specimens with different bonded lengths of 50 and 100 mm were prepared for each mortar type. The cylinders height was chosen equal to the bonded length according to the shown details.

Test Methods

The tests included compressive and flexural tests on mortar specimens, direct tensile tests on single flax yarns, flax fabric and fiber reinforced mortar specimens and fiber pull-out tests .

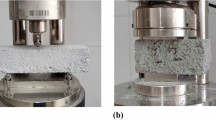

The mortar compressive and three-point bending tests were performed by means of a universal testing machine under force controlled conditions and according to EN 1015-11 (2007), see Fig. 5.

The tensile tests were performed on single flax yarn, flax fabric and fiber reinforced mortar specimens by means of a universal testing machine, see Fig. 6. All the tests were performed under displacement control conditions at the rate of 2 mm/min so that the results will be comparable. The applied load was recorded by a load cell integrated in the testing machine, while deformation was monitored by a clip gauge placed on the middle of the specimens.

Fiber pull-out tests were performed to characterize the bond behavior between flax fabrics and mortars. The specimens were fairly clamped to a supporting frame to avoid any movement during the tests, see Fig. 7. The fabrics were pulled from the mortar monotonically with a velocity of 0.3 mm/min. The tests were driven under displacement control conditions using a LVDT placed at the loaded end of the flax fabric. The resulting load was measured by means of a load cell.

Results and Discussion

Mortar Properties

The experimental mechanical properties of the mortars (three months curing) are listed in Tables 1 and 2. The values are presented as average of six tested specimens. It can be observed that the lime-based mortar has a compressive strength of 12.7 MPa, almost two times higher than the geopolymeric-based mortar (6.5 MPa). The elastic modulus of the mortars is 3247.5 and 7480.1 MPa for lime-based and geopolymeric-based mortars, respectively. The flexural tensile strength of the lime-based mortar, obtained from three-point bending test, is 6.1 MPa, being much larger than the geopolymeric-based mortar (1.12 MPa). The CoVs of the results are relatively small and in the acceptable range of materials testing. Although the mechanical properties of the geopolymeric-based mortar is lower than the lime-based mortar, it seems suitable for application to historical and masonry structures.

Tensile Tests Results

The summary of the results obtained from the tensile tests is presented in Table 3. Higher stiffness, but lower tensile strength is observed in the fabric specimens in comparison to single yarn tests. On the other hand, the tensile strength has increased in the fiber reinforced composite specimens in comparison to the bare flax fabrics. This can be due to the increased integrity of the system due to the mortar presence in the embedded specimens. The stiffness and tensile strength of both composite specimens (lime-based and geopolymeric-based) are similar.

The stress-strain curves of the FRM specimens are shown in Fig. 8. It should be noted that these curves are obtained based on the total deformation of the specimens consisting of the reinforced and unreinforced parts, see Fig. 3. In general, it can be observed that the lime-based composites have higher stiffness after mortar cracking in comparison to geopolymeric-based composite. The typical failure mode of the specimens was tensile rupture of the fibers after cracking of the mortar layer. The cracks were uniformly distributed along the specimens, as can be seen in Fig. 9, showing a good stress transfer between the fibers and mortar in both mortar types. As aluminum tabs were used at both ends of the specimens, no fiber slipping occurred during the tensile tests.

Pull-Out Tests Results

The summary of pull-out test results is presented in Table 4. The results are presented as the average of five tested specimens. The CoV of the obtained results is in an acceptable range of pull-out tests. It can be also observed that the matrix type and bonded length significantly affect the pull-out strength of the specimens.

In the specimens with lime-based mortar (FRM-LM), slipping of the fibers is observed when the bonded length is 50 mm. However, in the specimens with 100 mm bonded length, slipping of the fibers occurred in the beginning of the tests followed by the fibers tensile rupture. The maximum pull-out force, Fmax in Table 4, has increased from 0.39 kN in the specimens with 50 mm bonded length to 1.26 kN in the specimens with 100 mm bonded length. This increase of the maximum pull-out force together with the observed change of failure mode can be the evidence of having the effective bonded length between 50 and 100 mm.

In the specimens with geopolymeric-based mortar (FRM-GPM), the tensile rupture of the specimens has occurred in both bonded lengths. Therefore, the maximum pull-out force was not expected to change significantly. The observed small difference between the observed values can be attributed to the materials and specimens variability. According to the observed experimental failure modes, the effective bonded length in the specimens with geopolymeric-based mortar is less than 50 mm.

Conclusions

Use of inorganic based matrices, especially cement-free or lime-based, are highly recommended for strengthening of masonry and historical structures. This paper presented the results obtained from mechanical characterization of mortar-based composites made of natural fibers and two innovative matrices. The tests included mechanical characterization of mortar as well as tensile and pull-out bond tests on flax fiber reinforced mortar specimens. The selected mortars were a pozzolanic lime-based mortar and a geopolymeric-based mortar. The lime-based mortar was a commercially available mortar used for strengthening of masonry structures, while the geopolymeric-based mortar was produced in the laboratory as a sustainable and innovative matrix. The tensile tests were performed on single yarn, fabrics and fiber reinforced mortar specimens. Fiber reinforced mortar specimens showed higher tensile strength in comparison to the bare fabrics due to the presence of mortar. The failure occurred in the specimens due to tensile rupture of the fibers after a uniform development of tensile cracks along the mortar layers. Characterization of the tension stiffening behavior of FRMs made of natural fibers with the aim of full field measurement techniques is of great interest for numerical modeling approaches at this stage and can be the subject of future studies. The results from the pull-out tests showed that the mortar type can significantly affect the bond performance and failure mode. The effective bond length in both sets of specimens was observed to be in less than 100 mm. A comprehensive characterization of the bond -slip behavior and development of suitable bond constitutive laws are still required. Although the geopolymeric based mortar had lower mechanical properties in comparison to the lime-based mortar, the tensile and pull-out behavior seems satisfactory for application to historical masonry. Use of natural fibers for development of innovative composite materials seems interesting although issues such as wetability of the fibers and durability of the system remain open.

References

D’Ambrisi A, Feo L, Focacci F. Experimental analysis on bond between PBO-FRCM strengthening materials and concrete. Compos Part B 2013;44:524–32.

Carozzi FG, Milani G, Poggi C. Mechanical properties and numerical modeling of Fabric Reinforced Cementitious Matrix (FRCM) systems for strengthening of masonry structures. Compos Struct 2014;107:711–25.

[3] De Felice G, De Santis S, Garmendia L, et al. Mortar-based systems for externally bonded strengthening of masonry. Mater Struct 2014;47:2021–37.

Mobasher B. Mechanics of Fiber and Textile Reinforced Cement. CRC Press, 2012.

Codispoti R. Mechanical performance of natural fiber-reinforced composites for the strengthening of ancient masonry. PhD thesis, University of Calabria, 2013.

Sueki S, Soranakom C, Mobasher B, Peled A. Pullout-slip response of fabrics embedded in a cement paste matrix. J Mater Civ Eng 2007;19:718–27.

Carozzi FG, Poggi C. Mechanical properties and debonding strength of Fabric Reinforced Cementitious Matrix (FRCM) systems for masonry strengthening. Compos Part B 2015;70:215–30.

Olivito RS, Cevallos OA, Carrozzini A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater Des 2014;57:258–68.

EN 1015-11. Methods of test mortar for masonry. Part 11: Determination of flexural and compressive strength of hardened mortar. 2007.

Acknowledgments

The first author gratefully acknowledges the funding by Fundação para a Ciência e a Tecnologia (FCT), under the grant SFRH/BPD/92614/2013. The assistance of the technicians of the Structures Laboratory (LEST), where the experimental work took place, is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 RILEM

About this paper

Cite this paper

Ghiassi, B., Razavizadeh, A., Oliveira, D.V., Marques, V., Lourenço, P.B. (2016). Tensile and Bond Characterization of Natural Fibers Embeeded in Inorganic Matrices. In: Fangueiro, R., Rana, S. (eds) Natural Fibres: Advances in Science and Technology Towards Industrial Applications. RILEM Bookseries, vol 12. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7515-1_23

Download citation

DOI: https://doi.org/10.1007/978-94-017-7515-1_23

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7513-7

Online ISBN: 978-94-017-7515-1

eBook Packages: EngineeringEngineering (R0)