Abstract

Moisture damage in asphalt mixtures is a complicated mode of pavement distress that results from the loss of interfacial adhesion between the aggregate and bitumen and/or the loss of cohesion within the bitumen. Both adhesive and cohesive strength of aggregate-bitumen bonds can be determined in the tensile testing mode. This paper presents the development of suitable procedure consisting of an innovative sample preparation, controlled moisture conditioning and new pull-off test set-up to characterise moisture damage resistance of the bonding strength of aggregate-bitumen samples that is sensitive to the mineralogical and physicochemical properties of the aggregates as well as key bitumen physical properties. The test set-up consists of three main parts: a moisture conditioning step designed to ensure characteristic moisture diffusion into the aggregate-bitumen interface, accurate determination of bitumen film thickness using a modified dynamic shear rheometer and direct tension fixtures mounted on an Instron universal testing machine. The capability to vary loading rate, accurately control film thickness and ensure moisture diffusion to the aggregate-bitumen interface are an important improvement over most existing pull-off tests. The test was also found to be sensitive to moisture conditioning time, moisture uptake and the type of aggregate. All samples were subjected to the pull-off test to characterise their tensile strengths before and after moisture conditioning. The results show that the magnitude of the aggregate-bitumen bonding strength in the dry condition is mainly influenced by bitumen. However, the magnitude of the tensile strength after moisture conditioning was found to be influenced by mineralogical composition as well as the moisture diffusion properties of the aggregates. The new test was found to be repeatable with variability comparable to most advanced tensile testing systems for bitumen.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Asphalt mixtures are widely used as road construction materials. During their service life, asphalt pavements have to sustain harsh traffic loads and environmental conditions, which progressively deteriorate their structural capacity and performance with the passage of time. Moisture damage is considered to be one of the major causes of failure in asphalt pavements. Although not all damage is caused directly by moisture, its presence increases the extent and severity of existing distresses like cracking, potholes and rutting (Grenfell et al. 2014).

Moisture damage is a very complex phenomenon because it represents the combined action of various chemical, physical and mechanical processes that occur simultaneously at different intensities and rates (Caro et al. 2010). Existence of moisture in the pavement gradually reduces the overall functionality of asphalt mixtures due to the loss of cohesion within the bituminous binder itself (cohesive damage) and/or the loss of interfacial adhesion between binder and the aggregates (adhesive damage) (Grenfell et al. 2014). There are several parameters which may influence the durability of asphalt mixtures to moisture attack: porosity and roughness of the aggregates, wettability between bitumen and aggregates and chemical interaction at the interface (Horgnies et al. 2011). According to previous researchers, aggregate which has a porous, slightly rough surface and contains more calcium, aluminium and magnesium exhibits relative high moisture sensitivity (Bagampadde et al. 2004), whereas, bitumen which has more carboxylic acids and sulfoxides and good wettability will bond well with aggregate (Petersen and Plancher 1998). Moreover, other researchers demonstrated that the surface energy of the materials could control the wettability between bitumen and aggregate so as to influence the moisture sensitivity (Grenfell et al. 2014).

There are many experimental methods designed and used to characterise the moisture induced damage of bituminous mixtures over the last three decades. Testing methods such as the boiling water test and immersion test are used to characterise the adhesive properties of uncompacted mixes (Liu et al. 2014). The Indirect Tensile Test (Lottman 1982), Hamburg Wheel Tracking Device (Aschenbrener 1995) and Saturation Ageing Tensile Stiffness test (Aschenbrener 1995) are methods which focus on compacted mixtures to predict their degradation under simulated moisture conditioning. It can be seen that the most researches on moisture damage focused on loose bitumen-coated aggregate mixtures and compacted asphalt mixtures, whereas the degradation of bonding strength of bituminous film or aggregate-bitumen interfaces were less investigated. A major limitation of some aggregate-bitumen bonding strength tests is the lack of capability to precisely control loading rate (Kim et al. 2012). For a better understanding the performance of the aggregate-bitumen interface when exposed to moisture, this paper presents the development of a suitable procedure consisting of an innovative sample preparation, controlled moisture conditioning and new pull-off test set-up.

2 Materials

Two bituminous binders (B1 and B2) with the penetration grades of 40/60 and 70/100 respectively and similar chemical compositions were used in the study. The physical properties of the bitumen were characterised using softening point and penetration tests. Based on the tests, the softening points (ASTM D36) of B1 and B2 were 51.2 and 45.2 °C respectively, whereas the measured penetration (ASTM D5) of B1 at 25 °C was 46 (0.1 mm) compared with 81 (0.1 mm) for B2.

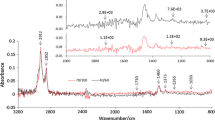

The dynamic shear rheometer (DSR) was adopted to characterise the visco-elastic behaviour of bitumen binders from 10 to 80 °C. Figure 1 shows the shear complex modulus and phase angle master curves for the two bituminous binders used in this research. Data in this figure were produced by means of DSR testing performed within the linear visco-elastic range. The reference temperature is 30 °C. According to the time-temperature superposition principle (TTSP), low shear frequencies correspond to high temperatures while the high frequencies correspond to low temperatures. It was found that bitumen B1 presents higher shear complex modulus than bitumen B2 from low to high shear frequency. With respect to the phase angle, the data seems to overlap as the frequency becomes lower than 10 Hz. However, the phase angle of bitumen B1 is somewhat higher than that of bitumen B2 as the frequency becomes greater than 10 Hz, but the difference is relatively minor. Bitumen showing higher complex modulus is likely to form a stiffer bond to resist the direct tensile forces.

Three types of aggregate from different quarries were selected as substrates. They included one limestone aggregate (L1) and two granite aggregates (G1 and G2). These aggregates are known to have different moisture sensitivity due to their mineralogical composition. Based on their mineral compositions, two of the aggregates (G1 and G2) can be classified as acidic and the third aggregate (L1) is considered basic.

3 Test Methods

The main objective of this paper is characterising the moisture sensitivity of aggregate-bitumen bond using a new designed pull-off test. This test is sensitive to the mineralogical and physicochemical properties of the aggregates as well as key bitumen physical properties. So, the mineralogical composition and moisture absorption of the selected aggregates were first studied. The test set-up consists of three main parts: a moisture conditioning step designed to ensure characteristic moisture diffusion into the aggregate-bitumen interface, accurate determination of bitumen film thickness using a modified dynamic shear rheometer (DSR) and direct tension fixtures mounted on an Instron universal testing machine. The capability to vary loading rate, accurately control film thickness and ensure moisture diffusion to the aggregate-bitumen interface is an improvement over most existing pull-off tests.

3.1 Mineral Liberation Analyser (MLA) Test

The mineralogical compositions of aggregates have a significant influence on moisture damage susceptibility of asphalt mixtures. The mineralogy of the different aggregates was studied using a Mineral Liberation Analyser (MLA) in order to understand the effect of their morphology on moisture damage resistance of aggregate-bitumen bonds. The experimental procedures used for the MLA included the following steps. Aggregates were first washed in water and then dried in an oven at 40 °C for 24 h. The oven-dried aggregates were cast in resin moulds with 25 mm diameter and 20 mm height, followed by polishing of the surface using a rotary polishing machine. Then, carbon coating was applied to get an electron conductive surface. An FEI Quanta 600 Scanning Electron Microscopy (SEM) with MLA capability was used for the mineral analysis. During testing, the SEM collects Back-scattered Electron (BSE) images and energy dispersive X-ray data for a series of frames step by step across the specimen surface. Measurement of the backscattered electron intensities allows for the segmentation of mineral phases within each particle section, while Energy Dispersive X-ray (EDX) analysis of a given phase allows for phase identification (Grenfell et al. 2012).

3.2 Aggregates Moisture Absorption

Another important parameter that influences moisture-induced damage in asphalt mixtures is the rate and amount of water absorption of the aggregates. This approach is in contrast to most previous studies that only consider conditioning time when evaluating moisture damage. The current approach recognises the differences in moisture absorption characteristics of different aggregates. To perform the moisture absorption experiments, rectangular aggregate beams with the dimension of 100 mm × 20 mm × 10 mm were first cut from boulders. Then the aggregate beams were cleaned using deionised water and dried in an oven at 40 °C for 24 h to remove all the moisture. The weight of each beam in the dry condition was measured using a balance with the precision of 0.1 μg. The aggregates were moisture conditioned by placing them in baths containing deionised water at 20 °C and weighing them periodically until steady conditions were reached. The results were used to calculate the mass of water absorbed by aggregate as a percentage of the dry aggregate weight (Eq. 1).

where M t is the moisture uptake at time t, w 0 is the initial mass of the aggregate in dry condition, w t is the mass of aggregate after time t of immersion.

3.3 Bonding Strength Evaluation

The innovation of this test is the ability to accurately determine bitumen film thickness using a modified dynamic shear rheometer, small aggregate substrate size that permits realistic moisture conditioning and simplified custom-made direct tension fixtures that can be easily mounted on an Instron universal testing machine. The pull-off test set-up has been successfully used in the past to evaluate aggregate-asphalt mastic bonds (Apeagyei et al. 2014).

3.3.1 Aggregate-Bitumen Sample Preparation and Conditioning

Figure 2 shows the whole procedure in terms of sample preparation. For sample preparation, boulders of each aggregate were first drilled using a coring tool to get aggregate cylinders with 25 mm diameter. A trimming saw was used to cut the aggregate cylinders into discs with 5 mm thickness. To obtain a relatively constant surface roughness, both surfaces of the aggregate discs were polished using a rotary polishing machine. All discs were cleaned in an ultrasound cleaning machine for 15 min and dried in an oven at a temperature of 40 °C for 24 h. The finished polished aggregate substrate is shown in Fig. 2a.

Two aluminum specimen holding plates (Fig. 2b) were specially designed (diameter and thickness) and fabricated to fit in a standard DSR (Gemini DSR). The plates had dimensions (diameter and thickness) which were similar to a DSR. They differ from a DSR top and bottom plate in terms of the provision of sample holders (2 mm tall rings with 3 screen pins, Fig. 2b).

With a view to precisely controlling the film thickness of the bitumen, two modified fixtures were designed to clamp the discs (Fig. 2b) and then fixed into the DSR machine (Fig. 2c). Firstly, the gap between upper and lower surfaces should be set to zero and these two surfaces should be parallel. After establishing the zero gap and ensuring that the discs are parallel, a small amount of hot bitumen was placed on the lower aggregate surface (Fig. 2d) and then pressed with the upper aggregate to achieve the required bitumen film thickness (Fig. 2e), with a gap resolution of 1 μm. It is found that the minimum bitumen film thickness between two substance surface was approximately 20 μm (Marek and Herrin 1968). So, in this research the sample was removed from the DSR after about 15 min of cooling and then the excess asphalt binder removed by means of a heated pallet knife, as shown in Fig. 2f.

The samples were then stored at 20 °C in water (as shown in Fig. 3) and periodically removed and tested using the pull-off test setup. During the moisture conditioning, moisture could reach the aggregate-bitumen interface in three different ways: through the top and bottom aggregate, through the edge of aggregate-bitumen interface and through the bitumen film.

3.3.2 Pull-Off Test

Before the pull off test, the prepared sample was first fixed by two direct tension fixtures with three screws on each, as shown in Fig. 4a. These two fixtures were then installed on the Instron machine (Fig. 4b). An extension speed of 10 mm/min and a temperature of 20 °C were applied to break the interface (Fig. 4c). During the test, the pull force as a function of elongation was recorded (Fig. 4d) and the failure surfaces of each broken sample were taken with a camera (Fig. 4e). At least four repeat tests were made for each aggregate-bitumen sample. The results were used to calculate the tensile strength. Tensile strength TS (kPa) was computed as the ratio of the peak load divided by the cross-sectional area of the bitumen film as follows:

where F is the Peak tensile force (N) and r is the Radius of aggregate disc (m).

4 Results and Discussion

4.1 Mineralogy of Aggregates

Figure 5 shows the mineralogical composition and distribution of the aggregates obtained from the Mineral Liberation Analyzer. As shown in this figure, minerals in the granite sample (G1 and G2) exhibit considerable texture and the distribution is more complex, while the limestone surface is simple and calcite makes up almost all of the area. For the limestone (L1) sample, calcite is the predominant phase when compared to the other minerals present, with 99.48 % by weight. However, granite is made up of a number of different mineral phases. Chlorite and Albite are the dominant minerals in G1 with a presence of 31.53 and 27.13 % by weight, followed by quartz, epidote and K-feldspar, which account for 19.11, 11.11 and 4.82 %, respectively. Different from G1, albite and anorthite are the predominant content minerals in G2, which account for 32.73 and 18.54 % by weight, but quartz and chlorite also have significant quantities. It is believed that the large proportion of the albite and quartz phases have the potential to lead to moisture damage, due to the poor adhesion between quartz and bitumen. Though Albite can form strong bond with bitumen in the dry condition, this bond is quickly broken in the presence of water. There is also evidence that feldspar is responsible for interfacial failure between bitumen and aggregate (Horgnies et al. 2011).

4.2 Water Absorption of Aggregate

Water absorption data were obtained from these three aggregates used for substrates in this research. In order to measure how much water was absorbed into aggregate during the conditioning time, the water absorption test was performed and the results of the three aggregates are shown in Fig. 6. It can be seen that for the aggregates considered, more than 80 % of the moisture was absorbed during the first 24 h of water conditioning. After that, the water absorption of L1 and G2 experienced a slow increase in comparison with the first 24 h and finally reached marginally over 0.5 % although the water absorption of L1 and G2 still seems to be increasing and has probably not reached their equilibrium. G1 showed the lowest water absorption with the value being only 0.13 % even after 600 h conditioning. The differences in the rate and amount of moisture absorption could be due to the effect of mineral composition and the structure of the aggregates.

4.3 Influence of Aggregate and Bitumen on Dry Bond Strength

Four replicate tests were performed on each aggregate-bitumen combination. The average tensile strength of each aggregate-bitumen bond in the dry condition was calculated according to Eq. 2. The results are depicted in Table 1 together with the test variability (standard deviation); the latter suggesting the new pull-off test has low variability with a coefficient of variability ranging from about 5–16 %. It can be seen from Table 1 that samples prepared with bitumen B1 have higher bonding strength in comparison with bitumen B2. This phenomenon correlates well with the DSR results with shear complex modulus higher for B1 than B2. In addition, bitumen B1 has a higher softening point and lower penetration than B2. It can be demonstrated that bitumen with higher shear complex modulus results in higher tensile strength. In terms of the same bitumen, samples prepared with different aggregates tend to yield similar tensile strength. This suggests that, in the dry condition, the tensile strength of samples is controlled mainly by the bitumen properties, aggregate effects appear minimal. One confirmation of this observation is that damage was mainly cohesive (i.e. within the bitumen) and not interfacial.

4.4 Effect of Moisture Conditioning on Load Behaviour

To simulate the effect of moisture on the stress-strain properties of the aggregate-bitumen samples, the pull-off tests were performed on samples moisture conditioned at 20 °C for 1 day and 7 days. Figure 7 shows the influence of increasing moisture conditioning time on the stress-strain behaviour of samples prepared with bitumen B1 and the three aggregates. From this figure it can be seen that the tensile loads for all specimens decreased after moisture conditioning. In terms of the load-extension curve, B1-L1 and B1-G2 with 1 day moisture conditioning experienced a sharp decrease once they reached the peak load, which is totally different from other specimens. This may be due to the short-term moisture conditioning for these two specimens hardening the bitumen film or acts on the adhesion bond between the bitumen and aggregate and having no chance to release during extension. Due to the lower moisture absorption of G1 aggregate as shown in Fig. 6, it is not easy for water to penetrate into the aggregate-bitumen interface and harden the bitumen so that the sharp decrease of tensile load does not appear in B1-G1.

4.5 Effect of Moisture on Retained Strength

Retained strength, the ratio of bond strength after a given level of moisture conditioning to the dry bond strength, is a common measure of moisture sensitivity of asphalt mixtures. The higher the retained strength of an asphalt mixture, the better the moisture damage resistance of the bond. Figure 8 shows the effect of conditioning time on retained tensile strength of the aggregate-bitumen bond. From this figure it can be seen that specimens which contain L1 or G1 aggregate show good moisture resistance with over 75 % tensile strength retained after 7 days conditioning. On the contrary, the moisture effect was more pronounced in the specimens containing G2 aggregate where the strength decreased by over 80 and 40 % for B1 and B2 bitumen, respectively. Aggregate L1 and G2 have similar moisture absorption properties (as shown in Fig. 6), but they show obviously different moisture sensitivity. This result suggests that the mineralogical property of aggregate is an important indicator of moisture damage. In fact, in the sample G2 the bonds formed with bitumen are quickly broken in the presence of water due to the large amount of albite and quartz within the aggregate. The results showing better resistance to moisture-induced damage for specimens containing limestone than granite are in agreement with previous studies (Apeagyei et al. 2014; Airey and Choi 2002). However, G1 is granite, but because of its lower moisture absorption, it is hard for water to diffuse through the aggregate into the aggregate-bitumen interface so that it cannot obviously weaken the bond. On this basis, it is reasonable to state that the moisture-induced damage of aggregate-bitumen bond is not only controlled by the mineralogical composition but the moisture absorption of aggregate should also be considered. The differences in retained strengths between G1 and G2 could be attributed to higher moisture absorption of the latter. This later result combined with the L1 results previously discussed leads one to conclude that for susceptible aggregates, the amount of moisture absorption is a significant factor.

In terms of the same aggregate, specimens prepared with B2 bitumen show better resistance to moisture damage in comparison with B1. This demonstrated that softer bitumen with lower complex modulus may have better performance with the presence of moisture. However, more tests need to be done so as to confirm this conclusion.

4.6 Moisture Effects on Failure Type

Figure 9 shows the effect of increasing conditioning time on the failure surface of aggregate-bitumen specimens. Without moisture conditioning, cohesive failure occurred into the bulk of the bitumen film. Under this condition, the tensile strength depends on the cohesive properties of the bitumen film. So, the same bitumen shows almost the same tensile strength, regardless of aggregate type. After moisture conditioning, the water could penetrate into the specimen and weaken the aggregate-bitumen bond. The failure tends to transfer from cohesive to an adhesive-cohesive mix with the increase of conditioning time. It can be seen that specimens prepared with L1 retained the most cohesive failure, followed by G1 and specimens with G2 showed the least cohesive failure. Specimens with G2 aggregate even show totally adhesive failure after 7 days moisture conditioning. The results demonstrated that, with similar moisture absorption properties, limestone showed better resistance to moisture-induced damage than granite.

4.7 Relationship Between Moisture Content and Retained Tensile Strength

Results in Figs. 8 and 9 clearly showed the effect of conditioning time on the aggregate-bitumen bond strength and failure type. If taking the moisture absorption into consideration (Fig. 6), the longer the conditioning time, the greater the amount of water that can penetrate into the aggregate and reach the aggregate-bitumen interface. Also, due to the porosity difference, a porous aggregate would absorb more moisture than a less porous aggregate over the same conditioning time.

Figure 10 shows the retained tensile strength, evaluated at both moisture conditioning times, of the specimens prepared with bitumen B1 versus the square root of moisture absorption. From this figure it can be seen that a linear negative relationship was found between retained tensile strength and square root of moisture content. This suggests that, for the same type of aggregate, the amount of water absorbed by the aggregate controls the degradation of the aggregate-bitumen bond strength. As the slope of granite is bigger than limestone, it means that specimens prepared with granite are more sensitive to moisture induced damage. The specimens prepared by bitumen B2 showed the same phenomenon. So, the amount of water absorbed by the aggregate may control the degradation of the aggregate-bitumen bond strength in both basic and acidic aggregates.

5 Conclusions

This paper reports on the findings from an investigation on the moisture conditioning effects on the bond properties of aggregate-bitumen systems through a new procedure based on pull-off testing that allows to accurately control bitumen film thickness as well as to take into account the aggregate moisture absorption. Tensile strength and retained tensile strength were used as measures of moisture sensitivity of aggregate-bitumen bonds. The results were also analysed by relating moisture absorption and mineralogical composition to retained tensile strength. The following conclusions were reached based on the results presented in this paper.

-

The new pull-off testing system developed in this study was found to be effective in characterising the bonding strength of aggregate-bitumen system. The variability in bond strength was low with a coefficient of variation that ranged from 5–16 %. The system is capable of controlling bitumen film thickness with a resolution of 1 μm.

-

In the dry state, the types of failure of all the aggregate-bitumen combinations were cohesive. The effect of bitumen grade was significant with samples prepared with 40/60 pen bitumen having higher tensile strength than those prepared with 70/100 pen bitumen. The results suggest the bitumen stiffness controls the aggregate-bitumen bond strength in the dry state to a higher extent than aggregate type.

-

The bond strength of the various aggregate-bitumen combinations measured with the new pull off test was shown to be sensitive to moisture conditioning. The failure pattern was shown to change from cohesive to mixed cohesive/adhesive and even adhesive failure as the conditioning time extended.

-

Results of pull off tests suggest that the moisture damage of different aggregate-bitumen combinations could be explained by the moisture absorption and mineralogical compositions of aggregates. With the same moisture absorption, limestone tends to have better resistance to moisture damage than granite. Furthermore, in terms of similar mineralogical compositions, lower moisture absorption may result in better moisture resistance.

-

For both limestone and granite used in this research, there was excellent correlation between the moisture content and retained tensile strength. The significant correlation between the moisture content absorbed by aggregate and retained tensile strength of aggregate-bitumen system suggests that the water absorption process of the aggregate controls the degradation of the aggregate-bitumen bond.

References

J. Grenfell, N. Ahmad, Y. Liu, A. Apeagyei, D. Large and G. Airey. Assessing asphalt mixture moisture susceptibility through intrinsic adhesion, bitumen stripping and mechanical damage. Road Materials and Pavement Design 2014, 15(1): 131-152.

S. Caro, E. Masad, A. Bhasin and D. Little. Micromechanical modeling of the influence of material properties on moisture-induced damage in asphalt mixtures. Construction and Building Materials 2010, 24: 1184–1192

M. Horgnies, E. Darque-Ceretti, H. Fezai, E. Felder. Influence of the interfacial composition on the adhesion between aggregates and bitumen: Investigations by EDX, XPS and peel tests. International Journal of Adhesion & Adhesives 2011, 3: 238–247

U. Bagampadde, U. Isacsson and B.M. Kiggundu, Classical and Contemporary Aspects of Stripping in Bituminous Mixes, Road Materials and Pavement Design 2004; 5(1): 7-43.

J.C. Petersen, H. Plancher, Model Studies and Interpretive Review and the Competitive Adsorption and Water Displacement of Petroleum Asphalt Chemical Functionalities on Mineral Aggregate Surfaces, Petroleum Science & Technology 1998; 16(1-2): 89-131.

J. Grenfell, N. Ahmad, Y. Liu et al. Assessing asphalt mixture moisture susceptibility through intrinsic adhesion, bitumen stripping and mechanical damage. Road Materials and Pavement Design 2014; 15(1): 131-152.

Y. Liu, A. Apeagyei, N. Ahmad et al. Examination of moisture sensitivity of aggregate-bitumen bonding strength using loose asphalt mixture and physic-chemical surface energy property tests. International Journal of Pavement Engineering 2014; 15(7): 657-670.

R.P. Lottman, Predicting Moisture-Induced Damage to Asphaltic Concrete Field Evaluation, NCHRP 246, 1982.

T. Aschenbrener, Evaluation of Hamburg wheel-tracking device to predict moisture damage in hot-mix asphalt. Transport Research Record 1995; 1492: 193-201.

Y-R Kim, I Pinto and S-W Park. Experimental evaluation of anti-stripping additives in bituminous mixtures through multiple scale laboratory test results. Construction and Building Materials 2012; 29: 386-393.

J. Grenfell, N. Ahmad, G. Airey, A. Collop and R. Elliott. Optimising the moisture durability SATS conditioning parameters for universal asphalt mixture application. International Journal of Pavement Engineering 2012; 13(5): 433-450.

A. Apeagyei, J. Grenfell, G. Airey. Moisture-induced strength degradation of aggregate–asphalt mastic bonds. Road Materials and Pavement Design 2014; 15(1): 239-262.

Marek CR, Herrin M. Tensile behavior and failure characteristics of asphalt cements in thin film. Proceeding, Association of Asphalt Paving Technologists 1968; 37: 387-421.

M. Horgnies, E. Darque-Ceretti, H. Fezai, & E. Felder. Influence of the interfacial composition on the adhesion between aggregates and bitumen: Investigations by EDX, XPS and peel tests. International Journal of Adhesion and Adhesives 2011; 31(5): 238–247.

G.D. Airey, Y.K. Choi. State of the art report on moisture sensitivity test methods for bituminous pavement materials. Road Materials and Pavement Design 2002; 3(4): 355-372.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 RILEM

About this paper

Cite this paper

Zhang, J., Apeagyei, A.K., Grenfell, J., Airey, G.D. (2016). Experimental Study of Moisture Sensitivity of Aggregate-Bitumen Bonding Strength Using a New Pull-Off Test. In: Canestrari, F., Partl, M. (eds) 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials. RILEM Bookseries, vol 11. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7342-3_58

Download citation

DOI: https://doi.org/10.1007/978-94-017-7342-3_58

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7341-6

Online ISBN: 978-94-017-7342-3

eBook Packages: EngineeringEngineering (R0)