Abstract

Back analyses are required to provide technical evidences to prove or to disprove the hypotheses made on the causes of failures and to establish scenarios of the failures. Analyses must be performed by experienced engineers who are familiar with the analytical tools to be adopted for analyses. The analytical tools adopted must be suitable for the cases to be investigated and the constitutive laws to be used in the analyses must be representative of the materials to be simulated. It is important to realize the fact that there are limitations associated with analyses and the results obtained must be interpreted by experienced engineers who have sufficient practical experience.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

9.1 Introduction

Failures seldom occur for a single reason and for cases in which litigation is involved, the causes of failures are inevitably difficult to ascertain. It is necessary to make various assumptions regarding why and how failures happen and perform analyses to prove or disprove these assumptions. Concession among the parties involved is often required in reaching conclusions. Sometimes, it has to be left to moderators to make final judgments.

Discussed herein are the general principles of back analyses. A case history is presented to illustrate the complexity of back analyses and the difficulties associated with the interpretation of the results obtained.

9.2 Common Causes of Failures

Defective design of temporary works will likely lead to failures during construction and such failures usually occur rather suddenly. The collapse of Nicoll Highway during the construction of the Circle Line of the Singapore Mass Rapid Transit System in April 2004 is a good example. The retaining system of a cut-and-cover tunnel collapsed suddenly while the excavation was about to reach the formation level and a section of the six-lane expressway fell into the sinkhole. Failure started as the waling on the northern wall buckled at 9 am on 20 April 2004 and by 3 pm all the struts in a 100 m section totally failed. The incident led to the death of three construction workers and one supervisory staff. The expressway was closed for 7.5 months. A Committee of Inquiry was immediately appointed by the Ministry of Manpower to investigate the causes of failure. It was concluded that the failure was mainly caused by the inadequate design of the retaining system (COI 2005; Moh and Hwang 2007; Yong and Lee 2007). Effective stress parameters were adopted for marine clay which is essentially an undrained material, resulting in much overestimates of soil strengths and underestimates of wall deflections and bending moments. However, the failure was triggered by buckling of the stiffeners of walings and propagated to all other members of the retaining system.

Defective design of permanent works, on the other hand, will lead to problems which may last for a very long time. The leaning Tower of Pisa is a notable example. The construction of the tower started in 1173. The incline of the tower was already apparent when the construction was halted in 1178. The tower was only 10.6 m tall and consisted of three stories then. The tower, 58 m in height, was completed in 1319 and the bell-chamber was not finally added till 1372. Geographical surveys show that the tower is founded on loose sediments accumulated in a river course. The tilt was obviously caused by differential settlements. There have been several attempts made for preventing the tilting from worsening but resulted in only adverse consequences. The incline reached 5.5° and the government officially closed the tower in 1990. The tilt was finally halted by extracting soil beneath the foundation on the north side and the tower was re-opened at the end of 2001. It is necessary to study the history of the tower and the measures taken in all these attempts to establish the entire scenario.

Failures are not always related to geotechnical problems. If there are no apparent ground movements, failures are most likely due to defective design of structures. A 15-year-old building, Lian Yak Building (commonly referred to as “Hotel New World”), in Singapore collapsed in 1986 and claimed 33 lives. An intensive investigation was conducted by the government and failure of the foundation was one of the possible causes studied. Of 33 columns in the building, the foundations of 5 of them were selected for detailed examination and serious defects were observed in piles and in pile caps (Hulme et al. 1993). However, it was found that the basement walls and slabs were virtually undamaged and there was no evidence of differential settlements. Checking of design calculations revealed that the dead loads of the structures were either grossly underestimated, as in the case of brickwalls, or completely missed, as in some case of self-weight of slabs. It was thus concluded that the failure was due to under-design of the structures and was not related to geotechnical problems.

Many failures could be attributed to conditions, such as adverse soil conditions, abnormal changes of groundwater level, heavy storms, or unexpected loading, etc., which were not accounted for in designs. Some of these conditions are unforeseeable but most of them are merely unforeseen because of the limited data available. Groundwater rushed into an arrival shaft as a portal was made on diaphragm wall for receiving the shield machine during the construction of the Taipei Metro. As a result, a section of twin tunnels was seriously damaged and 39 rings in the up-track and 34 rings in the down-track tunnels had to be replaced (Ju et al. 1998). A PVC pipe was found at the invert of the up-track tunnel after the shaft was drained and the shield machine exposed. It could be one time used for pumping water from the underlying water-bearing gravelly layer for irrigation or fish farming. The soils surrounding the tunnel had been solidified by jet grouting previously. A large piece of timber was found next to the PVC pipe and it is suspected that the treated ground was much disturbed, resulting in cracks which became water paths, as the shield machine forced its way out. Groundwater was then able to rush from the water-bearing gravelly layer into the shaft from the abandoned PVC pipe. Drift woods were frequently encountered during constructions in the Taipei Basin; however, there is no way to ascertain their locations beforehand. It was also a common practice to pumping groundwater for irrigation and fish farming in the area; however, pumping wells are equally difficult to locate.

Failures due to defective constructions are not uncommon. Of the five disastrous events in metro constructions in Asia Pacific in the period of 2001–2007, one was caused by defective ground freezing work, one was caused by defective diaphragm wall and two were caused by defective ground treatment by jet grouting (Moh and Hwang 2007). In all these four cases, water was the major source of the problem. In fact, water was responsible for a majority of failures in underground works carried out in soft ground.

9.3 Back Analyses

A timeline showing all the events chronologically will be very helpful in understanding what has happened. It will even be better if all major events can be presented in a Gantt chart with their durations clearly identified.

Analyses should be performed for “as-built” conditions because many of the assumptions made in design are either nonexisting or different from reality. Therefore, reconnaissance of the site is a must and may have to be conducted for more than once. It is preferably to be conducted jointly with all the parties involved in the case so differences in opinions can be sorted out at the site. Photos and videos will be very useful in helping one’s memory and will provide vital supports to the conclusions to be made.

In many cases, failures involve soil-structural interaction and advices from structural engineers are desirable. For cases involving failure of structures, analyses should be performed jointly with structural engineers.

9.3.1 Data Collection and Verification

A checklist should be prepared to document the data available in hand and the data which are still missing. The data needed will depend on the modes of failures. Although the cause of failure may appear to be obvious right at the beginning, it is still necessary to investigate all the potential modes of failure before they can be eliminated.

To ensure that the results of analyses are reliable, the data available must be carefully verified. For example, ground conditions may be misinterpreted, instrument readings may be erroneous, construction activities may be wrongly logged, etc. Some of the data may be misleading without being realized, and some of data may be contradictory and have to be sorted out. It is natural for patties involved to hind facts, intentionally or unintentionally, which are not in their favor; therefore, data must be critically reviewed and judgments must be applied whenever data appear to be dubious.

An appropriate appraisal of local geology sometimes is helpful in understanding ground conditions and historical events related to the site of interest should be investigated.

9.3.2 Checking Design and Calculations

If design drawings are available, it is necessary to check whether or not the works were constructed as designed. Design calculations, if available, should be first checked to see if they are appropriate. However, inconformity with specifications and/or codes of practice will not necessarily lead to failures and the redundancy demanded by specifications and codes may not be required at the time of failure.

It should be noted that ground conditions might have been altered once a failure occurs and it is necessary to figure out what they were prior to the event. This may not always be possible and guesswork may sometimes be required.

9.3.3 Analytical Tools

Depending on the complexity of the problem, analyses can be performed by using:

-

(a)

rules of thumb using indices such as stability number, overload factor, etc.

-

(b)

empirical relationship

-

(c)

closed-form solutions

-

(d)

simple numerical models

-

(e)

sophisticated numerical models

Simple models are available for many failure modes and many of them can be solved by hand calculations. Complicated problems can be solved by numerical analyses. In any case, the tools adopted for analyses must be suitable for the type of problem to be solved and must have sufficient technical backup.

The analytical tools adopted for analyses must have been validated in accordance with stringent quality assurance program and well documented. For this reason, commercial software packages are preferred to in-house programs because the former are usually well tested and improved based on the feedback from users.

Numerical methods have their limitations and the results cannot be trusted blindly. Depending on the algorithm and the numerical scheme adopted, different software packages many lead to drastically different results. Therefore, a few test runs are necessary to calibrate the parameters to be adopted by comparing the results of analyses with observations or with known solutions.

9.3.4 Limitations

With the rapid advancement of computer technology, finite element method and finite difference method have become important tools for design and they are very useful tools for back analyses as well. They have become so user-friendly that even fresh graduates from colleges can perform the analyses with little guidance. This, however, leads to the danger of mishandling of problems and misinterpretation of the results of analyses. After all, geotechnical engineering is an art rather than science. The results of analyses provide important evidences for judgments to be based on and experience should prevail at the end.

It is important to realize the limitations associated with analyses so the results can be correctly interpreted. First of all, although tools are available, three-dimensional analyses are extremely labor intensive and time consuming. Therefore, unless the cases are critical enough and resources are available, one-dimensional and two-dimensional analyses are performed and the results are usually appropriate for practical purposes. However, simulation of a 3D system by a 2D model inevitably alters the nature of the problem and introduces errors in the results of analyses.

Second, soils are usually classified as either drained materials, i.e., pure sand, or undrained materials, i.e., pure clay, in analyses. However, in reality, most of soils are neither pure sand nor pure clay and are mixtures of sand and clay. Their behavior will depend on how fast pore water pressures dissipate. In other words, problems are time-dependent. The rate of dissipation of pore water pressure will not only depend on the rate of loading, but will also depend on the permeability of soil and the length of drainage path. The reliability of the results of analyses will depend on how well this time-dependency of soil behavior is handled.

Third, it is a well-known fact that soil behavior is highly nonlinear and there are many soil models to handle the nonlinearity. The results of analyses may vary considerably if different constitutive laws, which describe the stress–strain relationship of soils, are selected.

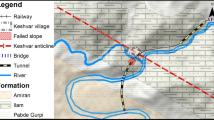

9.4 Case Study

The collapse of Nicoll Highway, refer to Fig. 9.1, is an ideal case for illustrating the points mentioned above. The site is located in a piece of land reclaimed in the 80s. As shown in Fig. 9.2, the subsoils at this site contain mainly two thick layers of marine deposits (namely, the upper marine clay and the lower marine clay) and are underlain by the Old Alluvium which is a competent base stratum. Figure 9.3 is a plot of the results of a cone penetration test carried out in the vicinity of the site. The excavation was supposed to be carried out to a depth of 33.5 m and diaphragm walls with a thickness of 800 mm (locally, 1000 mm) were used.

9.4.1 The Incident

Excavation for constructing the cut-and-cover tunnels was carried out by using the bottom-up method of construction. The collapse occurred in Section M3 on 20 April 2004 while the tenth dig was completed and excavation reached a depth of 30.5 m 4 days earlier. There were two inclinometers, i.e., I-65 and I-104, available for monitoring wall deflections. Figure 9.4 shows the wall deflection paths, which are the plots of maximum wall deflections versus depth of excavation in a log-log scale, for these two inclinometers (Hwang et al. 2007). Wall deflections on the two sides of the excavation were about the same till 9 March, 2004, when excavation reached a depth of 25 m, and deflections of 198 and 215 mm were recorded by Inclinometers I-65 and I-104, respectively. Subsequently, there was a period in which I-104 was not read because it was damaged. When monitoring resumed on 26 March, the deflection of the southern wall was found to have increased by 67 to 282 mm while the readings for Inclinometer I65 on the north were fairly steady in this period. The readings for Inclinometer I-104 kept on increasing while those for I-65 remained to be steady subsequently, presumably, because of the asymmetry of ground conditions. In fact, I-65 appeared to move outward by 27 mm and the maximum deflection reduced from 202 mm on 26 March to 175 mm on 20 April, as depicted in Figs. 9.2 and 9.4. On the other hand, Inclinometer I-104 moved inward by 90 to 441 mm in the 3-day period from 17 April to 20 April as shown in Fig. 9.5.

Failure started as the waling at the northern end of Strut S338 at the ninth level, refer to Fig. 9.2, buckled at 9 am on 20 April and failure propagated to other struts. By 3 pm of the day, all the struts for a 100 m section totally failed. As Nicoll Highway sank, gas, water, and electricity cables ruptured, causing power to go out for about 15,000 people and 700 businesses in the Marina and Suntec City area. Tremors were felt at Golden Mile Complex. Tenants and residents in the building were also evacuated.

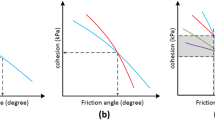

9.4.2 The Design

The contract was awarded as a design-and-build contract and temporary works were designed by the contractor. The computer program PLAXIS, which was first developed in 1987 at the Technical University of Delft and made commercially available by PLAXIS bv of Delft, Netherlands, was adopted in the design of retaining system. PLAXIS allows users to select different material types (drained, undrained, and nonporous) and different material modes (Mohr-Coulomb, soft soil, etc.) Mohr-Coulomb Model was adopted for defining failure of soils for the case of interest. When using the Mohr-Coulomb model, it is possible to input either effective stress parameters (c′ and ϕ′) or the undrained strength parameters (c′ = c u and ϕ′ = 0). The use of a Mohr-Coulomb soil model with effective strength parameter has been referred to as Method A in the report by the Committee of Inquiry (COI 2005). Method B refers to the use of Mohr-Coulomb soil model with undrained strength parameters in combination with undrained material type. Method A was adopted in the analyses and effective strength parameters, c′ and ϕ′, instead of the undrained strength parameters, c′ = c u and ϕ′ = 0, were used for marine clays.

This, as depicted in Fig. 9.6, drastically over-estimated the undrained strength of clays and analyses indicated that wall deflections and the associated bending moments were grossly underestimated by a factor of, roughly, 2. However, except Levels 6 and 9, the strut loads computed by using Model A were larger than those computed by using Model B. The strut loads computed by using Model B were 107 % of those computed by using Model A at Level 6 and 110 % at Level 9.

9.4.3 Back Analyses

Back analyses were carried out by reducing the stiffness of soils and JGP slabs to match the performance of the wall when the reading of I-65 reached 159 mm, exceeding the alert level of 105 mm, as the excavation reached a depth of 18 m in the sixth stage of excavation on February 23, 2004. The results of analyses predicted a maximum wall deflection of 253 mm in the subsequent stages of excavation. On April 1, the reading of I-104 reached 302.9 mm, back analyses were again carried out by further reducing the stiffness of materials and the maximum deflection was revised to 359 mm. Model A was continuously adopted in these back analyses.

9.4.4 Forensic Studies

Subsequent to the occurrence of failure, the Singapore Government immediately formed an independent Committee of Inquiry (COI), headed by a Senior District Judge, to look into the incident. After thorough investigations, in which 173 witnesses were interviewed and 20 experts offered their professional opinions, an Interim Report was released on 13 September 2004 and a very comprehensive Final Report was made available to the public on 13 May 2005 (COI 2005).

The Committee identified critical design and construction errors, particularly the design of stiffeners on the walings at the connections between the diaphragm walls and the struts, that led to the failure of the earth retaining system. The Committee also found deficiencies in the project management that perpetuated and aggravated the design errors, including inadequate instrumentation and monitoring of works, improper management of instrumentation data, and lack of competency of persons carrying out specialized work.

At the request of the Land Transport Authority, the Engineering Advisory Panel (EAP) conducted an extensive study to review the case and the design of other parts of the Circle Line. Three-dimensional analyses were carried out using the commercial software ABAQUS to analyze the performance of the retaining system. Each of the first nine layers of excavation was modeled as a uniform lift with all the elements removed at the same time. The tenth excavation step was simulated in three substeps, starting with the removal of the elements at the eastern end of the excavation and proceeding westwards (Yong and Lee 2007).

9.4.5 Causes of Failure

As mentioned in Sect. 9.4.2, wrong strength parameters were adopted for marine clay, leading to under-design of wall deflections and bending moments. Although back analyses were performed during the course of construction, they were performed by engineers who did not have experience on the program PLAXIS and the results were not reviewed by experienced engineers. In this regard, however, regarding soil parameters, the experts did differ in opinions in the Inquiry. It is amusing to note the statement made by the representative of the Contractor in the Inquiry that:

….. despite more than 6 months of intensive work by the six teams of experts who have been reviewing the collapse at M3, the experts still can not reach any agreement on the correct input parameters to be adopted in a back analysis. Very significant difference still remain, particularly respect to the parameters to be adopted for JGP. It is also noted that because of the stiffness characteristics of the ground, diaphragm wall and JGP are all highly non linear, it is virtually impossible to obtain agreement between the monitored strut loads and wall displacements throughout all the stages of excavation sequence using a single set of linear elastic stiffness value, as adopted in Plaxis analyses.

Although these statements may be exaggerating, they nevertheless illustrate the difficulty associated with analyses.

Model A was adopted by the contractor in analyses for all the cut-and-cover sections in this contract. Although considerable efforts have been made to deal with excessive wall deflections, the excavation in other sections was able to be completed. This indicates that the under-design of diaphragm walls is not solely responsible for the incident. The failure must be due to a combination of adverse factors.

As depicted in Fig. 9.3, the soft deposits on the two sides of the excavation differed in thickness while analyses were performed for only the southern half of the mesh on the assumption that the results would be conservative. This assumption may not be valid reality because the deflections of the southern wall tended to be larger due to the imbalance of earthpressures on the two sides of the excavation. The 3D finite element analyses conducted by EAP also indicated the significance of the curvature of the alignment. The wall panels tended to split at the joints as the wall moved inward as the excavation proceeded. This is particularly true for the south wall where wall deflections tend to widen the gaps.

The failure in fact was triggered by the buckling of walings. As mentioned in Sect. 9.4.2, except Levels 6 and 9, the strut loads computed by using Model A were larger than those computed by using Model B. Even for Levels 6 and 9, the strut loads computed by using Model B were only 7–10 % larger. Therefore, the buckling was not a result of the use of wrong material model for clay.

The Inquiry revealed that the loads at some of the connections between struts and walings were under-estimated either because a wrong type of joint was installed or because slays were omitted. Second, around February 2004, several instances of stiffener plate buckling as well as the buckling of a waling were reported at the Nicoll Highway Station, the contractor proposed replacing the stiffener plates by C-channels in an attempt to improve the performance of the connection. The replacement of double stiffener plates with C-channels, refer to Fig. 9.7, provided only minor improvement in terms of axial load bearing capacity for the waling connections, but this came at the expense of ductility. The change rendered it more susceptible to the brittle “sway” failure mode. This is clearly seen in results of the post collapse finite element analyses and physical tests. The poor detailing is exacerbated by the discontinuity of walings, as pointed out in the EAP study, which is particularly important at the curved south wall where deflection due to excavation caused separation of the joint between diaphragm wall panels.

The instrumentation and monitoring system was not properly executed and some of the crucial readings were found erroneous and misleading. This made it impossible to correlate the strut loads with the performance of the retaining system.

In addition to all the above-mentioned shortcomings in the design, the performance of the two grouted slabs was also questioned and investigated in the Inquiry and in the EAP study. The removal of sacrificial JGP layer above the formation level was not followed with timely installation and preloading of struts to compensate for the loss of reaction load sustained in the JGP layer. As a result, it caused significant lateral movement to the temporary walls and increase in load to the struts above. This triggered the local failure of connections at the joint between struts and walings at critical locations and contributed to the chain of collapse of diaphragm walls.

9.5 Conclusions

Failures frequently occur and back analyses enable their causes to be identified. The experience learned can then be passed on from generation to generation. For the results of analyses to be reliable,

-

(1)

the analytical tool used must be suitable for the type of problem to be analyzed

-

(2)

the analyses must be conducted by experienced engineers who have sufficient background on the algorithm of analyses

-

(3)

the input parameters must be representative of the materials to be studied

-

(4)

the construction sequence must be reliable

-

(5)

instrument readings must be faithful

-

6)

the results must be interpreted by experienced engineers who have sufficient practical experience on the performance of soils and structures.

It is however important to realize that there are limitations associated with analyses and the results obtained only play a role of providing supporting evidences and engineering judgments should always prevail.

References

COI (2005) Final report of the committee of inquiry into the incident of the MRT circle line worksite that led to the collapse of Nicoll highway on 20 April 2004, presented by committee of inquiry to minister for manpower on 10 May 2005, Singapore

Hulme TW, Parmar HS, Hou KH, Sripathy P (1993) The collapse of the hotel new world, Singapore, a technical inquiry. Struct Eng 71(6/16):91–98

Hwang RN, Moh ZC, Wong KS (2007) Reference envelopes for deflections of diaphragm walls in Singapore marine clay. In: Proceedings of the 16th southeast asian geotechnical conference, Kuala Lumpur, Malaysia, 8–11 May

Ju DH, Duann SW, Tsai HH (1998) Ground freezing for restoration of damaged tunnel. In: Proceedings of the 13th southeast asian geotechnical conference, Taipei, 16–20 Nov, pp 615–620

Moh ZC, Hwang RN (2007) Lessons learned from recent MRT construction failures in Asia Pacific, opening keynote address. In: Proceedings of the 16th southeast Asian geotechnical conference, 8–11 May, pp 3–20, also, Geotechnical Engineering, special issue, 38(3) December, Bangkok, Thailand, pp 121–137

Yong KY, Lee SL (2007) Collapse of Nicoll highway—a global failure at the curved section of a cut-and-cover tunnel construction, Chin Fun Kee Lecture. In: Proceedings of the 16th southeast Asian geotechnical conference 8–11 May, pp 23–36

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer India

About this chapter

Cite this chapter

Hwang, R.N. (2016). Back Analyses in Forensic Geotechnical Engineering. In: Rao, V., Sivakumar Babu, G. (eds) Forensic Geotechnical Engineering. Developments in Geotechnical Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2377-1_9

Download citation

DOI: https://doi.org/10.1007/978-81-322-2377-1_9

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2376-4

Online ISBN: 978-81-322-2377-1

eBook Packages: EngineeringEngineering (R0)