Abstract

In this work, an attempt has been made to design an intelligence technique-based expert system using adaptive neuro-fuzzy inference system (ANFIS) for predicting tool wear in milling operation. An artificial neural network is used for designing an optimized fuzzy logic system, so that the tool wear can be modeled for a set of input cutting parameters, namely feed rate, depth of cut, and cutting force. The proposed method uses two different learning approaches, namely back-propagation gradient descent method alone and hybrid method (i.e., combination of the least squares method and back-propagation algorithm) for training of first-order Sugeno-type fuzzy system. The predicted tool wear values derived from proposed ANFIS were compared with the experimental data.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The concept of tool condition monitoring has gained considerable importance in the manufacturing industry. This is mainly attributed to the transformation of the manufacturing environment from manually operated production machines to CNC machine tools and the highly automated CNC machining center. For modern machine tools, 20 % of the downtime is attributed to tool failure, resulting in reduced productivity and economic losses [1]. So in machining processes, tool condition is of vital importance, as it affects the quality of the product and the efficiency of the process. Different types of sensor have been used to detect tool wear. Yao et al. [2] and Lee et al. [3] used acoustic emission in the development of a tool wear monitoring system. Mehta et al. [4] employed an accelerometer to monitor tool wear and concluded that the frequency increases as the tool deteriorates. Konig et al. [5] used cutting force to predict tool wear and found that there is a positive correlation between cutting tools and tool deterioration. Lin and Yang [6] proposed a tool wear monitoring system in face milling operations using a force coefficient. Artificial neural network was used for predicting tool wear in milling by Chen et al. [7]. Wang et al. [8] presented a tool wear monitoring system using a fuzzy logic model called fuzzy clustering. However, this model is complicated and there is no current evidence of model validation. Moreover, the proper selection of the number, the type, and the parameters of the fuzzy membership functions and rules are crucial for achieving the desired performance. Yet, it has been often done through trial and error. This fact highlights the significance of fuzzy logic system tuning. To achieve this, adaptive neuro-fuzzy approach is used to model tool wear in milling operation as milling is one of the most common metal removal operations used in manufacturing industry. In this work, artificial neural network is used for designing an optimized fuzzy logic system, so that the tool wear can be modeled for a set of input parameters, namely feed rate, depth of cut, and cutting force.

2 Proposed Adaptive Neuro-Fuzzy Inference System

2.1 Fuzzy Logic System

Fuzzy set theory was developed by Prof. L.A. Zadeh [9] to capture the imprecise modes of reasoning employed in an environment characterized by uncertainty and vagueness. A fuzzy inference system employing fuzzy ‘if-then’ rules can model the qualitative aspects of human knowledge and reasoning processes without employing precise quantitative analysis. This fuzzy modeling first explored systematically by Takagi and Sugeno [10]. A fuzzy inference system is composed of a rule base, containing a number of fuzzy if-then rules; a database, which defines the membership functions of fuzzy sets used in fuzzy rules; a decision-making unit which performs inference operations on the rules; and a defuzzification interface, which transforms fuzzy results into a crisp output. The integration of neural network into fuzzy logic system makes it possible to learn from data prior.

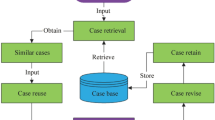

2.2 Adaptive Neuro-Fuzzy System

The adaptive neural-fuzzy system is a Sugeno fuzzy model put in the framework of adaptive systems to facilitate learning and adaptation [10]. Such framework makes the adaptive neuro-fuzzy modeling more systematic and less reliant on expert knowledge. To present the adaptive neural-fuzzy system architecture, let us consider two fuzzy if-then rules based on a first-order Sugeno model:

-

Rule 1: If (v is V 1) and (d is D 1), then f 1 = p 1 v + q 1 d + t 1

-

Rule 2: If (v is V 2) and (d is D 2), then f 2 = p 2 v + q 2 d + t 2

where V i and D i are the fuzzy sets, f i is the outputs within the fuzzy region specified by the fuzzy rule, and p i , q i , and t i are the design parameters that are determined during the training process. The entire system architecture consists of five layers, namely the fuzzy layer, product layer, normalized layer, de-fuzzy layer, and total output layer.

Fuzzy layer: Every node in this layer is an adjustable node, with node function as

where \( \mu_{{{\text{v}}_{\text{i}} }} \left( v \right) \) and \( \mu_{{{\text{d}}_{\text{i}} }} \left( d \right) \) can adopt any fuzzy membership function. For example, if the Gaussian membership function is employed, \( \mu_{{{\text{v}}_{\text{i}} }} \left( v \right) \) is given by:

where {σ i , c i } represents the parameter set. It is significant that if the values of these parameters set change, the Gaussian function will be changed accordingly. The parameters in this layer are named as ‘premise parameters.’

Product layer: Every node in this layer is a fixed node with node function to be multiplied by input signals to serve as output signal

The output signal w i means the firing strengths of a rule.

Normalized layer: Every node in this layer is a fixed node with node function to normalize firing strength by calculating the ratio of this node firing strength to the sum of the firing strength:

De-fuzzy layer: Every node in this layer is an adjustable node with node function as

where p i , q i , and t i are parameter set which is referred as the ‘consequent parameters.’

Total output layer: Every node in this layer is a fixed node with node function to compute the overall output by

2.3 Learning Algorithm of Adaptive Neuro-Fuzzy System

It can be observed that there are two adaptive layers in this architecture, namely the first layer and the fourth layer. In the first layer, there are two modifiable parameters {σ i , c i }, which are related to the input membership functions. In the fourth layer, there are also three modifiable parameters {p i , q i , t i }, pertaining to the first-order polynomial. The task of the learning algorithm for this architecture is to tune all the modifiable parameters, namely {σ i , c i } and {p i , q i , t i }, to make the adaptive neural-fuzzy system output match the training data. The learning algorithm may consist of either back-propagation learning algorithm or hybrid learning algorithm.

Approach 1:

In this approach, the basic learning method is back-propagation algorithm which is an error-based supervised learning algorithm. It employs an external reference signal, which acts like a teacher and generates an error signal by comparing the reference with the obtained response. Based on error signal, the network modifies the design parameters to improve the system performance. It uses gradient descent method to update the parameters.

Approach 2:

The hybrid learning algorithm applies a combination of least square estimator (LSE) and gradient descent method for training fuzzy logic system membership function parameters to emulate a given training data set. The LSE method is used to optimize the consequent parameters with the premise parameters fixed. Once the optimal consequent parameters are found, the gradient descent method is used to adjust optimally the premise parameters corresponding to the fuzzy sets in input domain. The output of the adaptive neuro-fuzzy system is calculated by employing the consequent parameters. The output error is used to adapt the premise parameters by means of a standard gradient descent method.

3 Results and Discussion

A training database with regard to machining parameters and tool wear is essential to train the fuzzy system for modeling and predicting tool wear. A number of milling experiments were carried out [7] on Fadal machine using 3-insert with a diameter 1.25 in. mill and 1,018 steel workpiece. The worn tools, which were ground artificially, were used in the experimental runs. The experimental design for collecting data was set up as the following combination of machining cuts: feed rate at 5.0, 7.0, 9.0, 11.0, and 13.0 in./min; depth of cut at 0.02, 0.03, 0.04, 0.05, and 0.06 in.; flank wear at 0.25, 0.35, 0.45, and 0.55 mm. Based on above combinations, 100 milling experiments were performed. The average peak cutting force in the y-direction collected through the experimental runs and unit for cutting force is measured in V. These sets of 100 data, as listed in Table 1, were used for training of the fuzzy system by both Approach 1 and Approach 2 as mentioned in Sect. 2.3. This training adjusts the membership function parameters. In general, this type of model works well if the training data presented are fully representative of the features of the data that the trained fuzzy system is intended to model. This is not always the case; however, in some cases, data are collected using noisy measurements, and the training data cannot be representative of all the features of the data that will be presented to the model. So, model validation is needed to cross validate the fuzzy system using testing data set. The testing data set is useful in checking the generalization capability of the resulting fuzzy system. That is why another 9 sets [7] were then used for testing after the training was completed to verify the accuracy of the predicted values of tool wear.

The fuzzy expressions for feed rate are LF: low feed, MF: medium feed, HF: high feed; for depth of cut are SA: shallow, MD: medium deep, DE: deep; and for cutting force are LFR: low force; MFR: medium force; HFR: high force. There are a total of 27 fuzzy rules in the architecture. Thus, a typical ith rule of the fuzzy system will be as follows:

If feed rate (f i ) is high feed (HF),depth of cut (d i ) is deep (DE), and cutting force (v i ) is medium force (MFR), then tool wear is (p i f i + q i d i + r i v i + c i ), where p i , q i , r i , and c i are the design parameters.

During training in adaptive neural-fuzzy system, 100 sets of experimental data were used to conduct 10,000 cycles and 200 cycles of learning for Approach 1 and Approach 2, respectively. Adaptive neuro-fuzzy system learning scenario for predicting tool wear is as follows:

Number of nodes = 78, Number of linear parameters = 108, Number of non-linear parameters = 18.

Table 2 compares the predicted values and experimental values [7] of tool wear after training by using Approach 1 and Approach 2 for some of the training cases. In almost all the cases, prediction of tool wear using Approach 2 (average error: 2.32 % approx.) is better than Approach 1 (average error: 8.57 % approx.).

Table 3 shows the comparative study between predicted tool wear using approach 1, approach 2, and experimental results obtained by Chen [7] for some of the test cases. Simulation result shows that the average error of the modeling of tool wear is approximately 3.51 and 9.01 % when Approach 2 and Approach 1 are used, respectively, whereas average error of ANN predicted model [7] is around 10.47 %. Approach 2 has been performed better than Approach 1, in most of the cases, for making prediction of tool wear in milling operation. It may happen because back-propagation algorithm is never assured of finding the global minimum. The error surface may have many local minima, so it may get stuck during the learning process on flat or near flat regions of the error surface. Results presented in Table 3 also show that the Approach 2 outperforms the ANN-based method in terms of test accuracy of tool wear.

4 Conclusions

The conclusions that were drawn from this study can be summarized in the following points: An adaptive neuro-fuzzy inference system (ANFIS) based on first-order Takagi–Sugeno fuzzy inference system is used to predict tool wear in milling operation. Simulation results show Approach 2 (i.e., hybrid learning of fuzzy system) performs better than approach 1 (i.e., back-propagation-based learning) and ANN-based predictive model. The hybrid learning algorithm converges much faster than pure back-propagation learning algorithm. The ability of the ANFIS for predicting tool wear of a machining process before carrying out actual experiment will help us to develop an intelligent manufacturing system.

References

Prickett, P.W., Johns, C.: An overview of approaches to end milling tool monitoring. Int. J. Mach. Tools Manuf. 39, 105–122 (1999)

Yao, Y., Li, X., Yuan, Z.: Tool wear detection with fuzzy classification and wavelet fuzzy neural network. Int. J. Mach. Tools Manuf. 39, 1525–1538 (1999)

Lee, L.C., Lee, K.S., Gan, C.S.: On the correlation between dynamic cutting force and tool wear. Int. J. Mach. Tools Manuf. 29, 295–303 (1989)

Metha, N.K., Pandey, P.C., Chakravarti, G.: An investigation of tool wear and the vibration spectrum in milling. Wear 91, 219–234 (1983)

Konig, W., Langhammer, K., Schemmel, H.U., Th, R.W.: Correlation between cutting force components and tool wear. Ann. CIRP 21, 19–25 (1972)

Lin, S.C., Yang, R.J.: Force-based model for tool wear monitoring in face milling. Int. J. Mach. Tools Manuf. 35, 1201–1211 (1995)

Chen, J.C., Chen, J.C.: An artificial neural networks based in-process tool wear prediction system in milling operation. Int. J. Adv. Manuf. Tech. 25, 427–434 (2005)

Wang, Z., Lawrenz, W., Rao, R.B.K.N., Hope, T.: Featured filtered fuzzy clustering for condition monitoring of tool wear. J. Intell. Manuf. 7, 13–22 (1996)

Klir G.J., Yuan B.: Fuzzy sets and fuzzy logic: theory and applications. Prentice-Hall of India Private Limited, Delhi (2001)

Roger Jang, J.S., Sun, C.T.: Neuro-fuzzy modeling and control. Proc. IEEE 83, 378–404 (1995)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Roy, S.S. (2015). An Application of ANFIS-Based Intelligence Technique for Predicting Tool Wear in Milling. In: Mandal, D., Kar, R., Das, S., Panigrahi, B. (eds) Intelligent Computing and Applications. Advances in Intelligent Systems and Computing, vol 343. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2268-2_32

Download citation

DOI: https://doi.org/10.1007/978-81-322-2268-2_32

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2267-5

Online ISBN: 978-81-322-2268-2

eBook Packages: EngineeringEngineering (R0)