Abstract

This chapter starts with the basic features of nitrogen including the existence of N-related defects, detection and measurements of N content, the solubility, and diffusion of N impurities in silicon materials. From the perspective of photovoltaic application, the nitrogen doping method for Czochralski silicon is then introduced, and the results about the influence of nitrogen impurity on N-O complexes, O-related defects, and mechanical properties are presented. A second focus of this chapter is toward N-related defects in directionally solidified photovoltaic multicrystalline silicon (mc-Si) materials. The existence and distribution of N-related defects, the formation, and influence of silicon nitride precipitates in mc-Si are comprehensively described. Then the results about mc-Si growth in ambient nitrogen are presented as an application to further understand the properties of nitrogen in mc-Si.

Access provided by Autonomous University of Puebla. Download reference work entry PDF

Similar content being viewed by others

Keywords

- Czochralski silicon

- Multicrystalline silicon

- Nitrogen doping

- Silicon nitride precipitates

- Ambient nitrogen

- Mechanical strength

Introduction

Crystalline silicon (c-Si) is the most important substrate material for solar cells, which occupies more than 90% of the market share in photovoltaic industry. Czochralski silicon (CZ-Si) and cast multicrystalline silicon (mc-Si) are the main types of c-Si materials. Nitrogen is one of the common light elemental impurities in silicon materials. Related research started decades ago. In the 1970s, nitrogen property in nitrogen-implanted silicon, Si3N4 films on silicon substrate and even in float-zone silicon was widely studied. And in the1980s, nitrogen was intentionally doped in CZ-Si wafers used for integrated circuit (IC) industry (Que et al. 1985; Yang et al. 1995). Due to the suppression of crystal-originated particles (COPs) (Yu et al. 2002), the enhancement on the nucleation of oxygen precipitates so as to improve the ability of internal gettering, and the increasement of mechanical strength, N-doped CZ-Si has been world widely applied (Yang et al. 2009; Yu et al. 2013). Moreover, N-doping in CZ-Si can also reduce high purity argon gas consuming expense, which helps to decrease the general cost of silicon crystal growth.

However, for photovoltaic materials as substrates of bulk devices, the modification by introducing oxygen precipitates is unwanted. Then the promising feature of nitrogen doping in CZ-Si crystal is to improve the material mechanical strength and to reduce the cost of protective gas by using cheaper nitrogen instead of high purity argon. So, intentional N-doping in CZ-Si becomes less attractive to photovoltaic manufactures. In the recent two decades, directionally solidified mc-Si has gradually become the leading photovoltaic substrate materials because of its low cost. Despite nitrogen was never intended to be doped into mc-Si, silicon nitride has been the optimal coating material to prevent the sticking between silicon ingots and quartz crucibles. The usage of silicon nitride coating made mc-Si growth in a N-rich environment so that the influence of N-related defects, especially Si3N4 precipitates, is very important to the crystal quality. Meanwhile, there are a few researches considering the further control of N impurity in mc-Si by other means.

This chapter firstly summarizes the basic properties of N-related impurity in general silicon materials. Then from the photovoltaic silicon perspective, we briefly introduce the influence of N-doping on the relevant properties in Czochralski silicon. Later, the existence and transformation of N-related impurity and precipitates in mc-Si are described. And finally, the growth of photovoltaic mc-Si using cheaper ambient nitrogen is presented and discussed.

Basic Properties of Nitrogen in Silicon

Existence

In crystalline silicon materials, soluble nitrogen atoms exist in the forms of monomer, dimer, or complex in Si lattice, and precipitates are formed when N concentration exceeds the solubility. Various N-containing defects can be formed based on the reaction and combination of N atoms (interstitial and substitutional, Ni, and Ns), defective Si atoms (interstitials and vacancies, I and V), and other impurity atoms like oxygen. The structure of the configurations determines the formation energy, thermal stability, and particular local vibrational modes (LVMs) of the defects. The actual form of N-related defects in a certain sample is strongly influenced by thermal history. And LVMs of the defects result in well-defined shifts in the vibrational frequencies, which help to identify the defects experimentally. The properties such as formation energy and LVMs of the N-containing configurations can be determined using first principle density functional theory; hence, the equilibrium stability can be predicted and the frequencies of the modes can be identified combined with infrared (and Raman) measurements (Jones et al. 1994b; Goss et al. 2003) (see the section “Detection and Measurements”). Table 1 gives the calculated formation energy per N atom of various combinations of Ni, Ns, I, and V, relative to the energy of the (Ni-Ni) defined as zero. The data shows that all configurations have higher formation energy compared with (Ni-Ni), the only exception, 2(Ni-Ni), possesses a very small binding energy, so it should not be stable and significant. Since (Ni-Ni) has a large binding energy of 4.30 eV (Sawada and Kawakami 2000), and isolated Ni has a high mobility (see the section “Diffusion”), therefore, di-interstitial pairs (Ni-Ni) should be the dominant equilibrium state of nitrogen atoms in silicon lattice under growth temperature (>1400 °C). The vibrational frequencies of many modes have been investigated (Goss et al. 2003), among which, Table 2 shows the calculated and observed frequencies of the vibration modes of (14Ni-14Ni) and 14Ns. These two modes are the only detectable modes at room temperature verified in experimental measurements (Goss et al. 2003). Moreover, the fraction of Ns in total N atoms is lower than 1%, which indicates that the final state of N dimer at room temperature is (Ni-Ni) and the concentration of Ns in normal N-doped Si is usually lower than 1013 cm−3. Therefore, the influence of ionized Ns donors on electrical properties can be ignored.

Detection and Measurements

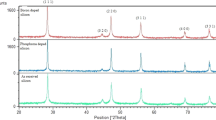

To date, secondary ion mass spectroscopy (SIMS) and Fourier transformation infrared spectroscopy (FTIR) are the most widely used methods to determine the N concentration in crystalline silicon. SIMS is usually adopted for total N concentration, independent of its chemical states, the lower detection limit can be extended to 1 × 1013 cm−3, but the measurement is relatively complicated and expensive when the N concentration is lower than 5 × 1014 cm−3, mainly limited by the background N concentration (Hockett and Sams 2000). IR measurements via the presence of N-related vibration modes can differentiate the forms of N atoms in silicon, as these modes have different absorption frequencies. Figure 1 shows the example of a mid-infrared range FTIR spectrum at room temperature. The quantitative measurement of concentration can be obtained from the absorbance at certain peaks:

where C is the impurity concentration, d is the sample thickness, α is the absorption coefficient, A is the absorbance at the peak, and I0 and I are the IR signal intensity of the peak and baseline, respectively.

N dimers exhibit main IR vibration absorption peaks at 963 and 766 cm−1, with the calibrated absorption coefficients of 1.83 × 1017 (Itoh et al. 1985) and 4.45 × 1017 cm−2 (Wagner et al. 1988), respectively. This method ensures a detection limit of ~5 × 1014/d cm−3 (~100/d ppba, the unit of d is cm).

As the main form of N in Si under room temperature is N dimer and N-O complex, in oxygen-free float-zone silicon (FZ-Si), the total N concentration measured by SIMS equals to the N concentration measured by FTIR (963 cm−1), which proves that the main existing form of N in FZ-Si is N dimers. However, in CZ-Si and mc-Si, the N dimer concentration measured by FTIR is lower than the one measured by SIMS, due to the formation of N-O complexes and the decrease in N dimer concentration. As shown in Fig. 1, N-O complexes also exhibit a series of IR vibration absorption peaks (including 801, 996, and 1026 cm−1) (Qi et al. 1991), without well-accepted absorption coefficient. The isotopic effects on these LVMs show that these modes all shift with 15N (Jones et al. 1994a), showing N atoms to be involved in the complexes. Especially, the absorption intensity of 801 cm−1 has a linear dependence on the product of [N][Oi], indicating that these bands arise from the N-O complexes. Therefore, FTIR at room temperature cannot be used to estimate the total N concentration in CZ-Si. While it is controversial to measure total N content in mc-Si because the interstitial oxygen concentration in mc-Si varies with growth details, so that a coarse measurement of total N content using N dimer IR absorption is somehow acceptable.

Low-temperature Fourier transformation infrared spectroscopy (LT-FTIR) helps to extend the detection limit. On one hand, the 963 cm−1 IR peak of N dimers shifts to 967 cm−1 and becomes narrower when the sample is cooled down to 77 K, with a calibrated absorption coefficient of 1.2 × 1017 cm−2 (Zhang et al. 2013), lower than the one under room temperature, which extends the N dimer detection limit to ~2 × 1014 cm−3 at 77 K. On the other hand, the determination of N concentration in CZ-Si lower than 1014 cm−3 can be performed using LT-FTIR in far-infrared range. The absorption peaks correspond to the ionization levels of the N-O complex donors in silicon, in the spectral range of 190–350 cm−1. (see the section “N-O Complex” part) Before the measurement, long-time thermal annealing (mostly at 500–650 °C) is needed to assure saturated transformation from N dimers into N-O complexes. The detection limit of LT-FTIR method is affected by signal intensity of the spectrometer and sample thickness. Several detection limits have been reported in the range of 5–90 × 1012 cm−3 (Nakatsu et al. 2004; Ono and Horikawa 2003; Porrini et al. 2003). Nevertheless, the calibration of IR absorption into absolute concentration is not enough by now.

In addition, there are many other detection techniques for N-related contents in Si, including charged particle activation analysis (CPAA) (Nozaki et al. 1970), deep level transient spectroscopy (DLTS) (Tokumaru et al. 1982), Rutherford backscattering spectrometry (RBS), Auger electron spectroscopy (AES), electron paramagnetic resonance (EPR), luminescence and electrical resistivity (Bucksbaum and Bokor 1984; Hemment et al. 1985). Some of these methods were used to measure implanted substitutional N atoms in the early researches. However, most of them could not reach the sensitivities required to measure a common concentration of N in photovoltaic CZ-Si and mc-Si as low as 1015 cm−3.

Solubility

The nitrogen solubility in molten silicon was measured as 6 × 1018 cm−3 by charged particle activation analysis (CPAA), using a sample at the end of fast cooled FZ-Si ingot (Yatsurugi et al. 1973). When N concentration in molten silicon exceeds the solubility, β-Si3N4 rods/particles will be segregated and float above the molten silicon. This phenomenon can be commonly observed in the growth industrial directionally solidified mc-Si ingots because the soluble N is usually saturated in the molten silicon at the end of growth, however, floating Si3N4 in CZ growth may cause failure of dislocation-free growth.

The solid solubility of N in Si was initially measured and reported as (4.5 ± 1) × 1015 cm−3 (Yatsurugi et al. 1973), which was determined by the solubility in molten silicon and the small equilibrium segregation coefficient of N in Si (k0 = 7.5 × 10−4 (Yatsurugi et al. 1973)). However, a larger solid N concentration at room temperature was measured as ~1 × 1016 cm−3 (FTIR, 963 cm−1) in directionally solidified mc-Si, where the effective segregation coefficient of N, keff, became larger than k0 due to the moderate convective transportation in casting method. According to Burton-Prim-Slichter theory, keff is defined by the following formula:

where R is the growth rate and δ the thickness of boundary layer which is determined by diffusivity (DL) of N and convection level. Obviously, compared to CZ growth, casting growth has much weaker convection level so that the boundary layer is thicker and then the keff become larger. As the N concentration in solidified mc-Si is determined by both the N concentration in molten silicon and segregation effect, which are all strongly affected by convection level, N concentration in molten silicon is also influenced by crucible size and diffusion time, which may cause very complicated local distribution in the whole system. In the cases with weak convection, the N concentration at ingot center is lower than that at the edge, but as the segregated N in the molten silicon increases fast, the N concentration in solid phase can keep increasing along ingot height due to segregation effect. Once the concentration (FTIR, 963 cm−1) in solid phase exceeds 1016 cm−3, Si3N4 precipitates will be rapidly generated, along with the decrease in N dimer IR absorption (Reimann et al. 2010) because the N dimers will further segregate on the precipitates. Therefore, the solid solubility of N in Si is usually noted as (4–10) × 1015 cm−3.

Diffusion

The diffusivity of N in silicon is controversial during the past decades because of the many forms of N-related defects. Researchers have reported theoretical and experimental results of various diffusion models. Theoretical investigation results indicate that the N monomer has a migration activation energy of 0.4 eV (Schultz and Nelson 2001; Nelson et al. 1998), which means they are highly mobile under high temperature. But the experimental measurements of the N monomer diffusivity in silicon are limited to its relatively low concentration and the detective techniques. Table 3 gives several experimental results, where the diffusion coefficient is expressed by Arrhenius formula:

where D is the diffusion coefficient (cm2/s), D0 is the pre-exponential factor (cm2/s), EA is the migration activation energy (eV), T is the absolute temperature (K), and k is the Boltzmann constant, 1.38064 × 10−23 m2·kg /s2·K.

The first measurement of N diffusion coefficient attempted by Clark et al. was based on Hall effect (Clark et al. 1968). After implanting 14N+ ions to form an n-type surface layer in the high resistive p-type silicon, the evolution of the p-n junction depth with the anneal temperature and time reflects the 14N+ diffusion behavior. Obviously, this experiment is not reliable for the major form of N dimers in N-doped CZ-Si and mc-Si.

The most well-accepted diffusivity of N dimers was based on N dimer model. Theoretical results show that dominant N dimers have a large migration activation energy of 2.5 eV (Sawada et al. 2002; Fujita et al. 2005; Stoddard et al. 2005), which is assumed to be practically immobile at room temperature, indicating the diffusion of N dimers happens before a sample is cooled. Itoh et al. used SIMS (Itoh and Abe 1988) to measure out-diffused N on the profiles of silicon. It was found that the total amount of out-diffused N corresponds with the variation of N dimer IR absorption at the frequency of 963 cm−1, confirming that the N impurities in silicon diffuse as the form of dimers. The experimental value of activation energy was measured as 2.8 eV, which is close to the calculated values using first principle method, so this model is supported by theoretical investigations.

Moreover, further experiments suggest that the diffusivity of N in silicon is more complicated when the influence of other parameters such as oxygen impurities or dislocations is considered. Hockett (1989) suggested that N dimers may not be the only species responsible for transport, since a small fraction of N diffused rapidly while the majority (N dimers) remained immobile. Later, Mannino et al. found that N diffusion can be enhanced in oxygen-rich CZ-Si (Mannino et al. 2004). Voronkov and Falster proposed a dissociative model to explain the N diffusion in silicon (Voronkov and Falster 2004), where N transport proceeds via dissociation of the practically immobile dimers into mobile monomers by oxygen catalyzing. Meanwhile, Murphy et al. pointed that the barrier of N monomer should be less than 1.5 eV through experiments on the pinning effect of N on dislocations (Alpass et al. 2009; Murphy et al. 2005). These models are not crucial for photovoltaic level CZ-Si and mc-Si materials.

Nitrogen in Czochralski Silicon

Doping of N in CZ-Si Growth

N-doping in bulk Si is usually achieved by introducing N atoms into molten silicon during crystal growth. Solid and gas N source can be used for constructing N-rich growth environment.

Silicon nitride (Si3N4) powders are the most widely used solid N-doping source. The major parameters of the powders are purity and size. The purity of powders should be better than 1 ppma. The powder size is associated with the dissolution rate. Incompletely dissolved powders will usually float above the molten silicon and generate dislocations and even grain boundaries in a CZ-Si ingot (Yu et al. 2011). Si3N4 powders can be added to the crucible prior to any heating of polycrystalline silicon (poly-Si) material or during the melting of poly-Si. Another solution is to use a crucible with Si3N4 coating on the inner walls. During the melting process, the Si3N4 coating keeps gradually dissolving into the molten silicon, and the N concentration in the molten silicon is determined by convective transport. This makes it difficult to precisely control the doping amount when a N concentration lower than 1015 cm−3 is needed. So, this technique is usually combined with empirical experience. In addition, boron nitride (BN) powders can also be used as N dopant for p-type Si crystal, where the doping amount of B should be well calculated for intended resistivity. BN is more refractory than Si3N4 at the melting point of Si so that the powder sizes should be further reduced to assure the complete dissolution of BN in the molten silicon, and meanwhile the melting time should be prolonged.

Nitrogen gas was once considered unable to serve as the protective ambient for CZ-Si growth, because N2 reacts with polycrystalline silicon (poly-Si) nuggets under high temperature with the regular partial pressure (Kaiser and Thurmond 1959), fierce reaction between solid Si and N2 generates macroscopic Si3N4 particles on the surface of poly-Si and therefore inhibits the growth of defect-free single crystal. The gas doping of N in CZ-Si was first introduced by Que et al. (1985, 1987, 1991, 2000), where N2 or N2/Ar mixture under reduced N2 partial pressure was used as the protective gas, and they successfully obtained N-doped Czochralski silicon (NCZ-Si) ingots. For the growth of NCZ-Si, the purity of protective N2 atmosphere should be ensured, and the total gas flow rate should be controlled at a relatively high speed to efficiently eliminate SiO vapored above the molten silicon. The doping mechanism is to control the reaction velocity between N2 and solid poly-Si feedstock by tuning the partial pressure of N2. During the melting stage, N2 reacts with poly-Si, and thin Si3N4 film (thickness less than 100 nm) is generated on the surface of poly-Si, and these N contents will completely dissolute in the molten silicon. Therefore, the doping amount can be controlled by manipulating the partial pressure and flow rate of N2. during the melting stage, instead of during the growth stage. With the decrease of N2 partial pressure, the chemical reaction of N2 with poly-Si becomes weak, and therefore, the final N concentration in silicon crystals is controllable. The N concentration in the tail of a CZ-Si is usually less than 5 × 1015 cm−3, due to the liquid solubility and segregation coefficient of N. When the N2 partial pressure is controlled well, the concentration of N in molten Si will not exceed its solubility, and no Si3N4 will float on the liquid surface, so that the CZ growth will not be disturbed, and a high yield of dislocation-free single crystal can be obtained. Considering the low cost of N2 against Ar, and the benefits of NCZ-Si, using N2 as the protective atmosphere under reduced pressure has been a cost-effective method for CZ-Si crystal growth.

N-O Complexes

N-O complexes introduce shallow thermal donors in CZ-Si. The ionization of these donors can be characterized by low-temperature FTIR. A typical LT-FTIR spectrum of shallow thermal donors (STDs) is shown in Fig. 2 (Alt and Wagner 2010). Three series of bands of the 1 s → 2p0, 1 s → 2p±, and 1 s → 3p± transitions were detected, and eight different species in each band were labeled as N-O-x (x = 1, 2, 3. . .) in Table 4. Several ionization energies of the STDs have been estimated, as shown in Table 5 (Alt and Wagner 2010). There are good agreements between the observed transition energies and the results of the effective mass approximation calculated for the STD states in silicon.

The absorption coefficients of the transitions (N-O-1, N-O-2, N-O-3, N-O-5) increase with the N content in square root dependence (Ewels et al. 1996; Alt et al. 2006). According to the mass action law for the reaction nN + mO = NnOm, it leads to the integrated absorption values equal to [N]n[Oi]m. The N predominantly exists in the dimer form, so the concentrations of interstitial N atoms [Ni] can be expressed as

where ρ is the lattice site density. Note that the square root dependence is obtained in the expression. This coincidence shows that the STDs should involve only one N atom. The oxygen concentration dependence of the STDs had been investigated by Wagner et al. (2007; Hara et al. 1989). The chemical compositions of the electrically active N-O complexes in silicon were determined in a specially doped ingot with variable oxygen concentrations and a fixed N concentration by FTIR technique. The result shows that the N-O-5, with its absorption at 249.8 cm−1 in 1 s → 2p± transition, has a linear dependency, proving N-O-5 to be NO (m = 1). The other two species of N-O-4 (242.5 cm−1) and N-O-6 (256.9 cm−1) also show the linearity between [NOm] and [Oi]; therefore they have the same NO stoichiometry. N-O-3 with its transitions 1 s → 2p± at 240.4 cm−1 has a square dependence on [Oi], indicating that it has a NO2 composition. The power dependency m = 3 of the complexes N-O-1 (233.8 cm−1), N-O-2 (237.8 cm−1), and N-O-8 (241.5 cm−1) identifies these STDs as NO3 defects. The composition of N-O-6 remains unknown.

As N-O complexes are shallow donors in silicon materials, they can influence the resistivity of both p-type and n-type wafers. Therefore, the thermal history of the wafers should be noted during the fabrication of solar cells or electronic devices. N-O complexes in CZ-Si gradually degenerate when the sample is annealed with the temperature higher than 750 °C. The degeneration velocity increases with annealing temperatures, while the formation of N-O complexes happens in the annealing temperature window of 450–750 °C, when N dimers react with interstitial oxygen and generate N-O complexes. Figure 3 shows the degeneration and regeneration process of N-O complexes in a N-doped CZ-Si sample. The left image shows that the annealing at 850 °C for 2 h can completely remove the N-O complex-related peaks at 801, 996, and 1026 cm−1, and the right image shows that the N dimer peaks at 766 and 963 cm−1 decrease the fastest when annealed at 550 °C, and the multiple new peaks are formed during the low-temperature annealing, indicating that the thermal stability of various complexes is different, which means that the degeneration and regeneration of N-O complexes are not absolutely reversible.

Influence on O-Related Defects

Thermal Donors

Thermal donors (TDs) are usually accumulated from enriched oxygen impurities during the cooling stage of CZ-Si ingots or in the long-time annealing in the temperature of 350–500 °C. TDs are doubly ionized at room temperature and cause downward shift of resistivity in n-type phosphorus (P)-doped silicon, which usually introduces two donor levels of Ec-0.05 eV and Ec-0.15 eV. TDs can be eliminated in the high-temperature courses of normal solar cell processes, i.e., phosphorus diffusion process, so their influence on the performance of wafers and solar cells does not get enough attention. With the developments of high efficiency and low-temperature SHJ solar cell process, this issue starts to become more and more important. Since the maximum temperature of SHJ processes remains below 300 °C, as mentioned above, the as-grown TDs are still retained in the bulk of silicon wafers. TDs have negative influences on the performance of SHJ solar cells. The decrease of minority carrier lifetime is the uppermost factor responsible for the deterioration of efficiency (Li et al. 2018). The results indicate that the solar cell manufacturers should choose the wafer with the concentrations of TDs as low as possible to limit their detrimental effect on the cell efficiency. Furthermore, it is of great importance for silicon crystal growers to manage to reduce the contamination of oxygen during the crystal growth and make the ingot cooling time as short as possible or develop appropriate methods to decrease oxygen concentration and suppress the formation of thermal donors.

Nitrogen has twofold effects on the generation of donors (TDs and STDs) in silicon. As mentioned above, a family of N-O complexes related to both N and O impurities forms at temperatures around 650 °C, and as a result, the formation of TDs associated only with oxygen impurity is suppressed. Early research identified new STDs (not as N-O complexes) in NCZ-Si using photothermal ionization spectroscopy (PLIS), along with the suppression of the formation of TDs (Griffin et al. 1989). Then using low-temperature far-infrared spectroscopy (LT-FTIR), as shown in Fig. 4, it was found that N suppresses the formation of TDs in CZ-Si annealed at 450 °C, while N interacts with oxygen atoms to form N-O complexes (Yang et al. 1995). The interaction of N and oxygen atoms is supposed to reduce the TDs.

LT-FTIR spectra related to thermal donors in CZ-Si. (a) High [N], (b) low [N], (c) N-undoped (Yang et al. 1995)

Oxygen Precipitates

Supersaturated interstitial oxygen atoms in CZ-Si can aggregate into oxygen precipitates (OPs) and further induce secondary lattice defects during thermal processing. These defects can getter harmful metal contaminants but induce punch-out dislocations causing the decrease of mechanical strength. The controlling of OPs in CZ-Si is very important for improving performance and yield of ICs. The formation of OPs consists of two stages, i.e., nucleation and growing up. It has been reported that N atoms in CZ-Si can introduce heterogeneous nuclei enhancing the generation of OPs (Karoui and Rozgonyi 2004); therefore, NCZ-Si has been well developed and applied in the IC industry since stronger internal getting is demanded when processing temperatures keeps decreasing (Yang and Yu 2004; Yu et al. 2013).

For solar cells as bulk devices, internal getting on the base of OPs and induced extended defects is not suitable. Moreover, OPs within CZ-Si wafers will introduce deep energy levels in band gap and become the recombination centers for minority carriers, so that the lifetime of wafers decreases. The degree of lifetime degradation was more pronounced in p-type silicon than in n-type silicon because the recombination of OPs takes place through their interface states, where the existence of positive fixed charges around OPs will boost the lifetime degradation in p-type silicon. The performance on p-type (Ga-doped) CZ-Si Al-BSF solar cells with intentionally formed OPs shows that the degradation increases sharply with the concentration of OPs, mainly contributed by the long-wave loss related to bulk recombination (Chen et al. 2011). In fact, the influence of N-related impurities on OPs should be noticed in the cases which the CZ-Si wafers containing high oxygen contents go through long-term annealing. However, currently the fabrication temperature of Al-BSF solar cells is lower than 900 °C, and the annealing time is shorter. Thus, the process does not introduce OPs in solar cells if as-grown oxygen contents are not high enough. Moreover, the N concentration in CZ-Si materials used for photovoltaic industry is very low. Therefore, N-doped CZ-Si could be used for the fabrication of solar cells due to the advantages of low-cost protective gas and higher mechanical strength.

Effect of N Impurity on Mechanical Properties

The mechanical properties of CZ-Si wafers for solar cells are crucial for ensuring manufacturing yield of wafers and cells, especially when the wafer thickness keeps decreasing in recent years. Silicon, as a brittle material at room temperature, is susceptible to breakage or fracture during cell manufacturing due to any localized stress. Generally, the mechanical properties of silicon are dictated by the generation and extension of microcracks, which is related to the generation and motion of dislocations. For CZ-Si, N as co-dopant also affects the mechanical properties of CZ-Si (Lu et al. 1998; Wang et al. 2001; Yu et al. 2013).

The effect of N-doping on Young’s modulus and hardness of silicon has been studied by nano-indentation. N-doping with a concentration of 2 × 1015 cm−3 can significantly increase the Young’s modulus (from 104 to 182 GPa) and hardness (from 6.49 to 8.11 GPa) of float-zone (FZ) silicon (Anderson 2004). The room temperature fracture strength of N-doped wafers was investigated with a double ring bending setup, where FZ silicon wafers with the low N and O concentration (<2 × 1014 and 3–4 × 1015 cm−3, respectively) exhibited a significantly higher fracture strength than conventional CZ ([Oi]: 7.2–8.6 × 1017 cm−3) or FZ ([Oi]: 4–15 × 1015 cm−3) wafers, whereas FZ-Si wafers with the high N concentration (1.7–3.6 × 1015 cm−3) but without O did not possess the improved fracture strength (Vedde and Gravesen 1996). Besides, for CZ-Si, N-doping can always improve fracture strength. This implies that the improvement in the fracture strength of silicon by N-doping relies on the presence of oxygen. Oxygen precipitates and N-O complexes are suggested to be responsible for the increase in fracture strength for NCZ-Si (Wang et al. 2001; Chen et al. 2008).

Interstitial oxygen can suppress slip and warpage of CZ-Si wafers (Hu and Patrick 1975; Yonenaga et al. 1984). Likewise, interstitial N dimers and N-O complexes have the similar effects. Interestingly, a minor concentration of N (<3 × 1015 cm−3) is found to be very effective in reducing slips in low-oxygen content silicon wafers (Wagner et al. 1988). N-doping with a concentration of 3.6 × 1015 cm−3 can reduce wafer warpage of CZ-Si wafers during annealing (Lu et al. 1998). Moreover, the dislocation glide around an indentation on CZ-Si at high temperatures is found to be significantly suppressed by N-doping (Hu and Patrick 1975; Yonenaga et al. 1984). In CZ-Si with different N concentrations, an increase in the N concentration leads to enhanced upper and lower yield points, as shown in Fig. 5 (Orlov et al. 2002). This implies that N-doping can increase the tolerable processing temperatures at which the plastic deformation of silicon wafers under load can be avoided. The locking of dislocations by N can be directly evidenced by the increased unlocking stress, which refers to the critical stress for dislocation movement. It is proved that the FZ silicon with higher N concentrations has larger unlocking stresses, implying the increase in N concentration results in a stronger locking effect (Murphy et al. 2006). The interaction energy between N and dislocations has also been studied by measuring the unlocking stress as a function of temperatures (Yonenaga 2005). The experimentally estimated energy for dislocation escaping from the locking of N atom is 4.1 eV, slightly higher than that of 3.6 eV between dislocations and oxygen (Yonenaga et al. 2005). This interaction energy cannot be understood in terms of the model in which the dislocations interact with individual impurity atoms. Consequently, it is proposed that impurity atoms segregate at dislocations and pipe diffuse along the dislocation line, forming complexes or clusters which immobilize dislocations strongly (Yonenaga 2005). Molecular dynamics (MD) modeling suggests that the binding energy of N with edge dislocation (1.66 eV/A°) is slightly lower than that of oxygen (1.8 eV/A°) (Sumino et al. 1983). In brief, both the experimental and theoretical results agree that N has a strong dislocation locking ability which is comparable with that of oxygen.

Stress-strain curves of dislocation-free Czochralski silicon crystals deformed in the <110> direction at 850 °C for different N concentrations. The concentrations of N in the samples are 3 × 1013–3 × 1014 cm−3 for low N-doped samples, 3 × 1014–3 × 1015 cm−3 for high N-doped samples, and < 3 × 1013 cm−3 for the N-undoped samples (Orlov et al. 2002)

Nitrogen in Cast Multicrystalline Silicon

Soluble Nitrogen

Cast multicrystalline (mc-Si) materials used in photovoltaic industry, including quasi-single crystal silicon (QSC-Si) which is also called as mono-like silicon (ML-Si), are fabricated using directional solidification method. In this technology, the size of the crucibles is much larger than that of CZ-Si, and the ingots are directly in contact with the crucible wall. However, the contact of molten silicon and quartz crucibles under high temperatures can cause sticking between them, which generates the crack of ingots during cooling because silicon and quartz have different thermal conductivities. Therefore, Si3N4 coating layer (usually a mixture of α-Si3N4 and β-Si3N4) on the inner surface of quartz crucibles is usually used to prevent the reaction between molten silicon and crucibles. However, N atoms are induced into mc-Si ingots by the Si3N4 coating (Ghosh et al. 1997). And, the convection of molten silicon in large-scale crucibles during the growth of mc-Si is much weaker compared to the growth of CZ-Si, which weakens the segregation of N during solidification. Consequently, the distribution of N-related impurities in cast mc-Si ingots is more complicated than that in N-doped CZ-Si ingots.

N Dimers

The distribution of N concentration in a mc-Si ingot is controlled by both the entrance and segregation of N atoms during the whole growth. For normal cast silicon materials, the only but excessive N source is Si3N4 coatings on the inner wall of crucibles. As the diffusivity and temperature is similar, the distribution of N concentration in molten silicon is strongly influenced by the size of crucible, melting time, and convection. Convection is also the main factor controlling the effective segregation. During melting and solidification, Si3N4 coating, as the only N dopant, keeps dissolving into the molten silicon; the doping rate is positively correlated with the contacting area between molten silicon and Si3N4 coating. Since the temperature and time duration respectively are high and long enough, the N concentration in molten silicon should be at high-level, especially almost saturated for the cases using small crucible, which is close to 6 × 1018 cm−3 as mentioned above.

Small crystals are better for investigating the influence of convection on segregation, where final N concentration in solid phase is usually only controlled by the segregation effect because N is usually well diffused in the molten silicon. Trempa et al. investigated the N distribution in a small ingot with width of 6 cm. Figure 6a shows the axial nitrogen distribution (measured by FTIR) of the central region of ingots. Two ingots (A1 and B1) were grown with enhanced convection using standard Si3N4 coating, and in one case (B1) additional Si3N4 powders were added to the feedstock and the homogenization time was extended to 10 h. Another two ingots (C1 and D1) used the crucibles with (D1) or without (C1) Si3N4 coating. For the process with strong convection (Ingot A1 and B1), nitrogen is axially homogeneously distributed in the range of (2–4) × 1015 cm−3 regardless of the adding of Si3N4 powders. For moderate convection with Si3N4 coating, Ingot D1, the axial nitrogen concentration keeps increasing at the beginning and reaches to the limit of 1 × 1016 cm−3 at 30% solidified fraction and then decreases to below 2 × 1015 cm−3 at 75% solidified fraction when Si3N4 and SiC precipitates were generated so that the soluble N concentration is reduced. As comparison, the sample grown under moderate convection without a Si3N4 crucible coating (ingot C1) has an extremely low nitrogen content below the detection limit of the FTIR measurement of 5 × 1014 cm−3. The radial distribution of N concentration is also strongly dependent on the convection. Figure 6b illustrates the measured radial N distributions at the height of 5 mm (A2, B2) and 30 mm (C2) from the bottom of the ingot. Here two ingots were grown from a pure feedstock in a Si3N4-coated crucible with strong (A2) and moderate (B2, C2) convection. With strong convection (A2), N concentration is homogeneously distributed in the range (2–4) × 1015 cm−3, and it holds also at a height of 30 mm for this sample (not shown in Fig. 6). As comparison, in the sample grown under moderate convection (B2), the radial N concentration increases slightly toward the center (8.5 × 1015 cm−3) from the edge (6 × 1015 cm−3). At the height of 30 mm, the nitrogen concentration increases from 6 × 1015 cm−3 at the edge to the highest values of (9–11) × 1015 cm−3 at about 1/4 and 3/4 positions (C2), and it then rapidly decreased to 3 × 1015 cm−3 at the center because the soluble N impurities have been segregated and become precipitates. Figure 7 shows the IR-transmission images of vertical cross sections of ingots grown with various growth rates, where the high growth rate corresponds to a thick boundary layer width and weak segregation effect. Si3N4 precipitates will generate when the soluble N concentration is over the solubility of N.

(a) The axial N concentration in the center of a mc-Si ingot grown in moderate and increased convection with various N sources, (b) the radial N concentration at the height of 5 mm and 30 mm from the bottom of the ingots grown with moderate and increased convection in Si3N4-coated crucible. (The data are extracted from Reimann et al. 2010)

IR-transmission images of vertical cuts through the ingot center for ingot grown with the growth rate of 2.2, 1.0, and 0.2 cm/h (Trempa et al. 2010)

Once the segregation effect with saturated N in molten silicon is clear, the general situation in larger crystal is easy to discuss. Generally, as the dopant is located at the crucible wall, the distribution of N concentration in molten silicon can be estimated combining diffusion and convection, which means N concentration in the molten silicon usually decreases from the edge toward ingot center, but strong convection and long melting time will reduce the horizontal concentration gradient. During solidification, the distribution of N in solid phase is determined by both the concentration in the molten silicon around the solid-liquid interface and the convection level, of which the latter affects both the effective segregation coefficient and the local enrichment above the growth interface. For the cases with poor convection, the concentration in both solid and local liquid phase might be increased at the same time. Si3N4 precipitates will generate in various forms when the concentration exceeds solubility (see the section “Silicon Nitride Precipitates”). If the convection is strong enough, the N concentration of most parts of the ingot will be stable.

N-O Complex

The formation of N-O complexes requires adequate N and O concentrations. Currently, the N and Oi concentrations in industrial mc-Si ingot are in the range of 4–6 × 1015 cm−3 and 0.5–5 × 1017 cm−3, respectively, enough for the formation of N-O complexes. The LT-FTIR absorption peaks of N-O complexes can be easily observed in n-type mc-Si (Ghosh et al. 1997). As the N concentration is relatively stable among the whole mc-Si ingot, the formation of N-O complexes is mainly determined by the concentration of interstitial Oi, which depends on the coating selection and decreases along the ingot height. Therefore, the generation of N-O complexes in mc-Si changes with the Oi concentration. It was reported that in n-type mc-Si, the fraction of N-O complexes in total soluble N-related impurities can be up to ~44% when [Oi] = 3.2 × 1017 cm−3, but smaller than 10% when [Oi] < 1.0 × 1017 cm−3 (Zhang et al. 2013). As a result, the distribution of N dimers and N-O complexes in mc-Si is complementary, determined by the distribution of interstitial oxygen Oi, that is, the fraction of dimers is higher at ingot top, while the complexes higher at bottom, as shown in Fig. 8 (Kusunoki et al. 2011).

Complementary distributions of the absorption peak intensities of (a) NN (963 cm−1) and (b) NNO (996 cm−1) over a vertical cross section of mc-Si brick (Kusunoki et al. 2011)

The common shallow thermal donor (STD) concentration in n-type mc-Si was measured as ~1 × 1014 cm−3 (Zhang et al. 2013), which is believed to be caused by N-O complexes. To date, the majority of industrial mc-Si ingots are B-doped p-type Si, where the B concentration is about 1016 cm−3, so N-O complex STDs with a concentration of ~1014 cm−3 should not obviously affect the resistivity of p-type wafers. Moreover, the majority of N-O complexes can be eliminated during the P diffusion process (under 800–900 °C), so that the influence of N-O complexes on the performance of p-type mc-Si solar cell is usually ignored.

Silicon Nitride Precipitates

Formation

The formation of nitrogen-related precipitates strongly depends on the local thermodynamic conditions and impurity transportation during crystallization. As mentioned, the solubility of N in mc-Si is ~1016 cm−3, and Si3N4 precipitates are segregated when the local concentration exceeds the solubility. The N concentration in mc-Si at the solid-liquid interface is determined by the effective segregation of N, which is dependent on equilibrium segregation coefficient and convection specifying how heat and mass transfer can take place between liquid and solid interface of silicon. If local N concentration exceeds the liquid solubility, Si3N4 precipitates will generate at the liquid part of the interface and sink into the solid phase. Then it has a probability to serve as a seed for further growth of Si3N4 crystal; thus, the convection has an important influence to determine how much N content can be transported nearby, which determines the final size of the precipitates. As a result, the common forms of Si3N4 precipitates in mc-Si include rods, fibers, and nets, the parameters of which are listed in Table 6 (Richter et al. 2017).

Si3N4 rods have relatively large diameter and small length and are perfectly grown as hexagonal, showing no position preference within the grain structure. It indicates that they are grown in liquid Si where the surrounding influence is much lower than that in solid phase. Poor convection could be the main reason for the formation of Si3N4 rods, when the N concentration in molten silicon is relatively high and the convection is relatively poor; most of the segregated N into the molten silicon cannot be transported away, once the concentration exceeds the solubility, and precipitates will be generated in the liquid phase. Because poor convection usually corresponds to fast growth and Si3N4 has a higher density (3.44 g/cm3) than liquid Si (2.55 g/cm3), Si3N4 rods can sink to the solid-liquid interface and get embedded in the solid phase.

Si3N4 fibers grow in vertical growth direction within grain. Compared to Si3N4 rods, they have obviously longer length and shorter diameter, which indicates that the fibers grow along with the silicon crystal so that the diameter of the fibers is limited and the length prolonged. Therefore, it can be assumed that Si3N4 fibers need seeds to start the growth. The equilibrium state of Si3N4 inclusion is β phase, while Si3N4 fibers show trigonal α-Si3N4 crystallographic structure, and they grow in preferred orientation. So far, there is no clear evidence that Si3N4 fibers start from Si lattice; some results show that the fibers start from a Si3N4 rod inclusion (Li et al. 2013). Consider that the lattice constant of trigonal α-Si3N4 (a = 0.775 nm and c = 0.562 nm), close to the hexagonal β-Si3N4 (a = 0.760 nm), and Si lattice constant (a = 0.543 nm), the lattice mismatch between the fiber seed and β-Si3N4 or Si, are both relatively low; therefore, it can be inferred that the seed of Si3N4 fibers should be generated at some tensile zone or precipitates enlarging the lattice constant.

Si3N4 nets are likewise α phase precipitates but multicrystal found at grain boundaries (GBs). GBs can offer more nucleation sites for the segregation of α-Si3N4, and then a series of fibers can grow within the preferential angle. Si3N4 fibers and nets are usually found parallel in one ingot, indicating they are same kind of inclusions with different nucleation sites. The extension of Si3N4 fibers/nets is strongly related to the transportation of N content, which is mainly determined by the convection details, and the butterfly shaped nets shown in Fig. 9 are an example to show the complexity of defect extension.

IR-transmission image of vertical cross section of the ingot with butterfly-shaped Si3N4 precipitates and schematic diagram of the convection fluctuation model during the formation (Li et al. 2013)

Influence on Wafering and the Mechanical Strength of Wafers

The wafering of mc-Si bricks mainly uses SiC slurry wire sawing in the past several decades, and now the wafering technique has been mostly changed to diamond wire sawing (DWS). As SiC particles are usually generated along with Si3N4 precipitates, the influence of SiC and Si3N4 precipitates on the mechanical properties should be considered together.

The embedded inclusions such as Si3N4 precipitates are harder than silicon bulk. Thus, for wire saw wafering process, the un-uniformed hardness of the Si material introduces local tensile stress on the wire and may cause wire rupture during cutting. Table 7 gives the hardness values of Si, SiC, α-Si3N4, β-Si3N4, and Fe-decorated β-Si3N4 (Richter et al. 2017). It is clear that the SiC and Si3N4 precipitates are harder than Si, which means they introduce extra local tensile stress on the wire. Despite β-Si3N4 is harder than SiC, it should be mentioned that the main form of Si3N4 in mc-Si is Fe-decorated β-Si3N4 rods (Buonassisi et al. 2006) and the hardness of β-Si3N4 can be reduced by Fe decoration, lower than the value of SiC but still higher than Si (Chakraborty and Mukerji 1980). Therefore, it is believed that SiC particles and filaments are the major hard inclusions in mc-Si. This supports the fact that the β-Si3N4 rods and very thin α-Si3N4 are usually easily cut during wafering. However, hard SiC particles are usually highly localized around β-Si3N4 rods. Therefore, the existence of SiC and Si3N4 precipitates is the main factor of wire rupture (Du et al. 2007, 2008).

Furthermore, embedded SiC and Si3N4 precipitates in mc-Si wafers also decrease the mechanical strength and increase fracture rate of wafers and devices. The adjacent phases have different thermal expansion coefficients (TEC) (Schoenfelder et al. 2009), and the mismatch of the TECs at the interface of precipitates introduces shear stress. The average tensile shear stresses at β-SiC/Si and β-Si3N4/Si interfaces were reported as ~24 and ~12 MPa, respectively, measured by infrared birefringence imaging (IBI) (Ganapati et al. 2010). Therefore, when the amount of SiC/Si3N4 precipitates increases, the heterogeneous degree of local tensile stresses will be increased with enlarged net local shear stress, and the probability of stress concentration is increased, which finally leads to the reduction of wafer fracture strength as the critical stress is more easily reached under same load.

Influence on Electric Properties of Cell Performance

The length of Si3N4 inclusions in mc-Si ingots is usually several millimeters, so they commonly penetrate the wafers (width from 160 to 180 μm). Despite the resistivity of penetrating Si3N4 is relatively high (Bauer et al. 2007), these inclusions can still serve as shunts in solar cells under forward bias (Breitenstein et al. 2004), as shown in Fig. 10. Generally, it is considered as shunts that cause degradation in fill factor (FF) and open-circuit voltage (Voc), However, for the industrial-level mc-Si cells, the series resistance of the devices cannot be ignored, and then the increase in shunts can also reduce the short-circuit current (Jsc) at the same time. Meanwhile, Si3N4 inclusions are the nucleation sites for SiC particles. Penetrating SiC filaments at grain boundaries are confirmed low-resistivity shunts, but the size of SiC particles is usually smaller compared to wafer thickness, and ~80%wt of the inclusions have a diameter between 75 and 385 μm (Søiland et al. 2004).

Lock-in thermogram of a cell containing a Si3N4 inclusion (arrow) (Breitenstein et al. 2004)

Growth of Multicrystalline Silicon in Ambient Nitrogen

Gas Doping of N for Cast Mc-Si

N-doping through utilizing ambient nitrogen (Yang et al. 2009) has been well applied in CZ-Si growth. NCZ-Si wafers have multiple benefits and features for IC industry, i.e., it provides the flexibility in controlling oxygen precipitates, suppressing void defects related to vacancies, and improving mechanical strength of wafers. However, for cast mc-Si (including QSC-Si), these features are not as important as for CZ-Si, and certain amounts of N content are incorporated into the crystal due to the reaction of the coated Si3N4 on the inner walls of crucible with molten silicon (Ghosh et al. 1997), so there are few interests on gas doping of N for mc-Si. To date, mc-Si ingots are mostly grown in ambient argon.

As discussed above, the N concentration in the molten silicon is relatively high, the ideal segregation coefficient of N in silicon is as small as 7.5 × 10−4, and the most important, the manufacturers usually do not intentionally change the convection level. Thus, the common range of N concentration in a regular mc-Si ingot is 4–6 × 1015 cm−3. And the soluble N concentration in the mc-Si crystal must be controlled lower than 1016 cm−3 in solid phase, or else Si3N4 precipitates must be generated and then cause dense defects in silicon crystal.

When casting mc-Si ingots in ambient nitrogen, additional N sources are introduced in the system as Si3N4 film or particles, and they are generated at the solid Si surface by the reaction between polycrystalline Si and N2 during the melting stage. Because the convection in casting method is much lower compared with CZ growth, the additional Si3N4 generated on poly-Si nuggets increases the contact area between Si3N4 and molten silicon, which increases the localized N concentration in both liquid and solidified silicon. Once the N concentration is oversaturated, Si3N4 precipitation should be generated in the crystal. Figure 11 shows the minority lifetime mapping images of mc-Si ingots grown in Ar (MC), N2 with (NMC1) reduced and (NMC0) regular pressure. The inset of Fig. 11 shows the Si3N4 precipitates and related cracks in the ingot MNC0 grown in ambient N2 with regular pressure of 600 mbar. The mapping of brick shows that the relatively high N2 partial pressure can cause many cracks in the crystal. These cracks are filled with Si3N4 precipitates, and dense dislocations/grain boundaries are generated nearby. SEM photo shows that the precipitates are mostly needle-like, suggesting that they are β-Si3N4, which means they are not unmelted coating because the coating is usually composed by α-Si3N4. Meanwhile, Si3N4 particles formed before solidification will float upward the surface of the molten silicon and cannot exist in the bulk. The generation of cracks should be related to the high thermal stress after solidification during the hot temperature phase of crystal growth, the fast diffuser N-N pairs could diffuse to the crack surfaces and then form silicon nitride particles. However, the detailed mechanism for the formation of the cracks with silicon nitride aggregation still needs more experiments to reveal.

The N concentration can be controlled through manipulating N2 partial pressure. Fine mc-Si ingots can be obtained under ambient nitrogen with reduced pressure. The total N concentration in the top samples was measured to be 9.4 × 1015 cm−3 by SIMS, which is much higher than the regular range of 4–6 × 1015 cm−3. This indicates that the N concentrations can be effectively improved by the utilization of ambient nitrogen with a reduced pressure. Figure 11 also shows that the minority carrier lifetime of NMC0 is lower than that of NMC1 due to the generation of massive cracks, and the carrier lifetime of NMC1 is even better than MC. This suggests that the increase in N concentrations up to 9.4 × 1015 cm−3 has no influence on the carrier recombination properties of cast mc-Si materials and, therefore, should do no harm on the performance of solar cells.

Improvement in Mechanical Strength

It is well known that the introduction of N can enhance the mechanical strength of CZ-Si (Wang et al. 2001); therefore, the extra N-doping in mc-Si can likewise further enhance the fracture strength of wafers. The influence of extra N-doping on fracture strength is investigated using twist breakage test combined with Weibull analysis. Twist test is the most widely used tool to characterize the fracture strength, considering the nonuniform grain structure of mc-Si wafers. Figure 12 shows the scheme of twist test for 156 × 156 mm2 wafers, where wafers were placed on fixed lower dowel pins and the upper dowel pins move downward until they reach the wafer surface, and then loads are applied by upper pins moving downward on the unsupported corners of the wafers until the breakage. Nevertheless, the stress distribution of twist test is nonlinear (Schoenfelder et al. 2007), and a characteristic fracture strength value can be defined as σ = CFb/ld 2 for evaluation, where C is a constant (C was set as 2 in this work), F is the fracture force, d the wafer thickness, and l and b the geometric parameters for wafer and tester, which are 156 and 130 mm, respectively. The Weibull method describes the failure probability as a function of strength,

where Pf is the failure probability at the applied stress σ and σθ and m are defined as the characteristic strength and the Weibull modulus, respectively. Pf = (n − 1/2)/N, dependent on its ranking number, n (N is the total number of samples). σθ equals to the stress when 63% of all samples fail and m describes the variability of strength data. High m value means smaller scattering of σ. Therefore, through a linear fit of ln(−ln(1 − Pf)) versus ln σ, σθ and m can be determined from the slope and intercept. Figure 12 also shows the Weibull distribution of the fracture strength of wafers from the ingots grown in N2 and Ar, the total number of wafers is 36 and 37, and the characteristic strengths are 175.62 and 159.61 MPa, respectively. It is clear that the wafers from the ingot grown in nitrogen are statically harder.

Schematic setup of the twist-test configuration and the Weibull plots of the variation of fracture strength with the applied stress for the wafers from the ingots grown in N2 and Ar (Yuan et al. 2018)

Impact of N-O Complexes in Mc-Si Grown in Ambient N2

The increase in N concentration in mc-Si grown in ambient N2 may cause increase in N-O concentration. N-O complexes introduce shallow thermal donors (STD) in silicon and may cause compensation in p-type mc-Si. As mentioned above, the fraction range of N-O complexes in mc-Si is 10–40% considering Oi concentration; therefore, when the total N concentration reaches ~1016 cm−3, the STD concentration can be higher than 1015 cm−3, when the influence on resistivity cannot be easily ignored.

Figure 13a shows the resistivity distribution of ingots grown in N2 and Ar along the ingot height. It is interesting that the resistivity of N-doped ingot grown in N2 increases with ingot height, while that of the referential ingot grown in Ar decreases normally. Since the boron doping is same for both ingots, the difference in resistivity distribution between the two ingots is attributed to the formation of N-O complexes, which serve as shallow donors and compensate boron acceptors (Yang et al. 1996). Note that N-O complexes also exist in normal mc-Si grown in argon, and they are commonly eliminated during phosphorus diffusion process (by annealing under 800–900 °C for ~30 min) so that the substrate material of final Al-BSF solar cell is not compensated. Figure 13b shows the resistivity variation of samples sliced from the top of N-doped and referential ingots, after the annealing under 900 °C and then 650 °C to degenerate and regenerate N-O complexes, respectively. The corresponding interstitial oxygen concentration at the ingot top is measured to be ~6.8 × 1016 cm−3 by FTIR. The resistivity of the N-doped sample obviously decreases when annealed under 900 °C and increases when latterly annealed under 650 °C. It can be explained by the degeneration and regeneration of N-O complexes in N-doped samples.

(a) The resistivity distribution of B-doped p-type ingots grown in N2 and Ar ambient versus various ingot heights. (b) The variation of average resistivity of top samples from the ingots grown in N2 and Ar after various thermal annealings (Yuan et al. 2018)

Standard Al-BSF solar cells based on wafers from the ingot grown in N2 with reduced pressure were fabricated. Since it has been shown that thermal annealing in Al-BSF cell manufacturing cannot totally eliminate N-O complex shallow donors, then the bulk resistivity of NMC1 wafers is higher than the reference after annealing under 900 °C, which causes higher series resistivity and lower fill factor of the solar cells. The distributions of fill factor values are shown in Fig. 14a. As a result, Fig. 14b shows the distribution of solar cell efficiencies for both kinds of the wafers. The average efficiencies are almost the same for the solar cells based on the ingot NMC1 and MC, which are 17.91% and 17.96%, respectively. This indicates that the high concentration of nitrogen has a little influence on solar cell performances. It can be inferred that a better overall resistivity distribution of the whole ingot can be obtained if N-O complex-related compensation is well controlled. For the consideration of application of N-doped silicon, an additional B doping should be adopted to fit the cell manufacturing process.

(a) Fill factor distribution of solar cells. (b) The resistivity variation after heat treatment of top samples sliced from ingot NMC1 and ingot MC (Yuan et al. 2018)

Conclusion

This chapter reviews the basic properties of nitrogen in photovoltaic silicon materials. The development of N-doped CZ-Si wafers is crucial for IC industry. As NCZ-Si has not been widely used in photovoltaic fields, related knowledge from the perspective of possible photovoltaic application are introduced. As for mc-Si, nitrogen impurity is important subject in casting method due to Si3N4-coated crucibles. The concepts of the existence, transportation, and influence of N-related defects are introduced and described to the readers to help understand the relevant phenomena during the solidification process. Finally, cheaper ambient nitrogen for casting multicrystalline silicon ingots has been achieved with comparable crystal quality and solar cell conversion efficiency.

Cross-References

References

C. Alpass, J. Murphy, R. Falster, P. Wilshaw, Nitrogen in silicon: diffusion at 500–750 °C and interaction with dislocations. Mater. Sci. Eng. B 159, 95–98 (2009)

H.C. Alt, H. Wagner, Piezospectroscopy of nitrogen-oxygen shallow donor complexes in silicon. Phys. Rev. B 82(11), 115203 (2010)

H.C. Alt, Y. Gomeniuk, F. Bittersberger, A. Kempf, D. Zemke, Analysis of electrically active N-O complexes in nitrogen-doped CZ silicon crystals by FTIR spectroscopy. Mater. Sci. Semicond. Process. 9(1–3), 114–116 (2006)

P.M. Anderson, in Nanoscale Materials and Modeling – Relations Among Processing, Microstructure and Mechanical Properties: Symposium held April 13–16, 2004, San Francisco, California, vol 821. Materials Research Society

J. Bauer, O. Breitenstein, J.P. Rakotoniaina, Electronic activity of SiC precipitates in multicrystalline solar silicon. Phys. Status Solidi A 204(7), 2190–2195 (2007)

O. Breitenstein, J. Rakotoniaina, M.H. Al Rifai, M. Werner, Shunt types in crystalline silicon solar cells. Prog. Photovolt. Res. Appl. 12(7), 529–538 (2004)

P.H. Bucksbaum, J. Bokor, Rapid melting and regrowth velocities in silicon heated by ultraviolet picosecond laser pulses. Phys. Rev. Lett. 53(2), 182 (1984)

T. Buonassisi, A.A. Istratov, M. Pickett, J.-P. Rakotoniaina, O. Breitenstein, M.A. Marcus, S.M. Heald, E.R. Weber, Transition metals in photovoltaic-grade ingot-cast multicrystalline silicon: assessing the role of impurities in silicon nitride crucible lining material. J. Cryst. Growth 287(2), 402–407 (2006)

D. Chakraborty, J. Mukerji, Characterization of silicon nitride single crystals and polycrystalline reaction sintered silicon nitride by microhardness measurements. J. Mater. Sci. 15(12), 3051–3056 (1980)

J. Chen, D. Yang, X. Ma, Z. Zeng, D. Tian, L. Li, D. Que, L. Gong, Influence of germanium doping on the mechanical strength of Czochralski silicon wafers. J. Appl. Phys. 103(12), 123521 (2008)

L. Chen, X. Yu, P. Chen, P. Wang, X. Gu, J. Lu, D. Yang, Effect of oxygen precipitation on the performance of Czochralski silicon solar cells. Sol. Energy Mater. Sol. Cells 95(11), 3148–3151 (2011). https://doi.org/10.1016/j.solmat.2011.06.044

A. Clark, J.D. Macdougall, K.E. Manchester, P. Roughan, F. Anderson, Nitrogen Donor Level in Silicon, Bulletin of the American Physical Society, vol 3 (American Institute of Physics Circulation and Fulfillment Division, Woodbury, 1968), p. 376

G. Du, L. Zhou, P. Rossetto, Y. Wan, Hard inclusions and their detrimental effects on the wire sawing process of multicrystalline silicon. Sol. Energy Mater. Sol. Cells 91(18), 1743–1748 (2007)

G. Du, N. Chen, P. Rossetto, Wire-sawing defects on multicrystalline silicon wafers grown by a directional solidification method. Semicond. Sci. Technol. 23(5), 055011 (2008)

C. Ewels, R. Jones, S. Öberg, J. Miro, P. Deak, Shallow thermal donor defects in silicon. Phys. Rev. Lett. 77(5), 865 (1996)

N. Fujita, R. Jones, J. Goss, P. Briddon, T. Frauenheim, S. Öberg, Diffusion of nitrogen in silicon. Appl. Phys. Lett. 87(2), 021902 (2005)

V. Ganapati, S. Schoenfelder, S. Castellanos, S. Oener, R. Koepge, A. Sampson, M.A. Marcus, B. Lai, H. Morhenn, G. Hahn, Infrared birefringence imaging of residual stress and bulk defects in multicrystalline silicon. J. Appl. Phys. 108(6), 063528 (2010)

M. Ghosh, D. Yang, A. Lawerenz, S. Riedel, H. Moller, Investigation of minority carrier lifetime degradation in multicrystalline silicon ingots, in Proceedings of the 14th European Photovoltaic Solar Energy Conference, (1997), pp. 724–727

J. Goss, I. Hahn, R. Jones, P. Briddon, S. Öberg, Vibrational modes and electronic properties of nitrogen defects in silicon. Phys. Rev. B 67(4), 045206 (2003)

J. Griffin, J. Hartung, J. Weber, H. Navarro, L. Genzel, Photothermal ionisation spectroscopy of oxygen-related shallow defects in crystalline silicon. Appl. Phys. A. 48(1), 41–47 (1989)

A. Hara, T. Fukuda, T. Miyabo, I. Hirai, Electron spin resonance of oxygen-nitrogen complex in silicon. Jpn. J. Appl. Phys. 28(1R), 142 (1989)

P. Hemment, R. Peart, M. Yao, K. Stephens, R. Chater, J. Kilner, D. Meekison, G. Booker, R. Arrowsmith, High quality silicon on insulator structures formed by the thermal redistribution of implanted nitrogen. Appl. Phys. Lett. 46(10), 952–954 (1985)

R. Hockett, Anomalous diffusion of nitrogen in nitrogen-implanted silicon. Appl. Phys. Lett. 54(18), 1793–1795 (1989)

R. Hockett, D. Sams, The measurement of nitrogen in silicon substrates by SIMS, in Proceedings-SPIE the International Society for Optical Engineering, 2000, (International Society for Optical Engineering, 1999), pp. 584–595

S. Hu, W. Patrick, Effect of oxygen on dislocation movement in silicon. J. Appl. Phys. 46(5), 1869–1874 (1975)

T. Itoh, T. Abe, Diffusion coefficient of a pair of nitrogen atoms in float-zone silicon. Appl. Phys. Lett. 53(1), 39–41 (1988). https://doi.org/10.1063/1.100116

Y. Itoh, T. Nozaki, T. Masui, T. Abe, Calibration curve for infrared spectrophotometry of nitrogen in silicon. Appl. Phys. Lett. 47(5), 488–489 (1985)

R. Jones, C. Ewels, J. Goss, J. Miro, P. Deak, S. Oberg, F.B. Rasmussen, Theoretical and isotopic infrared absorption investigations of nitrogen-oxygen defects in silicon. Semicond. Sci. Technol. 9(11), 2145 (1994a)

R. Jones, S. Öberg, F.B. Rasmussen, B.B. Nielsen, Identification of the dominant nitrogen defect in silicon. Phys. Rev. Lett. 72(12), 1882 (1994b)

W. Kaiser, C. Thurmond, Nitrogen in silicon. J. Appl. Phys. 30(3), 427–431 (1959)

A. Karoui, G. Rozgonyi, Oxygen precipitation in nitrogen doped Czochralski silicon wafers. II. Effects of nitrogen and oxygen coupling. J. Appl. Phys. 96(6), 3264–3271 (2004)

H. Kusunoki, T. Ishizuka, A. Ogura, H. Ono, Complementary distribution of NN and NNO complexes in cast-grown multicrystalline silicon for photovoltaic cells. Appl. Phys. Express 4(11), 115601 (2011)

J. Li, R.R. Prakash, K. Jiptner, J. Chen, Y. Miyamura, H. Harada, K. Kakimoto, A. Ogura, T. Sekiguchi, Butterfly-shaped distribution of SiNx precipitates in multi-crystalline Si for solar cells. J. Cryst. Growth 377, 37–42 (2013)

J. Li, X. Yu, S. Yuan, L. Yang, Z. Liu, D. Yang, Effects of oxygen related thermal donors on the performance of silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 179, 17–21 (2018)

H. Lu, D. Yang, L. Li, Z. Ye, D. Que, Thermal warpage of Czochralski silicon wafers grown under a nitrogen ambience. Phys. Status Solidi A 169(2), 193–198 (1998)

G. Mannino, V. Privitera, S. Scalese, S. Libertino, E. Napolitani, P. Pichler, N.E. Cowern, Effect of oxygen on the diffusion of nitrogen implanted in silicon. Electrochem. Solid-State Lett. 7(8), G161–G163 (2004)

J. Murphy, A. Giannattasio, S. Senkader, R. Falster, P. Wilshaw, Nitrogen transport in float-zone and Czochralski silicon investigated by dislocation locking experiments. Phys. Status Solidi A 202(5), 926–930 (2005)

J.D. Murphy, C. Alpass, A. Giannattasio, S. Senkader, R. Falster, P. Wilshaw, Nitrogen in silicon: transport and mechanical properties. Nucl. Instrum. Methods Phys. Res., Sect. B 253(1), 113–117 (2006)

M. Nakatsu, A. Hashimoto, A. Natsume, N. Inoue, H. Ono, Measurement of nitrogen concentration in cz-si below 1014/cm3 by IR absorption spectroscopy, in High Purity Silicon VIII: Proceedings of the International Symposium, (The Electrochemical Society, 2004), p. 102

J. Nelson, P. Schultz, A. Wright, Valence and atomic size dependent exchange barriers in vacancy-mediated dopant diffusion. Appl. Phys. Lett. 73(2), 247–249 (1998)

T. Nozaki, Y. Yatsurugi, N. Akiyama, Charged particle activation analysis for carbon, nitrogen and oxygen in semiconductor silicon. J. Radioanal. Nucl. Chem. 4(1), 87–98 (1970)

H. Ono, M. Horikawa, Quantitative detection of small amount of nitrogen in Czochralski-grown silicon crystals. Jpn. J. Appl. Phys. 42(3B), L261 (2003)

V. Orlov, H. Richter, A. Fischer, J. Reif, T. Müller, R. Wahlich, Mechanical properties of nitrogen-doped CZ silicon crystals. Mater. Sci. Semicond. Process. 5(4–5), 403–407 (2002)

P. Pavlov, E. Zorin, D. Tetelbaum, A. Khokhlov, Nitrogen as dopant in silicon and germanium. Phys. Status Solidi A 35(1), 11–36 (1976)

M. Porrini, M. Pretto, R. Scala, Measurement of nitrogen in Czochralski silicon by means of infrared spectroscopy. Mater. Sci. Eng. B 102(1), 228–232 (2003)

M. Qi, S. Tan, B. Zhu, P. Cai, W. Gu, X. Xu, T. Shi, D. Que, L. Li, The evidence for interaction of the N-N pair with oxygen in Czochralski silicon. J. Appl. Phys. 69(6), 3775–3777 (1991)

D. Que, X. Chen, Silicon Materials Science and Technology (Zhejiang University Press, Hangzhou, China, 2000). (in Chinese)

D. Que, L. Li, Y. Lin, Nitrogen protective ambiance for Czochralski growth of silicon. Chinese Patent CN85100295, 1985

D. Que, L. Li, X. Chen, Nitrogen gas doping in Czochralski silicon. Chinese Patent CN87105811, 1987

D. Que, L. Li, X. Chen, Y. Lin, J. Zhang, X. Zhou, J. Yang, Czochralski silicon crystal growth in nitrogen atmosphere under reduced pressure. Sci. China Ser. A Math. Phys. Astron. Technol. Sci. 34(8), 1017–1024 (1991)

C. Reimann, M. Trempa, J. Friedrich, G. Müller, About the formation and avoidance of C and N related precipitates during directional solidification of multi-crystalline silicon from contaminated feedstock. J. Cryst. Growth 312(9), 1510–1516 (2010)

S. Richter, J. Bauer, O. Breitenstein, Growth of carbon and nitrogen containing precipitates in crystalline solar silicon and their influence on solar cells. Phys. Status Solidi RRL 11(2), 1600354 (2017)

H. Sawada, H. Kawakami, First-principles calculation of the interaction between nitrogen atoms and vacancies in silicon. Phys. Rev. B 62(3), 1851 (2000)

H. Sawada, K. Kawakami, A. Ikari, W. Ohashi, Atomistic model of nitrogen-pair diffusion in silicon. Phys. Rev. B 65(7), 075201 (2002)

S. Schoenfelder, A. Bohne, J. Bagdahn, Comparison of test methods for strength characterization of thin solar wafer. in Proceedings of 22nd European Photovoltaic Solar Energy Conference, Milan, Italy, 2007, vol 7

S. Schoenfelder, A. Sampson, V. Ganapati, R. Koepge, J. Bagdahn, T. Buonassisi, Quantitative stress measurements of bulk microdefects in multicrystalline silicon. 24th EUPVSEC:977–980 (2009)

P.A. Schultz, J.S. Nelson, Fast through-bond diffusion of nitrogen in silicon. Appl. Phys. Lett. 78(6), 736–738 (2001)

L.L. Snead, T. Nozawa, Y. Katoh, T.-S. Byun, S. Kondo, D.A. Petti, Handbook of SiC properties for fuel performance modeling. J. Nucl. Mater. 371(1–3), 329–377 (2007)

A. Søiland, E. Øvrelid, T. Engh, O. Lohne, J. Tuset, Ø. Gjerstad, SiC and Si3N4 inclusions in multicrystalline silicon ingots. Mater. Sci. Semicond. Process. 7(1), 39–43 (2004)

N. Stoddard, P. Pichler, G. Duscher, W. Windl, Ab initio identification of the nitrogen diffusion mechanism in silicon. Phys. Rev. Lett. 95(2), 025901 (2005)

M. Suezawa, K. Sumino, H. Harada, T. Abe, Nitrogen-oxygen complexes as shallow donors in silicon crystals. Jpn. J. Appl. Phys. 25(10A), L859 (1986)

M. Suezawa, K. Sumino, H. Harada, T. Abe, The nature of nitrogen-oxygen complexes in silicon. Jpn. J. Appl. Phys. Part 1 27(1), 62–67 (1988). https://doi.org/10.1143/jjap.27.62

K. Sumino, I. Yonenaga, M. Imai, T. Abe, Effects of nitrogen on dislocation behavior and mechanical strength in silicon crystals. J. Appl. Phys. 54(9), 5016–5020 (1983)

Y. Tokumaru, H. Okushi, T. Masui, T. Abe, Deep levels associated with nitrogen in silicon. Jpn. J. Appl. Phys. 21(7A), L443 (1982)

M. Trempa, C. Reimann, J. Friedrich, G. Müller, The influence of growth rate on the formation and avoidance of C and N related precipitates during directional solidification of multi crystalline silicon. J. Cryst. Growth 312(9), 1517–1524 (2010)

L. Vandeperre, F. Giuliani, S. Lloyd, W. Clegg, The hardness of silicon and germanium. Acta Mater. 55(18), 6307–6315 (2007)

J. Vedde, P. Gravesen, The fracture strength of nitrogen doped silicon wafers. Mater. Sci. Eng. B 36(1–3), 246–250 (1996)

V.V. Voronkov, R.J. Falster, Nitrogen diffusion and interaction with oxygen in Si. in Solid State Phenomena, 2004. Trans Tech Publ, pp. 83–92

P. Wagner, R. Oeder, W. Zulehner, Nitrogen-oxygen complexes in Czochralski-silicon. Appl. Phys. A 46(2), 73–76 (1988)

H. Wagner, H.C. Alt, W. von Ammon, F. Bittersberger, A. Huber, L. Koester, N-O related shallow donors in silicon: stoichiometry investigations. Appl. Phys. Lett. 91(15), 152102 (2007)

G. Wang, D. Yang, D. Li, Q. Shui, J. Yang, D. Que, Mechanical strength of nitrogen-doped silicon single crystal investigated by three-point bending method. Phys. B Condens. Matter 308, 450–453 (2001)

D. Yang, X. Yu, Nitrogen in Silicon. Defect Diffus. Forum 230–232, 199–220 (2004)

D. Yang, D. Que, K. Sumino, Nitrogen effects on thermal donor and shallow thermal donor in silicon. J. Appl. Phys. 77(2), 943–944 (1995)

D. Yang, R. Fan, L. Li, D. Que, K. Sumino, Effect of nitrogen–oxygen complex on electrical properties of Czochralski silicon. Appl. Phys. Lett. 68(4), 487–489 (1996)

D. Yang, X. Yu, D. Que, Nitrogen doping in casting multicrystalline silicon by melting feedstocks in nitrogen ambience. Chinese Patent CN101597790, 2009

Y. Yatsurugi, N. Akiyama, Y. Endo, T. Nozaki, Concentration, solubility, and equilibrium distribution coefficient of nitrogen and oxygen in semiconductor silicon. J. Electrochem. Soc. 120(7), 975–979 (1973)

I. Yonenaga, Dislocation–impurity interaction in Si. Mater. Sci. Eng. B 124, 293–296 (2005)

I. Yonenaga, K. Sumino, K. Hoshi, Mechanical strength of silicon crystals as a function of the oxygen concentration. J. Appl. Phys. 56(8), 2346–2350 (1984)

I. Yonenaga, T. Taishi, X. Huang, K. Hoshikawa, Dislocation–impurity interaction in Czochralski-grown Si heavily doped with B and Ge. J. Cryst. Growth 275(1–2), e501–e505 (2005)

X. Yu, D. Yang, X. Ma, J. Yang, L. Li, D. Que, Grown-in defects in nitrogen-doped Czochralski silicon. J. Appl. Phys. 92, 188–194 (2002)

X. Yu, D. Yang, K. Hoshikawa, Investigation of nitrogen behaviors during Czochralski silicon crystal growth. J. Cryst. Growth 318(1), 178–182 (2011)

X. Yu, J. Chen, X. Ma, D. Yang, Impurity engineering of Czochralski silicon. Mater. Sci. Eng. R. Rep. 74(1), 1–33 (2013)

S. Yuan, D. Hu, X. Yu, F. Zhang, H. Luo, L. He, D. Yang, Controllable Nitrogen Doping in Multicrystalline Silicon by Casting Under Low Cost Ambient Nitrogen. Silicon 1–6 (2018)

H. Zhang, M. Stavola, M. Seacrist, Nitrogen-containing point defects in multi-crystalline Si solar-cell materials. J. Appl. Phys. 114(9), 093707 (2013)

Acknowledgments

The authors would like to thank the financial support from the National Natural Science Foundation of China (Nos. 51532007, 61721005). It was also partly supported by Key Project of Zhejiang Province (No. 2018C01034).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Section Editor information

Rights and permissions

Copyright information

© 2019 Springer-Verlag GmbH Germany, part of Springer Nature

About this entry

Cite this entry

Yuan, S., Yang, D. (2019). Nitrogen Impurity in Crystalline Silicon. In: Yang, D. (eds) Handbook of Photovoltaic Silicon. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-56472-1_22

Download citation

DOI: https://doi.org/10.1007/978-3-662-56472-1_22

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-56471-4

Online ISBN: 978-3-662-56472-1

eBook Packages: Chemistry and Materials ScienceReference Module Physical and Materials ScienceReference Module Chemistry, Materials and Physics