Abstract

A water distribution system is a complex assembly of hydraulic control elements connected together to convey quantities of water from sources to consumers. The typical high number of constraints and decision variables, the nonlinearity, and the non-smoothness of the head—flow—water quality governing equations are inherent to water supply systems planning and management problems. Traditional methods for solving water distribution systems management problems, such as the least cost design and operation problem, utilized linear/nonlinear optimization schemes which were limited by the system size, the number of constraints, and the number of loading conditions. More recent methodologies employ heuristic optimization techniques, such as genetic algorithms or ant colony optimization as stand alone or hybrid data driven—heuristic schemes. This book chapter reviews some of the more traditional water distribution systems problem algorithms and solution methodologies. It is comprised of sub sections on least cost and multi-objective optimal design of water networks, reliability incorporation in water supply systems design, optimal operation of water networks, water quality analysis inclusion in distribution systems, water networks security related topics, and a look into the future.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

A water distribution network is an interconnected collection of sources, pipes and hydraulic control elements (e.g., pumps, valves, regulators, tanks) delivering to consumers prescribed water quantities at desired pressures and water qualities. Such systems are often described as a graph, with the links representing the pipes, and the nodes defining connections between pipes, hydraulic control elements, consumers, and sources. The behavior of a water distribution network is governed by: (1) the physical laws which describe the flow relationships in the pipes and the hydraulic control elements, (2) the consumer demands, and (3) the system’s layout.

Management problems associated with water supply systems can be classified into: (1) layout (system connectivity/topology); (2) design (system sizing given a layout); and (3) operation (system operation given a design).

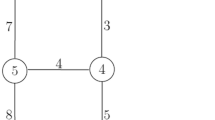

On top of those, problems related to aggregation, maintenance, reliability, unsteady flow and security can be identified for gravity, and/or pumping, and/or storage branched/looped water distribution systems. Flow and head, or flow, head, and water quality can be considered for one or multiple loading scenarios, taking into consideration inputs/outputs as deterministic or stochastic variables. Figure 1 is a schematic description of the above.

The typical high number of constraints and decision variables, the nonlinearity, and the non-smoothness of the head—flow—water quality governing equations are inherent to water supply systems planning and management problems. An example of this is the least cost design problem of a water supply system defined as finding the water distribution system’s component characteristics (e.g., pipe diameters, pump heads and maximum power, reservoir storage volumes, etc.), which minimize the system capital and operational costs, such that the system hydraulic laws are maintained (i.e., Kirchoff’s Laws no. 1 and 2 for continuity of flow and energy, respectively), and constraints on quantities and pressures at the consumer nodes are fulfilled.

Traditional methods for solving water distribution system management problems used linear/nonlinear optimization schemes which were limited by the system size, the number of constraints, and the number of loading conditions. More recent methodologies employ heuristic optimization techniques, such as genetic algorithms or ant colony optimization as stand alone or hybrid data driven—heuristic schemes.

This book chapter reviews part of the topics presented in Fig. 1. It consists of sub sections on least cost and multi-objective optimal design of water networks, reliability incorporation in water supply systems design, optimal operation of water networks, water quality analysis inclusion in distribution systems, water networks security related topics, and a look into the future.

2 Least Cost and Multi-Objective Optimal Design of Water Networks

2.1 Least Cost Design of Water Networks

The optimal design problem of a water distribution system is commonly defined as a single objective optimization problem of finding the water distribution system component characteristics (e.g., pipe diameters, pump heads and maximum power, reservoir storage volumes, etc.), which minimize the system capital and operational costs, such that the system hydraulic laws are maintained (i.e., Kirchoff’s Laws no. 1 and 2 for continuity of flow and energy, respectively), and constraints on quantities and pressures at the consumer nodes are fulfilled.

Numerous models for least cost design of water distribution systems have been published in the research literature during the last four decades. A possible classification for those might be: (1) decomposition: methods based on decomposing the problem into an “inner” linear programming problem which is solved for a fixed set of flows (heads), while the flows (heads) are altered at an “outer” problem using a gradient or a sub-gradient optimization technique [1–6]; (2) linking simulation with nonlinear programming: methods based on linking a network simulation program with a general nonlinear optimization code [7–9]; (3) nonlinear programming: methods utilizing a straightforward nonlinear programming formulation [10, 11]; (4) methods employing evolutionary/meta-heuristic techniques: genetic algorithms [12–16], simulated annealing [17], the shuffled frog leaping algorithm [18], ant colony optimization [19]; and (5) other methods: dynamic programming [20], integer programming [21].

Decomposition methods [1–6] are limited in the number of loading conditions that can be considered, to converging to local optimal solutions, and to fixed flow directions in the pipes as of the non-smoothness properties of the “outer” problem (excluding [2, 4] who used a sub-gradient scheme to minimize the “outer” problem), but can account for split pipe diameter solutions. Methods based on linking a network simulation program with a general nonlinear optimization code [7–9] divide the overall problem into two levels. In the lower level the system is analyzed for flows, pressures, and cost using a network simulation program, while in the upper level the system design variables: pipe diameters, pump heads, and reservoir volumes are modified according to the information provided by successive runs of the simulation program. The upper level is a general purpose optimization package, such as MINOS [22] or GRG2 [23]. The optimization algorithm uses values of the objective function generated in successive runs of the simulation program, and information on constraint violations to determine the next solution to be tested. Methods based on nonlinear programming simultaneously solve the optimal heads and flows, using general optimization schemes: [11] solved the least cost design of a water distribution system with pipes and pumps under one loading condition, with the design problem transformed into an unconstrained optimization problem using an exterior penalty method; [10] developed a methodology for the least cost design/operation of a water distribution system under multiple loading conditions based on the general reduced gradient (GRG) [24]. Methods based on using a straightforward nonlinear code are limited with respect to the water distribution system size that can be handled, the user intervention, the number of loading conditions, and most likely their convergence to local optimal solutions.

The capabilities of solving water distribution systems optimization problems have improved dramatically since the employment of genetic algorithms [25]. Genetic algorithms are domain heuristic independent global search techniques that imitate the mechanics of natural selection and natural genetics of Darwin’s evolution principle. The primary idea is to simulate the natural evolution mechanisms of chromosomes, represented by string structures, involving selection, crossover, and mutation. Strings may have binary, integer, or real values. Simpson et al. [14] were the first to use genetic algorithms for water distribution systems least cost design. They applied and compared a genetic algorithm solution to the network of [26], to enumeration and to nonlinear optimization. Savic and Walters [13] used genetic algorithms to solve and compare optimal results of the one-loading gravity systems of the Two Loop Network [1], the Hanoi network [27], and the New York Tunnels system [28]. Salomons [12] used a genetic algorithm for solving the least cost design problem incorporating extended period loading conditions, tanks, and pumping stations. Vairavamoorthy and Ali [15] presented a genetic algorithm framework for the least cost design problem of a pipe network which excludes regions of the search space where impractical or infeasible solutions are likely to exist, and thus improves the genetic algorithm search efficiency. Wu and Walski [16] introduced a self-adaptive penalty approach to handle the transformation from a constrained into a non-constrained framework of the least cost design and rehabilitation problems of a water distribution system, as applied in a genetic algorithm scheme. Loganathan et al. [17] used the decomposition idea proposed by [1] but with minimizing the “outer” problem through a simulated annealing scheme, showing substantial improvements over previous decomposition methods which used a gradient type procedure to minimize the “outer” problem. Eusuff and Lansey [18] developed a swarm based meta-heuristic algorithm, entitled the Shuffled Frog Leaping Algorithm (SFLA). The SFLA was applied and compared to the same problems as in [13]. Maier et al. [19] applied an ant colony algorithm based on [29, 30] to the gravitational network of [26] and to the New York Tunnels system [28]. Singh and Mahar [20] used dynamic programming to solve the optimal design problem of a multi-diameter, multi-outlet pipeline satisfying pressure outlet constraints. Samani and Mottaghi [21] employed branch and bound integer linear programming to solve the least cost design problem of one loading water distribution systems.

2.2 Multi-Objective Optimal Design of Water Networks

In reality the design problem (as almost any engineering problem) of a water distribution system involves competing objectives, such as minimizing cost, maximizing reliability, minimizing risks, and minimizing deviations from specific targets of quantity, pressure, and quality. The design problem is thus inherently of a multi-objective nature. In a multi-objective optimization problem there is not a single optimal solution but a set of compromised solutions, which form a Pareto optimal solution set. Thus, incorporating multiple objectives in the optimal design of water distribution systems provides a substantial improvement compared to using a single design objective, as a broader range of alternatives is explored, thus making the design outcome much more realistic.

Halhal et al. [31] were the first to introduce a multi-objective procedure to solve a water distribution systems management problem. Minimizing network cost versus maximizing the hydraulic benefit served as the two conflicting objectives, with the total hydraulic benefit evaluated as a weighted sum of pressures, maintenance cost, flexibility, and a measure of water quality benefits. A structured messy genetic algorithm was implemented to solve the optimization problem. Kapelan et al. [32] used a multi-objective genetic algorithm to find sampling locations for optimal calibration. The problem was formulated as a two-multi-objective optimization problem with the objectives been the maximization of the calibrated model accuracy versus the minimization of the total sampling design cost. The problem was solved using a Pareto ranking, niching, and a restricted mating multi-objective genetic algorithm. Karmeli et al. [33] applied a hybrid multi-objective evolutionary algorithm to the optimal design problem of a water distribution system. The hybrid approach employed a non-dominated sorting genetic algorithm coupled with a neighborhood search technique. Two objectives were considered: minimum cost versus minimum head shortage at the consumer nodes. Prasad and Park [34] applied a non-dominated sorting genetic algorithm for minimizing the network cost versus maximizing a reliability index. The reliability index used combined surplus consumer nodes pressure heads with loops having a minimum pipe diameter constraint. Prasad and Park [34] presented a multi-objective genetic algorithm approach to the optimal design of a water distribution network with minimizing the network cost versus maximizing the network resilience, where the network resilience is defined as a reliability surrogate measure taking into consideration excess pressure heads at the network nodes and loops with practicable pipe diameters. Farmani et al. [35] compared three evolutionary multi-objective optimization algorithms for water distribution system design through visualizing the resulted non-dominated fronts of each of the methods and by using two performance indicators. Vamvakeridou-Lyroudia et al. [36] employed a genetic algorithm multi-objective scheme to tradeoff the least cost to maximum benefits of a water distribution system design problem, with the benefits evaluated using fuzzy logic reasoning. Babayan et al. [37] used a multi-objective genetic algorithm to solve the design problem of a water distribution system under uncertainty. Two objectives were considered: minimum cost versus the probability of the network failure due to uncertainty in input variables. The first objective was evaluated by minimizing the total system cost, while the second by maximizing the nodal pressures above a minimum value. The stochastic problem which simulated the uncertainty of the system inputs was replaced with a deterministic numerical approach which quantified the uncertainties.

3 Reliability Incorporation in Water Supply Systems Design

Reliability considerations are an integral part of all decisions regarding the planning, design, and operation phases of water distribution systems. Quantitatively, the reliability of a water distribution system can be defined as the complement of the probability that the system will fail, where a failure is defined as the system’s inability to supply its consumers’ demands.

A major problem, however, in reliability analysis of water distribution systems is to define reliability measures which are meaningful and appropriate, while still computationally feasible. While the question, “Is the system reliable?”, is usually understood and easy to follow, the question, “Is it reliable enough?”, does not have a straightforward response, as it requires both the quantification and evaluation of reliability measures. Much effort has already been invested in reliability analysis of water supplies. These examinations, however, still commonly follow heuristic guidelines like ensuring two alternative paths to each demand node from at least one source, or having all pipe diameters greater than a minimum prescribed value. By using these guidelines, it is implicitly assumed that reliability is assured, but the level of reliability provided is not quantified or measured.

Reliability of water distribution systems gained considerable research attention over the last three decades. Research has concentrated on methodologies for reliability assessment and for reliability inclusion in least cost design and operation of water supply systems. A summary of these two major efforts is provided below.

3.1 Reliability Evaluation Models

Shamir and Howard [38] were the first to propose analytical methods for water supply system reliability. Their methodology took into consideration flow capacity, water main breaks, and maintenance for quantifying the probabilities of annual shortages in water delivery volumes.

Vogel [39] suggested the average return period of a reservoir system failure as a reliability index for water supply. A Markov failure model was utilized to compute the index, which defined failure as a year in which the yield could not be delivered. Wagner et al. [40] proposed analytical methods for computing the reachability (i.e., the case in which a given demand node is connected to at least one source) and connectivity (i.e., the case in which every demand node is connected to at least one source) as topological measures for water distribution systems reliability. Wagner et al. [41] complemented [40] through stochastic simulation in which the system was modeled as a network whose components were subject to failure with given probability distributions.

Reliability measures such as the probability of shortfall (i.e., total unmet demand), the probability of the number of failure events in a simulation period, and the probability of inter-failure times and repair durations were used as reliability criteria. Bao and Mays [42] suggested stochastic simulation by imposing uncertainty in future water demands for computing the probability that the water distribution system will meet these needs at minimum pressures. Duan and Mays [43] used a continuous-time Markov process for reliability assessment of water supply pumping stations. They took into consideration both mechanical and hydraulic failure (i.e., capacity shortages) scenarios, all cast in a conditional probability frequency and duration analysis framework. Jacobs and Goulter [44] used historical pipe failure data to derive the probabilities that a particular number of simultaneous pipe failures will cause the entire system to fail.

Quimpo and Shamsi [45] employed connectivity analysis strategies for prioritizing maintenance decisions. Bouchart and Goulter [46] developed a model for optimal valve locations to minimize the consequences of pipe failure events, recognizing that in reality, when a pipe fails, more customers are isolated than those situated at the pipe’s two ends. Jowitt and Xu [47] proposed a micro-flow simplified distribution model to estimate the hydraulic impact of pipe failure scenarios. Fujiwara and Ganesharajah [48] explored the reliability of a water treatment plant, ground-level storage, a pumping station, and a distribution network in a series, using the expected served demand as the reliability measure. Vogel and Bolognese [49] developed a two-state Markov model for describing the overall behavior of water supply systems dominated by carry-over storage. The model quantifies the trade-offs among reservoir system storage, yield, reliability, and resilience. Schneiter et al. [50] explored the system capacity reliability (i.e., the probability that the system’s carrying capacity is able to meet flow demands) for enhancing maintenance and rehabilitation decision making.

Yang et al. [51] employed the minimum cut-set method for investigating the impact of link failures on source-demand connectivity. Yang et al. [52] complemented the reliability connectivity model of [51] with Monte Carlo simulations for pipe failure impact assessments on a consumer’s shortfalls. Xu and Goulter [53] developed a two stage methodology for reliability assessment of water distribution systems using a linearized hydraulic model coupled with probability distributions of nodal demands, pipe roughnesses, and reservoir/tank levels. Fujiwara and Li [54] suggested a goal programming model for flow redistribution during failure events for meeting customers’ equity objectives. Tanyimboh et al. [55] used pressure-driven simulation to compute the reliability of single-source networks under random link failures. Ostfeld et al. [56] applied stochastic simulation to quantify the reliability of multi-quality water distribution systems, using the fraction of delivered volume, demand, and quality as reliability measures.

Shinstine et al. [57] coupled a cut-set method with a hydraulic steady state simulation model to quantify the reliability of two large-scale municipal water distribution networks. Ostfeld [58] classified existing reliability analysis methodologies and compared two extreme approaches for system reliability assessment: “lumped supply-lumped demand” versus stochastic simulation. Tolson et al. [59] used the same approach as [60] for optimizing the design of water distribution systems with capacity reliability constraints by linking a genetic algorithm (GA) with the first-order reliability method (FORM). Ostfeld [61] complemented the study of [4] by designing a methodology for finding the most flexible pair of operational and backup subsystems as inputs for the design of optimal reliable networks. Recently, [62] utilized first order reliability methods in conjunction with an adaptive response surface approach for analyzing the reliability of water distribution systems; and [63] compared the surrogate measures of statistical entropy, network resilience, resilience index, and the modified resilience index for quantifying the reliability of water networks.

3.2 Reliability Inclusion in Optimal Design and Operation of Water Supply Systems

Su et al. [64] were the first to incorporate reliability into least cost design of water distribution systems. Their model established a link between a steady state one loading hydraulic simulation, a reliability model based on the minimum cut-set method [65], and the general reduced gradient GRG2 [23] for system optimization. Ormsbee and Kessler [66] used a graph theory methodology for optimal reliable least cost design of water distribution systems for creating a one level system redundancy (i.e., a system design that guarantees a predefined level of service in case one of its components is out of service). Khang and Fujiwara [67] incorporated minimum pipe diameter reliability constraints into the least cost design problem of water distribution systems, showing that at most two pipe diameters can be selected for a single link. Park and Liebman [68] incorporated into the least cost design problem of water distribution systems the expected shortage of supply due to failure of individual pipes. Ostfeld and Shamir [4] used backups (i.e., subsystems of the full system that maintain a predefined level of service in case of failure scenarios) for reliable optimal design of multi-quality water distribution systems. Xu and Goulter [60] coupled the first-order reliability method (FORM), which estimates capacity reliability, with GRG2 [23] to optimize the design of water distribution systems. Ostfeld [69] developed a reliability assessment model for regional water supply systems, comprised of storage-conveyance analysis in conjunction with stochastic simulation. Afshar [70] presented a heuristic method for the simultaneous layout and sizing of water distribution systems using the number of independent paths from source nodes to consumers as the reliability criterion. Farmani et al. [71] applied for Anytown USA [72], a multi-objective evolutionary algorithm for trading off cost and the resilience index [73] as a reliability surrogate. Dandy and Engelhardt [74] used a multi-objective genetic algorithm to generate trade-off curves between cost and reliability for pipe replacement decisions. Agrawal [75] presented a heuristic iterative methodology for creating the trade-off curve between cost and reliability (measured as a one level system redundancy) through strengthening and expanding the pipe network. Reca et al. [76] compared different metaheuristic methodologies for trading off cost and reliability, quantified as the resilience index [73]. van Zyl et al. [77] incorporated reliability criteria for tank sizing. Duan et al. [78] explored the impact of system data uncertainties, such as pipe diameter and friction on the reliability of water networks under transient conditions. Ciaponi et al. [79] introduced a simplified procedure based on the unavailability of pipes for comparing design solutions with reliability considerations.

4 Optimal Operation of Water Networks

Subsequent to the well known least cost design problem of water distribution systems [1, 80, 81], optimal operation is the most explored topic in water distribution systems management. Since 1970 a variety of methods were developed to address this problem, including the utilizations of dynamic programming, linear programming, predictive control, mixed-integer, non-linear programming, metamodeling, heuristics, and evolutionary computation. Ormsbee and Lansey [82] classified to that time optimal water distribution systems control models through systems type, hydraulics, and solution methods. This section reviews the current literature on this subject.

4.1 Dynamic Programming

Dreizin [83] was the first to suggest an optimization model for water distribution systems operation through a dynamic programming (DP) scheme coupled with hydraulic simulations for optimizing pumps scheduling of a regional water supply system supplied by three pumping units. Sterling and Coulbeck [84] used a dynamic modeling approach to minimize the costs of pumps operation of a simple water supply system. Carpentier and Cohen [85] developed a decomposition-coordination methodology for partitioning a water supply system into small sub-systems which could be solved separately (i.e., decomposed) using dynamic programming, and then merged (i.e., coordinated) at the final solution. Houghtalen and Loftis [86] suggested aggregating training simulations with human operational knowledge and dynamic programming to minimize operational costs. Ormsbee et al. [87] developed a coupled dynamic programming and enumeration scheme for a single pressure zone in which the optimal tank trajectory is found using dynamic programming and the pumps scheduling using enumeration. Zessler and Shamir [88] used an iterative dynamic programming method to find the optimal scheduling of pumps of a regional water supply system. Lansey and Awumah [89] used a two level approach in which the hydraulics and cost functions of the system are generated first off-line followed by a dynamic programming model for pumps scheduling. Nitivattananon et al. [90] utilized heuristic rules combined with progressive optimality to solve a dynamic programming model for optimal pumps scheduling. McCormick and Powell [91] utilized a stochastic dynamic program framework for optimal pumps scheduling where daily demand for water are modeled as a Markov process.

4.2 Linear Programming

Olshansky and Gal [92] developed a two level linear programming methodology in which the distribution system is partitioned into sub-systems for which hydraulic simulations are run and serve further as parameters in an LP model for pumps optimal scheduling. This approach was used also by [93] who developed a linear programming model to optimize pumps scheduling in which the LP parameters are set through off-line extended period hydraulic simulation runs. Diba et al. [94] used graph-theory coupled with a linear programming scheme for optimizing the operation and planning of a water distribution system including reliability constraints.

4.3 Predictive Control

Coulbeck and Coulbeck et al. [95–97] suggested hierarchical control optimization frameworks for the optimal operation of pumps. Biscos et al. [98] used a predictive control framework coupled with mixed integer non-linear programming (MINLP) for minimizing the costs of pump operation. Biscos et al. [99] extended [98] to include the minimization of chlorine dosage.

4.4 Mixed-Integer

Ulanicki et al. [100] developed a mixed-integer model for tracking the optimal reservoirs trajectories based on the results of an initially relaxed continuous problem. Pulido-Calvo and Gutiérrez-Estrada [101] presented a model for both sizing storage and optimizing pumps operation utilizing a framework based on a mixed integer non-linear programming (MINLP) algorithm and a data driven (neural networks) scheme.

4.5 Non-Linear Programming

Chase [102] used an optimization-simulation framework coupling the general reduced gradient GRG2 [23] with a water distribution system simulation model WADISO [103] for minimizing pumps cost operation. Brion and Mays [104] developed an optimal control simulation-optimization framework for minimizing pumps operation costs in which the simulation solves the hydraulic equations and the optimization utilizes the non-linear augmented Lagrangian method [105]. Pezeshk et al. [106] linked hydraulic simulations with non-linear optimization to minimize the operation costs of a water distribution network. Cohen et al. [107–109] presented three companion papers on optimal operation of water distribution systems using non-linear programming: with water quality considerations only [107], with flow inclusion [108], and with both flow and quality [109].

4.6 Metamodeling

Broad et al. [110] used an artificial neural network (ANN) as a metamodel for optimizing the operation of a water distribution system under residual chlorine constraints. Shamir and Salomons [111] developed a framework for real-time optimal operation integrating an aggregated/reduced model, an artificial neural network, and a genetic algorithm. Broad et al. [112] extended [110] through comparing four different metamodelling scenarios and suggesting skeletonization procedures.

4.7 Heuristics

Tarquin and Dowdy [113] used heuristic analysis of pump and system head curves to identify pump combinations which reduce operation costs. Pezeshk and Helweg [114] introduced a heuristic discrete adaptive search algorithm for optimal pumps scheduling based on pressure readings at selected network nodes. Ormsbee and Reddy [115] linked a minimum-cost-constraint identification methodology with nonlinear heuristics for optimal pumps scheduling.

4.8 Evolutionary Computation

Sakarya and Mays [116] presented a simulating annealing [117] scheme for optimizing the operation of a water distribution system with water quality constraints. Cui and Kuczera [118] used a genetic algorithm (GA) [25, 119] and the shuffled complex evolution (SCE) method [120] to optimize urban water supply headworks. Ostfeld and Salomons [121, 122] minimized the total cost of pumping and water quality treatment of a water distribution system through linking a genetic algorithm with EPANET (www.epa.gov/nrmrl/wswrd/dw/epanet.html). van Zyl et al. [123] utilized a genetic algorithm (GA) linked to a hillclimber search algorithm for improving the local GA search once closed to an optimal solution. López-Ibáñez et al. [124] proposed an ant colony optimization (ACO) [125] framework for optimal pumps scheduling. Boulos et al. [126] developed the H2ONET tool based on genetic algorithms for scheduling pump operation to minimize operation costs.

4.9 Commercial Modeling Tool

Commercial applications for energy minimization have been developed by companies such as Derceto (http://www.derceto.com/), Bentley (http://www.bentley.com/en-US/Solutions/Water+and+Wastewater/), MWH Soft (http://www.mwhglobal.com/) and others. These applications allow system design, optimal pump scheduling and system operation while minimizing system operation cost and optimizing water supply.

5 Water Quality Analysis Inclusion in Distribution Systems

Research in modeling water quality in distribution systems started in the context of agricultural usage (e.g., [127, 128]) primarily in arid regions where good water quality is limited. In 1990 the United States Environmental Protection Agency (USEPA) promulgated rules requiring that water quality standards must be satisfied at the consumer taps rather than at treatment plants. This initiated the need for water quality modeling, the development of the USEPA simulation water quantity and quality model EPANET (EPANET 2.0@2000, [129]), and raised other problems and research needs that commenced considerable research in this area to assist utilities.

Shamir and Howard [130] were the first to classify water quality models for water distribution systems. Their classification was based upon the flow conditions in the network and the contaminant concentrations in the sources: (1) steady flow—steady concentration. This occurs in agriculture or industry; flows are rarely steady in municipal water distribution systems, (2) steady flow—unsteady concentration. This appears when a pulse of contamination is distributed within the distribution system under steady flow conditions, (3) unsteady flow—steady concentration. Contaminant concentrations in the sources remain constant while the flow regime is unsteady, and (4) unsteady flow—unsteady concentration. This occurs when a pulse of contamination enters the system under unsteady flow conditions.

The above classifications set the boundary conditions for the analysis of flow and water quality in water distribution systems. These involve four major categories: simulation, optimization, chlorine control, and monitoring. This section hereafter concentrates on the optimization of multi-quality water networks.

Optimization models of water distribution systems can be classified according to their consideration of time and of the physical laws which are included explicitly [131, 132]. In time the distinction is between policy and real time models. Policy models are run off - line, in advance, and generate the operating plans for several typical and/or critical operating conditions. Real time (on-line) models are run continuously in real time, and generate an operating plan for the immediate coming period. The classification with respect to the physical laws which are considered explicitly as constraints, is: (1) QH (discharge—head) models: quality is not considered, and the network is described only by its hydraulic behavior; (2) QC (discharge—quality) models: the physics of the system are included only as continuity of water and of pollutant mass at nodes. Quality is described essentially as a transportation problem in which pollutants are carried in the pipes, and mass conservation is maintained at nodes. Such a model can account for decay of pollutants within the pipes and even chemical reactions, but does not satisfy the continuity of energy law (i.e., Kirchoff’s Law no. 2), and thus there is no guarantee of hydraulic feasibility and of maintaining head constraints at nodes; and (3) QCH (discharge—quality—head) models: quality constraints, and the hydraulic laws, which govern the system behavior, are all considered. The QH and QC problems are relatively easier to solve than the full QCH.

Ostfeld and Shamir [131] developed a QCH policy model for optimal operation of undirected multi-quality water distribution systems under steady state conditions, which has been extended to the unsteady case in [132]. To overcome the non-smoothness problems, an approximation of the quality equations has been used, following [133]. In the unsteady case, instead of dividing each pipe into segments and tracking the movement of the quality fronts, a single approximated equation was developed, representing the average concentration of the water quality fronts in the pipes for a specific time increment. Both the steady and unsteady models were solved with GAMS [134]/MINOS [22], an on-shelf non-linear optimization package.

Ostfeld and Shamir [4] developed a QCH methodology which integrates optimal design and reliability of a multi-quality water distribution system in a single framework. The system designed is able to sustain prescribed failure scenarios, such as any single random component failure, and still maintain a desired level of service in terms of the quantities, qualities, and pressures supplied to the consumers. In formulating and solving the model, decomposition was used. The decomposition results in an “outer” non-smooth problem in the domain of the circular flows, and an “inner” convex quadratic problem. The method of solution included the use of a non-smooth optimization technique for minimizing the “outer” problem [135], for which a member of the sub-gradient group was calculated in each iteration. The method allowed reversal of flows in pipes, relative to the direction initially assigned. The methodology was applied to Anytown USA [72] for a single loading condition, and one quality constituent. Cohen et al. [109] solved the steady state operation model of an undirected multi-quality water distribution system by decomposing the QCH problem into the QH and QC sub—problems for given water flows in the distribution system, and removal ratios at the treatment plants. The QC and QH models are solved first. The combination of their solutions serves for solving the QCH. The model has been applied to the Central Arava Network in southern Israel, which consists of 38 nodes, 39 pipes, 11 sources and 7 treatment plants.

Goldman [136] developed a simulated annealing shell linked to EPANET for solving the scheduling pumping problem of a water distribution system with water quality constraints at the consumer nodes. Sakarya and Mays [116] solved the same problem by linking the GRG2 nonlinear code [23] with EPANET. In both models, treatment facilities, valves, and varying electrical energy tariffs throughout the simulation were not considered. In addition, the unsteady water quality constraints were applied only to the last operational time period, while in reality the problem of supplying adequate water quality to consumers is a continuous operational time dependent problem.

Ostfeld et al. [56] developed a QCH application of stochastic simulation for the reliability assessment of single and multi-quality water distribution systems. The stochastic simulation framework was cast in a program entitled RAP (Reliability Analysis Program), linking Monte Carlo replications with EPANET simulations. Three reliability measures were evaluated: the Fraction of Delivered Volume (FDV), the Fraction of Delivered Demand (FDD), and the Fraction of Delivered Quality (FDQ). Ostfeld and Salomons [121, 122] developed a genetic algorithm scheme tailored-made to EPANET, for optimizing the operation of a water distribution system under unsteady water quality conditions. The water distribution system consists of sources of different qualities, treatment facilities, tanks, pipes, control valves, and pumping stations. The objective is to minimize the total cost of pumping and treating the water for a selected operational time horizon, while delivering the consumers the required quantities, at acceptable qualities and pressures. The decision variables, for each of the time steps that encompass the total operational time horizon, included the scheduling of the pumping units, settings of the control valves, and treatment removal ratios at the treatment facilities. The constraints were domain heads and concentrations at the consumer nodes, maximum removal ratios at the treatment facilities, maximum allowable amounts of water withdraws at the sources, and returning at the end of the operational time horizon to a prescribed total volume in the tanks.

6 Water Networks Security Related Topics

Threats on a water distribution system can be partitioned into three major groups according to their resulted enhanced security: (1) a direct attack on the main infrastructure: dams, treatment plants, storage reservoirs, pipelines, etc.; (2) a cyber attack disabling the functionality of the water Supervisory Control and Data Acquisition (SCADA) system, taking over control of key components which might result water outages or insufficiently treated water, changing or overriding protocol codes, etc.; and (3) a deliberate chemical or biological contaminant injection at one of the system’s nodes.

The threat of a direct attack can be minimized by improving the system’s physical security (e.g., additional alarms, locks, fencing, surveillance cameras, guarding, etc.), while a cyber attack by implementing computerized hardware and software (e.g., an optical isolator between communication networks, routers to restrict data transfer, etc.).

Of the above threats, a deliberate chemical or biological contaminant injection is the most difficult to address. This is because of the uncertainty of the type of the injected contaminant and its effects, and the uncertainty of the location and injection time. Principally a contaminant can be injected at any water distribution system connection (node) using a pump or a mobile pressurized tank. Although backflow preventers provide an obstacle, they do not exist at all connections, and at some might not be functional.

The main course to enhance the security of a water distribution system against a deliberated contamination intrusion is through placing a sensor system (ASCE [137]; AWWA [138]).

In recent years there has been growing interest in the development of sensor systems with the majority of models using a single objective approach. The employment of multiobjective optimization for sensor placement started recently. This section reviews some models for sensor placement using the two approaches.

6.1 Single Objective Sensor Placement Models

Lee and Deininger [139] were the first to address the problem of sensor placement by maximizing the coverage of the demands using an integer programming model. Kumar et al. [140] improved the study of [139] by applying a greedy heuristic-based algorithm. Kessler et al. [141] suggested a set covering graph theory algorithm for the layout of sensors. Woo et al. [142] developed a sensor location design model by linking EPANET with an integer programming scheme. Al-Zahrani and Moeid [143] followed Lee and Deininger’s approach using a genetic algorithm scheme [25, 119]. Ostfeld and Salomons [121, 122] extended [141, 144] to multiple demand loading and unsteady water quality propagations. Ostfeld and Salomons [145] extended [121, 122] by introducing uncertainties to the demands and the injected contamination events. Berry et al. [146] presented a mixed-integer programming (MIP) formulation for sensor placement showing that the MIP formulation is mathematically equivalent to the p-median facility location problem. Propato [147] introduced a mixed-integer linear programming model to identify sensor location for early warning, with the ability to accommodate different design objectives.

6.2 Multiobjective Sensor Placement Models

Watson et al. [148] were the first to introduce a multiobjective formulation to sensor placement by employing a mixed-integer linear programming model over a range of design objectives. The Battle of the Water Sensors [149] highlighted the multiobjective nature of sensor placement: [150] developed a constrained multiobjective optimization framework entitled the Noisy Cross-Entropy Sensor Locator (nCESL) algorithm based on the Cross Entropy methodology proposed by [151, 152] proposed a multiobjective solution using an “Iterative Deepening of Pareto Solutions” algorithm; [153] suggested a predator-prey model applied to multiobjective optimization, based on an evolution process; [154] proposed a multiobjective genetic algorithm framework coupled with data mining; [155, 156] used the multiobjective Non-Dominated Sorted Genetic Algorithm–II (NSGA-II) [157] scheme; [158] used a multiobjective optimization formulation, which was solved using a genetic algorithm, with the contamination events randomly generated using a Monte Carlo procedure.

7 A Look into the Future

Traditionally, water distribution networks were designed, operated, and maintained through utilizing offline small discrete datasets. Those were the governing and limiting constraints imposed on modeling challenges and capabilities. This situation is dramatically changing: from a distinct framework of data collection to a continuous transparent structure. With multiple types of sensor data at multiple scales, from embedded real-time hydraulic and water quality sensors to airborne and satellite-based remote sensing, how can those be efficiently integrated into new tools for decision support for water distribution networks is a major challenge.

This new reality is expected to limit all current modeling efforts capabilities and require new thinking on approaches for managing water distribution networks: from a state of lack of data to a situation of overflowing information. New tools for data screening, algorithms and metamodeling constructions, as well as computational efficiency are anticipated to govern all future developments for water distribution networks analysis.

References

Alperovits, E., Shamir, U.: Design of optimal water distribution systems. Water Resour. Res. 13(6), 885–900 (1977)

Eiger, G., Shamir, U., Ben-Tal, A.: Optimal design of water distribution networks. Water Resour. Res. 30(9), 2637–2646 (1994)

Kessler, A., Shamir, U.: Analysis of the linear programming gradient method for optimal design of water supply networks. Water Resour. Res. 25(7), 1469–1480 (1989)

Ostfeld, A., Shamir, U.: Design of optimal reliable multiquality water supply systems. J. Water Resour. Planning Manage. Div. ASCE 122(5), 322–333 (1996)

Quindry, G.E., Brill, E.D., Liebman, J.C., Robinson, A.R.: Comment on “Design of optimal water distribution systems” by Alperovits E. and Shamir U. Water Resour. Res. 15(6), 1651–1654 (1979)

Quindry, G.E., Brill, E.D., Liebman, J.C.: Optimization of looped water distribution systems. J. Environ. Eng. ASCE 107(EE4), 665–679 (1981)

Lansey, K.E., Mays, L.W.: Optimization models for design of water distribution systems. In: Reliability Analysis of Water Distribution Systems, Mays L. W. Ed., pp. 37–84 (1989)

Ormsbee, L.E., Contractor, D.N.: Optimization of hydraulic networks. In: Proceedings, International Symposium on Urban Hydrology, Hydraulics, and Sediment Control, pp. 255–261. Kentucky, Lexington KY (1981)

Taher, S.A., Labadie, J.W.: Optimal design of water-distribution networks with GIS. J. Water Resour. Planning Manage. Div. ASCE 122(4), 301–311 (1996)

Shamir, U.: Optimal design and operation of water distribution systems. Water Resour. Res. 10(1), 27–36 (1974)

Watanatada, T.: Least-cost design of water distribution systems. J. Hydraul. Div. ASCE 99(HY9), 1497–1513 (1973)

Salomons, E.: Optimal design of water distribution systems facilities and operation. MS Thesis, Technion, Haifa, Israel (In Hebrew) (2001)

Savic, D., Walters, G.: Genetic algorithms for least cost design of water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 123(2), 67–77 (1997)

Simpson, A.R., Dandy, G.C., Murphy, L.J.: Genetic algorithms compared to other techniques for pipe optimization. J. Water Resour. Planning Manage. Div. ASCE 120(4), 423–443 (1994)

Vairavamoorthy, K., Ali, M.: Pipe index vector: a method to improve genetic-algorithm-based pipe optimization. J. Hydraul. Eng. ASCE 131(12), 1117–1125 (2005)

Wu, Z.Y., Walski, T.: Self-adaptive penalty approach compared with other constraint-handling techniques for pipeline optimization. J. Water Resour. Planning Manage. Div. ASCE 131(3), 181–192 (2005)

Loganathan, G.V., Greene, J.J., Ahn, T.J.: Design heuristic for globally minimum cost water-distribution systems. J. Water Resour. Planning Manage. Div. ASCE 121(2), 182–192 (1995)

Eusuff, M.M., Lansey, K.E.: Optimization of water distribution network design using the shuffled frog leaping algorithm. J. Water Resour. Planning Manage. Div. ASCE 129(3), 210–225 (2003)

Maier, H.R., Simpson, A.R., Zecchin, A.C., Foong, W.K., Phang, K.Y., Seah, H.Y., Tan, C.L.: Ant colony optimization for design of water distribution systems. J. Water Resour. Planning Manage. Div. ASCE 129(3), 200–209 (2003)

Singh, R.P., Mahar, P.S.: Optimal design of multidiameter, multioutlet pipelines. J. Water Resour. Planning Manage. Div. ASCE 129(3), 226–233 (2003)

Samani, M.V., Mottaghi, A.: Optimization of water distribution networks using integer linear programming. J. Hydraul. Eng. ASCE 132(5), 501–509 (2006)

Murtagh, B.A., Saunders, M.A.: A projected lagrangian algorithm and its implementation for sparse nonlinear constraints. Math. Program. Study 16, 84–117 (1982)

Lasdon, L.S., Waren, A.D.: GRG2 user’s guide. University of Texas, USA (1986). 50p

Abadie, J.: Application of the GRG method to optimal control problems. In: Abadie, J. (ed.) Integer and Nonlinear Programming, pp. 191–211. North Holland Publishing, Amsterdam (1970)

Holland, J.H.: Adaptation in natural and artificial systems. The University of Michigan Press, Ann Arbor, Ann Arbor (1975)

Gessler, J.: Pipe network optimization by enumeration. In: Proceedings Computer Applications for Water Resources, pp. 572–581. ASCE, New York, N. Y. (1985)

Fujiwara, O., Khang, D.B.: A two-phase decomposition method for optimal design of looped water distribution networks. Water Resour. Res. 26(4), 539–549 (1990)

Schaake, J.C., Lai, D.: Linear programming and dynamic programming application to water distribution network design. Report No. 116, Department of Civil Engineering, Massachusetts Institute of Technology, Cambridge, Massachusetts (1969)

Dorigo, M., Maniezzo, V., Colorni, A.: Ant system: optimization by a colony of cooperating agents. IEEE Trans. Syst. Man Cybern. Part B 26(1), 29–41 (1996)

Stützle, T., Hoos, H.H.: MAX–MIN ant system. Future Gener. Comput. Syst. 16, 889–914 (2000)

Halhal, D., Walters, G.A., Savic, D.A., Ouazar, D.: Scheduling of water distribution system rehabilitation using structured messy genetic algorithms. Evol. Comput. 7(3), 311–329 (1999)

Kapelan, Z.S., Savic, D.A., Walters, G.A.: Multi-objective sampling design for water distribution model calibration. J. Water Resour. Planning Manage. Div. ASCE 129(6), 466–479 (2003)

Keedwell, E.C., Khu, S.T.: More choices in water distribution system optimization. In: Advances in Water Supply Management, Proceedings of Computers and Control in the Water Industry, pp. 257–265. London (2003)

Prasad, T.D., Park, N.-S.: Multi-objective genetic algorithms for design of water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 130(1), 73–82 (2004)

Farmani, R., Savic, D.A., Walters, G.A.: Evolutionary multi-objective optimization in water distribution network design. Eng. Optim. 37(2), 167–183 (2005)

Vamvakeridou-Lyroudia, L.S., Walters, G.A., Savic, D.A.: Fuzzy multi-objective optimization of water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 131(6), 467–476 (2005)

Babayan, A., Savic, D.A., Walters, G.A.: Multi-objective optimization for the least-cost design of water distribution systems under correlated uncertain parameters. In: Proceedings of the EWRI/ASCE World Water and Environmental Resources Congress, Anchorage, Alaska, published on CD (2005)

Shamir, U., Howard, C.D.: Water supply reliability theory. J. Am. Water Works Assoc. 37(7), 379–384 (1981)

Vogel, R.M.: Reliability indices for water supply systems. J. Water Resour. Planning Manage. Div. ASCE 113(4), 563–579 (1987)

Wagner, J.M., Shamir, U., Marks, D.H.: Water distribution reliability: analytical methods. J. Water Resour. Planning Manage. Div. ASCE 114(3), 253–275 (1988)

Wagner, J.M., Shamir, U., Marks, D.H.: Water distribution reliability: simulation methods. J. Water Resour. Planning Manage. Div. ASCE 114(3), 276–294 (1988)

Bao, Y., Mays, L.W.: Model for water distribution system reliability. J. Hydraul. Eng. 116(9), 1119–1137 (1990)

Duan, N., Mays, L.W.: Reliability analysis of pumping systems. J. Hydraul. Eng. 116(2), 230–248 (1990)

Jacobs, P., Goulter, I.: Estimation of maximum cut-set size for water network failure. J. Water Resour. Planning Manage. Div. ASCE 117(5), 588–605 (1991)

Quimpo, R.G., Shamsi, U.M.: Reliability-based distribution system maintenance. J. Water Resour. Planning Manage. Div. ASCE 117(3), 321–339 (1991)

Bouchart, F., Goulter, I.: Reliability improvements in design of water distribution networks recognizing valve location. Water Resour. Res. 27(12), 3029–3040 (1991)

Jowitt, P.W., Xu, C.: Predicting pipe failure effects in water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 119(1), 18–31 (1993)

Fujiwara, O., Ganesharajah, T.: Reliability assessment of water supply systems with storage and distribution networks. Water Resour. Res. 29(8), 2917–2924 (1993)

Vogel, R., Bolognese, R.: Storage—reliability—resilience—yield relations for over—year water supply systems. Water Resour. Res. 31(3), 645–654 (1995)

Schneiter, C.R., Haimes, Y.Y., Li, D., Lambert J.H.: Capacity reliability of water distribution networks and optimum rehabilitation decision making. Water Resour. Res. 32(7):2271–2278 (1996)

Yang, S.-I., Hsu, N.-S., Louie, P.W.F., Yeh, W.-G.Y.: Water distribution network reliability: connectivity analysis. J. Infrastruct. Syst. 2(2), 54–64 (1996)

Yang, S.-I., Hsu, N.-S., Louie, P.W.F., Yeh, W.-G.Y.: Water distribution network reliability: stochastic simulation. J. Infrastruct. Syst. 2(2), 65–72 (1996)

Xu, C., Goulter, I.C.: Probabilistic model for water distribution reliability. J. Water Resour. Planning Manage. Div. ASCE 124(4), 218–228 (1998)

Fujiwara, O., Li, J.: Reliability analysis of water distribution networks in consideration of equity, redistribution, and pressure—dependent demand. Water Resour. Res. 34(7), 1843–1850 (1998)

Tanyimboh, T.T., Tabesh, M., Burrows, R.: Appraisal of source head methods for calculating reliability of water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 127(4), 206–213 (2001)

Ostfeld, A., Kogan, D., Shamir, U.: Reliability simulation of water distribution systems—single and multiquality. Urban Water, Elsevier Sci. 4(1), 53–61 (2002)

Shinstine, D.S., Ahmed, I., Lansey, K.E.: Reliability/availability analysis of municipal water distribution networks: case studies. J. Water Resour. Planning Manage. Div. ASCE 128(2), 140–151 (2002)

Ostfeld, A.: Reliability analysis of water distribution systems. J. Hydroinformatics 6(4), 281–294 (2004)

Tolson, B.A., Maier, H.R., Simpson, A.R., Lence, B.J.: Genetic algorithms for reliability—based optimization of water distribution systems. J. Water Resour. Planning Manage. Div. ASCE 130(1), 63–72 (2004)

Xu, C., Goulter, I.C.: Reliability-based optimal design of water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 125(6), 352–362 (1999)

Ostfeld, A.: Water distribution systems connectivity analysis. J. Water Resour. Planning Manage. Div. ASCE 131(1), 58–66 (2005)

Torii, A.J., Lopez, R.H.: Reliability analysis of water distribution networks using the adaptive response surface approach. J. Hydraul. Eng. (2011), posted ahead of print. doi:10.1061/(ASCE)HY.1943-7900.0000504

Tanyimboh, T.T., Tietavainen, M.T., Saleh, S.: Reliability assessment of water distribution systems with statistical entropy and other surrogate measures. Water Sci.Technol. Water Supply 11(4), 437–443 (2011)

Su, Y.C., Mays, L.W., Duan, N., Lansey, K.E.: Reliability-based optimization model for water distribution systems. J. Hydraul. Eng. 114(12), 1539–1556 (1987)

Tung, Y.K.: Evaluation of water distribution network reliability. In: Hydraulics and Hydrology in the Small Computer Age, Proceedings of the Specialty Conference, American Society of Civil Engineers Hydraulics Division, vol. 1, pp. 1–6. Orlando, FL (1985)

Ormsbee, L., Kessler, A.: Optimal upgrading of hydraulic-network reliability. J. Water Resour. Planning Manage. Div. ASCE 116(6), 784–802 (1990)

Khang, D., Fujiwara, O.: Optimal adjacent pipe diameters in water distribution networks with reliability constraints. Water Resour. Res. 28(6), 1503–1505 (1992)

Park, H., Liebman, J.C.: Redundancy-constrained minimum-cost design of water-distribution nets. J. Water Resour. Planning Manage. Div. ASCE 119(1), 83–98 (1993)

Ostfeld, A.: Reliability analysis of regional water distribution systems. Urban Water 3, 253–260 (2001)

Afshar, M.H., Akbari, M., Mariño, M.A.: Simultaneous layout and size optimization of water distribution networks: engineering approach. J. Infrastruct. Syst. 11(4), 221–230 (2005)

Farmani, R., Walters, G.A., Savic, D.A.: Trade—off between total cost and reliability for Anytown water distribution network. J. Water Resour. Planning Manage. Div. ASCE 131(3), 161–171 (2005)

Walski, T.M., Brill, D., Gessler, J., Goulter, I.C., Jeppson, R.M., Lansey, K.E., Lee, H.L., Liebman, J.C., Mays, L., Morgan, D.R., Ormsbee, L.: Battle of the network models: epilogue. J. Water Resour. Planning Manage. Div. ASCE 113(2), 191–203 (1987)

Todini, E.: Looped water distribution networks design using a resilience index based heuristic approach. Urban Water 2(3), 115–122 (2000)

Dandy, G.C., Engelhardt, M.O.: Multi—objective trade—offs between cost and reliability in the replacement of water mains. J. Water Resour. Planning Manage. Div. ASCE 132(2), 79–88 (2006)

Agrawal, M.L., Gupta, R., Bhave, P.R.: Reliability—based strengthening and expansion of water distribution networks. J. Water Resour. Planning Manage Div. ASCE 133(6), 531–541 (2007)

Reca, J., Martínez, J., Baños, R., Gil, C.: Optimal design of gravity - fed looped water distribution networks considering the resilience index. J. Water Resour. Planning Manage. Div. ASCE 134(3), 234–238 (2008)

van Zyl, J.E., Piller, O., Gat, Y.: Sizing municipal storage tanks based on reliability criteria. J. Water Resour. Planning Manage. Div. ASCE 134(6), 548–555 (2008)

Duan, H.-F., Tung, Y.-K., Ghidaoui, M.S.: Probabilistic analysis of transient design for water supply systems. J. Water Resour. Planning Manage. Div. ASCE (2010). doi:10.1061/(ASCE)WR.1943-5452.0000074

Ciaponi, C., Franchioli, L., Papiri, S.: A simplified procedure for water distribution networks reliability assessment. J. Water Resour. Planning Manage. Div. ASCE (2011), posted ahead of print. doi:10.1061/(ASCE)WR.1943-5452.0000184

Jacoby, S.: Design of optimal hydraulic networks. J. Hydraul. Div. ASCE 94(HY3), 641–661 (1968)

Karmeli, D., Gadish, Y., Meyers, S.: Design of optimal water distribution networks. J. Pipeline Div. ASCE 94(1), 1–9 (1968)

Ormsbee, L.E., Lansey, K.E.: Optimal control of water supply pumping systems. J. Water Resour. Planning Manage. Div. ASCE 120(2), 237–252 (1994)

Dreizin, Y.: Examination of possibilities of energy saving in regional water supply systems. M.Sc. Thesis, Technion—Israel Institute of Technology (1970), 85p

Sterling, M.J.H., Coulbeck, B.: A dynamic programming solution to optimization of pumping costs. Proc. Inst. Civil Eng. 59(4), 813–818 (1975)

Carpentier, P., Cohen, G.: Decomposition, coordination and aggregation in the optimal control of a large water supply network. In: Proceedings of IFAC World Congress, Budapest, Hungary, July. Proceedings of the 9th Triennial IFAC World Congress, Budapest, pp 3207–3212 (1984)

Houghtalen, R.J., Loftis, J.C.: Improving water delivery system operation using training simulators. J. Water Resour. Planning Manage. Div. ASCE 115(5), 616–629 (1989)

Ormsbee, L.E., Walski, T.M., Chase, D.V., Sharp, W.W.: Methodology for improving pump operation efficiency. J. Water Resour. Planning Manage. Div. ASCE 115(2), 148–164 (1989)

Zessler, U., Shamir, U.: Optimal operation of water distribution systems. J. Water Resour. Planning Manage. Div. ASCE 115(6), 735–752 (1989)

Lansey, K.E., Awumah, K.: Optimal pump operations considering pump switches. J. Water Resour. Planning Manage. Div. ASCE 120(1), 17–35 (1994)

Nitivattananon, V., Sadowski, E.C., Quimpo, R.G.: Optimization of water supply system operation. J. Water Resour. Planning Manage. Div. ASCE 122(5), 374–384 (1996)

McCormick, G., Powell, R.S.: Optimal pump scheduling in water supply systems with maximum demand charges. J. Water Resour. Planning Manage. Div. ASCE 129(5), 372–379 (2003)

Olshansky, M., Gal, S.: Optimal operation of a water distribution system.” IBM—Israel, Technical Report 88.239 (1988), 52p

Jowitt, P.W., Germanopoulos, G.: Optimal pump scheduling in water-supply networks. J. Water Resour. Planning Manage. Div. ASCE 118(4), 406–422 (1992)

Diba, A., Louie, P.W.F., Mahjoub, M., Yeh, W.W.-G.: Planned operation of large-scale water-distribution system. J. Water Resour. Planning Manage. Div. ASCE 121(3), 260–269 (1995)

Coulbeck, B.: Optimal operations in non-linear water networks. Optimal Control Appl. Methods 1(2), 131–141 (1980)

Coulbeck, B., Brdys, M., Orr, C.H., Rance, J.P.: A hierarchical approach to optimized control of water distribution systems: part I decomposition. Optimal Control Appl. Methods 9(1), 51–61 (1988)

Coulbeck, B., Brdys, M., Orr, C.H., Rance, J.P.: A Hierarchical approach to optimized control of water distribution systems: part II. Lower-level algorithm. Optimal Control Appl. Methods 9(2), 109–126 (1988)

Biscos, C., Mulholland, M., Le Lann, M.V., Brouckaert, C.J., Bailey, R., Roustan, M.: Optimal operation of a potable water distribution network. Water Sci. Technol. 46(9), 155–162 (2002)

Biscos, C., Mulholland, M., Le Lann, M.-V., Buckley, C.A., Brouckaert, C.J.: Optimal operation of water distribution networks by predictive control using MINLP. Water SA 29(4), 393–404 (2003)

Ulanicki, B., Kahler, J., See, H.: Dynamic optimization approach for solving an optimal scheduling problem in water distribution systems. J. Water Resour. Planning Manage. Div. ASCE 133(1), 23–32 (2007)

Pulido-Calvo, I., Gutiérrez-Estrada, J.C.: Selection and operation of pumping stations of water distribution systems. Environ. Res. J. 5(3), 1–20 (2011)

Chase, D.V.: A computer program for optimal control of water supply pump stations: development and testing. USACERL TECHNICAL REPORT N-90/14, US Army Corps of Engineers, Construction Engineering Research Laboratory (1990), 98p

Gessler, J., Walski, T.M.: Water distribution system optimization. Technical Report EL-85-11, U.S. Army Engineer Waterways Experiment Station, Vicksburg MS., NTIS No. AD A163 493 (1985)

Brion, L.M., Mays, L.W.: Methodology for optimal operation of pumping stations in water distribution systems. J. Hydraul. Eng. ASCE 117(11), 1551–1569 (1991)

Brion, L.M.: Methodology for optimal operation of pumping stations in water distribution systems. PhD thesis, University of Texas at Austin, Texas (1990)

Pezeshk, S., Helweg, O.J., Oliver, K.E.: Optimal operation of ground-water supply distribution systems. J. Water Resour. Planning Manage. Div. ASCE 120(5), 573–586 (1994)

Cohen, D., Shamir, U., Sinai, G.: Optimal operation of multi-quality networks-I: introduction and the Q-C model. Eng. Optim. 32(5), 549–584 (2000)

Cohen, D., Shamir, U., Sinai, G.: Optimal operation of multi-quality networks-II: the Q-H model. Eng. Optim. 32(6), 687–719 (2000)

Cohen, D., Shamir, U., Sinai, G.: Optimal operation of multi-quality networks-III: the Q-C-H model. Eng. Optim. 33(1), 1–35 (2000)

Broad, D.R., Dandy, G.C., Maier, H.R.: Water distribution system optimization using metamodels. J. Water Resour. Planning Manage. Div. ASCE 131(3), 172–180 (2005)

Shamir, U., Salomons, E.: Optimal real-time operation of urban water distribution systems using reduced models. J. Water Resour. Planning Manage. Div. ASCE 134(2), 181–185 (2008)

Broad, D.R., Maier, H.R., Dandy, G.C.: Optimal operation of complex water distribution systems using metamodels. J. Water Resour. Planning Manage. Div. ASCE 136(4), 433–443 (2010)

Tarquin, A.J., Dowdy, J.: Optimal pump operation in water distribution. J. Hydraul. Eng. ASCE 115(2), 158–168 (1989)

Pezeshk, S., Helweg, O.J.: Adaptive search optimization in reducing pump operating costs. J. Water Resour. Planning Manage. Div. ASCE 122(1), 57–63 (1996)

Ormsbee, L.E., Reddy, S.L.: Nonlinear heuristic for pump operations. J. Water Resour. Planning Manage. Div. ASCE 121(4), 302–309 (1995)

Sakarya, B.A., Mays, L.W.: Optimal operation of water distribution pumps considering water quality. J. Water Resour. Planning Manage. Div. ASCE 126(4), 210–220 (2000)

Kirkpatrick, S., Galett, C.D., Vecchi, M.P.: Optimization by simulated annealing. Science 220, 621–630 (1983)

Cui, L.-J., Kuczera, G.: Optimizing urban water supply headworks using probabilistic search methods. J. Water Resour. Planning Manage. Div. ASCE 129(5), 380–387 (2003)

Goldberg, D.E.: Genetic algorithms in search, optimization, and machine learning. Addison-Wesley, New York (1989)

Duan, Q., Sorooshian, S., Gupta, V.: Effective and efficient global optimization for conceptual rainfall-runoff models. Water Resour. Res. 28(4), 1015–1031 (1992)

Ostfeld, A., Salomons, E.: Optimal operation of multiquality water distribution systems: unsteady conditions. Eng. Optim. 36(3), 337–359 (2004)

Ostfeld, A., Salomons, E.: Optimal layout of early warning detection stations for water distribution systems security. J. Water Resour. Planning Manage. Div. ASCE 130(5), 377–385 (2004)

van Zyl, J.E., Savic, D.A., Walters, G.A.: Operational optimization of water distribution systems using a hybrid genetic algorithm. J. Water Resour. Planning Manage. Div. ASCE 130(2), 160–170 (2004)

López-Ibáñez, M., Prasad, T.D., Paechter, B.: Ant colony optimization for optimal control of pumps in water distribution networks. J. Water Resour. Planning Manage. Div. ASCE 134(4), 337–346 (2008)

Dorigo, M.: Optimization, learning and natural algorithms. Ph.D. thesis, Politecnico di Milano, Milan, Italy (1992)

Boulos, P.F., Wu, Z., Orr, C.H., Moore, M., Hsiung, P., Thomas, D.: Optimal pump operation of water distribution systems using genetic algorithms. www.rbfconsulting.com/papers/genetic_algo.pdf (2011)

Liang, T., Nahaji, S.: Managing water quality by mixing water from different sources. J. Water Resour. Planning Manage. Div. ASCE 109, 48–57 (1983)

Sinai, G., Koch, E., Farbman, M.: Dilution of brackish waters in irrigation networks—an analytic approach. Irrig. Sci. 6, 191–200 (1985)

EPANET 2.0 (2002). http://www.epa.gov/nrmrl/wswrd/dw/epanet.html

Shamir, U., Howard, C.D.D.: Topics in modeling water quality in distribution systems. In: Proceedings of the AWWARF/EPA Conference on Water Quality Modeling in Distribution Systems, pp. 183–192. Cincinnati, Ohio (1991)

Ostfeld, A., Shamir, U.: Optimal operation of multiquality distribution systems: steady state conditions. J. Water Resour. Planning Manage. Div. ASCE 119(6), 645–662 (1993)

Ostfeld, A., Shamir, U.: Optimal operation of multiquality distribution systems: unsteady conditions. J. Water Resour. Planning Manage. Div. ASCE 119(6), 663–684 (1993)

Cohen, D.: Optimal operation of multi-quality networks. D.Sc. Thesis, Faculty of Agricultural Engineering, Technion—Israel (in Hebrew), 400 p (1992)

Brooke, A., Kendrick, D., Meeraus, A.: GAMS: a user’s guide, Scientific Press, USA (1988), 289p

Shor, N.Z.: Minimization Methods for Non-Differentiable Functions. Springer, New York (1985), 159p

Goldman, E.F.: The application of simulated annealing for optimal operation of water distribution systems. PhD dissertation, Arizona State University, 242p (1998)

American Society of Civil Engineers (ASCE): Guidelines for designing an online contaminant monitoring system. http://www.asce.org/static/1/wise.cfm#Monitoring (2004). Accessed 2 Aug 2007

American Water Works Association (AWWA): Security guidance for water utilities. http://www.awwa.org/science/wise (2004). Accessed 2 Aug 2007

Lee, B., Deininger, R.: Optimal locations of monitoring stations in water distribution system. J. Environ. Eng. ASCE 118(1), 4–16 (1992)

Kumar, A., Kansal, M.L., Arora, G.: Identification of monitoring stations in water distribution system. J. Environ. Eng. ASCE 123(8), 746–752 (1997)

Kessler, A., Ostfeld, A., Sinai, G.: Detecting accidental contaminations in municipal water networks. J. Water Resour. Planning Manage. Div. ASCE 124(4), 192–198 (1998)

Woo, H.M., Yoon, J.H., Choi, D.Y.: Optimal monitoring sites based on water quality and quantity in water distribution systems. In: Bridging the Gap: Meeting the World’s Water and Environmental Resources Challenges, Proceedings of the ASCE EWRI annual conference, Orlando, Florida, published on CD (2001)

Al-Zahrani, M., Moied, K.: Locating optimum water quality monitoring stations in water distribution system. In: Bridging the Gap: Meeting the World’s Water and Environmental Resources Challenges, Proceedings of the ASCE EWRI annual conference, Orlando, Florida, published on CD (2001)

Ostfeld, A., Kessler, A., Goldberg, I.: A contaminant detection system for early warning in water distribution networks. Eng. Optim. 36(5), 525–538 (2004)

Ostfeld, A., Salomons, E.: Securing water distribution systems using online contamination monitoring. J. Water Resour. Planning Manage. Div. ASCE 131(5), 402–405 (2005)

Berry, J.W., Hart, W.E., Phillips, C.A., Uber, J.G., Watson, J.P.: Sensor placement in municipal water networks with temporal integer programming models. J. Water Resour. Planning Manage. Div. ASCE 132(4), 218–224 (2006)

Propato, M.: Contamination warning in water networks: general mixed-integer linear models for sensor location design. J. Water Resour. Planning Manage. Div. ASCE 132(4), 225–233 (2006)

Watson, J.P., Greenberg, H.J., Hart, W.E.: A multiple-objective analysis of sensor placement optimization in water networks. In: Critical Transitions in Water and Environmental Resources Management, Proceedings of the ASCE EWRI annual conference, Salt Lake City, Utah, published on CD (2004)

Ostfeld, A., Uber, J., Salomons, E.: Battle of the water sensor networks (BWSN): a design challenge for engineers and algorithms. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Dorini, G., Jonkergouw, P., Kapelan, Z., di Pierro, F. Khu, S.T., Savic, D: An efficient algorithm for sensor placement in water distribution systems. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Eliades, D., Polycarpou, M: Iterative deepening of Pareto solutions in water sensor Networks. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Rubinstein, R.Y.: The simulated entropy method for combinatorial and continuous optimization. Methodol Comput. Appl. Probab. 2, 127–190 (1999)

Gueli, R.: Predator—prey model for discrete sensor placement. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Huang, J.J., McBean, E.A., James, W.: Multi-objective optimization for monitoring sensor placement in water distribution systems. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Ostfeld, A., Salomons, E.: Sensor network design proposal for the battle of the water sensor networks (BWSN). In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Preis, A., Ostfeld, A.: Multiobjective sensor design for water distribution systems security. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Deb, K., Agrawal, S., Pratap, A., Meyarivan, T.: A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In: Proceedings of the Parallel Problem Solving from Nature VI Conference, pp. 849–858. Paris, France (2000)

Wu, Z.Y., Walski, T.: Multi objective optimization of sensor placement in water distribution systems. In: 8th Annual Water Distribution System Analysis Symposium Cincinnati, Ohio, USA, published on CD (2006)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Ostfeld, A. (2015). Water Distribution Networks. In: Kyriakides, E., Polycarpou, M. (eds) Intelligent Monitoring, Control, and Security of Critical Infrastructure Systems. Studies in Computational Intelligence, vol 565. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-44160-2_4

Download citation

DOI: https://doi.org/10.1007/978-3-662-44160-2_4

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-44159-6

Online ISBN: 978-3-662-44160-2

eBook Packages: EngineeringEngineering (R0)