Abstract

The efficiency of biomining and bioremediation operations is dependent on mineralogy and geochemistry of the system, i.e., the substrate, which defines the conditions in which a certain microbial community can develop and catalyze the biogeochemical processes, thus increases the kinetics of the reactions, the main objective in a biomining operation. However, many of the so-called biomining and bioremediation operations lack a thorough mineralogical, geochemical, and microbial community characterization during the process operations. Thus, many of these biomining operations become mainly acid leach operations with low recoveries and do not take advantage the enormous potential for bioleaching process improvements. Similarly in bioremediation, the mineralogy and the potential changes of the geochemical system due to microbial interaction controls the stability and mobility of certain potential environmental pollutants. Thus, in biomining and bioremediation areas a thorough knowledge of the mineralogy and geochemistry is required for the effective operation of these systems. The key process parameters that affect process efficiency and reaction kinetics and strategies for process improvement are discussed in this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

7.1 Introduction

Biomining is generally defined as a biotechnological process to enhance metal recovery by oxidative dissolution of sulfide ore minerals catalyzed by the activity of prokaryotic microorganisms like bacteria and archaea (Donati and Sand 2007; Rawlings and Johnson 2007). The bioleaching process is mainly used for metal liberation from copper sulfide ores (Domic 2007). New approaches also involve the reductive dissolution of oxide ores (Ni-laterites) by microbial interactions (Hallberg et al. 2011).

Many of the current large-scale biomining operations, especially in Cu-sulfide ores, are inefficient with recoveries mostly in the range of 5–10 %, with some exception of up to 40 %. This is in most cases due to inappropriate parameters for selection of leachable material. For example, in copper mining, like in porphyry copper systems, the cutoff ore grade (typical range between 0.3 and 0.6 wt.% Cu) defines if the material is to be sent to the flotation process or leached in low-ore grade (0.1–0.4 wt.% Cu) run-off-mine (ROM) dumps, heaps, or additionally crushed (Fig. 7.1). By using the cutoff as selection criteria, the properties and suitability for bioleaching of the mineral assemblage is ignored, as some key minerals like chalcopyrite are not acid soluble in sulfuric acid (Table 7.1).

Typical evolution of the cutoff grade during the evolution of a mine operation. Ore with ore grades above cutoff will be crushed, milled, and floated. Material below cutoff and above 0.1 wt.% Cu (blue area) will be sent to leach dumps (ROM or crushed to increase the reactive surface). Material below 0.1 wt.% Cu (red line) is normally classified as waste rock

Most of the currently exploited Cu-sulfide mines contain mainly chalcopyrite as target mineral, which is not acid leachable, thus it must be oxidized by microorganisms in order to solubilize the copper. This process at ambient conditions is relatively inefficient, as the typical bacterial communities (Acidithiobacillus ferrooxidans and Leptospirillum spp.) present at these conditions are not able to oxidize chalcopyrite efficiently. Thermophilic population dominated by archaea (e.g., Sulfolobus spp. ) are able to oxidize chalcopyrite efficiently with acceptable kinetics only above 50 °C as applied in some stirred tank operations for concentrates (du Plessis et al. 2007). In this chapter the influences of the mineralogy and geochemical conditions on the effectiveness of biomining operations and further potential for research and applications are discussed.

7.2 Sulfide Oxidation

Sulfide oxidation occurs when sulfide-rich rock units are exposed to the atmosphere and to water for example by erosion or is enhanced by anthropogenic activities like mining (Dold 2010). It is a natural process, which started to occur in geological times with the first presence of an atmosphere and has been going on ever since and might have an important role on the global iron cycle (Dold et al. 2013). This process is responsible for the formation of supergene ore deposit and the main environmental problem of mining industry called acid mine drainage (AMD). However, it can be used as a process for solubilization of metals from sulfide ores in biomining (Dold 2008).

The most common sulfide mineral in the earth crust is pyrite (FeS2). Oxidation of pyrite takes place in several steps including the formation of the metastable secondary products ferrihydrite (5Fe2O3·9H2O), schwertmannite [between Fe8O8(OH)6SO4 and Fe16O16(OH)10(SO4)3], goethite [FeO(OH)], and the more stable secondary jarosite [KFe3(SO4)2(OH)6] and hematite (Fe2O3) depending on the geochemical conditions (Bigham et al. 1996; Cornell and Schwertmann 2003). Oxidation of pyrite may be considered to take place in three major steps: (1) oxidation of sulfur [Eq. (7.1)]; (2) oxidation of ferrous iron [Eq. (7.2)]; and (3) hydrolysis and precipitation of ferric complexes and minerals [Eq. (7.3)]. The kinetics of each reaction is different and depends on the conditions prevailing in the system.

Reaction rates strongly increased by microbial activity (e.g., Acidithiobacillus spp. or Leptospirillum spp.)

Equation (7.1) describes the initial step of pyrite oxidation in the presence of atmospheric oxygen. Once ferric iron is produced by oxidation of ferrous iron, especially at low pH conditions, it becomes the primary oxidant [Eq. (7.4)] of pyrite and the reaction would be strongly accelerated by microbiological activity [Eq. (7.2)] (Ehrlich 1996; Moses et al. 1987; Nordstrom et al. 1979; Rimstidt and Vaughan 2003). Under abiotic conditions the rate of oxidation of pyrite by ferric iron is controlled by the rate of oxidation of ferrous iron, which decreases rapidly with decreasing pH. Below about pH 3 the oxidation of pyrite by ferric iron is about ten to a hundred times faster than by oxygen (Ritchie 1994).

Chalcopyrite is one of the main target mineral in copper mining. In order to solubilize the copper, chalcopyrite should be oxidized and complete oxidation of chalcopyrite may be written as:

The above reaction is without the acid production. However, the combination of ferrous iron oxidation and ferrihydrate hydrolysis is the main acid producing process.

Chalcopyrite, together with molybdenite, is known as one of the most resistant sulfides to oxidation (Plumlee 1999). Rimstidt et al. (1994) reported that the oxidation rate of chalcopyrite increases with increasing ferric iron concentration, but with an oxidation rate of 1–2 orders of magnitude less than pyrite.

It has been known for nearly 50 years that Acidithiobacillus ferrooxidans and Leptospirillum ferrooxidans obtain energy by oxidizing Fe2+ to Fe3+ from sulfides (Bryner et al. 1967) with increased rate of reaction (7.2) up to the factor of about 100 over abiotic oxidation (Singer and Stumm 1970). More recent results show that a complex microorganism community is responsible for sulfide oxidation (Baker and Banfield 2003; Johnson and Hallberg 2002; Johnson et al. 1993; Nordstrom 2000). The initial step of pyrite oxidation does require an elaborated sequence of different geochemical reactions that dominate at different pH ranges (Nordstrom and Southam 1997). Schippers and Sand (1999) have demonstrated that acid-insoluble metal sulfides are chemically reacted by iron (III) hexahydrate ions, generating thiosulfate, which is then oxidized to sulfuric acid (Table 7.1). The acid-soluble sulfides are attacked by iron (III) and protons, resulting in the formation of elemental sulfur via intermediary polysulfides.

Acidithiobacillus spp. form nano-environments to grow on sulfide mineral surfaces. These nano-environments can develop thin layers of acidic water that do not affect the bulk pH of the water chemistry. With progressive oxidation, the nano-environments may change to microenvironments. Evidence of acidic microenvironments in the presence of near neutral pH for the bulk water can be inferred from the presence of jarosite (forms around pH 2) in certain soil horizons and mine tailings where the current water pH is neutral (Carson et al. 1982; Dold et al. 2011a). Barker et al. (1998) observed the solution pH decreased from near neutral at the mineral surface to 3–4 around microbial colonies living within confined spaces at interior colonized cleavage planes of biotite.

When mine water, rich in ferrous and ferric iron, reaches the surface it may fully oxidize, hydrolyze, and may precipitate to ferrihydrite (fh), schwertmannite (sh), goethite (gt), or jarosite (jt) depending on pH–Eh conditions and availability of key elements such as potassium and sulfur (Fig. 7.2). Jarosite, schwertmannite, and ferrihydrite are metastable compared to goethite (Bigham et al. 1996). The hydrolysis and precipitation of iron hydroxides (and to a lesser degree, jarosite) would produce most of the acid in this process. If pH is less than about 2, ferric hydrolysis products like Fe(OH)3 are not stable and Fe3+ remains in solution.

pe–pH diagram for Fe-S-K-O-H system at 25 °C; total log activities of Fe2+ = −3.47; Fe3+ = 3.36 or −2.27; SO4 2− = −2.32; K+ = −3.78; log Kso values for solid phases for gt goethite, jt K-jarosite, fh ferrihydrite, sh schwertmannite are 1.40, −12.51, 4.5, and 18.0, respectively. Py pyrite. Mean composition of the schwertmannite used for the development of this pe–pH diagram was Fe8O8 (OH)4.8 (SO4)1.6. After Bigham et al. (1996), note that these stability fields have to be interpreted as indicative, as the thermodynamic data published from schwertmannite and ferrihydrite show high variability (Majzlan et al. 2004)

Note that the net reaction of complete oxidation of pyrite, hydrolysis of Fe3+, and precipitation of iron hydroxide (sum of reactions 1, 2, and 6) produces 4 mol of H+ per mole of pyrite; thus, pyrite oxidation is the most efficient producer of acid among the common sulfide minerals.

The precipitation of these secondary Fe(III) hydroxides can form coatings (Huminicki and Rimstidt 2009) and cemented layers (Blowes et al. 1991; Dold et al. 2009; Graupner et al. 2007), which can decrease the oxidation rates and change the flow direction of the pore solution. Evangelou and Zhang (1995) reported increased oxidation rates of pyrite by addition of HCO3 − due to the formation of pyrite surface Fe(II)-CO3 complexes resulting in a limitation of the iron availability. Additionally, the formation of silica gel can encapsulate minerals and limit the interaction with the environment (Evangelou 2001). This can lead to the formation of cemented layers, which limit oxygen and water flow as well as form preferential flow regimes (Graupner et al. 2007; Rammlmair et al. 2008). The formation of these secondary mineral phases can not only limit the access of bacteria to the sulfide mineral surface but can also inhibit the bacterial activity by co-precipitation of the bacterial cell into the mineral phase (Hedrich et al. 2011). The secondary mineralogy of the oxidation and cemented zones can scavenge environmentally critically elements under oxic condition. This effect can be reversed, when placed under reducing conditions like during bioremediation and has to be considered before a remediation approach is chosen.

7.3 How Is Biomining Done Today?

There are several criteria, which decide nowadays to which type of process the mined material is send. If a new mining operation is starting, there is often an oxidation zone on the surface present, which might contain some economic value in form of metal oxides (chalcanthite, azurite, malachite, chrysocolla, or Au and Ag concentrations among others). This oxide mineral assemblage is water soluble or acid leachable (Table 7.1), so that these metals can easily be recovered by an acid leach process, mainly using sulfuric acid. If the deposit shows important secondary enrichment due to supergene processes, as for example the porphyry copper deposits in northern Chile, the mineral assemblage is dominated by secondary sulfide minerals like covellite and chalcocite–digenite, which are also acid soluble. If the two latter cases are important in the system, usually a separated acid leach operation is installed in order to recover the soluble metals by solvent extraction electro-winning process (SX-EW).

If exploitation goes further on toward the primary zone or the oxide and enriched zone are less important, the criteria of decision making is the cutoff grade as explained above. In this case not the mineral assemblage, but only the element concentrations of the mayor target elements decide the process applied. This can then lead to a very low recovery of the target elements due to their mineral assemblage.

There are several options how the leaching or bioleaching is done in the mining operation (Fig. 7.3):

-

1.

In small leach piles (or heaps) of some meters high (Fig. 7.3a), where the material is exposed to acid leach by sulfuric acid irrigation (pH ~ 1) some days or weeks up to months. Sometime the material is crushed before or sulfuric acid is mixed with water in a reaction tank to fracture the material. The pregnant leach solutions (PLS) are recovered by underlying geomembrane basement liners (Fig. 7.4 and Fig. 7.6). The PLS is send to an SX-EW plant for metal recovery and then recycled to the leach pile. In these operations usually oxide ores or material from the supergene enriched zones is exploited. Afterwards, the material is replaced by fresh ore, and the residual is deposited on waste dumps. As in these operations usually high-ore grade (e.g., 1–2 wt.% Cu) is processed, the waste material still can contain 0.4–0.8 wt.% of Cu and the resulting waste dumps normally do not have impermeabilization, so that they can be a important source of groundwater contamination .

-

2.

Permanent leach deposits (leach dumps) for low-grade sulfidic ore material (i.e., Escondida, Chile; Figs. 7.3a and 7.5)

Fig. 7.5 . In this case material with ore grade below cutoff and normally above 0.1–0.2 wt. Cu is placed above an impermeabilized surface (usually by geotextile). When the first level is completed, new material is placed above in order follow on the leach process. Additionally, artificial ventilation ensures the air supply for the microbiological activity. Characterization of the microbial community is undertaken (Demergasso et al. 2005; Zepeda et al. 2009), however, mineralogical control is often missing. In cases that supergene enrichment is important, recovery is relatively high (up to 41 %) (Zepeda et al. 2007). However, as these operations are mainly from porphyry copper deposit (e.g., Escondida, Chuquicamata), only temperatures in the range for a mesophile community are reached, so that chalcopyrite leaching is not very efficient.

-

3.

Waste dumps, which, due to increased metal prices are redefined into leach dumps. They are usually only irrigated sulfuric acid and no baseliner to recover PLS is present. Instead, it is tried to recover the PLS by a series of piezometer or wells in order to recover the metals from the groundwater. This practice has to be evaluated very critically as often no detailed knowledge on the hydrogeology is available and therefore the flow directions are little know, resulting in a high risk for groundwater contamination by PLS.

-

4.

The trend in metal mining goes clearly into lower-ore grade and greater volumes mined; thus also the mobilized non-economic or low-grade material is increasing, so that, for example, in Chileans copper mines waste dumps or leach dumps are in planification to completely new dimensions with the associated technical challenges. For example, at the Andina porphyry copper mine (Central Chile) a dump is planed with 4 km length and 1 km high containing 1,900 Mt of low-grade material (Weibel et al. 2011). The challenge in this type of deposits is to design a dump, which can produce its own impermeabilization in order to prevent infiltrations to the groundwater and to enable the PLS recovery on a long-term perspective and optimize the leach kinetics.

-

5.

Tank or Reactor leaching operations are used to leach mainly concentrates or high-ore grade material with thermophile archaea communities (du Plessis et al. 2007).

7.4 Main Drawbacks of Today’s Bioleaching Operations

-

(A)

The most important drawback today is the inadequate selection of the material for the leaching process. This has to be seen as the main reason for the low recovery of these systems. In order to improve this it must be clear that a mineral deposits is exploited, not a metal deposit. Characterization and decision making are nowadays done on behalf of the ore grade of a material (i.e., the concentration of the target element), but the mineralogical association of this element is ignored. The mineral association is key to evaluate extraction of a certain element by the chosen mining process. Thus, not the ore grade but the mineralogical association of the target element has to be the process selection criteria.

-

(B)

In case of porphyry copper deposits , only around 2 % of pyrite is available for heat production during sulfide oxidation. This is usually not enough to reach the thermophile temperature range (>50 °C). Thus, the mesophilic bacterial community, dominated by Acidithiobacillus ferrooxidans and Leptospirillum ferrooxidans , are not able to oxidize efficiently chalcopyrite. Therefore, the primary ore mineralogy (cp, bn) is not suitable for bioleaching operations in porphyry copper systems.

-

(C)

Most of these leach dumps are built with ROM material. This ensures a relatively good aeration as the coarser material is in the lower part of each level of the dump, which promotes advection through the chimney effect. However, some operations crush additionally the material in order to increase surface for the oxidation process. This limits the airflow through the system and can so decrease the oxidation kinetics. Some operations have additionally ventilation infrastructure, which increases the operation costs (e.g., Escondida).

-

(D)

Many of the leach operations are managed at pH of 1 or even below. This pH is lower than the optimum range for the iron and sulfur oxidizers, hence might also play a role in the low efficiency of the operation. The low pH is generally used to prevent precipitation of secondary minerals like Fe(III)hydroxides and sulfates like, for example, jarosite and/or goethite.

-

(E)

The chemistry of the PLS is often ignored. In many of these operations, the PLS are recycled after the metal recovery. This is done to increase oxidation kinetics as the PLS have high concentrations of ferric iron, the predominant oxidant in this system. Due to evaporation during recycling, the concentrations of the solutes in the PLS tend to increase. As the solubility of the secondary minerals like jarosite is a function of pH, Eh, and concentrations, this increase of solutes makes it possible that, for example, jarosite might precipitate at lower pH as the ferric iron concentration increases during recycling (Figs. 7.6 and 7.7). The precipitation of secondary minerals like jarosite might inhibit sulfide minerals from oxidation by coating and cemented layer formation and thus lowers the recovery.

Fig. 7.6 -

(F)

The presence of other minerals like ferrihydrite, goethite, and schwertmannite in the leach material has to be considered, as they might dissolve due to the low pH conditions and increase the concentrations of ferric iron as an additional source, and thus decrease the pH where jarosite can precipitate. These secondary mineral precipitation can inhibit the sulfides from oxidation and change the solution flow path and make sectors of the leach pile inaccessible for the leach solution (Rammlmair et al. 2008).

7.5 How Can We Improve the Biomining Process?

To increase sulfide oxidation kinetics for bioleaching purpose, following parameters should be considered:

-

(A)

pH: The chemolithotrophic autotroph iron- and sulfur-oxidizer have their optimum in a pH range of 2–3. However, most of the bioleaching operations manage pH conditions around 1 or even lower due to constant irrigation with sulfuric acid and evaporation effects, which is below the optimum pH for the microbial activity and might be a reason for lower microbial activity (Hallberg 2010). This low pH prevent precipitation of secondary Fe(III)hydroxides, which could coat the sulfides and lower recovery. It must also be considered that the gangue mineralogy can be responsible of an important acid consumption, slowing down the recovery at the beginning due to increased pH conditions.

-

(B)

Redox potential: The redox potential (Eh) must be operated and maintained constantly in oxidizing conditions. Saturation with the leach solution has to be avoided.

-

(C)

Temperature: Acidithiobacillus spp. or Leptospirillum spp. have their optimum temperature between 20 and 40 °C (Johnson and Hallberg 2003). As sulfide oxidation is an exothermic reaction, increased temperatures are often reached in bioleaching operations. However, to effectively operate bioleaching of chalcopyrite, 40–50 °C or higher are needed in order to stimulate conditions for thermophile archaea, which have shown increased recovery of chalcopyrite oxidation under stirred tank conditions (Rawlings and Johnson 2007). In laboratory cell tests it has been shown that Cu release is enhanced at constant 40 °C and 100 % humidity (Dold et al. 2011b), in relation to the standard wet–dry cycles of the Standard humidity cell tests ASTM D5744-96. An elegant way to increase the heat production during sulfide oxidation can be the addition of pyrite, which was separated by an additional flotation step from the tailings. This would have a dual positive effect of increasing temperature in the leach dump to increase recovery, and lowering the acid potential of the tailings, where it might lead to AMD and produce high environmental damages and costs.

-

(D)

Humidity and air flow: Increased humidity can prevent precipitation of secondary soluble salts, which can inhibit the sulfide surface from reaction. As for sulfide oxidation atmospheric oxygen is needed at least at the beginning of the process (in a later stage Fe3+ will be the principal oxidant), and bacteria community is autotroph, a good airflow throughout the system has to be ensured during the operation. In Escondida, Chile, this is ensured by a giant ventilation system. Specific designs of the leach dumps in order to promote the chimney effect could enhance aeration at a lower energy cost.

-

(E)

Control of the geochemistry of the PLS: The water chemistry of the leach solution have to be controlled constantly in order to ensure optimum conditions for the microbial community and to limit the risk of mineral precipitations, which can coat the target minerals and change the flow path of the leach solutions.

7.6 Bioremediation

As explained before, sulfide oxidation is the biogeochemical process , which leads to the solubilization of sulfides and the subsequent formation of acid rock drainage (ARD). In biomining, this process is accelerated in a controlled environment in order to extract the metal content. If this process occurs uncontrolled in mine waste, it produces the most important environmental problem of the mining industry, called acid mine drainage, and needs remediation. There are different approaches in order to control and remediate the damage produced by AMD formation. The main principle of these approaches is to invert or close the biogeochemical cycle back from the oxidizing environment, which is responsible for acid production and metal liberation and mobilization, into a reducing environment, in order to remove the contaminant elements by precipitation or sorption processes from solution. Below the term bioremediation usually the precipitation of secondary sulfide minerals and the formation of alkalinity triggered by microbial activity is understood and used for remediation of mine waste systems like tailings (Dold et al. 2011a), waste dumps (Schippers et al. 2010), and pit lakes (Klapper et al. 1998; Fauville et al. 2004; Knoller et al. 2004). Sometimes also sorption processes onto organic matter falls below this definition, as well as phytoremediation (Sheoran et al. 2012).

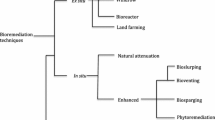

The microbiology of bioremediation process is extensively reviewed (Johnson 2002, 2003; Johnson and Hallberg 2002; Hallberg and Johnson 2005). Two principal approaches in bioremediation of mine waste can be distinguished:

-

1.

Treatment of AMD by enhanced biogeochemical processes (reduction, precipitation, sorption) in treatment facilities (Hallberg 2010) and constructed (Hallberg and Johnson 2005) or natural wetlands (Kalin 2001) or permeable reactive barriers (Benner et al. 2000; Blowes et al. 2000).

-

2.

Change of the geochemical conditions of the contamination source (e.g., mine tailings and waste dumps) to reducing environment in order to stop sulfide oxidation and AMD formation (Diaby 2008; Dold et al. 2011a).

In case of AMD treatment, the AMD chemistry is the key in order to guarantee a proper function of the treatment process and also decides if the process can function in an inorganic way or microbial intervention is needed. For example, the formation of the exotic deposit at the Chuquicamata mine, Northern Chile, is a good example of natural attenuation of ARD. The source of the ARD was the exposure of the porphyry copper ore body to natural oxidation through erosion and uplift of the Andes. The West-fault triggered the formation of a gravel filled paleo-channel, in which the acid, Cu, and Fe(III) rich-ARD were channeled in an oxic environment downstream. Close to the source, at the beginning of the paleo-channel, Fe(III) hydroxides precipitated and scavenged oxyanions like molybdate and arsenate, due to their known behavior of sorption onto Fe(III)hydroxides at low pH condition. Therefore Mo, one of the target elements in this system, is enriched close to the ARD source. Copper maintains mobile under the prevailing acid pH conditions and flew downstream, were it encountered two types of bedrock. On the east site of the channel prevailed bedrock altered by propylitic alteration, which adds a neutralization potential to the rock in the form of calcite. The other bedrock is mainly based on granodiorite and andesitic gravels, without any carbonates. This difference of bedrock controls the buffer capacity and subsequent the final pH conditions. The propylitic zone is able to buffer the pH to near neutral pH, necessary for the observed precipitation of chrysocolla, whereas the gravels only are able to buffer toward pH 5–6, where atacamite will form (Dold 2006). Thus, this system is mainly pH controlled, triggering the precipitation of the different mineral in a neutralization sequence and forming a secondary ore deposit, a modern way of pollution control.

In case of AMD treatment, there are two scenarios to consider. One is a neutral ferrous iron-rich plume and the other is an acid ferrous iron-rich plume out-groping from a mine waste system (tailings or waste dumps) or underground mines. In the first case, the contact with the atmosphere will initiate the autooxidation of the ferrous iron to ferric iron and initiate the hydrolysis of the Fe(III)hydroxides (ferrihydrite and/or goethite). If the ferrous plume is contaminated by oxyanions (e.g., As, Mo, Se, S) these will tend to be scavenged by these secondary precipitates. In this process still no bacterial interaction is needed.

If the ferrous plume is acid (< pH 4), then iron oxidizers will oxidize ferrous to ferric iron and the hydrolysis of schwertmannite and/or jarosite and goethite is initiated. Again, if oxyanions are in solution, they will be scavenged by the Fe(III)hydroxides. Bivalent metal cations can maintain in solution and can be extracted selectively. The most important role of microbial activity in these systems is now to use the ability of some microorganisms to modulate the redox state of a target element selectively in order to extract the element as pure as possible from solution in order to be able to recover the element as an economic value, instead of an environmental cost.

Many of the so-called bioremediation or microbiological treatment methods for AMD control are based on the action of heterotrophic iron and sulfate-reducing bacteria , which initiate the precipitation of secondary sulfide minerals in a wetland or a permeable reactive barrier. The main drawback of these methods is that they are not able to treat the AMD for selective metal recovery; instead, a mixture of organic matter and metal sulfides is produced, which itself represent a hazardous waste material, which has to be managed in a proper way. Thus, new research goes into the selective recovery of the metals from industrial waste solutions like AMD, in order to recover as much economic values as possible (Hallberg 2010; Kamradt et al. 2012).

In case of acid lake remediation , the heterotrophic approach has shown good results specially in pit lakes formed by coal mining where mainly iron and the acidity are the main problems to solve (Geller et al. 1998). In order to control and to limit an AMD source (tailings impoundment, waste dump, underground mine, pit lakes) by a bioremediation approach, usually the system is changed from an oxic environment toward a reducing environment. This can be reached by addition of organic matter or simply by flooding or is often done by implementation of geotechnical and soil covers, phytoremediation, or by implementation of wet covers with a wetland (Dold et al. 2011a).

As expressed above, natural processes can scavenge some of the pollutants in a very effective way. For example, oxyanions like arsenate are always associated to the Fe(III) hydroxides in an oxic AMD environment; this can be in a waste dump, in the oxidation zone from a tailings impoundment (Dold and Fontboté 2001; Smuda et al. 2007), or in the unsaturated zone of an underground mine or in the pit lakes walls. By the change toward reducing and increased pH conditions, the sorbent, in this case the Fe(III)hydroxides, will undergo reductive dissolution and liberate the sorbed arsenic into solution, thus, by solving a problem producing another, as happened in case of the flooding of the Wismut uranium mines (Jenk et al. 2009). Therefore, before a remediation approach is selected, a thorough knowledge of the mineralogy and element speciation is needed in order to predict geochemical stability and behavior during the remediation process.

7.7 Conclusions

Nowadays biomining operations are in most cases highly inefficient, mainly due to the lack of mineralogical, geochemical, and microbiological characterization and control before and during the operations. Most of them are not effectively bioleaching but mainly acid leaching operations and have therefore an enormous potential for process improvement. The goal must be to optimize these operations by a thorough characterization of the mineral assemblage and the microbiological community present or to be developed and to ensure the biogeochemical parameters for an optimized operation. Especially, the selection criterion (today cutoff grade) for the definition of the leachable units has to be changed toward the mineral assemblage.

Special attention has to be given to the impermeabilization of these operation, in order to be able to recover the PLS on a long-term perspective in the future and also with the objective to prevent groundwater contamination.

In bioremediation, special focus has to be given that the microbial community supposed to do the job has the suitable geochemical conditions in order to function in the optimum range. Mineralogical and geochemical studies of the element and mineral speciation have to be performed in order to prevent negative secondary pollution effects. Thus, biomining or bioremediation approaches need a detailed knowledge of the mineralogy and the geochemistry to predict and manage a proper function of the biogeochemical systems.

References

Baker BJ, Banfield JF (2003) Microbial communities in acid mine drainage. FEMS Microbiol Ecol 44:139–152

Barker WW, Welch SA, Chu S, Banfield JF (1998) Experimental observations of the effects of bacteria on aluminosilicate weathering. Am Mineral 83:1551–1563

Benner SG, Gould WD, Blowes DW (2000) Microbial populations associated with the generation and treatment of acid mine drainage. Chem Geol 169:435–448

Bigham JM, Schwertmann U, Traina SJ, Winland RL, Wolf M (1996) Schwertmannite and the chemical modeling of iron in acid sulfate waters. Geochim Cosmochim Acta 60:2111–2121

Blowes DW, Reardon EJ, Jambor JL, Cherry JA (1991) The formation and potential importance of cemented layers in inactive sulfide mine tailings. Geochim Cosmochim Acta 55:965–978

Blowes DW, Ptacek CJ, Benner SG, McRae CWT, Bennett TA, Puls RW (2000) Treatment of inorganic contaminants using permeable reactive barriers. J Contam Hydrol 45:123–137

Bryner LC, Walker RB, Palmer R (1967) Some factors influencing the biological and non-biological oxidation of sulfide minerals. Trans Soc Mining Eng AIME 238:56–65

Carson CD, Fanning DS, Dixon JB (1982) Alfisols and ultisols with acid sulfate weathering features in Texas. In: Kittrick JA, Fanning DS, Hossner LR (eds) Acid sulfide weathering, vol 10. Soil Science Society of America Publicaiton, Madison, WI, pp 127–146

Cornell RM, Schwertmann U (2003) The iron oxides. Wiley-VCH, Weinheim, 664 p

Demergasso CS, Galleguillos PA, Escudero G, Zepeda A, Castillo D, Casamayor EO (2005) Molecular characterization of microbial populations in a low-grade copper ore bioleaching test heap. Hydrometallurgy 80:241–253

Diaby N (2008) Biogeochemical evolution of a marine shore tailings deposit during bioremediation. University of Lausanne, Lausanne

Dold B (2006) Geochemical modeling of the exotic copper mineralization at the Exotica deposit, Chuquicamata, Chile. In: XI Congreso Geologico Chileno, vol 2, Antofagasta, Chile, pp 274–250

Dold B (2008) Sustainability in metal mining: from exploration, over processing to mine waste management. Rev Environ Sci Biotechnol 7:275–285

Dold B (2010) Basic concepts in environmental geochemistry of sulfide mine-waste management. In: Kumar S (ed) Waste management. Intech Open Access, Rijeka, pp 173–198 (http://www.intechopen.com/books/show/title/waste-management)

Dold B, Fontboté L (2001) Element cycling and secondary mineralogy in porphyry copper tailings as a function of climate, primary mineralogy, and mineral processing. J Geochem Explor 74:3–55

Dold B, Wade C, Fontbote L (2009) Water management for acid mine drainage control at the polymetallic Zn-Pb-(Ag-Bi-Cu) deposit of Cerro de Pasco, Peru. J Geochem Explor 100:133–141

Dold B, Diaby N, Spangenberg JE (2011a) Remediation of a marine shore tailings deposit and the importance of water-rock interaction on element cycling in the coastal aquifer. Environ Sci Technol 45:4876–4883

Dold B, Weibel L, Cruz J (2011b) New modified humidity cells test for acid rock drainage prediction in porphyry copper deposits. EnviroMine, Santiago de Chile

Dold B, Gonzalez-Toril E, Aguilera A, Lopez-Pamo E, Bucchi F, Cisternas M-E, Amils R (2013) Acid rock drainage and rock weathering in Antarctica – important sources for iron cycling in the Southern Ocean. Environ Sci Technol 47(12):6129–6136

Domic EM (2007) A review of the development and current status of copper bioleaching operations in Chile: 25 years of successful commercial implementation. In: Rawlings DE, Johnson DB (eds) Biomining. Springer, Heidelberg, pp 81–96

Donati ER, Sand W (2007) Microbial processing of metal sulfides. Springer, Dordrecht, 314 p

du Plessis CA, Batty JD, Dew DW (2007) Commercial applications of thermophile bioleaching. In: Rawlings DE, Johnson DB (eds) Biomining. Springer, Heidelberg, pp 57–80

Ehrlich HL (1996) Geomicrobiology. Dekker, New York, 719 p

Evangelou VP (2001) Pyrite microencapsulation technologies: principles and potential field application. Ecol Eng 17:165–178

Evangelou VP, Zhang YL (1995) A review; pyrite oxidation mechanisms and acid mine drainage prevention. Crit Rev Environ Sci Technol 25:141–199

Fauville A, Mayer B, Frommichen R, Friese K, Veizer J (2004) Chemical and isotopic evidence for accelerated bacterial sulphate reduction in acid mining lakes after addition of organic carbon: laboratory batch experiments. Chem Geol 204:325–344

Geller W, Klapper H, Salomons WE (1998) Acidic mining lakes: acid mine drainage, limnology and reclamation. Springer, Berlin

Graupner T, Kassahun A, Rammlmair D, Meima JA, Kock D, Furche M, Fiege A, Schippers A, Melcher F (2007) Formation of sequences of cemented layers and hardpans within sulfide-bearing mine tailings (mine district Freiberg, Germany). Appl Geochem 22:2486–2508

Hallberg KB (2010) New perspectives in acid mine drainage microbiology. Hydrometallurgy 104:448–453

Hallberg KB, Johnson DB (2005) Microbiology of a wetland ecosystem constructed to remediate mine drainage from a heavy metal mine. Sci Total Environ 338:53–66

Hallberg KB, Grail BM, du Plessis CA, Johnson DB (2011) Reductive dissolution of ferric iron minerals: a new approach for bio-processing nickel laterites. Miner Eng 24:620–624

Hedrich S, Lunsdorf H, Kleeberg R, Heide G, Seifert J, Schlomann M (2011) Schwertmannite formation adjacent to bacterial cells in a mine water treatment plant and in pure cultures of ferrovum myxofaciens. Environ Sci Technol 45:7685–7692

Huminicki DMC, Rimstidt JD (2009) Iron oxyhydroxide coating of pyrite for acid mine drainage control. Appl Geochem 24:1626–1634

Jenk U, Meyer J, Paul M (2009) Flooding of Wismut’s uranium mines after closure – key findings and unexpected effects. In: Securing the future and 8th ICARD, Skelleftea, Schweden

Johnson DB (2002) Acid mine drainage: bioremediation, the candidate process. In: Eccles HE (ed) Bioremediation. Taylor and Francis, London

Johnson DB (2003) The microbiology of acidic mine waters. Res Microbiol 154:466–473

Johnson DB, Hallberg KB (2002) Pitfalls of passive mine water treatment. Rev Environ Sci Biotechnol 1:335–343

Johnson DB, McGinness S, Ghauri MA (1993) Biogeochemical cycling of iron and sulfur in leaching environments. FEMS Microbiol Rev 11:63–70

Kalin M (2001) Biogeochemical and ecological considerations in designing wetland treatment systems in post-mining landscapes. Waste Manag 21:191–196

Kamradt A, Borg G, Schaefer J, Kruse S, Fiedler M, Romm P, Schippers A, Gorny R, Du Bois M, Bieligk C, Liebetrau N, Nell S, Friedrich B, Morgenroth H, Wotruba H, Merkel C (2012) An integrated process for innovative extraction of metals from Kupferschiefer mine dumps, Germany. Chem Ing Tech 84:1694–1703

Klapper H, Friese K, Scharf B, Schimmele M, Schultze M (1998) Ways of controlling acid by ecotechnology. In: Geller W, Klapper H, Salomons W (eds) Acidic mining lakes – acid mine drainage, limnology and reclamation. Springer, Berlin, pp 401–416

Knoller K, Fauville A, Mayer B, Strauch G, Friese K, Veizer J (2004) Sulfur cycling in an acid mining lake and its vicinity in Lusatia, Germany. Chem Geol 204:303–323

Majzlan J, Navrotsky A, Schwertmann U (2004) Thermodynamics of iron oxides: part III. Enthalpies of formation and stability of ferrihydrite (Fe(OH)3), schwertmannite (FeO(OH)3/4(SO4)1/8), and [epsiv]-Fe2O3 1. Geochim Cosmochim Acta 68:1049–1059

Moses CO, Nordstrom DK, Herman JS, Mills AL (1987) Aqueous pyrite oxidation by dissolved oxygen and by ferric iron. Geochim Cosmochim Acta 51:1561–1571

Nordstrom DK (2000) Advances in the hydrogeochemistry and microbiology of acid mine waters. Int Geol Rev 42:499–515

Nordstrom DK, Southam G (1997) Geomicrobiology of sulfide mineral oxidation. In: Banfield JF, Nealson KH (eds) Geomicrobiology, vol 35, Reviews in mineralogy. Mineralogical Society of America, Washington, DC, pp 361–390

Nordstrom DK, Jenne EA, Ball JW (1979) Redox equilibria of iron in acid mine waters. In: Jenne EA (ed) Chemical modeling in aqueous systems, vol 93, ACS symposium series. American Chemical Society, Washington, DC, pp 51–79

Plumlee GS (1999) The environmental geology of mineral deposits. In: Plumlee GS, Logsdon MJ (eds) The environmental geochemistry of ore deposits. Part A: Processes, techniques, and health issues, vol 6A, Reviews in economic geology. Society of Economic Geologists, Littleton, CO, pp 71–116

Rammlmair D, Grissemann C, Furche M, Noell U, Graupner T, Meima JA, Romero-Baena A (2008) Evidence of reduced water infiltration by microhardpans – electrical resistivity measurements at Pena de Hierro, Rio Tinto, Spain. In: Proceedings of the 9th international congress for applied mineralogy, ICAM 2009, the Australasian Institute of Mining and Metallurgy, Publication Series (8/2008), Brisbane, Australia, pp 349–356

Rawlings DE, Johnson DB (2007) Biomining. Springer, Berlin, 314 p

Rimstidt JD, Vaughan DJ (2003) Pyrite oxidation: a state-of-the-art assessment of the reaction mechanism. Geochim Cosmochim Acta 67:873–880

Rimstidt JD, Chermak JA, Gagen PM (1994) Rates of reaction of galena, spalerite, chalcopyrite, and arsenopyrite with Fe(III) in acidic solutions. In: Alpers CN, Blowes DW (eds) Environmental geochemistry of sulfide oxidation, vol 550, ACS symposium series. American Chemical Society, Washington, DC, pp 2–13

Ritchie AIM (1994) Sulfide oxidation mechanisms: controls and rates of oxygen transport. In: Jambor JL, Blowes DW (eds) Short course handbook on environmental geochemistry of sulfide mine-waste, vol 22. Mineralogical Association of Canada, Nepean, pp 201–244

Schippers A, Sand W (1999) Bacterial leaching of metal sulfides proceeds by two indirect mechanisms via thiosulfate or via polysulfides and sulfur. Appl Environ Microbiol 65:319–321

Schippers A, Breuker A, Blazejak A, Bosecker K, Kock D, Wright TL (2010) The biogeochemistry and microbiology of sulfidic mine waste and bioleaching dumps and heaps, and novel Fe(II)-oxidizing bacteria. Hydrometallurgy 104:342–350

Sheoran V, Sheoran AS, Poonia P (2012) Phytoremediation of metal contaminated mining sites. Int J Earth Sci Eng 5:428–436

Singer PC, Stumm W (1970) Acid mine drainage: the rate-determining step. Science 167:1121–1123

Smuda J, Dold B, Friese K, Morgenstern P, Glaesser W (2007) Mineralogical and geochemical study of element mobility at the sulfide-rich excelsior waste rock dump from the polymetallic Zn-Pb-(Ag-Bi-Cu) deposit, Cerro de Pasco, Peru. J Geochem Explor 92:97–110

Weibel L, Dold B, Cruz J (2011) Application and limitation of standard humidity cell tests at the Andina porphyry copper mine, CODELCO, Chile. In: SGA biennial meeting, Antofagasta, Chile

Zepeda V, Galleguillos F, Castillo D, Lastra M, Demergasso C (2007) Bacterial activity at low temperature in cultures derived from a low-grade copper sulphide bioleaching heap at the Escondida Mine, Chile. Adv Mater Res 20–21:543–546

Zepeda V, Galleguillos F, Urtuvia V, Molina J, Demergasso C (2009) Comparison between the bacterial populations from solutions and minerals in 1m test columns and the industrial low grade copper sulphide bioleaching process in the Escondida Mine, Chile. Adv Mater Res 71–73:63–66

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Dold, B. (2014). Mineralogical and Geochemical Controls in Biomining and Bioremediation. In: Parmar, N., Singh, A. (eds) Geomicrobiology and Biogeochemistry. Soil Biology, vol 39. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-41837-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-642-41837-2_7

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-41836-5

Online ISBN: 978-3-642-41837-2

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)