Abstract

This chapter deals with the review on natural backbone-based superabsorbent hydrogels and their classification based upon method of preparation, monomer type, and ionic charge. The applications of hydrogels in different fields like biomedical, pharmaceuticals, agriculture, metal ion sorption, etc., have been discussed in this chapter. The polysaccharide-based hydrogels are eco-friendly, cost effective, biodegradable, and biocompatible in nature. They can be characterized by different techniques like FTIR, SEM, XRD, AFM, TGA, DTA, DTG, and DSC.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

Hydrogels are three-dimensional network systems which can imbibe large amount of solvent without showing solubility. They are considered as superabsorbent as they can absorb aqueous solvent more than 20 times of their initial weight. The era of hydrogels begins from the late 1950s with the synthesis of biomaterials based upon copolymers of 2-hydroxyethylmethacrylate and ethylene dimethacrylate by Wichterle and Lim [1]. The late 1960s and early 1970s were the era of research on the synthesis of hydrogels by different methods and techniques [2]. The early methods of synthesis of hydrogels were focused on the control of detailed structure of hydrogels, whereas recent scenario has shifted to applicability of hydrogels in diversity fields. They form three-dimensional swollen networks through covalent or ionic linkages between homopolymer and copolymers. Three-dimensional networks can be obtained by different techniques like copolymerization, interpolymer complexes, and semi-interpenetrating polymerization. The hydrophobicity of backbone polymers and density of cross-linking are the governing parameters for different structural properties. The advancement in technology and novel methodologies of genetic engineering diverts the research towards the synthesis of stimuli responsive hydrogels. Hydrogels can respond distinctively towards the external environmental conditions like temperature, pH, magnetic field, electric stimuli, and ionic strength. Such hydrogels are called smart polymers and have widened the area of applicability. Hydrogels with controlled biodegradability, stability towards chemicals and biochemicals, shape stability, biocompatibility, and high permeability of water-soluble nutrients and metabolites are the novel biomaterials of present era. The distinct features make them successful polymeric biomaterials in different fields. Various biomaterials like cellulose, starch, chitosan, and guar gum have been modified for their use in metal ion sorption, controlled drug delivery systems, water treatment processes, pesticides and herbicides delivery, and many other agricultural, biotechnological, and medicinal fields [3–6].

7.2 Classification of Hydrogels

Polysaccharide hydrogels can be classified on the basis of method of synthesis, types of monomer involved, and ionic charges.

7.2.1 On the Basis of Method of Preparation

On the basis of method of synthesis, hydrogels can be physically cross-linked or chemically cross-linked.

7.2.1.1 Physical Hydrogels

These are reversible and unstable hydrogels in which polymer networks are held together by secondary forces. The forces of interactions between polymeric networks may be ionic, hydrogen bonding, or hydrophobic interactions. The stability of these hydrogels depends upon the external conditions. The interactions may get weak by change in environment or by application of stress. Physically cross-linked hydrogels have wide applications in biomedical and pharmaceutical field as it does not require any cross-linking agent. Blends of starch–carboxymethylcellulose, gelatine–agar form physically cross-linked hydrogels [7–9]. Chitosan solution containing glycerol-2-phosphate results in the formation of hydrogel at 37 °C due to hydrophobic interactions [10].

7.2.1.2 Chemical Hydrogels

These are irreversible and stable hydrogels involving chemical cross-linking between polymeric networks. Chemical cross-linking involves reaction of polymeric backbone with cross-linking agent. Polysaccharides have functional groups like hydroxyl or amine group which on reaction with cross-linking agent form gel structure. Cross-linking may occur by different mechanisms like condensation, addition, and vulcanization. These hydrogels having strong covalent bonds can attain equilibrium swelling state which depends upon the polymer–solvent interactions and cross-link density. Polysaccharides like cellulose and its derivatives, chitosan, alginate, dextran, guar gum, and starch, can be cross-linked in the presence of chemical reagents and in the presence of radiations to form chemical hydrogels [11, 12].

7.2.2 On the Basis of Types of Monomer Units Involved

Hydrogels can be categorized into three types: homopolymer hydrogels, copolymer hydrogels, and interpenetrating polymeric hydrogels.

7.2.2.1 Homopolymer Hydrogels

Homopolymer hydrogels have single specie as basic unit in the polymer matrix. The single monomer unit cross-links to form three-dimensional network structures. The cross-linked networks are formed in the presence of cross-linking agent or without the presence of cross-linking agent. Cellulose hydrogels were reported through one-step method in which cellulose was dissolved directly in urea/NaOH solutions in the presence of epichlorohydrin as cross-linker. It resulted in fully transparent hydrogel with macroporous inner structure [13]. Irradiation of polysaccharide solutions results in the formation of hydrogels in the absence of gelating agent. Commercial polysaccharides like xanthan, pectin, guar gum, alginate, starch, xanthan, chitin, and chitosan can be modified in the presence of high-energy radiations to form hydrogels [14].

7.2.2.2 Copolymer Hydrogels

Copolymer hydrogel contains two or more monomeric units in which at least one of the monomer is hydrophilic. Copolymer hydrogels have different arrangements of copolymers like random, block, or alternative with respect to main polymeric chain. The properties of copolymer hydrogels depend upon the varied combination of polymeric units and respective arrangements of these polymeric networks. Polysaccharide copolymer hydrogels may involve two different polysaccharide units or combination of a polysaccharide with synthetic polymer. Blend hydrogels based upon carboxymethylcellulose and carboxymethyl chitosan were reported for metal absorption of Pb and Au [15, 16].

7.2.2.3 Interpenetrating Polymer Network Hydrogels

These hydrogels involve two independent cross-linked networks. These cross-linked networks intermesh into each other in the presence of cross-linker. One polymeric network swells in the network of another polymer results in the formation of interpenetrating polymeric network. These are called semi-IPN when one of the components is cross-linked, while the other component remains uncross-linked. The properties of these interpenetrating polymer network hydrogels (IPNs) depend upon relative hydrophilicity and hydrophobicity of two polymeric networks. IPN hydrogels of alginate and hydrophobically modified ethyl hydroxyl ether cellulose have been studied for gelation behavior [17]. pH and temperature-sensitive semi-interpenetrating polymer network hydrogel based on linear carboxymethyl chitosan and poly(N-iso-polyacrylamide) cross-linked with organic clay were reported [18]. IPN hydrogel based on chitosan and N-vinylpyrrolidone was prepared with photopolymerization technique [19].

7.2.3 On the Basis of Ionic Charge

On the basis of ionic charge, hydrogels are divided into three categories: neutral, ionic, and ampholytic hydrogels.

7.2.3.1 Neutral Hydrogels

These hydrogels have neutral monomeric units which cross-link to form three-dimensional networks. These nonionic hydrogels may be homopolymeric or copolymeric in nature. The copolymeric polysaccharide hydrogels with monomers like acrylamide, hydroxyalkyl methacrylates, and N-vinyl pyrrolidone result in neutral hydrogels. These hydrogels are temperature sensitive resulting in swelling–deswelling behavior with change in temperature. Swelling behavior depends upon the equilibrium between sub-chain stretching and osmotic pressure of solvent. Neutral polysaccharide hydrogels mainly involve covalent cross-linking. These hydrogels have permanent polymer networks as linkages formed are irreversible. This type of linkage allows absorption of water without dissolution and thus allows drug release by diffusion [20].

7.2.3.2 Ionic Hydrogels

Ionic hydrogels contain charged anionic or cationic monomeric species. These may be homopolymeric involving only ionic polymer network or copolymer of ionic and neutral polymer network. These may be formed by modifications in neutral hydrogels by partial hydrolysis or addition of excess of polyelectrolytes. Monomers like acrylic acid derivatives, crotonic acid, and sodium styrene sulphonate result in anionic hydrogels, whereas monomers like aminoethylmethacrylate and 4-vinyl pyridine form cationic hydrogels. Ionic hydrogels are biocompatible and well tolerated. They result in the formation of nonpermanent network due to reversible links. Ionically cross-linked chitosan hydrogels show a higher swelling sensitivity to pH changes compared to covalently cross-linked chitosan hydrogels [21].

7.2.3.3 Ampholytic Hydrogels

Ampholytic hydrogels have polymeric networks having both positively and negatively charged monomeric species. The properties of ampholytic hydrogels depend upon the presence of ionic species along the polymer chain. Oppositely charged solutions have coulombic attractions between them due to which ampholytic hydrogels have interionic as well as intra-ionic attractions. These interactions are weaker than covalent interactions but are stronger than van der Waals forces. Monomeric units like acrylic acid, maleic anhydride, and N-vinyl succinimide result in ampholytic hydrogels [22].

7.3 Synthesis of Hydrogels

Hydrogel synthesis involves the linking of macromolecular chains together which progressively results in the development of three-dimensional networks. Formation of network structure involves formation of branched polymer at initial stage which slowly increases in size and results in gel/network structure. This process can be recognized as sol–gel transition or gelation. Cross-linking may be achieved by different techniques depending upon involvement of physical or chemical cross-linking. Various synthesis methods have been reported for the synthesis of polysaccharide-based hydrogels like cellulose, chitin, and alginate.

7.3.1 Physical Cross-Linking

It results in the formation of hydrogels in which networks are held together by secondary forces like ionic interactions, hydrophobic interactions, and hydrogen bonding. Synthesis of hydrogels involving physical cross-linking does not require any cross-linking agent. Physical cross-linked polysaccharide hydrogels can be synthesized by different techniques like heating/cooling of polymer solution, ionic interactions, H-bonding, heat-induced aggregation, complex coacervation, and freeze drying.

Cooling of hot solution of polysaccharide results in the formation of hydrogel. On cooling of hot solution of polymer, helix formation takes place which results in the formation of junction zones having physical interactions. The stable gels are formed if cooling occurs in the presence of salts like K+, Na+ which further aggregates the helices to form stable gels. Physical cross-linking may also occur by reverse process, i.e., heating of polymer solution. Heating of polymer solution results in block copolymerization. Synthesis of carrageen hydrogels has been reported by cooling of hot solution [23].

Ionic interaction results by mixing of negatively charged polymer with positively charged polymer. This can be achieved by addition of di- or trivalent counter ion polymer solution. Dextran coated with anionic and cationic polymers when mixed together results in the formation of network structure due to formation of ionic complex between oppositely charged polymers. Formation of ionic hydrogels have been reported for chitosan–dextran, chitosan–glycerol phosphate, and chitosan–poly(lysine) hydrogels [24].

Hydrophobic interaction may also result in the formation of physically cross-linked hydrogels. Chitosan–poly(ethylene oxide) hydrogels have hydrophobic interactions which result in the formation of cross-linked network. These hydrogels have been studied for the release of bovine-serum albumin [25].

Hydrogen-bonded hydrogels can be synthesized at low pH. It involves cross-linking of polymeric solution in the presence of acid or polyfunctional monomer. Carboxymethylated chitosan hydrogel can be synthesized in the presence of acid. H-bonding can be achieved by mixing of two polymeric solutions having desirable functional groups for hydrogen bonding. Mixing of alginate and xanthan polysaccharides results in the formation of hydrogels due to intermolecular hydrogen bonding between them [26].

Freeze drying is a simple and effective method to develop physically cross-linked hydrogels. It involves the formation of microcrystals in polymeric structure. Microporous hydroxypropyl cellulose hydrogels were synthesized by freeze drying and subsequent rehydration of gels. This method of synthesis has also been reported for xanthan hydrogels [27].

Self-assembling of polymer to form stereocomplex is a new concept for the formation of physically cross-linked hydrogel. To form hydrogel cross-linked by stereocomplex formation, enantiomeric lactic acid and methylmethacrylate oligomers have been used. These enantiomeric oligomers were coupled to polymer backbone to form hydrogel structure. Self-assembled hydrogels can be obtained by mixing of aqueous solution of each polymeric solution at room temperature. Self-assembled hydrogel has been reported by stereocomplex formation in aqueous solution of enantiomeric lactic acid grafted to dextran [28].

7.3.2 Chemical Cross-Linking

Chemical cross-linking results in permanent or chemical hydrogels having covalent linkages. These hydrogels can attain equilibrium swelling state depending upon the cross-linking density and intensity of interaction of polymer with water. Chemical cross-linking may proceed with polymerization of functional groups present on backbone, polymerization in the presence of cross-linking agent, and polymer–polymer cross-linking. Polysaccharide-based hydrogels involving chemical cross-linking can be synthesized by different techniques.

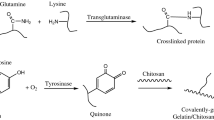

Chemically cross-linked polysaccharide hydrogels can be synthesized in the presence of cross-linking agent. Different cross-linking agents like glyceraldehydes, formaldehyde, epichlorohydrin, and N,N′-methylenebisacrylamide have been reported for the synthesis of polysaccharide-based hydrogels. Cross-linking involves active reaction sites like –OH groups on the polysaccharide backbone. Cross-linking on polysaccharide backbone may proceed via condensation reaction [29], Michael addition [30], hydrazone bonding [31], and enzymatic cross-linking [32]. A carboxymethyl cellulose sodium salt and hydroxyethyl cellulose hydrogels have been prepared using divinyl sulfone as cross-linker to develop novel system for the body water elimination for treatment of edema [33]. Cross-linked carboxymethyl konjac glucomannan was synthesized by reaction of monochloroacetic acid, konjac glucomannan, and monochloroacetic acid. Cross-linked hydrogels were used to absorb Cu2+, Pb2+, and Ca2+ ions from aqueous solution [34]. Hyaluronic acid has been cross-linked with α-β-polyacryl hydrazide [35].

Radiation cross-linking is another technique to synthesize hydrogels. It does not involve the use of chemical agents, thereby an important method to develop biocompatible hydrogels. Single-step synthesis and cost-effectiveness are the other advantages of radiation cross-linking. Radiation cross-linking of hydrogels may proceed in the presence of high-energy radiations like gamma radiations, electron beam, or X-rays [36]. The cross-linking may occur in dilute solution, in concentrated solution, or in solid state. In case of radiation-induced cross-linking, in aqueous state, irradiation of dilute solution results in the absorption of radiation by water molecules which generate free radicals to activate polysaccharide backbone. Radiation-induced cross-linking of carboxymethyl cellulose was investigated in aqueous solution at various radiation doses. Cross-linking was observed in 5 % aqueous solution [37]. Blend hydrogels of carboxymethylcellulose and carboxymethyl chitosan were prepared by gamma irradiation of high-concentrated aqueous solution for metal adsorption of Pb and Au [38]. Irradiation of polysaccharides in solid state results in the generation of free radicals directly on polymer chain. The breakdown of glycosidic bond is the primary reaction involved in solid state irradiation. It may result in degradation of polysaccharide which depends upon the concentration of reactants and temperature. Carboxymethyl cellulose, gum arabic, and dextran have been modified in solid state by high-energy radiations to synthesize hydrogels [39].

Graft copolymerization is one of the promising techniques for the synthesis of chemical hydrogels [40]. Grafting involves covalent linkages of a monomer onto polymer backbone. Graft copolymerization in the presence of suitable chemical reagent or high-energy radiations results in the formation of macro-radicals which further cross-link to form gel structure [41]. The presence of initiators and radiations activates the polysaccharide backbone chain which leads to infinite branching and cross-linking [42]. The use of different chemical reagents as initiators has been reported to activate the backbone. Psyllium has been functionalized with acrylamide in the presence of potassium persulfate (KPS)-hexamethylenetetramine (HMTA) as an initiator–cross-linker system. After the initial optimization of different reaction parameters, the resultant hydrogel was used for the absorption of water from different water–oil emulsions [43]. Psyllium hydrogels have also been synthesized under the influence of gamma radiations in the presence of hexamethylenetetramine as cross-linker [44]. Electosensitive hydrogels based upon gum ghatti were synthesized by graft copolymerization with acrylamide using potassium persulfate–ascorbic acid initiator system and N,N-methylenebisacrylamide as cross-linking agent [45]. Thermo- and pH-sensitive hydrogels have been prepared by graft copolymerization of chitosan and N-isopropyl acrylamide. Radiation-induced grafting of acrylamide onto chitosan resulted in the synthesis of hydrogels which can act as excellent flocculants [46]. Carboxymethyl cellulose-based hydrogels have been synthesized using electron beam irradiated grafting of acrylic acid onto CMC [47].

7.4 Characterization

The characterization of hydrogels gave idea about their structural as well as physicochemical properties. Techniques employed for characterization depend upon the target application. Different techniques have been developed to study the properties like swelling behavior, release kinetics, and mechanical properties [48].

Macroscopic studies have been done to understand the properties of hydrogels at microscopic and nanoscale. SEM is widely utilized to examine the surface morphology of polysaccharide hydrogels. SEM was used to study the interior morphology of dextran hydrogels and to determine the pore characteristics [49]. SEM analysis of gel networks differentiated between enzymatically and chemically synthesized dextran hydrogels on the basis of pore size. The enzymatically synthesized hydrogels showed more uniform pore size than chemically prepared hydrogels [50]. SEM images have also been utilized to compare acetone-dehydrated versus air-dried cellulose-based hydrogels. Acetone-dehydrated hydrogel showed folding and voids, whereas air-dried cellulose hydrogel showed smooth and dense surface [51]. SEM images provide evidences for the occurrence of chemical modifications like graft copolymerization onto hydrogel surface. The graft copolymerization onto glucomannose with acrylic acid was confirmed by SEM micrograms of before and after graft copolymerization. Surface was found to be less smooth, having caves and holes after graft copolymerization [52]. SEM images of psyllium hydrogel showed marked differences before and after cross-linking (Fig. 7.1). Psyllium has smooth homogeneous surface, while cross-linked psyllium with poly(acrylic acid) showed network structure with cross-linking in the form of overlapped fibrils [53].

SEM of (a) psyllium and (b) cross-linked Psy-g-poly(AA) [53]

AFM is an important technique to study smooth gel surface with nanometer-sized protrusions and provide quantitative information regarding topography. AFM also provides information regarding mechanical properties and local elastic properties of hydrogel surface [54].

Fourier transform infrared spectroscopy is used to determine the nature of modification of hydrogels [55]. Introduction of acrylamide group in psyllium was confirmed by FTIR spectrum which showed emergence of new bands at 1666.7 cm–1 (C=O stretch) and 1425.4 cm−1 (N–H in plane bending) and 1249.9 cm−1 (C–N stretching vibration) besides peaks obtained with that of psyllium (Fig. 7.2) [56]. Gum arabic showed peaks for O–H stretch at 3365.2 cm−1 and C–O stretch at 1042.9 cm−1. On the other hand, cross-linked gum arabic revealed peaks at 1725.1 cm−1 and 1631.2 cm−1 due to C–O stretch which confirms the graft copolymerization onto gum arabic [57].

FTIR spectra of (a) psyllium and (b) Psy-cl-poly(AAm) [56]

TGA, DTA, DTG, and DSC are the different techniques to study the thermal behavior and stability of hydrogels. Thermogravimetric analysis of polysaccharide hydrogels is carried out as a function of weight loss versus temperature. Degradation of hydrogels that occurs in different stages corresponds to deacetylation, dehydration, and decarboxylation which may result in single phase or two or more phases of decomposition. TGA of gum ghatti as well as of cross-linked hydrogel showed two stages of decomposition. However, final decomposition temperature of cross-linked hydrogel was found to be higher than that of gum ghatti itself. This could be accounted to the strengthening of amorphous region on cross-linking which increased the stability of hydrogels [58]. Cross-linking of gum arabic with methylmethacrylate enhanced the thermal stability of hydrogel. This is evident from TGA and DTA studies. Cross-linked hydrogel shows high final decomposition temperature in TGA studies which were further proved with DTA studied showing high decomposition temperature (Fig. 7.3, [57]).

DTA/TGA of (a) gum arabic and (b) GA-cl-poly(MAA) [59]

The knowledge of mechanical properties of hydrogels is required to adequately design and for the efficient use of hydrogels. Polysaccharide hydrogels have been widely studied for tissue engineering applications. Assessment of mechanical properties is useful to design adequate scaffolds for engineering tissues. Modification of polysaccharide hydrogels also affects the mechanical properties of these hydrogels. Many of these properties have been determined for different polysaccharide hydrogels. There is significant data published in regard to mechanical properties of alginate hydrogels. Compressive strength of alginate hydrogels was found to be in the range of less than 1 kPa to more than 1,000 kPa [59, 60]. Shear strength of alginate showed values in the range of 0.02–0.04 kPa [61]. Mechanical properties of hydrogels depend on the cross-linker, storage environment, and gelling environment [62]. Dynamo-mechanical analysis of guar gum hydrogel was performed at three different temperatures to analyze hardness, cohesion, and young modulus which were found to be temperature dependent [63].

7.5 Applications of Polysaccharide Hydrogels

Polysaccharide hydrogels due to their dynamic structural properties have been employed for various potential applications. Polysaccharide-based hydrogels have been commonly utilized in numerous biomedical applications like coatings, as homogeneous materials like contact lenses and devices like sustained drug delivery systems, and as agricultural applications like water storage granules and controlled release of pesticides. These hydrogels are also used in important industrial fields like electrophoresis, chromatography, and protection of technical and electronic instruments, food industry, cosmetic industry, and many more [64, 65].

7.5.1 Biomedical Applications

Polysaccharide hydrogels have been employed for a wide range of biomedical applications. The success of polysaccharide hydrogels as biomaterials is mainly due to their satisfactory performance upon in vivo transplantation and their ability to fabricate into a wide range of morphologies. The use of polysaccharide hydrogels is related to their biocompatibility. Low toxicity, structural similarity to natural materials, and degradation by enzymes are the other properties which make polysaccharide hydrogels a suitable candidate for different biomedical applications.

Among various biomedical applications, hydrogel-based drug delivery devices have become the major area of interest and gained success at the industrial level. A large number of polysaccharide hydrogels have been studied for colon-specific drug carrier systems like chitosan, pectin, dextran, guar gum, and konjac glucomannan [52]. Colon region has been considered as potential adsorption site for proteins and peptides. Carboxymethylcellulose and acrylic acid-based hydrogels have been studied for colon-specific drug carrier for the release of theophylline as a function of time at pH 1 and 7 [66]. Cross-linked hydroxypropyl methyl cellulose hydrogel was found to be a promising drug delivery system for the colon-specific release of antiulcerative colitis drugs [67]. Dextran hydrogels cross-linked with diisocyanate showed potential application for colon-specific drug delivery [68]. Kulkarni and Sa studied the drug release characteristics of (polyacrylamide-g-xanthan)-carboxymethyl cellulose-based IPN hydrogels [69]. The different cellulose ether-based hydrogels were investigated for swelling behavior, and order of mesh size was found to be the most important parameter for drug diffusion and release [70]. Thermoresponsive acrylic hydrogels having carboxymethylcellulose matrix prepared by emulsion polymerization were employed for transdermal drug release systems at different temperatures [71]. Hydrogel matrix tablet of acarbose was formulated using hydroxypropylmethyl cellulose and guar gum to study the release kinetics and to attain a near-zero release kinetics. These matrix tablets were found suitable for maintenance portion of oral-controlled release tablet [72]. Semi-interpenetrating network hydrogel blends of gelatine and hydroxyethyl cellulose were investigated for the controlled release of antiasthamatic drug theophylline. Drug release profile was investigated in terms of the amount of cross-linker and percentage loading [73].

Chitosan hydrogels have been extensively studied as drug delivery systems. Due to biological properties, it is an attractive material for ophthalmic drug delivery, nasal delivery, intestinal drug delivery, and transdermal delivery [74, 75]. Covalently cross-linked chitosan hydrogels showed pH-controlled drug delivery as the presence of chemical linkages allows drug release by diffusion [76]. N-chitosan derivative-based ophthalmic drug delivery system has been developed using supercritical solvent impregnation technique. The tuneable SSI method was found to be an easy and efficient method for desired drug levels according to patient’s need [77]. Injectable hydrogels have also been developed as drug carriers, gene carriers, and scaffolds. Injectable chitosan-based hydrogels were investigated as drug delivery matrix to be applied as sealant after ear–nose–throat surgery. These chitosan-based hydrogels showed controlled drug delivery profile for dexamethasone. On cross-linking with oxidized polymer material, chitosan showed more promising results [78].

Polysaccharide hydrogels have been widely studied in the tissue engineering applications. Longer and Vacantie elucidate the ways in which polymer gels are utilized in tissue engineering to repair damage tissues. Hydrogels have been used as scaffolds for cellular organization, as tissue barriers and bioadhesives, and to encapsulate and deliver cells [79]. Hydrogels can be used as scaffold materials as their mechanical properties can be modified to match with natural tissues. Homogeneous alginate hydrogels were formulated as scaffolds for cell culture due to their ability to encapsulate cells under milder conditions. Alginate hydrogels have been employed for the encapsulation of number of cell type like osteoblasts, chondrocytes, neutral stem cells, and mesenchymal cells [80, 81]. Chitosan-based hydrogels have been widely studied for cell transplantation and tissue regeneration. Biodegradable hydrogels based on guar gum methacrylate macromonomer have been studied for in situ fabrication of tissue engineering scaffolds [82]. Methacrylated glycol chitosan hydrogels using blue light initiator riboflavin offer a promising photoinitiator system in tissue engineering application. RF photoinitiated hydrogels supported proliferation of encapsulated chondrocytes and extracellular matrix deposition. The feasibility of these system in situ gelling hydrogels was further demonstrated in osteochondral and chondral defect models for potential cartilage tissue engineering [83]. Hyaluronic acid grafted with dextran tyramine conjugate was investigated as injectable biomimetic hydrogels for cartilage tissue engineering. The design of these hybrid hydrogels was based on the molecular structure of proteoglycans present in the extracellular matrix of natural cartilage. These hydrogels have enhanced chondrocyte proliferation and matrix production which is an important cartilage tissue engineering application [84].

Wound dressing is one of the important biomedical applications for polysaccharide hydrogels. Their adhesive nature, antifungal and bactericidal characteristics, and permeability to oxygen are the important properties associated with treatment of wound and burns. Chitosan and its derivative-based hydrogels have been widely studied as wound dressing materials [85]. A wound dressing material from alginates was developed by loaded asiaticoside on alginate films by indirect cytotoxicity and direct cell culture [86]. Periodic oxidized alginate cross-linked gelatin in the presence of borax to give in situ forming hydrogels. These hydrogels have hemostatic effect of gelatine, wound healing feature of alginate, and antiseptic property of borax which make it a potential wound dressing material [87]. Synthetic extracellular matrix, implantable devices, biosensors, valve to control permeability across porous membranes, and smart microfluidics are the other applications of polysaccharide hydrogels in biomedical field.

7.5.2 Agriculture Applications

Storage of water in different agriculture fields has remained a challenging task. Hydrogels have been commonly utilized as water storage granules in agriculture fields. Cellulose-based hydrogels are the potential materials to absorb and retain water. Sannino and coworkers develop cellulose-based hydrogels which can absorb 1 l of water per gram of dry material. The hydrogel sorption capacity has been tested at different ionic strengths. The soil with the small amount of hydrogel remains humid for period four times more than without hydrogel. Polysaccharide hydrogels have attracted great deal of attention as potential delivery devices for control release applications [88]. The sodium alginate cross-linked with glutaraldehyde was investigated as a vehicle carrier for the encapsulation and release of natural liquid pesticide neem seed oil. An increase in the degree of cross-linking decreased the release of pesticide [89]. Starch–alginate–clay beads with different compositions were investigated for the release of thiram, a dithiocarbamate fungicide. The maximum release of thiram was of about 10 mg after 30 h [90]. Microsphere of sodium alginate and starch using CaCl2 as a cross-linker was found to be a promising carrier for the control release of pesticide chlorpyrifos. Optimum fractional release accounts for a bead composition with more alginate and less starch [91]. Starch/ethylene glycol-co-methacrylic acid was designed for controlled delivery of pesticides like fluometuron, thiophanate methyl, and trifluralin. The pesticide release rate was found to decrease as the irradiation was done and pH was increased and found to increase with MMA content, pesticide concentration, and temperature increase [92].

7.5.3 Metal Ion Sorption

Heavy metal ion sorption is an important application of polysaccharide hydrogels. Psyllium husk and acrylic acid-based polymeric networks using N,N′-methylene bis-acrylamide as cross-linker were studied for removal, separation, and enrichment of hazardous metal ions from aqueous solution [93]. Polymer networks based on cellulose and its derivatives like hydroxypropyl cellulose, cyanoethyl cellulose, hydroxyethyl cellulose, hydrazinodeoxy cellulose, cellulose phosphate with acrylamide, and N,N ′-methylene bis-acrylamide were studied for sorption of Fe2+, Cu2+, and Cr2+ ions [94]. Hydrophilic hydrogels based on poly(acrylic acid) and sodium alginate prepared through gamma radiation method showed affinity towards the metal sorption of Cu2+, Co2+, and Ni2+ ion [95].

7.6 Conclusion

Polysaccharide-based hydrogels are biodegradable and eco-friendly materials which exhibit promising applications in different fields. Moreover, their availability from natural resources and low cost make them more attractive smart polymeric materials. Innovative hydrogel products have thus been developed as personal hygiene products, underwater devices, water reservoirs for dry soils, and biomedical devices, including soft contact lenses, lubricating surface coatings, phantoms for ultrasound-based imaging, controlled drug release devices, wound healing dressings, and bioactive scaffolds for regenerative medicines.

References

Wichterle O, Lim D (1960) Hydrophilic gels for biological use. Nature 185:117–118

Krejci L, Harrison R, Wichterle O (1970) Hydroxyethyl methacrylate capillary strip animal trials with a new glaucoma drainage device. Arch Ophthal 84:76–82

Kaith BS, Jindal R, Mittal H (2010) Superabsorbent hydrogels from poly(acrylamide-co-acrylonitrile) grafted Gum ghatti with salt, pH and temperature responsive properties. Der Chemica Sinica 1:92–103

Kaith BS, Ranjta S (2010) Synthesis of pH—thermosensitive gum arabic based hydrogel and study of its salt-resistant swelling behavior for saline water treatment. Desalin Water Treat 24:28–37

Jamnongkan T, Kaewpirom S (2010) Controlled-release fertilizer based on chitosan hydrogel: phosphorus release kinetics. Sci J UBU 1:43–50

Leonardis M, Palange A, Dornelles RF, Hund F (2010) Use of cross-linked carboxymethyl cellulose for soft-tissue augmentation: preliminary clinical studies. Clin Interv Aging 5:317–322

Liu J, Lin S, Li L, Liu E (2005) Release of theophylline from polymer blend hydrogels. Int J Pharm 298:117–125

Bajpai AK, Shrivastava J (2005) In vitro enzymatic degradation kinetics of polymeric blends of crosslinked starch and carboxymethyl cellulose. Polym Int 54:1524–1536

Gupta D, Tator CH, Shoichet MS (2006) Fast-gelling injectable blend of hyaluronan and methylcellulose for intrathecal, localized delivery to the injured spinal cord. Biomaterials 27:2370–2379

Chenite A, Chaput C, Wang D, Combes C, Buschmann MD, Hoemann CD, Leroux JC, Atkinson BL, Binette F, Selmani A (2000) Novel injectable neutral solutions of chitosan form biodegradable gels in situ. Biomaterials 21:2155–2161

Gao C, Liu M, Chen J, Zhang X (2009) Preparation and controlled degradation of oxidized sodium alginate hydrogel. Polym Deg Stab 94:1405–1410

Mittal H, Kaith BS, Jindal R (2010) Microwave radiation induced synthesis of gum ghatti and acrylamide based crosslinked network and evaluation of its thermal and electrical behavior. Der Chemica Sinica 1:59–69

Zhou J, Chang C, Zhang R, Zhang L (2007) Hydrogels prepared from unsubstituted cellulose in NaOH/urea aqueous solution. Macromol Biosci 7:804–809

Phillips GO, Du Plessis TA, Al-Assaf S, Williams PA (2005) Biopolymers obtained by solid state irradiation in an unsaturated gaseous atmosphere. US Patent 6841644

Hirsch SG, Spontak RJ (2002) Temperature-dependent property development in hydrogels derived from hydroxypropyl cellulose. Polymer 43:123–129

Mitsumata T, Suemitsu Y, Fujii K, Fujii T, Taniguchi T, Koyama K (2003) pH-Response of chitosan, κ-carrageenan, carboxymethyl cellulose sodium salt complex hydrogels. Polymer 44:7103–7111

Choudhary S, White JC, Stoppel WL, Roberts SC, Bhatia SR (2011) Gelation behavior of polysaccharide-based interpenetrating polymer network (IPN) hydrogels. Rheol Acta 50:39–52

Khalid MN, Ho L, Agnely F, Grossiord JL, Couarraze G (1999) Swelling properties and mechanical characterization of a semi-interpenetrating chitosan/polyethylene oxide network—comparison with a chitosan reference gel. Stp Pharm Sci 9:359–364

Ng LT, Swami S (2005) IPNs based on chitosan with NVP and NVP/HEMA synthesised through photoinitiator-free photopolymerisation technique for biomedical applications. Carbohydr Polym 60:523–528

Ostroha J, Pong M, Lowman A, Dan N (2004) Controlling the collapse/swelling transition in charged hydrogels. Biomaterials 25:4345–4353

Hariharan MTA, Peppas NA (1995) Factors influencing drug and protein transport and release from ionic hydrogels. React Polym 25:127–137

Gupta KC, Kumar MNVR (2000) Semi-interpenetrating polymer network beads of crosslinked chitosan–glycine for controlled release of chlorphenamine maleate. J Appl Polym Sci 76:672–683

Funami T, Hiroe M, Noda S, Asai I, Ikeda S, Nishimari K (2007) Influence of molecular structure imaged with atomic force microscopy on the rheological behavior of carrageenan aqueous systems in the presence or absence of cations. Food Hydrocolloids 21:617–629

Bajpai AK, Shukla SK, Bhanu S, Kankane S (2008) Responsive polymers in controlled drug delivery. Prog Polym Sci 33:1088–1118

Bhattarai N, Ramay HR, Gunn J, Matsen FA, Zhang M (2005) PEG-grafted chitosan as an injectable thermosensitive hydrogel for sustained protein release. J Control Release 103:609–624

Pongjanyakul T, Puttipipatkhachorn S (2007) Xanthan–alginate composite gel beads: molecular interaction and in vitro characterization. Int J Pharm 331:61–71

Giannouli P, Morris ER (2003) Cryogelation of xanthan. Food Hydrocolloids 17:495–501

De Jong SJ, De Smedt SC, Wahls MWC, Demeester J, K-van den Bosch JJ, Hennink WE (2000) Novel self-assembled hydrogels by stereocomplex formation in aqueous solution of enantiomeric lactic acid oligomers grafted to dextran. Macromolecules 33:3680–3686

Eiselt P, Lee KY, Mooney DJ (1999) Rigidity of two-component hydrogels prepared from alginate and poly(ethylene glycol)-diamines. Macromolecules 32:5561–5566

Cai S, Liu Y, Shu XZ, Prestwich GD (2005) Injectable glycosaminoglycan hydrogels for controlled release of human basic fibroblast growth factor. Biomaterials 26:6054–6067

Motokawa K, Hahn SK, Nakamura T, Miyamoto H, Shimoboji T (2006) Selectively crosslinked hyaluronic acid hydrogels for sustained release formulation of erythropoietin. J Biomed Mat Res Part A 79:459–465

Kurisawa M, Chung JE, Yang YY, Gao SJ, Uyama H (2005) Injectable biodegradable hydrogels composed of hyaluronic acid–tyramine conjugates for drug delivery and tissue engineering. Chem Commun 34:4312–4314

Sannino A, Esposito A, De Rosa A, Cozzolino A, Ambrosio L, Nicolais L (2003) Biomedical application of a superabsorbent hydrogel for body water elimination in the treatment of edemas. J Biomed Mater Res A 67:1016–1024

Niu C, Wu W, Wang Z, Li S, Wang J (2007) Adsorption of heavy metal ions from aqueous solution by crosslinked carboxymethyl konjac glucomannan. J Hazard Mater 141:209–214

Pitarresi G, Palumbo FS, Tripodo G, Cavallaro G, Giammona G (2007) Preparation and characterization of new hydrogels based on hyaluronic acid and α,β-polyaspartylhydrazide. Eur Polym J 43:3953–3962

Kumar K, Kaith BS, Jindal R, Mittal H (2012) Gamma-radiation initiated synthesis of psyllium and acrylic acid based polymeric networks for selective absorption of water from different oil-water emulsions. J Appl Polym Sci 124:4969–4977

Fei B, Wach RA, Mitomo H, Yoshii F, Kume T (2000) Hydrogel of biodegradable cellulose derivatives I radiation-induced crosslinking of CMC. J Appl Polym Sci 78:278–283

Hiroki A, Tran HT, Nagasawa N, Yagi T, Tamada M (2009) Metal adsorption of carboxymethyl cellulose/carboxymethyl chitosan blend hydrogels prepared by gamma irradiation. Radiat Phys Chem 78:1076–1080

Al-Assaf S, Phillips GO, Williams PA, Plessis TA (2007) Application of ionizing radiations to produce new polysaccharides and proteins with enhanced functionality. Nucl Inst Meth Phys Res B 265:37–43

Kaith BS, Sharma S, Jindal R, Bhatti MS (2011) Screening and RSM optimization for synthesis of gum tragacanth-acrylic acid based device for in-situ controlled cetirizine dihydrochloride release. Soft Mat 8:2286–2293

Kumari A, Kaith BS, Singha AS, Kalia S (2010) Synthesis, characterization and salt resistant swelling behavior of Psy-g-poly(AA) hydrogel. Adv Mat Let 1:123–128

Mittal H, Kaith BS, Jindal R (2010) Synthesis, characterization and swelling behaviour of poly(acrylamide-co-methacrylic acid) grafted Gum ghatti based superabsorbent hydrogels. Adv Appl Sci Res 1:56–66

Kaith BS, Kumar K (2007) Preparation of psyllium based hydrogels and their application in oil sector. Iran Polym J 16:529–538

Kumar K, Kaith BS, Jindal R, Mittal H (2012) Gamma-radiation initiated synthesis of psyllium and acrylic acid-based polymeric networks for selective absorption of water from different oil–water emulsions. J Appl Polym Sci 124:4969–4977

Kaith BS, Jindal R, Mittal H, Kumar K (2010) Temperature, pH and electric stimulus responsive hydrogels from Gum ghatti and polyacrylamide-synthesis, characterization and swelling studies. Der Chemica Sinica 1:44–54

Wang JP, Chen YZ, Zhang SJ, Yu HQ (2008) A chitosan-based flocculant prepared with gamma-irradiation-induced grafting. Biores Tech 99:3397–3402

Said HM, Alla SGA, El-Naggar AWM (2004) Synthesis and characterization of novel gels based on carboxymethyl cellulose/acrylic acid prepared by electron beam irradiation. React Funct Polym 61:397–404

Kaith BS, Jindal R, Mittal H, Kumar K (2011) Synthesis, characterization, and swelling behavior evaluation of hydrogels based on gum ghatti and acrylamide for selective absorption of saline from different petroleum fraction–saline emulsions. J Appl Polym Sci 124:2037–2047

Donald AM (2003) The use of environmental scanning electron microscopy for imaging wet and insulating materials. Nat Mat 2:511–516

Ferreiraa L, Gila MH, Cabrita AMS, Dordick JS (2005) Biocatalytic synthesis of highly ordered degradable dextran-based hydrogels. Biomaterials 26:4707–4716

Sannino A, Demitri C, Madaghiele M (2009) Biodegradable cellulose-based hydrogels: design and applications. Materials 2:353–373

Chen LG, Liu ZL, Zhuo RX (2005) Synthesis and properties of degradable hydrogels of konjac glucomannan grafted acrylic acid for colon-specific drug delivery. Polymer 46:6274–6281

Kumar K, Kaith BS, Mittal H (2012) A study on effect of different reaction conditions on grafting of psyllium and acrylic acid-based hydrogels. J Appl Polym Sci 123:1874–1883

Weisenhorn AL, Khorsandi M, Kasas S, Gotzos V, Butt HJ (1993) Deformation and height anomaly of soft surfaces studied with an AFM. Nanotechnology 4:106–113

Kaith BS, Kumar K (2007) Selective absorption of water from different oil–water emulsions with Psy-cl-poly(AAm) synthesized using irradiation copolymerization method B. Bull Mater Sci 30:387–391

Kaith BS, Kumar K (2007) In air synthesis of Psy-cl-poly(AAm) network and its application in water-absorption from oil-water emulsions. eXPRESS Polym Let 1:474–480

Kaith BS, Ranjita S, Kumar K (2008) In air synthesis of GA-cl-poly(MAA) hydrogel and study of its salt- resistant swelling behavior in different salts. e-Polymers 158

Kaith BS, Jindal R, Mittal H, Kumar K, Nagla KS (2010) Synthesis and characterization of Gum ghatti based electrosensitive smart networks. Trends Carbohydr Res 2:35–44

Draget KI, Skjak-Braek G, Smidsrd O (1997) Alginate based new materials. Int J Biol Macromol 21:47–55

Kuo CK, Ma PX (2001) Ionically crosslinked alginate hydrogels as scaffolds for tissue engineering: Part I Structure, gelation rate and mechanical properties. Biomaterials 22:511–21

Rowley JA, Mooney DJ (2002) Alginate type and RGD density control myoblast phenotype. J Biomed Mater Res 60:217–23

Drurya JL, Dennis RG, Mooney DJ (2004) The tensile properties of alginate hydrogels. Biomaterials 25:3187–3199

Sandolo C, Matricardi P, Alhaique F, Coviello T (2007) Dynamo-mechanical and rheological characterization of guar gum hydrogels. Eur Polym J 43:3355–3367

Kaith BS, Kiran K (2007) In vacuum preparation of Psy-cl-Poly(AAm) super-absorbent and its applications in oil-industry. e-Polymers 002.

Kaith BS, Kiran K (2008) In vacuum synthesis of psyllium and acrylic acid based hydrogels for selective water absorption from different oil-water emulsions. Desalination 229:331–341

El-Hag Ali A, Abd El-Rehim H, Kamal H, Hegazy DES (2008) Synthesis of carboxymethyl cellulose based drug carrier hydrogel using ionizing radiation for possible use as site specific delivery system. J Macromol Sci A 45:628–634

Davaran S, Rashidi MR, Khani A (2007) Synthesis of chemically cross-linked hydroxypropyl methyl cellulose hydrogels and their application in controlled release of 5-amino salicylic acid. Drug Dev Ind Pharm 33:881–887

Hovgaard L, Brndsted H (1995) Controlled release dextran hydrogels for colon-specific drug delivery. J Control Release 36:159–166

Kulkarni RV, Sa B (2008) Evaluation of pH-sensitivity and drug release characteristics of (polyacrylamide-grafted-xanthan)-carboxymethyl cellulose-based pH-sensitive interpenetrating network hydrogel beads. Drug Dev Ind Pharm 34:1406–1414

Baumgartner S, Kristl J, Peppas NA (2002) Network structure of cellulose ethers used in pharmaceutical applications during swelling and at equilibrium. Pharm Res 19:1084–1090

Don TM, Huang ML, Chiu AC, Kuo KH, Chiu WY, Chiu LH (2008) Preparation of thermo-responsive acrylic hydrogels useful for the application in transdermal drug delivery systems. Mater Chem Phys 107:266–273

Kumar G, Juyal V, Badoni PP, Rawat MSM, Semalty A (2009) Formulation and release kinetic study of hydrogel containing acarbose using polymers as hydroxypropylmethyl cellulose and guar gum. J Pharm Res 2:370–374

Kajjari PB, Manjeshwar LS, Aminabhavi TM (2011) Semi-interpenetrating polymer network hydrogel blend microspheres of gelatin and hydroxyethyl cellulose for controlled release of theophylline. Ind Eng Chem Res l50:7833–7840

Anders R, Merkle HP (1989) Evaluation of laminated mucoadhesive patches for buccal drug delivery. Int J Pharm 49:231–240

Cerchiara T, Luppi B, Bigucci F, Zecchi V (2003) Chitosan salts as nasal sustained delivery systems for peptidic drugs. J Pharm Pharmacol 55:1623–1627

Berger J, Reist M, Mayer JM, Felt O, Peppas NA, Gurny R (2004) Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur J Pharm Biopharm 57:19–34

Braga MEM, Pato MTV, Silva HSRC, Ferreira EI, Gil MH, Duarte CMM, de Sousa HC (2008) Supercritical solvent impregnation of ophthalmic drugs on chitosan derivatives. J Supercrit Fluids 44:245–257

Schaffhausen N, Tijsma E, Hissong B (2008) Injectable chitosan-based hydrogels for drug delivery after ear–nose–throat surgery. J Control Release 132:e47–e48

Slaughter BV, Khurshid SS, Fisher OZ, Khademhosseini A, Peppas NA (2009) Hydrogels in regenerative medicine. Adv Mater 21:3307–3329

Augst AD, Kong HJ, Mooney DJ (2006) Alginate hydrogels as biomaterials. Macromol Biosci 6:623–633

Drury JL, Mooney DJ (2003) Hydrogels for tissue engineering: scaffold design variables and applications. Biomaterials 24:4337–4351

Tiwari A, Grailer JJ, Pilla S, Steeber DA, Gong S (2009) Biodegradable hydrogels based on novel photopolymerizable guar gum–methacrylate macromonomers for in situ fabrication of tissue engineering scaffolds. Acta Biomater 5:3441–3452

Hu J, Hou Y, Park H, Choi B, Hou S, Chung A, Lee M (2012) Visible light crosslinkable chitosan hydrogels for tissue engineering. Acta Biomater 8:1730–1738

Jin R, Teixeira LSM, Dijkstra PJ, Blitterswijk CAV, Karperien M, Feijen J (2010) Enzymatically-crosslinked injectable hydrogels based on biomimetic dextran–hyaluronic acid conjugates for cartilage tissue engineering. Biomaterials 31:3103–3113

Jayakumar R, Prabaharan M, Kumar PTS, Nair SV, Tamura H (2011) Biomaterials based on chitin and chitosan in wound dressing applications. Biotech Adv 29:322–337

Sikareepaisan P, Ruktanonchai U, Supaphol P (2011) Preparation and characterization of asiaticoside-loaded alginate films and their potential for use as effectual wound dressings. Carbohydr Polym 83:1457–1469

Balakrishnan B, Mohanty M, Umashankar PR, Jayakrishnan A (2005) Evaluation of an in situ forming hydrogel wound dressing based on oxidized alginate and gelatine. Biomaterials 26:6335–6342

Kiran K, Kaith BS (2010) Psyllium and acrylic acid based polymeric net-works synthesized under the influence of γ-radiations for sustained release of fungicide. Fibres Polym 11:147–152

Aouada FA, de Moura MR, Henrique L, Mattoso C (2011) Biodegradable hydrogel as delivery vehicle for the controlled release of pesticide. In: Stoytcheva M (ed) Pesticides—formulations, effects, fate. CC BY-NC-SA

Singh B, Sharma DK, Kumar R, Gupta A (2009) Controlled release of the fungicide thiram from starch–alginate–clay based formulation. Appl Clay Sci 45:76–82

Roy A, Bajpai J, Bajpai AK (2009) Dynamics of controlled release of chlorpyrifos from swelling and eroding biopolymeric microspheres of calcium alginate and starch. Carbohydr Polym 76:222–231

Abd El-Mohdy HL, Hegazy EA, El-Nesr EM, El-Wahab MA (2011) Control release of some pesticides from starch/(ethylene glycol-co-methacrylic acid) copolymers prepared by γ-irradiation. J Appl Polym Sci 122:1500–1509

Singh B, Chauhan GS, Bhatt SS, Kumar K (2006) Metal ion sorption and swelling studies of psyllium and acrylic acid based hydrogels. Carbohydr Polym 64:50–56

Chauhan GS, Singh BS, Chauhan S, Verma M, Mahajan S (2005) Sorption of some metal ions on cellulosic-based hydrogels. Desalination 181:217–224

Nizam El-Din HM, Abou Taleb MF, Abdel Wahab AM, El-Naggar AM (2008) Metal sorption and swelling characters of acrylic acid and sodium alginate based hydrogels synthesized by gamma irradiation. Nucl Inst Meth Phys Res B Beam 266:2607–2613

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Bhatia, J.K., Kaith, B.S., Kalia, S. (2013). Polysaccharide Hydrogels: Synthesis, Characterization, and Applications. In: Kalia, S., Sabaa, M. (eds) Polysaccharide Based Graft Copolymers. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-36566-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-642-36566-9_7

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-36565-2

Online ISBN: 978-3-642-36566-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)