Abstract

In this paper, a new methodology is proposed to optimize a passive suspension system of a full vehicle system based on ride and handling. In passive suspension design, the conflicting design objectives are the ride comfort and handling performances. The ride comfort is defined as the level of comfort experienced by the passenger in a form of numerical values i.e. weighted root mean square (RMS) of acceleration (ISO 2631). The acceleration is measured when the car travels on a Class C random road profile adopted from ISO 8606:1995 standard. Meanwhile, handling performance is defined by quality of handling, which relate to subjective feeling of human driver and also objective measurement of the vehicle characteristics. Impulse steers maneuver (ISO7401) is employed to measure the required objectives defining handling performance, which included the RMS roll gain, phase angle of yaw rate at 0.2 and at 0.6 Hz, phase angle of lateral acceleration at 1 Hz and ratio of yaw rate gain at resonant frequency against the static yaw rate gain. These objectives will be minimized through multi-objective optimization methodology, which involves sampling technique, and regularity model based on multi-objective estimation of distribution algorithm (RM-MEDA) to solve more than 100 dimensional spaces of design parameters. This methodology showed promising results in optimizing full vehicle suspension design compared to the conventional workflow of suspension tuning.

F2012-E01-026

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In automotive industry, ride comfort and handling performance are important objectives required to define the vehicle dynamic characteristics. Ride comfort measures the comfort level experienced by the passengers while travel through rough road. In contrast, handling performance measures the response of maneuvers of the vehicle whilst maintaining its stability during cornering. However, in passive suspension design, both requirements are conflicting to each other. Softer suspension is required for a better ride comfort resulting in poor handling performance. On the other hand, stiffer suspension provides good handling and stability during cornering but at the expense of a bumpy ride. Conventionally, solving this problem often follows the suspension design cycle which require knowledge from experienced engineers or experimental benchmark to define the new performance target of the new suspension system. It follows by iterative tuning process and redesign until the target is met. This target orientated optimization process has a drawback in which the suspension system optimization is bounded by the predefined targets. In addition, most of the suspension tuning is performed using gradient-based approach which have a drawback in solving multi-objective functions and may trap in local optimum. These methods work well for a small number of design variables. As the design variables increase along with the conflicting design objectives, this method becomes inefficient. Therefore, in this paper, a new methodology is proposed specifically to address the problem of large design variables with conflicting design requirements. It consists of design of experiment (DOE) and a Regularity Model-Based Multi-Objective Estimation of Distribution Algorithm (RM-MEDA) to provide the Pareto Front to achieve the best compromised set of solutions between ride and handling performances.

2 Ride Comfort Criteria

Ride comfort often describes the subjective feeling of human experiences as the vehicle travels through the irregular road surface. However, subjective feeling may vary from one person to another thus requiring some measurement technique to quantify the comfort level. Thus random road profiles are employed to simulate the rough road surfaces and ISO 2631: 1997 standard [1] is then used to measure the ride comfort of passenger in the vehicle.

International Standard Organization (ISO 2631) has developed detailed recommendations concerning acceptable vibration limits for both people and structures. Frequency analysis computes the weighted RMS acceleration to determine the human comfort level (Table 1). In the random road simulation, the vehicle is selected to travel at 80 km/h on a class C road profile adopted from the ISO 8606:1995 standard. Class C road profile emulates a rough road surface. Study showed that this objective measurement has a good correlation with the suspension design parameters in minimizing the objective function that improved the ride comfort [2–4]. In order to achieve the best comfort criteria, large suspension travel space is needed. However, the suspension working space is limited depending on the suspension packaging. Therefore, minimization of the RMS suspension travel for front and rear are crucial.

In addition to the ride comfort criteria by ISO 2631:1997 standard, there are other important ride comfort criteria based on the vehicle characteristics. Maurice Olley was one of the founders of modern vehicle dynamics established guidelines back in 1930s for designing vehicles with good rides. Those guidelines are considered as valid rule of thumb even for today’s modern cars. In Olley criteria [5, 6], it stated that the front suspension should have a 30 % lower ride rate than the rear suspension, the pitch and bounce frequencies should be close together, and neither frequency should be greater than 1.3 Hz. Besides, there is a magic number in suspension design which also used to define the ride comfort vehicle characteristics. It is in the form of an empirical results based on experience from the engineer as proposed by Barak [6]. Both Olley and magic number criteria will be employed as constraints in the optimization problem formulation to optimize the vehicle suspension system. The pitch and bounce frequencies of the vehicle can be computed with the used of half vehicle mathematic model as follows:

where, \( a = (K_{f} + K_{r} )/m_{s} ,\;b = coupling\;coefficient = (K_{r} l_{r} - K_{f} l_{f} )/m_{s} \), \( c = (K_{r} l_{r}^{2} + K_{f} l_{f}^{2} )/I_{y} ,\;DI = Dynamic\;Index = (K^{2} /l_{f} l_{r} ),\,I_{y} = m_{s} K^{2} ,K^{f} \) = Front spring stiffness, \( K_{r} \) = Rear spring stiffness, \( l_{f} \) = Distance from the front axle to the center of gravity (CoG), \( l_{r} \) = Distance from the rear axle to the CoG, K = Radius of gyration, \( I_{y} \) = Pitch moment of inertia, and Z = vertical displacement of body at CoG.

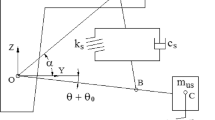

The half vehicle model in Fig. 1 is an undamped two degrees of freedom model. It consists of two principal vibration modes, i.e. pitch and bounce motion. By summing the equilibrium force and moment of the system at CoG and the solution will lead to the two equations in Eqs. (2), (3) representing the two natural frequencies. Both equations have a common coupling coefficient. If the system is uncoupled (coupling coefficient = 0), the pitch motion and bounce motion will have an independent motion. However, the two vibration modes are generally coupled. Dynamic index is an indicator to identify when the pitch frequency and bounce frequency are equal. When the dynamic index close to one, it will eliminate the heterodyning effect on the vehicle. Heterodyning is a phenomenon when two closely spaced frequencies interact to produce a “beat” frequency which can induce motion sickness symptom.

3 Handling Performance Criteria

Handling performance involves subjective and objective evaluation of a vehicle. Subjective evaluation refers to driver feeling of the vehicle response when performing manoeuvring whereas objective evaluation refers to vehicle dynamic characteristics. It varies from one person to another and makes the evaluation difficult to be quantified. Many studies had been carried out using various methodologies to measure subjective feeling to ascertain the relationship between subjective and objective measurements [1, 4, 7–9]. Each methodology is suited for different cases of measurement and manoeuvring tests. At present, there is no general methodology to deal with relationship between subjective and objective evaluation of a vehicle handling performance [7]. However, there is common outcome from various methodologies that can be adopted as the objective measurement function in the optimization process. Impulse steers maneuver (ISO7401—lateral transient response with open loop method [10]), is suitable to assess the quality of handling performance. Additionally, the measurement of frequency response function of steer input provides good interpretation between subjective and objective measurements [7, 11, 12]. Ash employed nonlinear correlation analysis to determine the relationship between the subjective evaluations through questionnaire and numerical measurement of vehicle motion [12]. The analysis suggested that the natural frequency of yaw rate within 1.7–2.1 Hz; damping ratio around 0.7; lateral acceleration phase delay at 1 Hz < −75 deg; static yaw gain rate 0.1–0.2; will give good subjective rating. Additionally, in other works [7, 11] also suggested that the objective measurement of phase delay angle for yaw rate frequency response against steering at 0.2 Hz (which represents the yaw response at low speed steer) and 0.6 Hz (which represents the yaw response at high speed steer) should have a smaller phase delay to allow faster vehicle response. Ratio of yaw rate response gain against steering frequency resonant G(f r ) over static yaw rate gain G(f 0 ) should kept at minimum to minimize changes in yaw rate gain throughout the frequency range for better handling and improve stability during driving maneuver.

4 Vehicle Model Setup

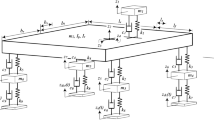

The vehicle suspension is modelled using MSC.ADAMS/CAR as illustrated in Fig. 2. The suspension model is developed based on the existing CAD data. The front suspension of the vehicle is a McPherson strut, and rear suspension is a trailing arm design. All design variables that contribute to the ride and handling performance are identified. There are about 121 design variables comprises of design hard points of suspension in x, y, and z directions, bushing stiffness, spring stiffness, damper profiles and antiroll bar stiffness. The design space of each design variable is defined based on the existing design which serves as a reference by considering the dimensional space of suspension packaging.

The nonlinear damper profiles used in original vehicle model are parameterized with the used of piecewise function (4) and the profile is shown in Fig. 3. This is to emulate the characteristics of nonlinear suspension damper whilst manipulation of damper profiles is possible with the optimization algorithms. Bushing profiles in x, y translational directions as well as rotational x, and rotational y directions are modelled as linear function similarly for other components of suspension such as spring and antiroll bar stiffness. All the suspension components are connected using joints to define the degree of freedom for each component relative to others according to the actual physical suspension design. The complete full vehicle model consists of 61 degrees of freedom.

where, F(v) is the damper force function, C 1 − C 4 are the damper coefficients, and V 1 − V 2 are the corresponding velocities.

5 Optimization

RM-MEDA is a statistical-based algorithm originates from the Estimation of Distribution Algorithm (EDA) [8]. RM-MEDA employed the regularity property of Karush–Kuhn–Tucker condition to solve continuous multi-objective optimization problems with variable linkages [13]. It uses local principal component analysis (LPCA) algorithm for building a model in a promising area of design variable space based on the previous search and estimated samples. Non-dominant sorting method is utilized for selecting the non-dominant solution from the evaluated samples for next generation. Statistical tests on RM-MEDA demonstrate that it is not sensitive to the algorithm’s parameters. It has good scalability in solving a large number of design variables and performs better in solving various kind of benchmark problems [13]. This makes the algorithm suitable to be employed to optimize full vehicle suspension system since it involves large design variables and robust in handling multi-objective problems.

In the optimization process, MSC.ADAMS/Car is integrated with RM-MEDA to perform software in the loop optimization as shown in Fig. 4. DOE is used to perform an initial searching on the large dimension design variables space. Sobol sequence sampling method [14] is employed to maximize the sparseness of each design variables combination across the design spaces. The optimization algorithm setup is initialized by population selected from the previous DOE results. This helps to speed up the searching into the Pareto Front and searching starts from the region of interest preselected from the DOE results. The preselected samples will be used to build LPCA meta-model and generate new solution (Reproduction step). Each solution consists of a vector of design variable. Each design variable in the solution is used to generate necessary model file required by MSC.ADAMS to perform different simulation to evaluate the objectives values (Fig. 4). Termination condition of the optimization algorithm is defined by 100 generations. Extending the search with increasing number of generation will help in improving the optimized results but at the expense of extensive solution time. In this study, 100 generations took one week of solving time.

There are eight objectives used as minimization function defined by ride comfort and handling performance together with 6 constraint functions (Table 2). There are three objectives functions, which defined by ride comfort criteria i.e. weighted RMS acceleration (5), average RMS suspension travel for front and rear suspension (6–7).

Besides, it is also important to maintain the robustness of the vehicle in providing ride comfort in different road conditions. Therefore, the guidelines of magic ride numbers and Olley criteria are employed as the constraints (13–15). In handling performance, there are five objectives to be minimized (8–12). RMS roll gain against steer input is selected due to safety concerned in handling maneuver. A high roll gain with a given steer input is dangerous and may cause the vehicle to roll over. The penalty values for handling performance are defined in Eqs. (16–18). The constraint function in handling is included to enhance the subjective feel of handling performance.

In RM-MEDA constraint functions are handled by penalty values (soft constraint method). Non-dominant solution with minimal violation of constraint or minimal penalty values will be selected for the next generation to regenerate new offspring. All the constraint penalty values are defined in terms of a ratio which standardize the scale of the function and thus by employed the summation of all penalty will give the overall penalty value of equal weighting towards every constraint function of a given solution evaluated through simulation (19).

6 Results and Discussions

The Pareto solution in Fig. 5 represented the comparison between the optimized solutions and the original design values. It is noticeable that the original vehicle design is not fully optimized as compared to the Pareto solution. The original vehicle design has a good ride (RMS acceleration) as compared to the other Pareto design solution shown in Table 3. However, it showed a poor performance in terms of quality of handling i.e. high RMS roll gain, high yaw gain ratio, and poor yaw damping coefficient. Five Pareto solutions are selected out of 50 Pareto solutions for comparison and are shown in Table 3. Each of the design solutions represented the different characteristics of optimized vehicle dominating in different objectives. Comparison study is conducted on the selected Pareto design solution for further explore its different in the performance of vehicle’s ride and handling characteristics. First and second vehicle designs were selected from Table 3. The first design showed equivalent ride comfort level as compared to original design which fell in the fairly uncomfortable (refer to Table 1). However, it gave a good performance rating in handling aspects. It has minimal of phase lag in lateral acceleration, yaw rate phase lag (either in high or low frequency steer) and yaw gain ratio. The second vehicle design has about the similar performance as compared to the first design. However, it has a slightly higher phase lag in lateral acceleration and yaw rate response. The selected designs were benchmarked against that of the original vehicle.

Transient maneuver test of double lane change and quasi-static constant cornering radius test were selected to study the vehicle dynamic handling characteristics. For double lane change, comparison between newly optimized designs plotted against the original design is shown in Fig. 6. Noticeable improvement of the optimized designs can be observed. The lateral phase lags in the optimized design are lesser as compared to the original design (Table 3) thus indicates faster lateral response time. The optimized designs also generate less roll gain (1st design < 2nd design < original design). Similar improvement can be observed in the transient response for roll angle and yaw rate response. The two optimized designs produce higher damping and reduce the yaw oscillation when performing the double lane change. Besides, the optimized designs also have less suspension working space as the spring deformation is smaller than that of the original design (Fig. 6). All these results suggest that the optimized suspension designs much better quality handling performance as compared to the original vehicle except for the RMS roll gain where the 2nd design gives a slightly higher roll gain. In constant cornering radius test as shown in Fig. 7, it is clearly noticeble that both designs give a different understeer characteristic. Design 1 has the similar understeer gradient as compared to the original design at low lateral acceleration level. However, as the lateral acceleration increases the understeer gradient of design 1 decreases compared to original design. Whereas, for the design 2 the vehicle generally gives much lower understeer gradient compared to the others design.

Based on the case study, the optimized designs showed reasonable improvement as compared to the original design.

7 Conclusion

This methodology of optimizing full vehicle suspension based on ride and handling performances has been developed and examined. It was found suitable to optimize large suspension design variables with conflicting design requirements. The optimization technique can be employed as alternative technique in suspension tuning which can shorten the suspension design cycle thus reducing the vehicle development time during the design phase.

References

ISO (1997) Mechanical vibration and shock—evaluation of human exposure to whole-body vibration—Part 1: General requiremetns, in ISO 2631-1:1997(E). Geneva: International Organization for Standardization

Tey JY et al (2010) Multi-objective optimization based on realistic quarter vehicle model, in international conference on sustainable mobility. SAE, Kuala Lumpur

Tey JY, Ramli R (2010) Comparison of computational efficiency of MOEA\D and NSGA-II for passive vehicle suspension optimization, in 24th European conference on modelling and simulation. ECMS, Kuala Lumpur

Ramli R et al (2011) Multi-objective optimization based for realistic quarter vehicle model. In: Proceedings computationally optimised fuel-efficient concept car (COFEC), University of Kebangsaan Malaysia, Bangi

Olley M (1961) Notes on Suspension

Barak P (1991) Magic numbers in design of suspensions for passenger cars. SAE International, 911921(SP-878):53–88

Abe M (2009) Vehicle handling dynamics: theory and application. Butterworth-Heinemann, Oxford

Larrañaga P, Lozano EJA (2001) Estimation of distribution algorithms: a new tool for evolutionary computation. Kluwer Academic, Norwell

Uys PE, Els PS, Thoresson MJ (2006) Criteria for handling measurement. J Terrramech 43(1):43–67

ISO (2003) Road vehicles—lateral transient response test methods—open-loop test methods, in ISO 7401:2003 (E). Geneva: International organization for standardization

Dukkipati RV et al (2010) Road vehicle dynamics. SAE International, Warrendale

Ash HAS Correlation of subjective and objective handling of vehicle behaviour. Doctor of Philosophy, School of Mechanical Engineering, The University of Leeds

Zhang Q, Zhou A, Jin Y (2008) RM-MEDA: a regularity model-based multiobjective estimation of distribution algorithm. IEEE Trans Evol Comput 12(1):41–63

Sobol IM (1993) Sensitivity analysis or nonlinear mathematical models. Math Model Comput Exp 1(4):407–414

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Yuen, T.J., Rahizar, R., Mohd Azman, Z.A., Anuar, A., Afandi, D. (2013). Design Optimization of Full Vehicle Suspension Based on Ride and Handling Performance. In: Proceedings of the FISITA 2012 World Automotive Congress. Lecture Notes in Electrical Engineering, vol 195. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-33835-9_8

Download citation

DOI: https://doi.org/10.1007/978-3-642-33835-9_8

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-33834-2

Online ISBN: 978-3-642-33835-9

eBook Packages: EngineeringEngineering (R0)