Abstract

Within this chapter, the case of the nonlinear elasticity, meaning strain-dependent modulus of elasticity, will be considered. The problem will be illustrated with the example of bar elements. First, the stiffness matrix or alternatively the principal finite element equation will be derived under consideration of the strain dependency. For the solving of the nonlinear system of equations three approaches will be derived, namely the direct iteration, the complete Newton–Raphson iteration and the modified Newton–Raphson iteration, and will be demonstrated with the help of multiple examples. Within the framework of the complete Newton–Raphson iteration the derivation of the tangent stiffness matrix will be discussed in detail.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Stiffness Matrix

- Iteration Scheme

- Raphson Method

- Displacement Boundary Condition

- Element Stiffness Matrix

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

10.1 Introductory Remarks

In the context of the finite element method it is common to distinguish between the following kind of nonlinearities [1]:

-

Physical or material nonlinearities: This relates to nonlinear material behavior, as, for example, in the elastic area (covered within this chapter) of rubber or elasto-plastic behavior (covered in Chap. 11).

-

Nonlinear boundary conditions: This is, for example, the case that in the course of the load application, a displacement boundary condition changes. Typical for this case are contact problems. This will not be covered within this book.

-

Geometric or kinematic nonlinearity: This relates to large displacements and rotations at small strains. As examples structure elements such as wires and beams can be named. This will not be covered within this book.

-

Large deformations: This relates to large displacements, rotations and large strains. This will not be covered within this book.

-

Stability problems: Here, one has to distinguish between the geometric instability (as, for example, the buckling of bars and plates) and the material instability (as, for example, the necking of tensile samples or the formation of shear bands). Within this book only the buckling of bars will be covered in Chap. 12.

The basic characteristic of elastic material behavior is that the strains go back to zero completely after unloading.Footnote 1 In the case of linear elasticity with a constant modulus of elasticity the loading and unloading takes places in the stress–strain diagram along a straight line, see Fig. 10.1a. The slope of this straight line equals exactly the constant modulus of elasticity \(E\), according to Hooke’s law. In generalization of this linear elastic behavior the loading and unloading can also take place along a nonlinear curve, and in this case one talks about nonlinear elasticity, see Fig. 10.1b. In this case Hooke’s law is only valid in an incremental or differential form:

One considers here that the denotation ‘linear’ or alternatively ‘nonlinear’ elasticity relates to the behavior of the stress–strain curve. Furthermore, the modulus of elasticity can also be dependent on the coordinate. This is, for example, the case of functionally graded materials, the so-called gradient materials. Therefore the modulus of elasticity in general, under the consideration of the kinematic relation, can be indicated as

However, a dependency from the \(x\)-coordinate can be treated as a variable cross-sectionFootnote 2 and demands no further analysis at this point. Therefore, in the following, the focus is on dependencies of the form \(E=E(u)\) or alternatively \(E=E\left(\frac{\text{d} u}{\text{d} x}\right)\).

10.2 Element Stiffness Matrix for Strain Dependent Elasticity

The following derivations will be carried out for the example case that the modulus of elasticity is dependent linearly on the strain, see Fig. 10.2. Under this assumption, the according Fig. 10.2a, a nonlinear stress–strain diagram results. The linear course of the modulus of elasticity can be defined in the following via the two sampling points \(E(\varepsilon =0)=E_0\) and \(E(\varepsilon =\varepsilon _1)=E_1\).

Therefore, the following course of the function for the strain dependent modulus of elasticity results for the two sampling points:

It needs to be remarked at this point that the principal route for the derivation does not change as long as the strain dependency of the modulus of elasticity can be described via a polynomial. This is often the case in practical applications, since experimental values are often approximated through a polynomial regression.

After the introduction of the kinematic relation for a bar, meaning \(\varepsilon = \frac{\text{d} u}{\text{d} x}\), herefrom the modulus of elasticity results in dependence of the displacement—or, to be precise, dependence of the derivative of the displacement—in:

This strain dependent modulus of elasticity can be integrated analytically via the differential Hooke’s law and the following stress distribution resultsFootnote 3:

One notes that the classical relations for linear elastic material behavior result for \(E_0=E_1\) or alternatively \(\alpha _{01}=0\).

For the derivation of the element stiffness matrix, the differential equation for a bar has to be considered. For simplification reasons it is assumed at this point that the bar cross-section \(A\) is constant and that no distributed loads are acting. Therefore the following formulation for the differential equation results:

At first, the case is regarded that \(E(u)\) is replaced by the expression according to Eq. (10.4):

After the completion of the differentiation the following expression results for the differential equation, which describes the problem:

Within the framework of the weighted residual method the inner product results herefrom through multiplication with the weighting function \(W(x)\) and subsequent integration via the bar length in:

Partial integration of the first expression in brackets yields:

Accordingly, the second expression in brackets can be reformulated via partial integration:

Finally, the following results for the partial integration of the second expression:

The following expression results, when the expressions of the partial integrations according to Eqs. (10.10) and (10.12) are inserted into the inner product according to Eq. (10.9) and when the domain and boundary integrals are arranged:

The introduction of the approaches for the displacement and the weighting function, meaning \(u (x) = {\varvec{N}}{\varvec{u}}_\text{p}\) and \(W(x) =\delta {\varvec{u}}_\text{p}^\text{T} {\varvec{N}}^\text{T}(x)\), leads to the following expression, after canceling of the virtual displacement \(\delta {\varvec{u}}_\text{p}^\text{T}\) and factoring out the displacement vector \({\varvec{u}}_\text{p}\):

Therefore, in dependence of the nodal displacement \(\varvec{u}_\text{p}\) the element stiffness matrixFootnote 4 results in:

If the shape functions are known, the stiffness matrix can be evaluated. The second expression in the outer brackets yields an additional symmetrical expression, which can be superposed to the classical stiffness matrix for linear elastic material behavior. For a constant modulus of elasticity \(\alpha _{01}=0\) results and one receives the classical solution. The following dimensions of the single matrix products results if the bar element has \(m\) nodes and therefore \(m\) shape functions:

However, in the following an alternative strategy is illustrated, which leads slightly faster to the principal finite element equation. On the basis of the differential equation in the form (10.6), the inner product can be derived without replacing the expression for \(E(u)\) a priori:

Partial integration yields

and the weak form of the problem appears as follows:

Via the approaches for the displacement and the weighting function, the following results herefrom:

The right-hand side can be handled according to the procedure in Chap. 3 and yields the vector of the external loads. The left-hand side, however, requires that the modulus of elasticity \(E(u)\) is considered appropriately. If the approach for the displacement, meaning \(u(x)= \varvec{N}(x)\varvec{u}_\text{p}\), is considered in the formulation of the modulus of elasticity according to Eq. (10.4), the following results:

It can be considered at this point that the expression \( \frac{\text{d} \varvec{N}}{\text{d} x}\,\varvec{u}_\text{p}\) yields a scalar parameter. Therefore, the stiffness matrix results in:

This stiffness matrix is—as Eq. (10.15)—symmetric since the symmetric matrix \(\frac{\text{d} \varvec{N}^\text{T}}{\text{d} x}\frac{\text{d} \varvec{N}}{\text{d} x}\) is multiplied by a scalar.

In the following, a bar element with two nodes, meaning linear shape functions, can be considered. Both shape functions and their derivatives in this case result in:

Therefore the stiffness matrix results in:

or alternatively under consideration of the derivatives of the shape functions

After completion of the integration herefrom the element stiffness matrix results in

or the principal finite element equation as:

One considers that for the constant modulus of elasticity, meaning \(\alpha _{01}=0\), the classical solution from Chap. 3 results. For the variable modulus of elasticity the following system of equations results in matrix notation:

or, alternatively, with various elements for the total system

Since the stiffness matrix is dependent on the unknown nodal displacements \(\varvec{u}\), a nonlinear system of equations results, which cannot be solved directly through inverting of the stiffness matrix.

10.3 Solving of the Nonlinear System of Equations

The solving of the nonlinear system of equations can be explained in the following for a bar, which is fixed on one side and loaded by a single force \(F\) on the other side, with the help of various methods, see Fig. 10.3. The modulus of elasticity is, according to Eq. (10.3), linearly dependent on the strain. First the discretization via one single element takes place, so that, under consideration of the fixed support, a system with one single degree of freedom results. The resulting equations are therefore solely dependent on one variable, the nodal displacement at the loading point. In the following step, one merges to the general case of a system with various degrees of freedom. The illustration takes place via a discretization of the problem according to Fig. 10.3a with two elements and therefore with two degrees of freedom.

For the example according to Fig. 10.3, the following values can be assumed: Geometry: \(A=100\) mm\(^2\), \(L=400\) mm. Material characteristics: \(E_0=70,000\) \(\text{MPa}\), \(E_1=49,000\) \(\text{MPa}\), \(\varepsilon _1=0.15\). Load: \(F = 800\) kN.

10.3.1 Direct Iteration

At the direct or Picard’s iteration [2, 3], the system of Eq. (10.31) is solved by evaluating the stiffness matrix in the previous and therefore known step. Through the selection of a reasonable initial value—for example from a linear elastic relation—the solution can be determined via the following formula through gradual inserting:

The schematic illustration of the direct iteration is shown in Fig. 10.4.

This method converges for modest nonlinearities with linear convergence rate.

10.3.1.1 Direct Iteration for a Finite Element Model with One Unknown

For the example corresponding to Fig. 10.3 and the principal finite element equation according to (10.29), under consideration of the fixed support, the iteration formula results in:

or alternatively solved for the new displacement:

The evaluation of Eq. (10.34) for the example corresponding to Fig. 10.3 is summarized in Table 10.1 for an arbitrary initial value of \(u_2^{(0)}=20\) mm. The normalized displacement difference was indicated as convergence criteria, whose fulfillment requires 23 iterations for a value of \(10^{-6}\). Furthermore, one considers the absolute value of the displacement at the 31st increment, which is also consulted as a reference value in other methods.

10.3.1.2 Direct Iteration for a Finite Element Model with Various Unknowns

For the application of the direct iteration on a model with various unknowns, the bar, according to Fig. 10.3 can be considered in the following. The discretization should occur through two bar elements, which have the same length. Therefore, the following element stiffness matrix results for each of the two elements with length \(\frac{L}{2}\):

The following reduced system of equations results, if the two matrices are summarized to the global principal finite element equation and if the boundary conditions are considered:

Through inversion one obtains the following iteration formula of the direct iteration:

whereupon the determinant of the reduced stiffness matrix is given through the following equation:

In general, the iteration instruction according to Eq. (10.38) can also be written as

The numerical results of the iteration for the example according to Fig. 10.3 with two elements are summarized in Table 10.2. A comparison with the direct iteration with one element, meaning Table 10.1, yields that the division in two elements has practically no influence on the convergence behavior. One considers that the displacements on node 2 and 3 are listed in Table 10.2 and that only in the converged situation the condition \(u_2 = \frac{1}{2}\,u_3\) results.

10.3.2 Complete Newton–Raphson Method

10.3.2.1 Newton’s Method for a Function with One Variable

For the definition of the root of a function \(f(x)\), meaning \(f(x)=0\), Newton’s iteration is often used. For the derivation of the iteration method, one develops the function \(f(x)\) around the point \(x_0\) in a Taylor’s series

If the expressions of quadratic and higher order are disregarded, the following approximation results:

When considering that the derivative of a function equals the slope of the tangent line in the considered point and that the slope-intercept equation of a straight line is given via \(f(x)-f(x_0)= m \cdot (x-x_0)\), one can see that the approximation via a Taylor’s series of first order is given through the straight line through the point \((x_0,f(x_0))\) with slope \(m = (\text{d} f/\text{d} x)_{x_0}\), see Fig. 10.5.

For the derivation of the iteration formula for the definition of the roots, one sets Eq. (10.42) equal 0 and obtains the following calculation instruction via the substitutions \(x_0 \rightarrow x^{(j)}\) and \(x \rightarrow x^{(j+1)}\):

The principle course of action of a Newton’s iteration is illustrated in Fig. 10.6. At the initial point of the iteration, the tangent is pictured on the graph of the function \(f(x)\) and subsequently the root of this tangent will be defined. In the ordinate value of this root, the next tangent will be formed and the procedure will be continued according to the course of action in the initial point. If \(f(x)\) is a continuous and monotonic function in the considered interval and if the initial point of the iteration lies ‘close enough’ to the unknown solution, the method converges quadratically against the root.

10.3.2.2 Newton–Raphson Method for a Finite Element Model with One Unknown

For the example according to Fig. 10.3, the problem reduces to locating the roots of the function, under consideration of the boundary conditions on the left-hand node

When applying the iteration instruction of the previous Sect. 10.3.2.1 on the residual function \(r(u_2)\), the following Newton–Raphson iteration instructionFootnote 5 results in

whereupon the parameter \(K_\text{T}\) is in general referred to as the tangent stiffness matrix.Footnote 6 In the example considered at this point, \(K_\text{T}\) however reduces to a scalar function. On the basis of Eq. (10.44) the tangent stiffness matrix for our example results in:

When using the last result in the iteration instruction (10.45) and when considering the definition of the residual function according to (10.44), the iteration instruction for the regarded example finally results in:

The application of the iteration instruction according to Eq. (10.48) with \(\alpha _{01}=2\) leads to the summarized results in Table 10.3. One can see that only six iteration steps are necessary for the complete Newton–Raphson iteration, due to the quadratic convergence behavior, to achieve the convergence criteria \(({<}10^{-6})\) and the absolute value of \(u_2 = 70.722998\) mm. In the general case of the method however, the huge disadvantage arises that the tangent stiffness matrix has to be recalculated and inverted for each iteration step. For huge systems of equations this leads to quite calculational intensive operations and can perhaps compensate the advantage of the quadratic convergence.

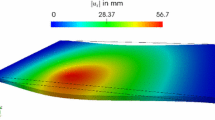

When increasing the external load \(F_2\), a limit value results, however, from which no convergence can be achieved with the Newton–Raphson method any longer. A strain dependent modulus of elasticity according to Eq. (10.4) leads through integration to the illustrated parabolic stress distribution in Fig. 10.7. Based on this illustration the maximal stress to \(\sigma _\text{max}=\frac{E_0}{2\alpha _{01}}\) or alternatively the maximal force in a bar to \(F_\text{max}=\frac{E_0A}{2\alpha _{01}}\) can be defined.

Stress–strain course for a strain dependent modulus of elasticity according to Eq. (10.4)

However, through gradual increasing of the external force \(F_2\) in the regarded example, it results that the convergence limit is achieved clearly lower than the maximal force of \(F_\text{max}=1,750\) kN. Via a few iteration cycles it can be shown that starting with a value of about 900 kN, no convergence can be achieved any longer in the considered example. One also considers that a reasonable physical choice of the external force always has to meet the condition \(F_2 \le F_\text{max}\).

To explain the loss of convergence, the residual function according to Eq. (10.44) has to be considered more closely, whereupon it has to be considered that the iteration method needs to define the roots of this function. The considered residual function is a quadratic function in \(u_2\), which can be changed into the following equation of a parabola by completing the square:

Therefore Eq. (10.44) represents an upward facing parabola with the vertex \(\left(\frac{L}{2\alpha _{01}},\left(\frac{F_2}{E_0A}-\frac{1}{4\alpha _{01}}\right)\frac{L^2}{\alpha _{01}}\right)\). Depending on the position of the vertex, a different number of roots results (see Fig. 10.8), so that the boundary value for the convergence of the iteration method is defined through the boundary point of the parabola with the \(u_2\)-axis:

Therefore, the Newton–Raphson iteration method for the considered case, that the modulus of elasticity according to Eq. (10.4) is dependent linearly on the strain, converges solely within the following boundaries:

Illustration of the residual function according to Eq. (10.44) for different external loads \(F_2\)

The schematic process of the Newton–Raphson iteration is illustrated in Fig. 10.9. The tangent stiffness matrix \(K_\text{T}^{(j)}\) is calculated in every single iteration point \(u_2^{(j)}\), to conclude the follow-on value \(u_2^{(j+1)}\) via a linearization. It is important at this point that the tangent stiffness matrix can be identified as the derivative in the force displacement diagram, see Fig. 10.9a. To receive the illustration in a stress–strain diagram, one has to divide the residual equation (10.44) through the cross-sectional area and has to scale the displacement with the length, so that one obtains the following form:

or alternatively in the variables stress and strain as

It is important at this point to note that the last equation is not confused with the stress–strain course according to Eq. (10.5), since the last equation deals with the outer and inner forces. Application of the iteration instruction according to Eq. (10.45) leads to the following formula at this juncture

whereupon

is referred to as the consistent modulus \(E_\text{T}\) to the iteration formula. One considers the difference for the continuum mechanical modulus according to Eq. (10.3). Solely in the case of \(\alpha _{01}=0\), meaning for a constant modulus of elasticity, both moduli match.

At this point it needs to be remarked that the residual equation (10.44) can be further generalized by introducing a displacement dependent external load \(F_2=F_2(u_2)\):

In this generalized case, the tangent stiffness matrix would result as follows:

10.3.2.3 Newton–Raphson Method for a Finite Element Model with \(m\) Unknowns

The complete Newton–Raphson method [1, 5, 6] for a model with various unknowns is, in general, expressed through the following equation

whereupon the tangent stiffness matrix in general is defined as

The vectorial function of the residuals is generally defined as

and can be illustrated in components for a model with two linear bar elements as follows:

The Jacobian matrix \(\displaystyle \frac{\partial \varvec{r}}{\partial \varvec{u}}\) of the residual function results in general from the partial derivatives \(r_i\) to:

The partial derivatives in Eq. (10.64) can be calculated the easiest, if the residual equation (10.63) are written in detail:

As an example, two partial derivatives are given in the following:

Therefore, the tangent stiffness matrix results in the illustrated form in Eq. (10.75), which is composed from the stiffness matrix and a matrix with partial derivatives, which are multiplied with the nodal displacements. In general, the tangent stiffness matrix can therefore be formulated for a model with \(m\) degrees of freedom as

or alternatively in matrix notation as

As a concluding remark, two important special cases need to be listed at this point:

-

Scalar tangent stiffness matrix (see Sect. 10.3.2.2):

$$\begin{aligned} K_\text{T}(u)=K(u)+\displaystyle \frac{\text{d} K}{\text{d} u}\,u. \end{aligned}$$(10.72) -

Two-dimensional tangent stiffness matrix (for example linear bar element without displacement boundary conditions):

The general case with \(\varvec{u} = [\begin{array}{l}u_1, u_2, \ldots , u_m \end{array}]^\text{T}\) and \(\text{dim}(\varvec{K})=m \times m\) can easily be derived from the above considerations.

In the following, the model with two bar elements according to Fig. 10.3 can be considered again. The discretization for two elements with the length \(\displaystyle \frac{L}{2}\) leads the residual equation to:

A graphical illustration of the residual functions according to Eq. (10.76) is given in Fig. 10.10. Both functions are dependent on two variables, \(u_2\) and \(u_3\), in this case, and therefore at this point, surfaces in the space result, whose intersection curves have to be found via the \(u_2{-}u_3\) planes. For this purpose, a tangent plane is built on the corresponding surface in every single point within the iteration scheme.

Illustration of the residual functions according to Eq. (10.76)

The application of the calculation instruction according to Eq. (10.73) leads to the tangent stiffness matrix as follows in this special case:

The two matrices in the last equation can still be summarized and one obtains the following illustration for the tangent stiffness matrix:

The tangent stiffness matrix still has to be invertedFootnote 7 for the iteration scheme according to Eq. (10.85) and after a short calculation one obtains:

Therefore, the iteration scheme \(\varvec{u}^{(j+1)}=\varvec{u}^{(j)}-\left(\varvec{K}_\text{T}^{(j)}\right)^{-1}\varvec{r}(\varvec{u}^{(j)})\) can be applied as follows for the example according to Fig. 10.3:

The numerical values of the iteration are summarized in Table 10.4. Due to a comparison with the values from Table 10.3 for a model with one single element, one can see that the convergence behavior is identical.

For practical applications however one would not calculate the tangent stiffness matrix of the global total system but the derivatives element by element. Subsequently the tangent stiffness matrices of the single elements—as in the case of the total stiffness matrix—can be put together for the tangent stiffness matrix of the global total system:

For a linear element with a strain dependent modulus of elasticity according to Eq. (10.3) follows from the stiffness matrix according to Eq. (10.28), meaning

under application of the calculation instruction (10.73), the following tangent stiffness matrix for a single element with two nodes:

10.3.3 Modified Newton–Raphson Method

10.3.3.1 Modified Newton–Raphson Method for a Finite Element Model with One Unknown

The disadvantage of the complete Newton–Raphson method is that the tangent stiffness matrix has to be calculated and inverted subsequently at each iteration step. If the tangent stiffness matrix is only calculated once at the beginning, one attains the modified Newton–Raphson method [1, 5, 6]. From Eq. (10.45) the modified iteration scheme results in:

A schematic illustration is given in Fig. 10.11. One can see that the same initial tangent is used in every iteration step, whereby in comparison with the complete method, more iteration steps result; the method does not converge quadratically anymore but only linearly. However, the calculation intensive inversion of the tangent stiffness matrix in every step drops out and the calculation simplifies significantly.

If the iteration instruction of the modified method according to Eq. (10.84) is applied to the problem according to Fig. 10.3, the summarized results in Table 10.5 are obtained. Thirty-six steps are necessary at this point for the fulfillment of the convergence criteria \(({<}10^{-6})\) and the reference value of \(u_2=70.722998\) can only be achieved after 53 iteration steps. A comparison with the two other iteration schemes shows that the modified Newton–Raphson method—with functions of one variable—converges the slowest. However one considers that this conclusion does not have to be valid for a system of equations anymore.

10.3.3.2 Modified Newton–Raphson Method for a Finite Element Model with Various Unknowns

The modified Newton–Raphson method for a model with various unknowns is generally given through the following equation

or alternatively for the example according to Fig. 10.3:

The numerical values of the iteration are summarized in Table 10.6. Due to a comparison with the values from Table 10.5 for the model with one single element, one can see that the convergence behavior is identical.

10.3.4 Convergence Criteria

For the evaluation, if an iterative scheme converges, the following normalized displacement difference in the form

was already used in previous chapters, whereupon \(m\) represents the number of unknown degrees of freedom. If this value is below a certain limit value, for example the computational accuracy in the program, the iteration can be regarded as converged.

Alternatively, the residual vector \(\varvec{r}^{(j)}=\varvec{K}(\varvec{u}^{(j)})\varvec{u}^{(j)}- \varvec{F}^{(j)}\) can be regarded, whose norm can be indicated as follows

If this norm is below a certain limit value, convergence is achieved.

At the end of this chapter, the discussed iteration instructions are summarized in Table 10.7, and those are opposed to the calculation procedure for linear elasticity.

It needs to be remarked at this point that the three listed procedures for linear elasticity simplify as the method of inversion of the stiffness matrix in the case of linear elasticity.

In the literature, a further series of methods are known, as for example the arc length method, with which the convergence range of the discussed methods here can be expanded significantly [7–9].

10.4 Sample Problems and Supplementary Problems

10.4.1 Sample Problems

10.1 Example: Tension Bar with Quadratic Approach and Strain Dependent Modulus of Elasticity

One needs to derive the stiffness matrix for a bar element with quadratic shape functions for a strain dependent modulus of elasticity in the form

In this, the element has length \(L\) and the inner node is placed exactly in the middle of the element. Subsequently one needs to calculate the tangent stiffness matrix \(\varvec{K}_\text{T}\) based on the stiffness matrix.

10.1 Solution

Based on Eq. (10.90), meaning

and the shape functions for a quadratic bar element, or alternatively their derivatives

the stiffness matrix in general results in:

After completion of the integration, the element stiffness matrix results herefrom to:

Application of the calculation instruction for a \((3 \times 3)\) matrix according to Eq. (10.75) leads to the tangent stiffness matrix as:

or, alternatively, after the summarization of the two matrices with the nodal displacements to:

10.2 Example: One-Sided Fixed Tension Bar with Quadratic Approach and Strain Dependent Modulus of Elasticity

With the derived bar element in example 10.1 with quadratic shape function and strain dependent modulus of elasticity one can calculate a bar, which is fixed supported on the left-hand end and is loaded through a single force of 800 kN on the right-hand end. The material behavior is assumed as in example 10.1, whereupon the values \(E_0 = 70,000\) MPa and \(\alpha _{01}= 2\) can be used. The length of the bar accounts \(L = 400\) mm and the cross-sectional area is \(A = 100\) mm\(^2\). For the solution one can make us of the complete Newton–Raphson method.

10.2 Solution

Under consideration of the boundary conditions, the principal finite element equation results as follows from Eq. (10.95)

and from Eq. (10.97) the tangent stiffness matrix follows under consideration of the boundary conditions as

The tangent stiffness matrix still has to be inverted for the iteration scheme according to Eq. (10.85) and one obtains the following representation after a short calculation:

The numerical results of the iteration are summarized in Table 10.8. A comparison with the results of the discretization with two linear elements in Table 10.4 shows that the results for the regarded case are identical.

10.3 Example: Tension Bar with Three Different Elements for Strain Dependent Modulus of Elasticity and Force Boundary Condition

The illustrated finite element model in Fig. 10.12 of a one-sided fixed bar consists of three elements, which exhibit different characteristics. The bar is loaded with a point load \(F_0\) on the right-hand end.

One considers the case that all three bars have a linear strain dependent modulus of elasticity according to Eq. (10.3) in the form

For the considered problem the following relations for the initial axial rigidity can be assumed:

As a numerical value one can use \(F_0=800\) kN, \(A=100\) mm\(^2\), \(L^\text{I}=L^\text{II}=L^\text{III}=400/3\) mm, \(E_0=70,000\) \(\text{MPa}\), \(E_1=49,000\) \(\text{MPa}\), \(\varepsilon _1=0.15\) and one can define the displacement of the nodes with the complete Newton–Raphson iteration procedure.

10.3 Solution

The element stiffness matrices according to Eq. (10.28) for the three elements result in

which can be composed to the following reduced system of equations under consideration of the fixed support:

The tangent stiffness matrices for the three elements result in the following according to Eq. (10.83)

and can be combined to the following tangent stiffness matrix of the reduced system of equations under consideration of the fixed support:

The iteration scheme \(\varvec{u}^{(j+1)}=\varvec{u}^{(j)}-(\varvec{K}_\text{T}^{(j)})^{-1}\varvec{r}(\varvec{u}^{(j)})\) can be used via the reduced system of equations and the tangent stiffness matrix. The numerical results are summarized in Table 10.9.

10.4 Example: Tension Bar with Three Different Elements for Strain Dependent Modulus of Elasticity and Displacement Boundary Condition

The finite element model of an one-sided fixed bar, which is illustrated in Fig. 10.13, consists of three elements, which exhibit different characteristics. A displacement \(u_0\) is given on the right-hand end of the bar.

One can consider the case that all three bars exhibit a linear strain dependent modulus of elasticity according to Eq. (10.3) in the form

The following relations for the initial axial rigidity can be assumed for the considered problem:

whereupon two different cases need to be analyzed:

As further numerical values one can use \(A=100\) mm\(^2\), \(L^\text{I}=L^\text{II}=L^\text{III}=400/3\) mm, \(E_0=70,000\) \(\text{MPa}\), \(E_1=49,000\) \(\text{MPa}\), \(\varepsilon _1=0.15\) and one can define the displacement of the nodes and the reaction force on the right-hand end via the complete Newton–Raphson iteration method.

10.4 Solution

According to the procedure in example 10.3, the total stiffness matrix results as follows, under consideration of the fixed support on the left-hand end:

If the known displacement is brought to the ‘right-hand side’ of the system of equations, the following reduced \((2 \times 2)\) system of equations results after canceling of the column and line, which belong to \(u_4\):

According to the procedure in example 10.3 the tangent stiffness matrix results in \((2 \times 2)\) form in:

The iteration scheme \(\varvec{u}^{(j+1)}=\varvec{u}^{(j)}-(\varvec{K}_\text{T}^{(j)})^{-1}\varvec{r}(\varvec{u}^{(j)})\) can be used due to the reduced system of equations and the tangent stiffness matrix. The reaction force \(F_{\text{r}4}\) on the right-hand end can be calculated after each iteration step by evaluating the 4th equation of the total system. The numerical results are summarized in Tables 10.10 and 10.11.

Case (a) with the results in Table 10.10 can be considered as a test case for the iteration scheme. Due to the displacement boundary condition on the right-hand end and the identical elements, the iteration needs to result in \(u_2 = \frac{1}{3}\,u_0\) and \(u_3 = \frac{2}{3}\,u_0\) at this point. As can be seen from Table 10.10, this is the case after five iterations for the chosen convergence criteria. The case (b) with the results in Table 10.11 represents the reversion of example 10.3. Since the result for the displacement from example 10.3 has been brought up as a boundary condition, the reaction force in the converged condition has to achieve a value of \(800\) kN. This is the case after four iteration steps.

10.4.2 Supplementary Problems

10.5 Strain Dependent Modulus of Elasticity with Quadratic Course

The strain dependent modulus of elasticity, which is illustrated in Fig. 10.14 was defined by experiment. Approximate the course with a quadratic function of the form \(E(\varepsilon )=a+b\varepsilon +c\varepsilon ^2\) and define the constants \(a,\ldots ,c\). Subsequently, calculate the stress–strain course through integration and illustrate the course graphically. In the next step, derive the element stiffness matrix for a linear bar element under consideration of the strain dependent modulus of elasticity. In the last step, define the tangent stiffness matrix.

10.6 Direct Iteration with Different Initial Values

Discretize the bar according to Fig. 10.3 with one single linear element and use the direct iteration for the solution at different initial values: \(u_2^{(0)}= 0\) or \(30\) or 220 mm. Further data can be taken from Table 10.1.

10.7 Complete Newton–Raphson Scheme for a Linear Element with Quadratic Modulus of Elasticity

The beam illustrated in Fig. 10.15a can be discretized via one single linear element. The strain dependent modulus of elasticity exhibits a quadratic course according to Fig. 10.15b. Based on the element stiffness matrix from problem 10.5, solve the problem with the complete Newton–Raphson scheme for an external force of \(F=370\) kN. As convergence criteria use a relative displacement difference of \({<}10^{-6}\). Subsequently, analyze the convergence range of the iteration scheme in general. For the geometry the concrete values \(A=100\) mm\(^2\) and \(L=400\) mm and for the material behavior the concrete values \(E_0=70,000\) MPa and \(\varepsilon _1=0.15\) can be used.

10.8 Strain Dependent Modulus of Elasticity with General Quadratic Course

In extension of problem 10.5 one can consider the illustrated course in Fig. 10.16 with the three sampling points \((0,E_0)\), \(( \frac{1}{2}\varepsilon _1,\beta _{05}E_0)\) and \((\varepsilon _1,\beta _1E_0)\). The form of the curve can be adapted more easily to the sampling points with the scale values \(\beta _{05}\) and \(\beta _{1}\). The curve course can be approximated through a quadratic course in the form \(E(\varepsilon )=a+b\varepsilon +c\varepsilon ^2\). Define the constants \(a,\ldots ,c\) and derive the element stiffness matrix for a linear bar element under consideration of the strain dependent modulus of elasticity.

Notes

- 1.

At plastic material behavior remaining strains occur. This case will be covered in Chap. 11.

- 2.

For this, see the treatment of bar elements with variable cross-sectional areas \( A= A(x)\) in Chap. 3.

- 3.

At this point it was assumed that for \(\varepsilon = 0\) the stress turns 0. Therefore, for example no residual stress exists.

- 4.

One considers that the associative law applies for matrix multiplications.

- 5.

In the context of the finite element method Newton’s iteration is often referred to as the Newton–Raphson iteration [4].

- 6.

Alternative names in literature are HESSIAN, JACOBIAN or tangent matrix [1].

- 7.

One considers that the calculation of the inverse has to be carried out numerically in commercial programs.

References

Wriggers P (2001) Nichtlineare Finite-Element-Methoden. Springer, Berlin

Reddy JN (2004) An introduction to nonlinear finite element analysis. Oxford University Press, Oxford

Betten J (2004) Finite Elemente für Ingenieure 2: Variationsrechnung, Energiemethoden, Näherungsverfahren, Nichtlinearitäten, Numerische Integrationen. Springer, Berlin

Belytschko T, Liu WK, Moran B (2000) Nonlinear finite elements for continua and structures. Wiley, Chichester

Cook RD, Malkus DS, Plesha ME, Witt RJ (2002) Concepts and applications of finite element analysis. Wiley, New York

Bathe K-J (2002) Finite-Elemente-Methoden. Springer, Berlin

Riks E (1972) The application of newtons method to the problem of elastic stabilty. J Appl Mech 39:1060–1066

Crisfield MA (1981) A fast encremental/iterative solution procedure that handles snap through. Comput Struct 13:55–62

Schweizerhof K, Wriggers P (1986) Consistent linearization for path following methods in nonlinear fe-analysis. Comput Method Appl Mech Eng 59:261–279

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Öchsner, A., Merkel, M. (2013). Nonlinear Elasticity. In: One-Dimensional Finite Elements. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-31797-2_10

Download citation

DOI: https://doi.org/10.1007/978-3-642-31797-2_10

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-31796-5

Online ISBN: 978-3-642-31797-2

eBook Packages: EngineeringEngineering (R0)