Abstract

Back-scattered Scanning Electron Microscopy (BSEM) has been used to identify weathering mechanisms occurring in two oolitic limestones from urban areas in London and Cambridge, United Kingdom. From a petrographical point of view, the two stones can be described as oosparite and oomicrite, their main distinctive feature being the crystal size of the cement binding the limestone grains together. The sulphation mechanism, i.e. the replacement of calcium carbonate (calcite: CaCO3) by calcium sulphate dehydrate (gypsum: CaSO4 2H2O), at the surface and within the stone fabric is confirmed as the general decay process. Differences in macroporosity/permeability distribution in the two limestones lead to different weathering patterns. BSEM provides evidence that gypsum patinas still commonly found on limestone facades in polluted urban locations are advancing inside the diseased stone and that their removal is urgently needed to arrest the growth of the in-growing weathering front.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

6.1 The Application of Back-Scattered Scanning Electron Microscopy to Unravel Building Stone Decay Mechanisms in Urban Environments

Abstract Back-scattered Scanning Electron Microscopy (BSEM) has been used to identify weathering mechanisms occurring in two oolitic limestones from urban areas in London and Cambridge, United Kingdom. From a petrographical point of view, the two stones can be described as oosparite and oomicrite, their main distinctive feature being the crystal size of the cement binding the limestone grains together. The sulphation mechanism, i.e. the replacement of calcium carbonate (calcite: CaCO3) by calcium sulphate dehydrate (gypsum: CaSO4 2H2O), at the surface and within the stone fabric is confirmed as the general decay process. Differences in macroporosity/permeability distribution in the two limestones lead to different weathering patterns. BSEM provides evidence that gypsum patinas still commonly found on limestone facades in polluted urban locations are advancing inside the diseased stone and that their removal is urgently needed to arrest the growth of the in-growing weathering front.

6.1.1 Introduction

Rising levels of air pollution in modern urban agglomerates not only have deleterious effects on human health but may also be correlated with the onset of serious decay patterns on a variety of earth materials used in built heritage monuments. Stone is no exception. One of the most commonly used lithotypes is limestone, a high porosity sedimentary rock composed of a framework of grains (minerals, fossils and, as in the case illustrated in this chapter, ooids) bound together by a “cement” of calcium carbonate crystals (i.e. calcite: CaCO3) either fine (<5 μm—micrite) or coarse grained (>5 μm—sparite). Ooids (also named oolites) are spherical or ellipsoidal grains which have regular concentric laminae of fine-grained carbonate developed around a nucleus, usually a quartz grain. Through laboratory and field based studies, studies focusing on the decay of limestones in polluted urban environments have highlighted the importance of the sulphating mechanism, by which atmospheric SO2, released mainly by the combustion of fossil fuels such as coal and oil, in reacting with the stone’s CaCO3 promotes the growth of decay-inducing sulphate patinas [1–7]. Despite the recent implementation of environmental laws setting strict limits to SO2 levels in urban areas [8], which has now resulted in a significant reduction of SO2 emissions in today’s urban environments, gypsum patinas are still disfiguring building façades in several major European towns especially where high-sulphur coal had been extensively used in the past such it is the case in the UK [2, 7, 9] and Eastern Europe [10].

The growth of black gypsum-rich crusts on the stone surface in areas sheltered from episodes of rain wash-outs is therefore a well-known and still active phenomenon. However, the detailed growth mechanism and related chemical weathering pathways correlated with these patinas are still the subject of some debate. With regards to the progression of the weathering front inside the stone, for instance, some researchers suggest that gypsum crystals replacing calcite now seen at the outermost crust–atmosphere interface are the “oldest”, i.e. the ones precipitated first. Others noted that that the distribution of aerosol particulate matter derived from fossil fuel burning imbedded within gypsum patinas seems to record an outward growth of the crusts during historic changes in urban pollution sources [2, 4, 11, 12]. Indeed, a “stratigraphical” pattern in the distribution of particulate pollutants in particularly thick gypsum crusts from central London (Westmister Palace) has been recognised [12]: in these studies, particles from historical coal burning activities were found concentrated close to the innermost crust–stone interface while particles typical of “recent” oil burning sources were most common near the outermost crust–atmosphere interface. This stratigraphical distribution, while supportive of the outward growth hypothesis, is, however, by no means present in all samples of black crusts from monument façades in urban areas. The scientific debate regarding the inward versus outward crust growth mechanism is of no trivial nature as it relates directly to a conservation open issue between conservators advocating a protective role of these crusts against further attack by environmental agents and those who strongly advise their prompt removal by different cleaning methods (wet chemical and/or laser assisted).

In this chapter, we examine the application of Scanning Electron Microscopy (SEM) interfaced with Energy Dispersive X-ray Spectroscopy (EDS) to examine the urban weathering behaviour of oolitic limestones in two British monuments (Fig. 6.1): King’s College Chapel, Cambridge and St. Luke’s Church, Chelsea, London. The SEM is used here in back-scattered mode (BSEM). BSEM is particularly useful in the examination of thin sections spanning the weathering patina–stone substrate interface as in this mode the brightness of individual mineral phases under SEM is directly correlated with the average atomic number of the elements forming the chemical composition of the same phases: in other words, the heavier the elemental composition of the mineral under view (for example Fe-containing minerals) the brighter the image in the SEM monitor.

Aim of this BSEM study was threefold: (a) assess the role played by petrographical differences in pollution-derived decay of apparently similar building limestones; (b) compare the relative soundness of two limestone lithologies subjected to different levels of past and present air pollution (Cambridge vs. London); (c) further investigate the detailed growth mechanisms of gypsum weathering patinas on limestone.

6.1.2 Petrographical Notes and Methodology

Both monuments are built in oolitic limestone. The main petrographical difference between the two limestones is the type of cement binding the constituent grains together: in the King’s College stone, the cement is mainly composed of microcrystalline calcite (oomicrite) whereas in the St. Luke’s stone the cement is largely composed of large interlocking calcite crystals (oosparite). Oolitic limestones, at least in the Cambridge case [13] were probably chosen because of their high degree of original cementation as both limestones show postdepositional features (such as interpenetrating grain boundaries) suggesting that they were subjected to considerable compaction during their geological history.

Polished surfaces of the samples were sputter-coated with gold and then examined with a JEOL 820L SEM interfaced with LINK system AN10000 EDS microanalysis system.

6.1.3 BSEM Observations

In both monuments, decay leads to the built-up of gypsum crusts of variable thickness (up to 1 cm). Thicker crusts in the London samples probably correlate with higher degrees of atmospheric pollution. Apart from gypsum crystals, other constituents include anthropogenic particles, calcite, silicate particles (quartz and feldspar) and fossil fragments. In particular, anhedral (i.e. with a not well-formed crystal habit) calcite grains are very common and evenly distributed throughout the crusts. Continuous calcite horizons are also present. Fossil grains can often be seen even near the crust–atmosphere interface. Aerosol particles from fossil fuel burning activities do sometimes show a “stratigraphic” distribution with a higher number of oil derived (i.e. recent pollution) carbonaceous particles at the outer edge and coal derived (i.e. historic pollution) aluminosilicate spherical particles (together with wood fragments) closer to the stone substrate interface. A typical feature within gypsum patinas is the presence of ooid “ghosts”, i.e. areas now completely filled with acicular gypsum crystals still retaining a faint spherical oolitic outline (Fig. 6.2). These areas are free of imbedded particles and clearly represent areas formerly occupied by the stone substrate prior to sulphate attack.

Despite these apparent similarities, detailed BSEM investigation reveals how atmospheric chemical attack progressed differently in two building stones examined.

6.1.3.1 St. Luke’s Church

The sulphation weathering front starts at the stone–crust interface and may reach a depth of several centimetres inside the stone. Calcitic oolites have been and are presently undergoing gypsum replacement. The preservation of calcitic remnants and the lower S content (as revealed by EDS analysis) at the centre of the oolites suggests that the replacement occurs from the outer edges of the oolites towards the centre (Fig. 6.2). The original ooid texture is commonly preserved suggesting that the gypsum replacement is a slow replacive process not always involving previous dissolution of the calcite with an intervening void phase before gypsum precipitation. In some cases, however, the typical oolitic texture is destroyed although the spherical outline of the ooid is still visible. Occasionally, the space previously occupied by the ooid is now filled with anthropogenic particles and mineral fragments. The sulphation also affects the sparite cement but not through a replacement process: gypsum instead crystallises within fractures and cleavage planes splitting calcite crystals apart; detached calcite fragments are slowly incorporated into the growing crust (Fig 6.3).

St. Luke’s Church: stone–crust interface. Gypsum crystals (G) crystallising within cleavage planes and intercrystalline boundaries split calcite cement into fragments (C) which are then incorporated into the growing crust. Anthropogenic particles from fossil fuel burning are also present (red arrows)

6.1.3.2 King’s College Chapel

Most of the oolites in Kings Chapel weathered stone samples, in contrast with St. Luke’s ones, do not show extensive gypsum replacement, although crystallisation of gypsum within ooid laminae and microfractures has been observed (Figs. 6.4, 6.5, 6.6). The micritic cement is, however, almost completely replaced by acicular gypsum crystals up to a depth of several centimetres underneath the current stone–crust interface (Fig. 6.4). Authigenic dog-toothed calcite is also seen precipitating at the oolite edges as a fringe cement (Fig. 6.6). This type of decay may deceitfully lead to an overestimation of the stone soundness because of the apparent high degree of cementation. Widespread sulphation of the cement can also be seen in areas of the stone where exposure to episodes of rain wash-outs have prevented the development of fully grown gypsum patinas. The net effect of sulphation is a sharp increase in intergranular porosity: a fragile framework of oolite grains with intervening void spaces is thus created. Macroscopically, this leads to superficial crumbling of the stone into a fine “oolitic” powder and to a complete loss of cohesion. In many instances, a band of clear gypsum crystal (i.e. with no imbedded anthropogenic and/or soil dust particulate matter) is present near the stone–crust interface (Fig. 6.5).

6.1.4 Discussion and Decay Model

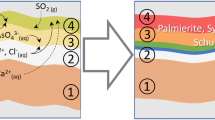

The ubiquitous presence of authigenic gypsum at the surface and within the pore spaces of the studied oolitic limestones confirms sulphation as the main decay process. The BSEM examination suggests that the following decay mechanisms have affected the building stones. Atmospheric pollutants, namely SO2, are adsorbed on the stone surface either by wet or dry deposition. Wetting of the stone cause sulphation to begin and calcite starts to get replaced by gypsum. Weathering solutions penetrate within the stone along cracks and intercrystalline boundary planes. At this stage, differences in stone microtexture lead to different decay patterns (Fig. 6.7).

Oosparite (St. Luke’s Church-London). The oolitic grains are preferentially replaced with respect to the cement. The mechanism of replacement my follow one of two routes: (i) dissolution of the calcite followed by precipitation of gypsum in the void thus created; (ii) slower atom by atom replacement via a thin film mechanism similar to that reported for the transformation of the mineral aragonite (CaCO3) into its polymorph (i.e. same chemistry, different crystalline structure) calcite [14]. The preservation of laminae within the cortex of many ooids (Fig. 6.2) would suggest the second mechanism to be predominant although episodes of dissolution and void creation are present. Gypsum crystals precipitating within cleavage planes and intercrystalline boundaries of calcite cement crystals results in their fragmentation (Fig. 6.3). Incorporation of these crystalline fragments into the growing crust is clearly visible and suggests that most of the anhedral calcite imbedded within the crust are not soil dust but remnants of the desegregated cement.

Oomicrite (King’s College-Cambridge). Most of the oolite grains are still calcitic whereas the microcrystalline cement (micrite), despite its low permeability, is almost completely replaced by gypsum (Fig. 6.4). The replacement process is likely, in this case, to have involved early dissolution of the fine-grained micrite as suggested by the presence of intergranular microcavities in areas not yet subjected to sulphation. Microsplitting of ooid laminae due to gypsum growth is present but, in this case, does not greatly affect the overall stone soundness (Fig. 6.5).

Differences in micropore distributions between cement and ooid grains in oosparite and oomicrite are responsible for the observed selective replacement features. Limestone porosity studies indicate that in oosparites the microporosity is mainly located within ooid grains whereas in oomicrites, most of the interconnecting pores, affecting stone permeability are located within the micritic cement. The smaller crystal size of the micrite cement in King’s College samples offers a greater specific area for chemical attack explaining why micrite is more easily replaced than large sparite calcite crystals. The fact that most of the ooid grains are still composed of calcite might also reflect the lower degree of SO2 air pollution in Cambridge as opposed to London. The dissolution/replacement of micrite is probably occurring at a fairly early stage in the decay process: further decay would probably result in the in the replacement of ooids as seen in St. Luke’s samples. In both examples, the presence of gypsum filled “ghosts” within the crusts near the stone–crust interface provides clear evidence that the chemically active weathering occurs inside the limestone and that crusts grow in thickness mainly at the expense of the stone substrate. Gypsum crystals get “younger” in an inward direction.

6.1.5 Conclusions

Compared to standard Optical Microscopy, BSEM is a useful tool in the investigation of building stone surface weathering in urban environments due to its higher magnification, higher lateral resolution and “instant” phase information based on changes in image brightness between minerals containing elements of various atomic numbers. In the case study illustrated in this chapter, for instance, the technique revealed slightly different decay pathways in the two similar but distinct lithological types examined. In oosparites, the main cause of decay is crystallisation pressures arising from gypsum crustallisation within cleavage planes and intercrystalline boundaries of the sparitic cement. In oomicrites, the main cause of decay is the dissolution of secondary gypsum cement replacing the original micrite.

In conservation terms, the oosparite seems to provide a better resistance to decay. The growth of gypsum crusts occurs in both directions, inwards and outwards, with respect to the original stone surface. The predominant direction is towards the interior of the stone, though, highlighting the need for an urgent removal of the patinas followed by the application of stone consolidants and water repellents.

6.2 Application of Microscopy, X-ray Diffractometry (XRD) and Stable-Isotope Geochemistry in Provenance Determination of the White Marbles Used in the Ancient Great Theatre of Larisa, Thessaly, Greece

Abstract The present work aims in identifying the exact source of the marbles used in the koilon from the ancient Great Theatre of Larisa, for maintenance purposes. Emphasis is given on the C–O isotopes of marble (δ13C = +2.62 to +2.93 ‰ and δ18O = −4.75 to −5.78 ‰). Mineralogical and petrographical investigations further refine the marble characteristics. Based on the comparison with seven different quarrying sites in Thessaly, it is concluded that the marble for the construction of the theatre was from the Kastri quarries.

6.2.1 Introduction

The Great Theatre of Larisa is one of the biggest well-preserved ancient theatres of Greece, totally built by stone. It was constructed in the beginning of the third century BC based on the Classical architecture [15, 16]. It consists of three major parts: the Scene, the Orchestra and the Koilon, a semicircular area of stepping seats, comprising the main part of the theatre. Koilon was built by fine-quality white-marble blocks. Fourteen series of seats are still preserved (Fig. 6.8), whereas the higher part (epitheatron) has been mostly removed or covered by modern buildings [15]. During the second century BC, a Doric style proscenium was added in front of the scene. Between the second and the first century BC, the theatre was subjected to extensive reconstructions due to a partial destruction attributed to a seismic event [17]. The Great Theatre was in use until the end of the third century A.D., when was probably flooded by the sediments of Pinios river which flows only 200 m to the West [18].

Map of Thessaly in central Greece, showing the location of the ancient Great Theatre in Larisa (small photograph at the upper left corner) and the ancient white-marble quarrying sites: 1. Tisaion mount (ancient Atrax), 2. Olympos mount (ancient Gonnoi), 3. Ossa mount (Tempi), 4. Chasanbali, 5. Kalochori, 6. Mavrovounion mount (Kastri) and 7. Magnesia–Tisaion mount

The first works for unearthing the theatre started in 1910, but the large revelation of the monument was due to the broader excavation programme between 1985 and 2000, by the fifteenth Ephorate of Prehistoric and Classical Antiquities, directed by Tziafalias. Today, a large project focusing on the preservation and restoration of the koilon is in process. The main problems are concentrated in damages, such as displacements and breaks of the large marble blocks, attributed to strong earthquakes [18]. For the maintenance purposes, it is of critical importance for the archaeologists to know the precise quarries in order to replace the broken and damaged slabs from the same quality marble with equivalent features.

The present work aims in identifying the exact ancient source of the marbles used in the koilon from the Great Theatre of Larisa, through a mineralogical, petrographical and isotopic study. In fact, the provenance studies contribute in the location of the best materials for restoration, but also offer valuable information in the ancient trading and communication routes during ancient times.

6.2.2 Sampling and Methodology

A total of six marble samples (AThL1-6) were collected from the koilon of the ancient theatre, especially from the main part, apart from one sample which is from the upper section, the epitheatron. It should be mentioned that all the samples were detached from hidden broken parts of damaged seats and they do not exceed 2 × 2 × 1 cm in dimensions.

From each sample, a thin section was prepared for the purpose of mineralogical and petrographical study by polarising microscopy at the Department of Mineralogy-Petrology-Economic Geology, Aristotle University of Thessaloniki (AUTh). Microscopy was employed to determine the fabric of the mineral constituents, with particular reference to calcite, as well as to detect the frequency and distribution of the accessory grains. The maximum grain size (MGS) of calcites and the geometric relationships of the carbonate grains, such as the grain boundary shape, were also evaluated.

In addition, powders of the samples were processed by X-ray diffraction (XRD) in order to distinguish calcite from dolomite and to verify the related abundances in each sample. The XRD analyses were performed at the Department of Mineralogy-Petrology-Economic Geology, AUTh, with a PHILIPS PW1710 diffractometer (Ni-filtered CuKα/Ni: 40 kV, 0.01° 2θ, 3–63°, 0.02° 2θ/s).

Oxygen and carbon isotope analyses of the marble samples were carried out at the Department of Earth Sciences, Royal Holloway University of London. The oxygen and carbon isotope ratios are referred to the standard VDPB (Belemnitella americana from the Cretaceous Pee Dee Formation, South Carolina).

The applied methods have been successively used so far by many researchers, such as Coleman and Walker [19], Herz [20], Herrmann et al. [21], Capedri and Venturelli [22], Maniatis et al. [23, 24] and Al-Naddaf [25], for the source identification of ancient marble artefacts.

This study is based on the documentation of the ancient white-marble quarries of Thessaly, the development of well-defined data-bases with mineralogical, petrographical and oxygen and carbon isotope ratios, and the statistical treatment of the measured parameters. Previous works from Germann et al. [26], Capedri et al. [27], Melfos [28] and Melfos et al. [29] have defined the geological and isotopic characteristics of the marbles at seven ancient quarrying sites in Thessaly, located: at Titanos mountain (ancient Atrax), at Olympos mountain (ancient Gonnoi), at Ossa mountain (Tempi), at Mavrovouni mountain (Kastri), at Kalochori and Chasanbali, nearby the famous quarries of the ophicalcitic Green Thessalian stone [30], and at Tisaion mountain in Magnesia (Fig. 6.8). The mineralogical composition, the textural features, the MGS and a brief description of the marbles from each ancient quarry are depicted in Table 6.1, which also reports O and C isotope compositions.

6.2.3 Results

All the marble samples from the ancient theatre have a white colour and they are coarse grained, with visible calcite crystals. In some cases, grey-green coloured thin orientated stripes are observed parallel to the schistosity. The XRD analyses and the microscopic investigation showed that the mineralogical composition remains almost the same in the whole sample suite and consists mainly of calcite, with dolomite quartz, white mica, opaque minerals (sulphides) and Fe-oxides as accessory minerals. Traces of chlorite, when observed, are related to the grey-green orientated stripes.

The maximum grain size (MGS), a diagnostic feature for discriminating marbles, is 5–6 mm. This MGS is typical of the coarse-grained marbles from different localities in Thessaly, such as Gonnoi, Tempi and Kastri (Table 6.1). The marble samples exhibit a heteroblastic texture with small grains, up to 500 μm in diameter, coexisting with larger crystals with a size reaching 6 mm, and only occasionally they show a homeoblastic texture. This is typical of Atrax, Kalochori and Kastri marbles (Table 6.1). In some samples (AThL3, AThL4, AThL5), the marble is characterised by a high degree of preferred orientation of the calcite crystals which are considerably distorted by elongation, flattening and bending as a result of intensive strain. This fabric has been observed in some cases in marbles from Tempi and Kastri (Table 6.1). The shape of the grain boarders is sutured to dentate and frequently embayed (e.g. grains are interlocked) indicating non-equilibrated metamorphic conditions.

All the samples contain small flakes of white mica and rounded quartz grains with a length up to 1 mm. Chlorite flakes with a maximum size 500 μm were observed in one only sample. Opaque minerals (probably sulphides) are seldom found among the calcite crystals and their size does not exceed 5 μm. This mineralogical composition resembles the Kastri and partly the Gonnoi marbles.

The C–O isotopic results of the marble samples from the ancient theatre are plotted in the diagram of Fig. 6.9. The δ13C values range from +2.62 to +2.93 ‰ and the δ18O values from −4.75 to −5.78 ‰. It is obvious that these values have a consistent signature and in the diagram of Fig. 6.9 they plot in a restricted field. Reference isotopic fields of the marbles from the ancient quarries in Thessaly are also shown in the same diagram.

A δ18O–δ13C diagram for the archaeological marble samples from the ancient Great Theatre of Larisa. Reference isotopic fields of the marbles from the ancient quarries in Thessaly are also shown: Kalochori, Kastri, Gonnoi, Atrax, Tisaion, Tempi, Atrax and Ghasanbali, published by Germann et al. [26], Capedri et al. [27], Melfos [28] and Melfos et al. [29]

6.2.4 Discussion

The microscopic investigation, the XRD and the stable-isotope analyses of six marble samples from the ancient Great Theatre of Larisa demonstrate consistent results with regard to the mineralogical composition, the petrographical features and mainly the C–O isotope ratios (Fig. 6.9).

Especially, the isotopic ratios of C and O provide usable signatures for determining the provenance of marbles. Isotopic analyses involve measuring of the 13C/12C and 18O/16O ratios in marble and the results are expressed in terms of the deviation from a conventional standard. This deviation, called δ, is expressed as δ13C and δ18Ο in parts per thousand (% or per mil) and forms the isotopic signature. The values exhibit a relatively restricted range in each quarry area or limited parts of a geological formation [31, 32]. On the δ13C–δ18O correlation diagram, the geological samples of the marbles fall into well-defined groups and each quarrying site is therefore discriminated.

Comparing the isotopic results of the studied marbles from the theatre with the marbles from the Thessalian ancient quarries, it is evident that they plot in the groups of Tempi and Kastri and partly of Chasanbali marbles (Fig. 6.9). Consequently, all the other quarries are excluded as possible sources.

Based on mineralogical and petrographical features, discrimination among the possible sources (Tempi, Kastri or Chasanbali) is possible. The marble in Tempi consists only of calcite and its texture is mostly homeoblastic. The marble in Chasanbali contains calcite and quartz and is fine grained with homeoblastic texture. In contrast, the marbles from the theatre are made of calcite with traces of dolomite, white mica, quartz, opaque minerals, Fe-oxides and rarely chlorite and have a coarse-grained heteroblastic texture. Therefore both quarrying sites, Tempi and Chasanbali, are also excluded as possible marble sources for the theatre of Larisa. In addition the white-marble quarry in Chasanbali is small and unimportant and could not provide such a large amount of raw materials for the theatre construction.

Mineralogical composition obtained by XRD and microscopy showed that the Kastri marble is almost identical with the whole suite of the eleven studied marbles from the theatre. The textural features have also significant similarities being mainly coarse-grained heteroblastic, and in some cases elongated calcite crystals are observed. The large MGS, in the case of Kastri and the marbles from the theatre, are 5–6 mm.

It is evident that only the Kastri marble quarry demonstrates similar mineralogical and isotopic features with the studied marbles and shows that it is the most probable source for the marbles of the Great Theatre of Larisa (Fig. 6.8).

6.3 Case Studies: Investigation of Mortars by Infrared and Raman Spectroscopy

Abstract Infrared (IR) and Raman spectroscopy permit the identification of X-ray amorphous minerals. Mechanisms of material decay and principles of cause and effect can be elucidated. We discus three examples: (i) decay due to alkaline-rich mortar, (ii) effect of nitrate-rich mortar, (iii) identification of historic mortar. Damages to historic buildings may not only be caused by their actual utilisation or by contemporary pollutants. Natural influences acting for centuries even without any human interference may have put deteriorating strain on a historic structure as well. The impact of such strains rises if inappropriate materials were chosen or combined for construction, restoration or refurbishment. This kind of damages is known since many years. The underlying mechanisms can still not always satisfactorily be explained. Important sources of salt formation are (i) the historic building material itself, (ii) environmental pollution (air, soil), (iii) mistakes during restoration. Minerals may be mobilised in the presence of water, salt efflorescences subsequently become directly visible. Sometimes, these salts are merely recognisable by the damages they induced. Analytical data are needed to identify original sources of the material, to reveal the ancient technologies and to restore the works of art sustainably. Inorganic material is often characterised by its atomic composition, e.g. the content in Mg2+ and Ca2+ as well as and SO42− and CO32−. Under moist conditions, these ions may undergo ion exchange and form compounds of distinctly different properties. A crucial property is their solubility in water (Table 6.2):

As solubility data indicate, single ion concentrations do not provide full information about the material. If local limestone contained appreciable amounts of dolomite (CaCO3 * MgCO3), the mortar may lose its strength gradually due to the enhanced mobility of Mg2+ components. Mobilisation is often indicated by salt coatings (efflorescences). Even non-crystalline samples can easily be identified by Raman or IR spectroscopy ([33], cf. also Sect. 3.3).

6.3.1 Choosing Mortar for Restoration

Salt coatings on stone were commonly called saltpetre in the past, nowadays they are usually considered sulphate depositions due to environmental pollution. Wall saltpetre is Ca(NO3)2, formed in staples everywhere in settlements. Coatings by wall saltpetre indicate high salt concentration inside the structure. Environmental sulphate depositions may be CaSO4 * xH2O (anhydrite, bassanite, gypsum), Na2Ca(SO4)2 (glauberite) or various alkali sulphates. Salt coatings may appear rather localised on the surface due to varying permeability of different stone layers (Fig. 6.10). The chemical composition of the different salt bands may vary across the stone surface caused by a separation effect of the mobility mechanism.

The IR analysis of the efflorescences in Fig. 6.10 indicated natrite (Na2CO3 * 10H2O). Natrite would have been instantaneously transformed into sodium sulphate if environmental pollution played a role during formation of the salt bands. The formation of natrite indicates mortar of high alkali content used to position the sandstone slabs or the application of water glass to seal and strengthen the system. The recommendation based on the IR analysis was replacement by new sandstone and selection of an appropriate mortar type.

A high salt load may cause severe hazard to building material, particularly in case of high soluble salts like sodium sulphates. The solubility of thenardite (Na2SO4) in water at 20 °C is 162 g/l, that of mirabilite (Na2SO4 * 10H2O) is 900 g/l. The solutions migrate into the pores of the stone and equilibrate with the humidity in the surrounding air. The minerals crystallise/dissolve upon changes of the atmospheric humidity: mirabilite at 87 % relative humidity, thenardite at 81 % relative humidity. Thenardite requires a 4.2 times larger volume than that of mirabilite. The conversion from mirabilite to thenardite breaks up the pores inside the stone. The conversion temperature between the two minerals is at 32.5 °C. Both can be identified by details in their IR spectra.

-

Alkali content of mortar is crucial.

-

Efflorescences may be caused by raw material, diffusion or deposition.

-

Exact analysis is necessary to control the decay of stones

6.3.2 Analysis of Injuries in Historic Mortar

The Frauenkirche (Church of Our Lady) Dresden is an outstanding example of rebuilding a largely destroyed monument and preserving most of the old substance. New sandstones were obtained from historic quarries. Questions arose about the historic lime mortar (Fig. 6.11).

Local limestone is known to contain dolomite (CaCO3 * MgCO3). The solubility in water increases in the order CaCO3 < MgCO3 * CaCO3 < MgCO3. Acid (from rain or soil) dissolves magnesium ions, the corresponding salts migrate, the mortar inside the joints is weakened, and the stability of the building decreases.

After clearance of the debris, a preserved part of the outer wall just above ground showed intense signs of disintegration within its joints at the outside wall. Joints at the inside wall were weakened as well but to a much lesser degree. A nearby pillar did not exhibit any mortar decay within its joints. Samples were taken from the three sites and investigated by IR spectroscopy. All samples exhibited the characteristic features of lime mortar, lime and quartz (Fig. 6.12). Clay minerals would be indicated by a distinct band in the low-frequency wing of the quartz band. They cannot be identified in the actual samples.

The band sizes in the IR spectrum of mortar from the intact pillar indicate a normal ratio between lime (around 1,425 cm−1) and quartz (below 1,100 cm−1). The band assigned to lime becomes smaller for the inside wall and weak for the outside wall. This band indicates the amount of binding agent (lime) in the mortar. At the same time, a small feature below 1,400 cm−1 becomes visible. This little band indicates nitrate. It is generally weak but very characteristic. After this finding, a search in the archive revealed a former burial site near the outer wall.

6.3.3 Age Determination for Historic Mortar

The famous August the Strong, Elector of Saxony, ordered the construction of the Taschenberg palace. The palace next to Dresden Castle replaced earlier town houses, which dated back to around 1250. The building was destroyed in 1945 with only few parts remaining. We collected 120 mortar samples from the old ground walls. The sampling sites were recommended by archaeologists and cover the complete history of the historic building from the thirteenth to the eighteenth century. Minerals in the samples were analysed (i) by atomic absorption spectrometry (AAS) after dissolution in HF/HCl/HNO3 and (ii) by FT-IR spectroscopy after milling the samples and preparing KBr pellets [34].

Chemometric evaluations (i) may indicate and/or quantify relations between the samples (called objects) and the measured data (called variables) or (ii) may be used to model interdependencies between variables. Multivariate procedures evaluate several independent variables simultaneously. We employed Principal Component Analysis (PCA) and Cluster Analysis (CA). PCA reveals hidden, complex relations within the data set. CA merges the objects of a data set into homogeneous classes (clusters). Both kinds of evaluations are particularly helpful if no preliminary information is available, like in case of the historic mortar samples.

Figure 6.13 shows the PCA result for 87 mortar samples. AAS parameters are given in italics, FT-IR data are printed bold. The top three principal components, PC1–PC3, cover 71.30 % of the variance within the data set. The contribution of PC4 is distinctly lower than that of PC3. The samples (dots) are well distributed across the feature space. The orientation of the vectors within the cube is reasonable: the two aggregates feldspar and quartz point to opposite directions, as the mortar is either rich in feldspar or in quartz. The direction of lime (calcite) is orthogonal to (i.e. independent of) the feldspar/quartz ratio. Clay (illite/muscovite/kaolinite) is located opposite of calcite. Both clay and lime are binders, their content was well matched in historic mortar.

Subsequently, a hierarchical CA was performed for the FT-IR data of Fig. 6.13. The resulting dendrogram is shown in Fig. 6.14. The date of origin of roughly 50 % of the samples was assigned by archaeologists and could be taken as reference. The references were used to assign dates of origin to the obtained clusters. This information helped to gain new insights into the construction history of the palace. Inspections of the spectra indicate that the cluster “disorder” may be caused by a former storage of construction material, the “special cases” may indicated wall repairs in the early twentieth century.

Cluster analysis of the FT-IR data of the 87 mortar samples of Fig. 6.13. The assignment of the clusters to time periods of origin is based on reference data by archeaologists for approx. 50 % of the samples

6.4 Mortars-Thermal Analysis

6.4.1 Introduction

Mortars and plasters in ancient structures are composite materials which have exhibited excellent durability through time and are constituted of a binder, such as lime (CaO) and/or gypsum (CaSO4 * 2H2O) and aggregates, such as sand or grit. The composition of mortars and plasters varies greatly and they are commonly divided into lime, gypsum and mixed, depending on the binding material and into hydraulic and non hydraulic depending on their ability to set under water. The main steps for lime processing are:

In the case of gypsum plaster, the plaster is produced by the addition of water and an aggregate to the hemihydrate (CaSO4 * 1/2H2O) and/or the soluble anhydrite (CaSO4). In this way, interlocking crystal structures are developed corresponding to calcium sulphate dehydrate [35].

6.4.2 Experimental

Thermal analysis (TG–DTA) involves measuring the thermal variations associated with physical and chemical transformations (such as dehydration and decomposition) which occur during the heating of a sample. TG–DTA simultaneous analyses were performed using a SETARAM SETSYS 1750 TG–DTA system. Samples around 7.5 mg were placed in alumina crucibles. An empty alumina crucible was used as reference. The samples were heated from ambient temperature to 900 °C, with heating rate 10 °C min−1, in N2 atmosphere.

The studied samples are from six monasteries and churches (Fig. 6.15). Most of them have been built after the tenth century but belong to different time periods. However, the majority of them are of the sixteenth century. Also, the studied samples in this work come from churches or monasteries from various Balkan countries. According to various sources, two of the studied wall paintings must have been done by the same iconographer. From one church, two types of samples were collected in order to examine the differences of the plaster between the two iconographers (two periods) (samples SA6, SB7). The plaster was taken from already damaged areas of the wall paintings, while from two other churches the plaster was removed, with the use of a microscalpel, beneath the pictorial layer (samples S1 and S2). Due to the destructive nature of sampling, the samples were carefully chosen from areas that had no aesthetic or iconographic value for future reconstruction.

6.4.3 Results and Discussion

For the examined samples, typical thermal curves obtained by DTG/TG analysis are shown in Fig. 6.16. For the thermal characterisation of the materials, the temperature range, can be divided into four regions corresponding to the mass loss in the thermal curve [36]: (i) <120 °C, (ii) 120–200 °C, (iii) 200–600 °C, and (iv) >600 °C. The first region is attributed to absorbed water evaporation (hygroscopic water), while the second to the evaporation of chemically bound water of the hydrated salts, such as gypsum. The third region refers to the evaporation of water chemically bound to hydraulic compounds—probably calcium silico-aluminate hydrates [36–39]. Finally, the fourth region corresponds to the carbon dioxide developed during the decomposition of carbonates. The endothermic peaks after 750 °C correspond to calcite decomposition (Eq. 6.4).

While pure calcite decomposes near 840 °C, the lower degradation temperature for the plasters is characteristic of the CO2 loss from CaCO3 formed by recarbonation reaction of lime with atmospheric CO2 (Eq. 6.3) [37, 38].

Figure 6.16a is representative of the samples taken from three churches, namely S1, S2 and S3. From that TG curve, a monotonous reduction of the sample mass was recorded up until 600 °C, which corresponds to the three of the four already discussed regions of mass loss. Above that temperature, the main mass loss was recorded as well as the corresponding endothermic peak.

The main difference between the other two examined samples which are presented in Fig. 6.16b, c respectively is located in the temperature range 120–200 °C. The samples S5 and SB7 from two different churches show endothermic peaks with minimum values at 132 and 149 °C, respectively. This peak is attributed, to a loss of moisture, and also to the dehydration of the gypsum (CaSO4 * 2H2O), which takes place in two stages (Eqs. 6.5 and 6.6), between 130 and 160 °C [37, 38, 40].

It can be seen from Fig. 6.16b and c that the TG curves of these samples, mainly differ at the mass loss step of the area 130–160 °C. In Fig. 6.16b, it is difficult to see the step of mass loss, yet a small endothermic peak in the heat flow plot is visible, but the mass loss step is very clear in Fig. 6.16c. This difference means that the quantity of gypsum in the sample SB7 is larger than in the sample S5. Consequently, it is clear from the thermal curves that in samples S5 and SB7 there is gypsum participation. The presence of gypsum in these plaster samples was also verified by the FT-IR and EDS measurements which gave analogous results. Beyond the use of gypsum as a binding material of the plaster, it can also be formed during sulfation, as a result of Eq. 6.7, which involves the dry deposition reaction between limestone (CaCO3) and sulphur dioxide (SO2) gas, in the presence of high relative humidity, an oxidant and a catalyst (Fe2O3 or NO2). In that case, gypsum is primarily detected close to the surface, especially in cracks and voids.

Comparing the results of thermal analysis measurements for the samples S5 and SB7 with the results of other techniques, we can conclude that both frescoes painted by the same iconographer. SA6 which is a sample from the same church as of SB7 but from another wall had no traces of gypsum. This means that gypsum was not a deterioration result but the iconographer used it as a component in the initial mixture of the plaster. For this reason, we can conclude that the origin of the sample SA6 is from a wall painting which has been created by a different artist. Table 6.3 summarises the results from the thermal analysis studies. It is obvious that in all samples the main constituent is calcite as can be seen from the mass loss in the temperature range >600 °C. S3 has the greatest mass loss 39.4 % in this temperature area. SB7 and S5 perform in the second region mass losses of 1.1 and 2.3 % respectively due to gypsum dehydration, which means that gypsum was in greater proportion in the mixture of the plaster S5. S1 has a mass loss almost 1 % in the temperature range 120–200 °C, but the heat flow curve shows no peak corresponding to gypsum.

In Fig. 6.17, the thermal curves of the sample S4 are presented. The minimum value of the first endothermic peak was recorded at 142 °C, due to gypsum dehydration and the respective mass loss was 1.1 %. The sample was collected from an area where the painted layer was damaged, so the plaster was exposed to air. From the FT-IR and EDS measurements, there was no evidence of gypsum in the plaster studied below the pictorial layer in painted samples. On the contrary, gypsum was identified on the external surface of the painted layer. Therefore, the presence of gypsum can not be attributed to its inclusion in binder but is more likely to be related to the sulphation of the carbonate component, due to environmental pollution [39]. The FT-IR and EDS results are in good agreement with the TG–DTA analysis.

6.4.4 Conclusions

The historic plasters studied can be classified in two distinct groups depending on their thermal behaviour. From this set of measurements, the possibility that different wall paintings from different churches must have been made from one artist can be concluded. Also, the fact that different parts inside one church must have been done by different artists is proposed through the thermal analysis studies of each church. Thermal Analysis seems to be a reliable method for plasters’ discrimination. The results give useful information on the understanding of the technology of historic plasters and on planning syntheses for restoration of wall paintings. Our work allows a consistent approach to the wall paintings conservation and repair to be achieved.

6.5 Electrochemical Impedance Spectroscopy Measurements for the Corrosion Behaviour Evaluation of Epoxy: (Organo) Clays Nanocomposite Coatings

Abstract Aim of the present work is the evaluation of corrosion behaviour of steel coated with epoxy–(organo) clay nanocomposite coatings by electrochemical impedance spectroscopy measurements. Electrochemical impedance basics and main characteristics of nanocomposite for protective coatings are presented. The investigation was carried out by electrochemical impedance measurements and the polarisation resistance for four types of specimens, non-coated, coated with pristine glassy epoxy polymer or with two types of epoxy–clay nanocomposites at various times of exposure in the corrosive environment was determined. Both epoxy–clay nanocomposite tested have improved anticorrosive properties in comparison with these of the pristine glassy epoxy polymer. The epoxy–montmorillonite clay modified with primary octadecylammonium ions, Nanomer I.30E, had a better behaviour than the modified with quaternary octadecylammonium ions, Nanomer I.28E.

6.5.1 Introduction

Organic coatings are widely used to prevent corrosion of metallic structures because they are easy to apply at a reasonable cost. It is generally accepted that the coating efficiency is dependent on the intrinsic properties of the organic film (barrier properties), on the substrate/coating interface in terms of adherence, on the inhibitive or sacrificial pigments used and on the degree of environment aggressiveness.

Over the years, polymeric coatings are developed due to their good barrier properties. However, these pristine polymeric coatings are still permeable to corroding agents such as water and oxygen. In order to enhance the barrier properties of polymeric coatings, various kinds of additives such as extenders and inorganic pigments which inhibit corrosion have been used.

During the last years, polymer clay nanocomposites have attracted a lot of attention. It has been reported that the incorporation of a small amount (1–5 %) of layered clay in organic polymers leads to significant improvements in mechanical performance, thermal stability, and barrier properties of organic coatings. These improvements are related to the morphology of the layered silicates and to the specific incorporation of the nanoparticules in the polymer [41–47].

EIS Basics

The development of electrochemical impedance methods in recent years has made possible the planning of electrochemical laboratory research into applications that traditional DC techniques could not be applied, such as corrosion measurements in cases where organic coatings and low conductivity materials are used. This technique allows analysis of the stages of a reaction when wide frequency ranges were used. Also, in the field of study of the materials is used to reveal relationships between electrical properties of materials and physical and chemical properties. The areas that have been demonstrated as appropriate for using EIS for corrosion measurements are:

Suspension or retardation of corrosion (uniform or local). Passivation of metals. Behaviour and properties of polymeric materials used as protective coatings against the corrosion of metals, which is very widespread and complex due to the high resistance of the coatings. Rapid estimation of corrosion rates. Estimation of extremely low corrosion rates and metal contamination rates (<10−4 mm/year, <0.01 mpy) and in low conductivity media. Rapid assessment of corrosion inhibitor performance in aqueous and nonaqueous media.

Impedance

A resistance to direct current can be corresponded with an equivalent resistance to alternating current. This equivalent resistance is called “complex resistance” (Impedance). Measurements can be performed with dynamostatic control, i.e. when a voltage is applied and the respective current is measured. In this technique, typically, a small amplitude sinusoidal potential perturbation is applied to the working electrode at a number of discrete frequencies, ω. At each one of these frequencies, the resulting current waveform will exhibit a sinusoidal response that is out of phase with the applied potential signal by a certain amount (Φ) and has a current amplitude that is inversely proportional to the impedance of the interface. The electrochemical impedance, Z(ω), is the frequency-dependent proportionality factor that acts as a transfer function by establishing a relationship between the excitation voltage signal and the current response of the system:

where: Z(ω) = the impedance, ohm-cm2; ω = frequency, radians-s−1; Ε = the time varying voltage across the circuit, volts, Ε = Ε 0 sin (ωt); Ι = the time varying current density through the circuit, amp-cm−2; for linear systems (i.e. where there is a continuous evolution of the phenomenon of corrosion: non-breaking of the coating of corrosion products), the response is defined as: Ι = Ι 0 sin (ωt + Φ); Ε 0 = the size of disturbance of the voltage; I 0: the size of disturbance of the current; t = time, s; Φ = phase angle, deg.

Only for linear systems the resulting current is pure sinusoidal. But in electrochemical systems, there is seldom a clean linear relationship between potential and current (Figs. 6.18 and 6.19).

The impedance of a single frequency can be represented by a vector of a length |Z| with an angle φ between the real axis of impedance Z′ (real part of impedance) and a vector Z″ (imaginary part of impedance = the part of the capacity of the impedance) (Figs. 6.20 and 6.21).

These figures show that when a small amplitude sinusoidal potential perturbation is applied, there is a current response of small amplitude. When the amplitude remains small, it can be used the first term of Taylor series,

resulting in an approximately linear system and represents the response current. The voltage application and the resulting current can be written as a function: \( E = E_{0} \exp \left( {j\omega t} \right),I = I_{0} \exp \, (j\omega \tau - \varphi ), \) where j imaginary part (−1)1/2.

The complex resistance (impedance) is:

Οr: Real Current = I’ = |I| cos (ωt), (in-phase component); Imaginary Current = I” = |I| sin (ωt), (out-of-phase component); \( E = E_{\text{real}} + {\text{E}}_{\text{imag}} = E^{\prime} + jE^{\prime\prime};I = {\text{I}}_{\text{real}} + {\text{I}}_{\text{imag}} = I^{\prime} + I^{\prime\prime}; \)

-Grafic representation of impedance

Impedance of a system can be represented graphically by using Nyquist diagrams. The impedance is derived from the connection of the points between the edges of the impedance vectors as a function of frequency. An example of a Nyquist vector for an equivalent circuit of DC with a resistor in parallel with a capacitor is shown in Fig. 6.22.

Another method of expression of the impedance is Bode diagrams. In this expression, the logarithm of the absolute value of impedance enters in a diagram as a function of the logarithm of frequency. The phase angle enters in the same diagram using an additional vertical axis on the right part of the Bode diagram. For the same circuit as the previous, the Bode diagram is shown in Fig. 6.23.

The electrochemical impedance is a fundamental characteristic of the electrochemical system it describes. Knowledge of the frequency dependence of impedance for a corroding system enables a determination of an appropriate equivalent electrical circuit describing that system.

The following expression describes the impedance for a system of Fig. 6.24: \( Z\left( \omega \right) = {\text{Rs }} + {\text{ Rp}}/\left( { 1 + \, \omega^{ 2} {\text{Rp}}^{ 2} {\text{C}}^{ 2} } \right)-{\text{j}}\omega {\text{CRp}}^{ 2} /\left( { 1+ \omega^{ 2} {\text{Rp}}^{ 2} {\text{C}}^{ 2} } \right), \) where ω = the frequency of the applied signal (ω = 2πf, rad-s−1); f = the frequency of the applied signal, Hz (cycles-s−1); Rs = the solution resistance, ohm-cm2; Rp = the polarisation resistance, ohm-cm2; C = the interfacial capacitance, Farad-cm−2 (Fig. 6.25).

Electrical equivalent circuit model simulating a simple corroding metal/electrolyte interface. Rs = solution resistance, Rp = polarisation resistance, C = interfacial capacitance, Rs = solution resistance, Rd = diffusion controlled resistance, Rct = charge transfer controlled resistance, Cd = coating capacitance, Cct = double layer coating-metal capacitance

The above equation and the Bode magnitude and phase information of Fig. 6.26 show that at very low frequencies:

Bode phase angle and magnitude plots demonstrating the frequency dependence of the impedance for the circuit model shown in Fig. 6.24

Zω→0(ω) = Rs + Rp, while at very high frequencies Zω→∞(ω) = Rs.

Determination of Rp is attainable in media of high resistivity because Rp can be mathematically separated from Rs by taking the difference between Z(ω) obtained at low and high ω

Determination of the corrosion rate using the corresponding equation of the polarisation resistance method, also requires knowledge of Tafel slopes βa, βc and electrode area, which must be calculated according a suitable experiment as they are not obtained in the impedance experiment.

Either the anodic or cathodic half-cell reaction can become mass transport limited and restrict the rate of corrosion at Ecor. The presence of diffusion controlled corrosion processes does not invalid the EIS method, but does require extra precaution and a modification to the above presented circuit model. In this case, the finite diffusional impedance is added in series with the usual charge transfer parallel resistance (Fig. 6.25).

In a such case, Rp is the sum of the charge transfer controlled Rct, and diffusion controlled Rd contributions to the polarisation resistance assuming that Rd + Rct ≫ Rs → Rp = Rct + Rd [48–52].

6.5.2 Experimental Procedure

The steel tested was cold rolled steel (DC 01), the specimens were cut from a plate 0.3 cm thickness, the dimensions were 5 × 1.5 cm, the total exposed area was 6 cm2.

The metallic specimens were coated with a ~20 μm thin film of pristine glassy epoxy polymer or epoxy–clay nanocomposites. The pristine liquid epoxy was diglycidyl ether of bisphenol A (DGEBA) (EPON 828RS, Hexion) with an average epoxide equivalent weight of ~187 (M.W. = 370) and was mixed at 50 °C with the appropriate amount of an aliphatic polyoxypropylene diamine (Jeffamine D-230, Mw ≈ 230, Huntsman) which acted as curing agent. The metallic specimens were dipped in the liquid uncured mixture and where then kept vertically so that the excess of liquid was removed and left to cure at ambient conditions for 24 h. Finally, post-curing was performed at 75 °C for 3 h and 125 °C for another 3 h. The same procedure was applied for the coating of the specimens with the epoxy–clay nanocomposites, except that prior to adding the curing agent, the epoxy prepolymer was mixed with the (organo) clays for 1 h at 50 °C. The clays used were the Nanomer I.28E and the Nanomer I.30E (from Nanocor Inc.) which are montmorillonite clays that have been modified with quaternary and primary octadecylammonium ions, respectively.

Four types of specimens tested, blank (non-coated), coated with pristine glassy epoxy polymer, coated with the two types of epoxy–clay nanocomposites) and the times of exposure were 0 (measurement immediately after the immersion in the corrosive environment) 1, 2 or 4 days.

The electrochemical impedance spectroscopy measurements were carried out according standard methods [51, 52] in a corrosive environment of 3.5 % NaCl. They are realised in a typical electrochemical cell, in deaerated conditions and at the potential value of the corrosion potential (Ecor). The electrochemical impedance data is collected between 10,000 Hz (10 kHz) and 0.1 Hz (100 mHz) at 8–10 steps per frequency decade and the potential amplitude (E 0) was 10 mv.

6.5.3 Results and Discussion

The experimental data processing and fitting of the electrochemical impedance measurements was based on the equivalent circuits of Fig. 6.24 for bare steel and Fig. 6.25 for the coated steels and a suitable nonlinear regression analysis. The results are presented in Figs. 6.27, 6.28, 6.29, 6.30, 6.31 and 6.32 (Nyquist diagrams) and Table 6.4 (Polarisation Resistance values).

From the above results, it follows that all coatings used increase polarisation resistance and both nanocomposites have greater polarisation resistance values than pristine glassy epoxy polymer, indicating improved anticorrosive properties. The epoxy–montmorillonite clay modified with primary octadecylammonium ions, Nanomer I.30E, had a better behaviour than the modified with quaternary octadecylammonium ions, Nanomer I.28E.

A great polarisation resistance value in the case of bare steel in conditions of no prior exposure in the corrosive environment (0 days) is observed that decreases dramatically in any conditions of exposure, indicating great corrosion rate values and fast evolution of corrosion.

In the case of coated steel, the polarisation resistance values decrease for all coatings during the initial days of exposure, as it is expected due to corrosion initiation. But the decrease is much smaller and so corrosion evolution is too lower. Also, an increase of polarisation resistance values is observed in a longer exposure time of 4 days, more significant for nanocomposite coatings. This observation, indicating lower corrosion rates, may be is due to a passivation of the surface, but further examination is needed for a clear explanation.

A combination of Nyquist plots and also Bode plots of impedance spectra evaluation can give more precious information about corrosion reaction evolution and behaviour and properties of the polymeric and nanocomposite materials.

6.5.4 Conclusions

EIS method is a useful tool for the qualitative and quantitative study of corrosion, especially into applications that traditional DC techniques could not be successfully applied, such as corrosion measurements in cases where organic coatings are used and low conductivity materials, suspension or retardation of corrosion (uniform or local), passivation of metals. The study of the behaviour and properties of polymeric materials used as protective coatings against the corrosion of metals, which is very widespread and complex due to the high resistance of the coatings and the estimation of extremely low corrosion rates is possible with EIS technique.

From the above electrochemical impedance measurements, it follows that both epoxy–clay nanocomposite tested have improved anticorrosive properties in comparison with these of the pristine glassy epoxy polymer, as it is shown from the electrochemical impedance spectroscopy measurements and the determined polarisation resistance values. The epoxy–montmorillonite clay modified with primary octadecylammonium ions, Nanomer I.30E, had a better behaviour than the modified with quaternary octadecylammonium ions, Nanomer I.28E.

6.6 Study of Vatican Masterpieces

6.6.1 Introduction

A number of masterpieces of the St. Peter’s Basilica and its Museum have been studied, mainly during restoration works that were needed to improve the state of conservation and valourisation. The purpose of the investigation has been twofold, a better knowledge of the production technologies used and an assessment of the State of conservation of the objects. It has become a routine to fulfil diagnostic and archaeometric analyses and conservative investigations on metal works of great historical interest with the use of in situ tests and laboratory examinations. On previous occasions, as for the study of Perseus by Benvenuto Cellini and the statue of Bartolomeo Colleoni by Verrocchio [53] results have been of considerable utility for better planning the restoration operations and to better understanding of the work of art. In the last decade, the large availability of new portable instrumentations improved the diagnostic procedures that are becoming a rationale plan of measurements. A better understanding of the complementarity of the results obtained from the different techniques and the definition of the order to follow the experimental plans is an important result of these studies. The final goal is to develop protocols to obtain the maximum information with the minimum of scientific exams.

To some extent the purpose of our work is to provide, to avail non-destructive investigations and to get assisted by a limited number of laboratory tests, the basic experimental conservation plan, and to outline the subsequent conservation actions, the best way to control the degradation processes [54].

6.6.2 The Funeral Monument of Pope Sixtus IV: A Masterpiece of Italian Renaissance

The bronze funeral monument for Pope Sixtus IV (1471–1484) by Antonio del Pollaiolo, originally placed in the Choir Chapel in the Constantine Basilica of San Peter’s in the Vatican and now in the Museum of the Vatican Basilica, has a complex composition with the Pope placed at the centre of an inner ring with the personification of the virtues and an outer one with ten allegories of Art and Science. The work was commissioned by the Cardinal Giuliano della Rovere, nephew of Pope Sixtus, himself a future pope later known as Giulio II. The work was created between 1484, the year in which the Pope died, and 1493, the date inscribed on the monument together with the artists signature by Antonio del Pollaiolo (1431–1498) one of the greatest painter, sculptor and goldsmith of the time.

The diagnostic campaign was [55] carried out by first making a series of non-invasive measurements using a transportable EDXRF and a portable Raman system, to map the deterioration processes that had altered the bronze surface and quantify the alloy used in the several pieces the monument was made of. As a consequence of the first non-invasive diagnostic campaign, the second campaign of micro-invasive tests was planned and carried out. The samples were analysed with SEM–EDS, NMR and XRD techniques. The procedure implemented was focused to maximise the diagnostic information gathered and minimise the microsampling on the work of art.

The EDXRF investigations were carried out in two different ways;

-

without any removal of the patina, but after cleaning to remove the layer of wax, with a tube HV sufficient to reveal some light elements (S, Cl, Ca, K);

-

by scratching an area of 2 mm of patina, in order to study the bulk alloy, and with the instrumental set-up so it would pick up also on tin and antimony.

On some areas of the bronze panels 2, 3, 4, examined in the first way, some control measurements were taken after cleaning with water and EDTA.

With the first method, 101 areas were examined (which were quite well distributed over all the panels) and nine control measurements were taken after a further cleaning.

Finally, 33 quantitative analysis were carried out on some of the parts put together to build the panels.

The portable EDXRF system used, is composed of an air cooled low power tube (35 kV and 0.2 mA) plus a Silicon Drift Detector (SDD) detector with 150 eV energy resolution at the iron K line. The tube worked with a 2 mm aluminium filter for the quantitative analysis on the bronze alloy while it worked without filter for the analysis on the patina.

In Fig. 6.33, we can see a moment of the non-invasive measurements. In Fig. 6.34, it is possible to see the analysed spots are shown on the “Music” panel.

The measures were divided in low energy and high energy. In the low-energy set-up, the elements from sulphur (2.3 keV) to iron (6.4 keV) were measured while in the high-energy set-up the elements from iron (6.4 keV) to antimony (26.4 keV) were analysed.

The systematic low-energy EDXRF measurements allowed us to analyse elements which are part of the surface treatment. These are: K, Ca, Mn and Fe. With the 111 surface areas studied on the ten panels, it has in fact been possible to demonstrate a good correlation between such elements. As a confirmation of the idea of a surface treatment, SEM/EDS and 1H-NMR on samples were fulfilled. In the latter signals of an unsaturated waxy or oily substance, as well as signals relating to the use of cleaning products were found. While in the former the presence on all of the panels of the aforementioned elements agreed with a generalised surface treatment with coloured waxes and pigments such as bone black, (given that in the EDS test on the swabs residual powder the phosphorous and calcium were found in stoichiometric ratios suggesting the presence of calcium phosphate) and Hearth pigment containing iron oxides and/or manganese which confer the characteristic dark colour of the statue.

In the high-energy set-up, 33 different bronze subparts of the burial monument were analysed to understand the bulk alloy composition. The quantitative analyses were fulfilled on the areas where the patina had been removed to avoid contamination of degradation products. In Table 6.5, the quantitative results are shown.

In the last two rows of the table, the mean composition and the standard deviation of the measurements are reported. The composition is typical of a bronze from that period.

The analysis of the individual elements gathered in the table allows us to verify whether Pollaiolo used alloys with different composition. The analysis of the variance for the four principle elements (copper, tin, lead, and antimony) has permitted us to demonstrate that the differences in composition of the alloys used to create the body of the masterpiece, in respect of those used for the panels and the floral decorations are significant.

If we observe the table, we can see that the only area on a foil that has no presence of antimony is foil 10. It is also the only one with nickel and zinc, we can therefore hypothesise that we are dealing with later reparation.

6.6.3 The Golden Globe Placed on the Top of San Peter’s Dome

The restoration and maintenance works of the famous golden globe placed on the top of San Peter’s dome have been a unique opportunity to access the inside and outside of it and verify some aspects of the ancient production technologies and set-up of the big bronze artefacts. The analyses were fulfilled with a portable EDXRF system, maybe the only non-invasive technique that was possible to carry to such an inaccessible position. In Fig. 6.35, we can see the inscription present on the external gilded surface with the name of the architect Jacopo della Porta whom in 1593 moulded the globe.

The globe weighs 1,862 kg and his diameter measures 2.5 m. It is put right on top of the dome and just below the cross at 130 m from the floor of the Basilica. The globe is composed by 39 panels mutually soldered, numbered in longitudinal by letters and in latitudinal by numbers (starting from the 1 element top). The panels are composed of bronze and the external surface is gilded [56].

In Fig. 6.36, the Basilica of Saint Peter is shown and pinpointed is the golden globe.

The bronze alloy has a mean composition of 85.8 ± 0.5 % of copper, 10.1 ± 0.3 % of tin and 2.8 ± 0.1 % of lead. Minor elements, such as iron, silver and antimony, were as well quantified. The origin of these minor elements is related to impurities from the extraction processes for copper, tin and lead. Of major importance were the results related to the soldering processes that connected all the panels. The process was of autogenous welding. The alloy of the panels and the alloy of the welding material are the same.

In Table 6.6, the quantitative results plates and welding are shown.

The archaeometric analyses confirmed that the alloy has a very good mechanical resistance as it should be for a bronze object exposed to the weather in such a high position. The high homogeneity of the alloy of the different plates and welding material shows that the work was fulfilled with great attention and cure and proves the knowledge of the craftsmen in melting techniques. The welding is composed of approximately the same alloy of the plates indicating the use of autogenous welding that was not easy to fulfill in such an unreachable position.

6.6.4 The Bronze Statue of Saint Peters in the Saint Peters Basilica in Rome

The bronze statue of Saint Peters is positioned in the interiors of the Saint Peters Basilica in Rome. It was believed to belong the late roman period (fifth century A.D.) but some late studies, based on typological comparisons, changed its origin to Arnolfo di Cambio (thirteenth century A.D.); but discussion it is still open.

The scientific analyses conducted on the statue were mainly non-invasive. Too important is the votive aspect of the statue to intervene in more destructive ways. The analyses conducted were:

-

Determination of the alloy composition availing of a portable non-invasive XRF system

-

International Annealed Copper Standard (IACS) on the surface of the statue for non-invasive qualitative valuation of the homogeneity of the alloy.

-

Spectrocolorimetic non-invasive analyses of the surface of the statue.

-

Metallographic destructive examination on samples

-

SEM/EDS destructive analyses of samples

-

XRD on surface powder

-

Lead isotopic ratio on a sample

About the EDXRF measures, nine different points were cleaned. In Table 6.7, the XRF results are shown.

In Fig. 6.37, a moment of the XRF measures is shown.

The XRF results show a very high homogeneity of the statue except at the right hand and the fingers of the right hand that are supposed to be of restoration and so different from the original alloy of the statue.

The results of the non-invasive techniques and the metallographic analysis indicate that:

-

The alloy is very rich in Tin, that is typical of a bell bronze, than can be casted by artisans doing this work. They were present in the area from the fifth to the thirteenth century.

-

The colorimetric measurement raised the suspect of a different alloy for the legs.

-

The results of metallographic and SEM studies show the presence of large Tin and Lead segregation zone and the presence of dendritic structure, typical of an alloy melted with already casted metals.

6.7 Laser Applications in the Preservation of Cultural Heritage: An Overview of Fundamentals and Applications of Lasers in the Preservation of Cultural Heritage

6.7.1 Laser Fundamentals for Non-Specialists

Lasers do emit a special type of light which can be useful in an extremely wide range of applications. To understand what makes laser light special and how it is produced, we will begin our introduction to lasers with a short discussion of what is the nature of light and what is different with laser light. From here, it will become quite obvious that what is basically needed to build a laser producing this kind of light. We will then discuss a very simple and intuitive set of equations, the so-called rate equations, which allow describing many laser phenomena quantitatively. Finally, some specific laser systems will be looked at, the disc and fibre laser as two versions of solid-state lasers, and the diode laser.

6.7.1.1 The Nature of Light

People have always been wondering what light is made of. The dispute became famous between Huygens, who considered light as a kind of wave, and Newton, who thought of light as particles, propagating in straight lines (light beams). This dispute seemed to be finally settled when Maxwell came up with his famous set of equations unifying the description of both electric and magnetic phenomena:

Here, E and D are the electric field and electric displacement vectors, H and B are the magnetising and magnetic field vectors, and ρ and j the macroscopic charge and current densities, respectively. Maxwell could show that his equations include the propagation of electromagnetic fields through space as waves described by the wave equations

They can be derived using some mathematical transformations from the Maxwell equations assuming vacuum (ρ = j = 0; D = ε 0 E; B = μ 0 H)

The propagation speed of these electromagnetic waves

happens to be identical to the speed of light. From then on, it was clear that light is just a (small) part of the electromagnetic spectrum which ranges from radiowaves and microwaves via Infrared, Visible and UV, all the way to X and γ rays (Fig. 6.38).

The electromagnetic spectrum. Only a very small section with wavelengths between 400 and 700 nm is visible to the human eye [57]

There are many different classes of solutions to the wave equation. Perhaps, best known are plane harmonic waves in space and time (and their linear combinations):

The relation between wavelength λ and frequency ν is given by the speed of light: c = λν (Fig. 6.39).

Electromagnetic plane wave propagating along z [58]

In principle, plane waves extend from −∞ to +∞. Laser beams with a well-defined beam diameter are better described by “Gaussian beams” which have a Gaussian field and intensity distribution in the cross-section perpendicular to their propagation direction.

In the beginning of the twentieth century, people became aware that there might be more to it than what is described by Maxwell’s equations: An important observation was the photo-electric effect. Lenard noticed that electrons escaping from a surface which is hit by light have a kinetic energy that does not depend on the light intensity or power density—which is proportional to the product of E 0 and B 0—but rather depends on the light frequency ν:

χ is a material constant describing the energy necessary to get the electron out of material (work function). Einstein noticed in 1905 that this equation is simply the energy conservation law if one assumes that light comes in energy packages of hν or ħω, so-called light quanta or photons. h = 6.626 × 10−34 Js is a constant which had to be introduced by Planck a couple of years earlier to correctly describe the blackbody radiation spectra (Fig. 6.40).

Visualisation of the photo-electric effect [59]

Perhaps, even more puzzling was the double-slit experiment that could be done with light or with matter particles, electrons, for example. In both cases, one did not find a simple superposition of the images of the two slits but rather interference effects—of course not so much surprising in case of light (electromagnetic waves!) but rather strange in case of what were thought to be classical particles. These interference effects also showed up if the intensity was so much reduced that only one electron, photon, etc. passed the slits at a time. Adding up all these single-photon/single-electron experiments again resulted in interference effects. So, each single particle (electron or photon) must have “known” of the existence of both slits or might have passed through both slits (Fig. 6.41).

a The double-slit experiments with particles resulting in interference effects known from similar experiments with light [60]. b These effects show up even if only one particle (electron or photon) passes the double slit at a time. Shown here are the interference patterns of 8/270/2000/60000 (single!) electrons [61]. c The macroscopic analogue to the double-slit experiment [62]

In the 1920s, a formalism was developed by Schrödinger, Heisenberg and others that could handle the wave–particle dualism of classical (mechanical) particles (quantum mechanics); somewhat later a similar formalism was developed for classical fields (quantum field theory; in case of the electromagnetic field: quantum electrodynamics, QED). In QED, the proven classical solutions of the Maxwell equations (consistent with the boundary conditions, e.g. given by a laser resonator)—the so-called “modes”—form the basis. The state of the system is then characterised by the number of photons that occupy each mode. This means the energy that can be found in each of the electromagnetic modes cannot be chosen arbitrarily but can have discrete numbers—multiples of hν—only. In most practical cases, there is no need to use the full QED formalism. Instead, one can consider light either as classical electromagnetic field (characterised by frequency ν, wavelength λ, electric and magnetic field amplitudes E and H) or alternatively think of it as classical particles moving with the speed of light c, having an energy E = hν and a momentum p = h/λ—whichever is more convenient.