Abstract

The slope stability analyses in large-scale iron ore mining are usually conducted using two-dimensional models. Although this methodology helps to interpret the hydro-geomechanical behavior of open-pits, it might not capture the great complexity associated with mining environments. The geological formations associated to ore deposits may present complex spatial distribution of lithologies and ore grades as well as mechanical/hydraulic behaviors and properties. The distribution of lithologies and the ore grades are sufficiently well represented in the mining block model. However, the geotechnical model usually lacks reliable estimations of the properties and geologic structures due to the inherent complexity of this environment. Thus the block model appears as a potential vehicle for incorporating the geotechnical data and feeding some mechanical analysis routine to perform stability analysis in an integrated way. In this paper, we present some results of a FLAC3D model fully implemented using Python programming developed in the IPython console embedded in the FLAC3D 6.0 environment. The Numpy and Scipy libraries are used to fasten the calculations. The rock mass behavior is represented using the Mohr–Coulomb, generalized Hoek–Brown and Ubiquitous joints constitutive models according to the lithology. GSI is interpolated based on the borehole locations, and the properties of the intact rocks are considered homogeneous for each lithology. The attitude of the weakness planes considered in the ubiquitous model is attributed according to the structural domain discretization previously observed in the field. A case study of an iron ore mine of the state of Minas Gerais in Brazil is also presented. Some results of the stress–strain are presented. This promising tool is still under development to account for monitoring-based self-calibration.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The stability of the slopes excavated by the mining activities in surface is of key importance when dealing with large-scale projects because failure events may lead to large financial loses and delays, safety issues and even to the complete interruption of an entire mining project. In this context, the knowledge of the mechanical behavior of the geotechnical environment before the new conditions imposed by the mining activity is fundamental. All of the information necessary to represent this behavior must be contained in the geotechnical model for the mine planning. The geotechnical model of an open–pit mine is constituted essentially by four parts: geology, structural, geomechanics, and hydrogeology. The assertiveness of the material spatial distribution as well as their geotechnical properties are fundamental for the quality, accuracy and safety problems prediction. However, the large amount of uncertainty sources turns this a colossal task. In this sense, any kind of reduction of the uncertainty in the components of the geotechnical model improves the safety of the project by means of reducing the geotechnical risk.

The open-pit slope design should minimize risks to personnel and equipment, maximize ore recovery and minimize waste volume to maximize the profits. For the case of geotechnical analyses, two-dimensional models of slope stability are usually employed. Two-dimensional slope stability methods are mostly used due to their simplicity; however, they consider some simplifying assumptions to reduce the three-dimensional reality to a two-dimensional representation, and so, the accuracy of the estimation of the factor of safety will vary according to each case as much as 30% [1]. Limit equilibrium is typically used for analyzing standard problems and numerical method codes are occasionally used in few more complicated cases.

Open-pit iron ore mines have been reaching greater depths, with some slopes having more than 300 m height. With the increasing pit depths and slopes heights, there is a growing concern that stability analyses should be based on assumptions closer to the geometric, geological and geomechanical reality of the deposit. The three-dimensional models can contribute greatly to solve this problem.

According to [1], the three-dimensional analysis becomes important in cases where the geometry of the deposit is so complex that it is difficult to select a typical two-dimensional section to analyze. A 3D analysis may be necessary when the geometry of the slope and slip surface varies significantly in the lateral direction, the material properties are highly inhomogeneous or anisotropic, amongst other complicating factors.

The majority of the works of stability analysis strongly suggests that the 2D factor of safety is conservative when compared to the 3D factor of safety. Three-dimensional analysis is more realistic in being able to account properly for the slope geometry, leading to a better understanding of the fundamental nature of slope failure mechanisms [2]. Thus, this paper presents a geotechnical safety modeling routine that incorporates information from the geological model and uses this basis to build up automatically the geotechnical model using geological, structural, geomechanical and hydrogeological data. The study case of a large iron ore mine located in the Iron Quadrangle in Brazil is presented to show some results obtained using the routine.

2 Methodology

The geological block model constructed for any deposit can also bring together different rock mass characteristics. This block model contains geological and geometrical information such as the lithotype and the spatial distribution of lithologies in absolute coordinates. In addition, other information such as the Geological Strength Index (GSI), typical structural sectors, and the presence of faults were added to the existing information in order to complement the data needed to create the model. The following attributes were exported in order to create an enhanced geological block model:

-

IJK Indexes

-

block centroids coordinates (XC, YC, ZC)

-

cell size—Cartesian dimensions of the block (XINC, YINC, ZINC)

-

rock type (3 character alias)

-

fault indicator (0 when false, 1 when true)

-

origin coordinates (XMORIG, YMORIG, ZMORIG)

-

number of blocks in the original prototype (NX, NY, NZ)

-

GSI.

This enhanced geological model is the first keystone of the modeling routine presented following.

The three-dimensional numerical modeling was carried out in a software based on finite differences—FLAC3D [3]—because this code is adequate to solve the majority of the problems related to geotechnical engineering. FLAC3D simulates the three-dimensional behavior of structures constructed in soil, rock or other possible materials subject to plastic flow when their limits in terms of rupture are reached. The available programming environment is unique and called FISH [3]. Also, FLAC3D incorporated a Python console in its version 6.0 as well as a FLAC3D library to handle the model variables from the Python console. Python language is commonly used in scientific computing because of its excellent support for scientific and numerical programming solutions. The FLAC3D geotechnical model was implemented combining FISH and Python programming.

2.1 Numerical Grid

The routine to build up the geotechnical block model consists in constructing the FLAC3D grid file using an external routine written in Python, including all the characteristics mentioned above grouping zones according to similar characteristics when possible. The reading process creates a list of zone objects by filling in and calculating the attributes. The enhanced block model must be in text format such as .csv, .txt or another one keeping the order listed above. Finally, the grid file is loaded into FLAC3D.

2.2 GSI Representation

Once the GSI values read from the enhanced block model, they are saved using a Python array to be used later. The GSI array is loaded after the grid has been created in FLAC3D since the GSI of each block is free to be different.

2.3 Hydrogeology

The local hydrogeological behavior can be represented by a full conductivity tensor flow analysis or a phreatic/hydrostatic pore-pressure generation. In the case of the full tensor analysis, the conductivity is calculated using the structural information relative to sectors and geometric/hydraulic properties of the joints in each lithotype and sector. Otherwise, pore-pressures are simply calculated based on a phreatic surface.

2.4 Geomechanics

The geomechanical behavior of the rock mass can be represented using three failure criteria coexisting in the same model: generalized Hoek–Brown (HB), Mohr–Coulomb (MC), and Ubiquitous-Joint (UJ). An input file containing the mechanical parameters of the intact rock and foliations, as well as the corresponding failure criterion must be provided in text format. The structural sector is also taken into account to define the dominant orientation of the foliated lithotypes. The input parameters of the three models are calculated in Python for each block and saved in the FLAC3D model. A disturbance factor \(D = 0.7\) was considered to represent the probable reduction in physical properties of faulted materials (HB and UB) and reduced parameter was used for MC materials as well. A short description of the failure criteria used in this model is explained following.

2.4.1 Failure Criteria

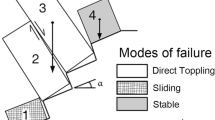

The Generalized Hoek–Brown criterion is an empirical failure criterion, which establishes the strength of rock according to major and minor principal stresses. It was used as the basis of the geomechanical model. However, it is known that this criterion is isotropic and, hence, it is not able to represent the anisotropic behavior imposed by the presence of structural geological features such as foliations. The geological mapping showed the presence of foliations in some lithotypes of the study site. The ubiquitous-joint model was adopted, in order to consider this type of feature.

Hoek et al. [4] showed the generalized Hoek–Brown criterion [5], in terms of major and minor principal stresses \(\sigma_{1}^{'}\) and \(\sigma_{3}^{'}\),

where \(\sigma_{ci}\) is the uniaxial compressive strength (UCS) of the intact rock material.

where \(m_{i}\) is a material constant for the intact rock, GSI (the Geological Strength Index) relates the failure criterion to geological observations in the field, and \(D\) is a “disturbance factor” which depends upon the degree of disturbance to which the rock mass has been subjected by blast damage and/or stress relaxation (\(D = 0\), for high quality blasting and \(D = 1\), for poor quality blasting).

The ubiquitous-joint model available in the FLAC3D is based on the Mohr–Coulomb isotropic model, except for the weakness planes orientation. The presence of weakness planes is considered with another Mohr–Coulomb criterion (with lower resistance) superposed to the isotropic material, which occurs only for a predetermined orientation.

Using the equivalence between the generalized Hoek–Brown model and the Mohr–Coulomb model it is possible to use the ubiquitous-joint model. To obtain the equivalence, the range of working stresses must be previously known. In practice, the maximum value of \(\sigma_{3}^{ '}\), \(\sigma_{{ 3 {\text{max}}}}^{ '}\) is estimated as, in the case of slopes:

where \(H\) is the slope height, \(\gamma\) is the rock mass specific weight and \(\sigma_{\text{cm}}^{ '}\) the rock mass strength.

With the defined stress range, it is possible to estimate the parameters of the Mohr–Coulomb model:

where \(\sigma_{3n}^{'} = \sigma_{{ 3 {\text{max}}}}^{'} /\sigma_{ci}\)

The shear strength of rock discontinuities, foliations, and fractures was interpreted based on the Barton-Bandis model [6]. In these models, three strength parameters are necessary: the basic friction angle of the failure surface (\(\phi_{b}\)), the joint roughness coefficient (JRC) and the joint wall compressive strength (JCS). In general, the strength parameters of the discontinuities were retroanalyzed based on the parameters described in the geological survey: Joint roughness number (Jr) and Joint alteration number (Ja).

The basic friction angle of the failure surface was obtained through the direct shear test, when possible. For the other situations, the friction angle was adopted in a manner compatible with the intact rock. The JCS was obtained as the uniaxial compression strength reduced by the value of the corresponding joint alteration number. The spacing of the discontinuities in the same family (S) was quantified based on the measurements made during the geological survey in the case of fractures. For foliations, the spacing was disregarded because its presence will be considered as ubiquitous.

2.5 Slope Stability Analysis

Once the slope model is created stresses are geostatically initialized and then the equilibrium is solved to find the in-situ stresses. Lateral earth pressure coefficient is considered during the geostatic initialization. Next, the mining process is simulated by removing the corresponding zones using a progressive stiffness/weight reduction. After the excavation, the factor of safety is calculated using the Shear Strength Reduction method.

3 Case Study: Large-Scale Iron Ore Mine

The methodology described was considered for the stability analysis of an iron deposit located in the Iron Quadrangle, south-central of Minas Gerais state in Brazil. The structural features of the deposit show a complex pattern of planar and linear elements which may be referred to at least three events of deformation. The iron bodies and their country rocks have a deformed structural type with a lithological anisotropy recognized as foliation.

From the bottom to the top, the local stratigraphy can be simply described as the basement mainly composed by gneiss rock in fault contact with meta volcanic-sediments (schists). Above those sediments, a younger sequence of quartzite, schists and itabirites (iron formation) constitute the largest part of the mine slopes and are identified as the Supergrup Minas formation.

The geomechanical quality of the rock mass was considered through the Geological Strength Index—GSI. The GSI was evaluated and classified in 821 points corresponding to 83 drill holes (georeferenced). Figure 1 shows the spatial distribution of the samples in the deposit.

Spatial distribution of GSI samples [7]

These data were used to interpolate the GSI by using the Inverse distance weighting method. The interpolation was carried out on the regular mesh of the prototype block model, with 50 × 50 × 10 m dimensions. Each sub-block within the original block (even IJK) inherited the GSI from the block. The result of this process is shown in Fig. 2.

Spatial distribution of the interpolated GSI in the pit [7]

The analysis resulted in surface displacements with a great concentration in the northeast wall and a floor heave of the order of 100 mm. Additionally, it can be observed that there is a displacement concentration in the region of the fault outcrop. Section A was sampled to show the behavior of the most critical region of the pit, the northeast wall (Fig. 3). In this region, the slope present 250 m height and 40° global inclination. In general, the displacements are below 100 mm of magnitude and below 20 mm in the horizontal direction, except of the middle region of the slope where it can be observed horizontal movements of more than 200 and 350 mm of magnitude.

Displacements of surface in the final pit, section A [7]

The stress–strain ratio (SSR) indicates the presence of two regions of considerable concentration at the top of the slope and at the middle region of the slope height (Fig. 4). The concentration region near the top is located in friable quartzites and the intermediate region is found in the friable shale as an extension of about 40 m.

SSR in the final pit [7]

The main result of the safety analysis in this study is the factor of safety (FS). The current method consists in projecting the pit slopes by evaluating the factor of safety and to compare this result with a minimum predefined factor. This minimum value is commonly adopted from values used in practical operations. Table 1 summarizes the typical values of factor of safety and probability of failure used as acceptance criteria in the mining industry [8].

In the case of safety evaluations using three-dimensional numerical models, there are still no direct comparison values in the literature. It should be remembered that the typical recommendations are based on two-dimensional analyses, which provide values of factor of safety intrinsically different from those obtained through three-dimensional analyses [1, 9, 10].

However, the values showed in Table 1 were taken as a reference only for comparison purposes. More accurate three-dimensional security analyses should have as a basis of comparison the target probabilities of failure (presented in the same table), however, this type of analysis is not the scope of this study.

The final open-pit studied presented an overall safety factor of 1.78, with the main occurrence in the northeast slope. This behavior might be originated by the presence of the fault, which cuts the wall pit and contributes for the presence of low resistance materials outcropping in the northeast wall. However, it should be noted that these results correspond to a deep mechanisms and do not exclude the occurrence of small surface events such as thin planar landslides, buckling or falling blocks that were not represented in this analysis.

Finally, the computational routine presented along this paper is advantageous when compared to the typical manual procedure because, first, it is fast at building up complex models automatically, and, second, it is capable of being controllable by an external routine, e.g., to perform sensitivity, calibration, or probabilistic analyses. However, one of the main problems is the programming interface which may seem complicated for practitioners. In this sense, the ongoing improvements are focused on improving the input interface. Additionally, incorporation of damage and self–calibration are being implemented to improve the representativeness of the models as well as hybrid limit equilibrium to fasten the safety calculations.

4 Conclusions

Geological models are usually constructed in a three-dimensional way using information obtained through sample drilling and interpreted according to the local geology. These models contain information of ore grades and contaminants and are also capable of incorporating geotechnical data. However, regarding geomechanical models, 3D models are hardly used, being replaced by simplified models.

In the present study, it was demonstrated how it is possible to take advantage of the information available in geological block models and core data to reconstruct, generate and analyze the three-dimensional behavior of the geomechanical stability of slopes of open-pit mines. The 3D-modeling method developed for this study case proved to be accurate, systematic and fully reproducible. The incorporation of the IPython console into FLAC3D has reduced the computational effort in terms of the construction and execution of the geotechnical model.

The use of 3D models supports the automatic identification of the most problematic regions and can enable decision-makers to take corrective measures, to evaluate the areas that need more systematic monitoring and even to propose some change in the final slope angle, for a better economic use of the reserve.

References

Albataineh, N.: Slope Stability Analysis Using 2D and 3D Methods. University of Akron (2006)

Griffiths, D.V., Marquez, R.M.: Three-dimensional slope stability analysis by elasto-plastic finite elements. Geotechnique 57(6), 537–546 (2007). https://doi.org/10.1680/geot.2007.57.6.537

Itasca Consulting Group INC.: FLAC3D (Fast Lagrangian Analysis of Continua in 3 Dimensions) (2012)

Hoek, E., Carranza-Torres, C., Corkum, B.: Hoek-Brown failure criterion—2002 Edition. In: Proceedings of NARMS-Tac, pp. 267–273 (2002)

Hoek, E.: Strength of jointed rock masses. Geotechnique 23, 187–223 (1983). https://doi.org/10.1680/geot.1983.33.3.187

Barton, N., Bandis, S.: Review of predictive capabilities of JRC-JCS model in engineering practice. In: Barton, N., Stephansson, O. (eds.) International Symposium on Rock Joints, Loen, pp. 603–610 (1990)

Torres, V.F.N., Napa-García, G.F., Trópia, I.R., Capelli, R.B.: Análises numéricas integradas ao monitoramento hidrogeotécnico para avaliação da estabilidade de taludes em cavas: relatório final do projeto Análises numéricas integradas ao monitoramento hidrogeotécnico para avaliação da estabilidade de taludes em cavas. Ouro Preto, MG: Instituto Tecnológico Vale (2018). https://doi.org/10.29223/prod.tec.itv.mi.2018.10.torres

Read, J., Stacey, P.: Guidelines for Open Pit Slope Design. CSIRO Publishing/CRC Press, Collingwood (2009)

Lu, H., Xu, L., Fredlund, M., Fredlund, D.: Comparison of 3D finite element slope stability with 3D limit equilibrium analysis. In: Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, p. 4, Paris, France: ISSMGE (2013)

Chen, Z., Mi, H., Zhang, F. and Wang, X.: A simplified method for 3D slope stability analysis. Can Geotech. J. (2003)

Acknowledgments

The authors thank the Vale Institute of Technology (ITV) for permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Napa-García, G.F., Navarro Torres, V.F., Trópia, I.R., Capelli, R.B., Câmara, T.R. (2019). Three-Dimensional Integral Modeling of Large Open-Pit Slopes: An Innovative Stability Analysis. In: Widzyk-Capehart, E., Hekmat, A., Singhal, R. (eds) Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection - MPES 2018. Springer, Cham. https://doi.org/10.1007/978-3-319-99220-4_30

Download citation

DOI: https://doi.org/10.1007/978-3-319-99220-4_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-99219-8

Online ISBN: 978-3-319-99220-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)