Abstract

Cemented granular material is featured by the presence of inter-particle bonds. In mechanical loading, bond breakage results in a transition from an intact state to a fully disturbed state. However, it is impossible to directly track and measure the breakage of each individual bond among the millions of bonds in a small sample. This study applied discrete element method simulation to associate the evolution of a micro-scale-based damage variable with the degradation of measurable shear modulus in cemented sand. The simulations show that bond breakage is highly non-uniform in a sample. As a result, the sample is deteriorated by the detachment of particles from the main skeleton and the detached particles are found to take no load in the initial stage. This explains the observed sharp degradation of shear modulus. With further bond breakage, the skeleton is disassembled into assembly of particle-clusters, but the shear modulus only varies slightly. The implication for establishment of a physically robust constitutive model for cemented sand is discussed.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Cemented granular materials are common in geotechnical field, e.g. cemented sand [1], gas hydrate bearing sediment [2] and weak rock [3]. Constantly increasing knowledge in micro-structure facilitates the development of constitutive model with consideration of particle-scale mechanism [4]. However, the lack of understanding in the association of microscopic quantities and macroscopic measurable quantities hinders reliable determination of some model parameters that has been embedded with microscopic meaning. This study focuses on the association of particle-scale bond breakage and degradation of macroscopic shear modulus.

2 DEM Simulation of Cemented Sand

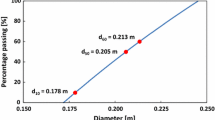

Cemented sand was idealized as an assembly of bonded spheres in this study. The bonding material is assumed to sparsely distribute at distinct contacts. The bond contact model, particle size distribution and the basic set of contact model parameters in [5] were used. Cubic samples with 40,000 spherical particles were simulated. Four samples were modelled to study the effects of sample density and bond content: S1 (initial void ratio e0 = 0.80, bond content c = 1.0% which was defined as the ratio of total bond material volume over total particle volume), S2 (e0 = 0.80, c = 3.0%), S3 (e0 = 0.92, c = 1.0%), and S4 (e0 = 0.92, c = 3.0%). Constant-p triaxial shear tests were simulated with p = 400 kPa.

Figure 1 shows that increase in sample density (decrease in void ratio) and bond content can increase the peak strength and dilation. The softening behavior of sample S3 is accompanied with contraction, which is a feature of loose weakly-cemented soil.

3 Bond Breakage and Shear Modulus Degradation

A damage variable θ is defined as the fraction of unbonded contacts in an assembly to describe the degree of bond breakage. Shear modulus G was measured at various points along the constant-p loading path by applying one unloading-loading loop with a variation in deviator strain of 0.2%. The loop is realized by reversing the velocity of the loading plate perpendicular to the major principal stress direction. The shear modulus was determined from the average slope of the unloading-loading path in the deviator strain- deviator stress plot. Figure 2 presents the degradation of shear modulus (normalized by the initial value G0) with the development of bond breakage. Figure 2 shows that the shear modulus drops sharply when θ is less than 0.1, which is followed by a much slower degradation to a minimum around θ = 0.2. After that, little variation in shear modulus is observed. The degradation of shear modulus keeps sound pace with the decrease in coordinate number Z as shown in Fig. 2.

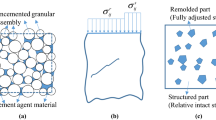

The microscopic structure change is examined here to explain the numerically observed nonlinear degradation of shear modulus with bond breakage. Our DEM simulation results show that the heterogeneous nature of granular material leads to spatially non-uniform bond breakage events. This allows the formation of bonded particle clusters, which are groups of particles connected through bonded contacts. The presence of clusters had been confirmed in experiments [6]. With the aid of DEM simulation, Fig. 3 visualizes the spatial configuration of particle clusters, which are distinguished by colors (see the online version of this paper). The initial intact cemented assembly can be viewed as a particle skeleton. Bond breakage mainly leads to detachment of small clusters (usually consisting of several particles) from the skeleton when θ is less than 0.2. The skeleton bears external load and it is gradually deteriorated due to the detachment of particles. With further bond breakage, the skeleton is disassembled into assembly of particle-clusters. To quantitatively examine this feature, the average stress \( \sigma_{{\text{ij}}} \) of a granular assembly is expressed as

where V is the sample volume, fj is the contact force, li is a vector pointing from particle centroid to contact center, Np is total particle number, Ns is particle number in the skeleton and Nc,k is the number of contacts around particle k. The stress can be partitioned into skeleton stress (\( \sigma_{{\text{ij,s}}} \)) and detached particle stress (\( \sigma_{{\text{ij,d}}} \)), respectively.

Figure 4 presents the contribution of detached particles to the overall stress. When θ is less than 0.2, the very little contribution of \( \sigma_{{\text{ij,d}}} \) (less than 1.0%) suggests that detached particles actually float in the skeleton voids. That is, the detached particles take no load and act as voids in the sample. The degradation in shear modulus therefore is a result of the deterioration of the initially intact skeleton.

The damage variable θ can be inserted into a constitutive model for cemented soil while its association with the measurable shear modulus allows the determination of the damage evolution law. This issue deserves further study.

References

Collins, B.D., Sitar, N.: Stability of steep slopes in cemented sands. J. Geotech. Geoenviron. Eng. 137(1), 43–51 (2011)

Hyodo, M., Yoneda, J., Yoshimoto, N., Nakata, Y.: Mechanical and dissociation properties of methane hydrate-bearing sand in deep seabed. Soils Found. 53(2), 299–314 (2013)

Ciantia, M.O., Castellanza, R., Crosta, G.B., Hueckel, T.: Effects of mineral suspension and dissolution on strength and compressibility of soft carbonate rocks. Eng. Geol. 184, 1–18 (2015)

Jiang, M.J., Zhang, F.G., Sun, Y.G.: An evaluation on the degradation evolutions in three constitutive models for bonded geomaterials by DEM analyses. Comput. Geotech. 57, 1–16 (2014)

Shen, Z.F., Jiang, M.J., Thornton, C.: DEM simulation of bonded granular material. Part I: contact model and application to cemented sand. Comput. Geotech. 75, 192–209 (2016)

Lo, S.R., Wardani, S.P.: Strength and dilatancy of a silt stabilized by a cement and fly ash mixture. Can. Geotech. J. 39(1), 77–89 (2002)

Acknowledgement

The research is funded by National Natural Science Foundation of China with Grant Nos. 51678300 and 51639008 (key program) and the Youth Program of Natural Science Foundation of Jiangsu Province of China with Grant No. bk20171006, which are sincerely appreciated.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Switzerland AG

About this paper

Cite this paper

Shen, Z., Jiang, M., Wang, Z., Wang, S. (2018). Shear Modulus Degradation and Its Association with Internal Damage in Cemented Granular Material. In: Wu, W., Yu, HS. (eds) Proceedings of China-Europe Conference on Geotechnical Engineering. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-319-97112-4_48

Download citation

DOI: https://doi.org/10.1007/978-3-319-97112-4_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97111-7

Online ISBN: 978-3-319-97112-4

eBook Packages: EngineeringEngineering (R0)