Abstract

Whilst it is recognised that aggressive ground conditions are associated with a wide range of factors encompassing physical, chemical and biological processes, a high proportion of such problems relate to the presence of sulfate ions in groundwater. Such conditions, which are implicated in the degenerative attack on ground-placed engineering materials and sometimes to volume changes, arise due either to the dissolution of primary sulfate minerals or, more commonly, to the oxidation of sulfide minerals, where in the latter case the groundwater may also become acidic. Notwithstanding that pyrite-bearing strata are distributed widely across the UK and are frequently encountered in foundation works and during the construction and improvement of the arterial highway infrastructure, consideration of the possible adverse implications of pyrite for construction and highway works tends to be overlooked. Furthermore, adverse impacts can develop rapidly during construction in periods of adverse weather, whereas under favourable conditions they would not be suspected. Equipping the design team with the necessary information to identify and address the problems should enable an optimum construction sequence and on-going management during the design life of the structure to be used. British, European and other standards promote good practice in carrying out ground investigations, but often potential problems are not adequately anticipated and catered for. The paper discusses reasons for this and provides guidance on avoiding problems, without the need to preclude the inclusion of the sulfur bearing materials from projects.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Sulfur is one of the most abundant elements in the earth’s crust and occurs as a solid, liquid and gas. It is highly mobile and can change form and properties rapidly in response to changes in the environment, such as those brought about by and in the course of ground engineering works. In geological and construction materials sulfur commonly occurs as sulfates in solution or as crystals of selenite/gypsum: Ca2SO4 2H2O) and in a reduced form (pyrite: FeS2) and other sulfides (pyrrhotite (FeS and marcasite FeS2). It may also occur in organic compounds and waste products from industrial and mining operations. Hence deposits containing sulfur compounds are widely distributed and are frequently encountered in civil and environmental engineering projects (Czerewko et al. 2016). Not all forms of sulfur are troublesome for construction, although this depends upon the environmental conditions. For example barytes, celestine, and organic sulfur are relatively stable in weathering environments, and do not normally contribute to the sulfur present in groundwater. This paper discussed examples from the UK, but cases of structural damage caused by expansion of pyritic mudstone have also been documented on a number of occasions from areas of USA (Hoover and Lehman 2009) and Canada (Quigley and Vogan 1970).

BRE (1991) have provided guidance for routine UK assessment of potential ground aggressivity based upon water and acid soluble sulfate content and acidity of soil and groundwater samples, this worked well for many decades with few instances of sulfate attack on buried concrete reported. However following investigation of sulfate attack and disruptive ground heave cases, Hawkins and Pinches (1987) noted that the possible consequences of pyrite were not being considered. As a result of this, problems of the types listed below due to the presence of pyrite, were not being identified:

-

Rapid degradation of mudrock fill, reduced permeability of limestone drainage layers and fatal production of carbon dioxide (Pye and Miller 1990);

-

Heave damage to structural foundations and highway subgrades (Hawkins and Pinches 1987; Wilson 1987; Czerewko 2015);

-

Rapid deterioration and degradation of natural ground material and slope failure (Vear and Curtis 1981; Steward and Cripps 1983; Czerewko et al. 2011);

-

Heave problems associated with ground stabilisation for highway construction, (Snedker 1990);

-

Heave in ground stabilised for foundation construction (Longworth 2004);

-

Chemically aggressive conditions during tunneling and construction (Bracegirdle et al. 1996; Dunster 2001);

-

Corrosion of buried steel structures (Reid et al. 2001, 2005);

-

Thaumasite form of concrete attack (Floyd 2003; Thaumasite Expert Group 1999).

In these problems chemically aggressive soluble sulfates and acidity resulted from the oxidation of the pyrite present in the ground material or fill. Prior to 2001 appropriate guidance was not available: merely determining the total sulfate content of a soil or fill would be insufficient. But revision to recommendations for assessing structural backfills (Reid et al. 2001, 2005) and the design of concrete in aggressive ground (BRE 2001) were produced that involve not only the determination of sulfate content of material but also potential sulfate content, derived from the sulfide present.

Although macroscopic crystalline pyrite (FeS2) is easily identified from its appearance as gold coloured cubic crystals or nodular aggregates (Fig. 1), it commonly occurs in unweathered, dark coloured, organic rich over-consolidated clays, mudrocks and argillaceous limestones as scattered microscopic crystals and clusters of microcrystals <1 to 10 s microns in size, known as framboids (Fig. 2). Due to small size and black colour the latter are not visible to the naked eye. UK deposits containing pyrite in this form occur in formations from and including the Carboniferous to the Recent, such that as Fig. 3 shows they are very widely distributed. On account of a high specific surface area and lower density (Pugh et al. 1981) which can increase oxidation rate 10 fold, framboidal and microscopic forms of pyrite are susceptible to rapid breakdown when exposed to atmospheric conditions, such that problems during construction are very likely to occur.

Revised protocols for evaluating potential ground aggressiveness (Reid et al. 2001, 2005; BRE 2001) advocate a staged approach for the appraisal of ground aggressiveness based on an initial review of the geological setting, followed by a planned investigation programme and detailed ground assessment. This requires an awareness of potentially aggressive material and importance of a focused chemical testing. Besides crystal form the rate and severity of the consequences of pyrite oxidation depend on the permeability and chemistry of the host deposits as well as the groundwater conditions. It also requires that the consequences of the construction activity and weather related issues in the construction period and beyond, need to be fully addressed to provide an adequate basis for the design of appropriate preventative and mitigation measures.

2 Development of Pyrite Oxidation

Pyrite is unstable in the presence of both air and water during surface or-near surface weathering conditions, as shown in Eq. 1. The sulfuric acid thus liberated is aggressive to buried steel and concrete and can raise sulfate to harmful levels. Reactions with other minerals such as calcite in Eq. 2, give rise to selenite/gypsum, and this involves expansion. The oxidation process can be greatly accelerated by the presence of bacteria, such as Acidithiobacillus sp that rely on electron transfer between Fe2+/Fe3+ for their metabolic process (Sasaki et al. 1998). These microbes thrive in acidic, warmed conditions generated by pyrite oxidation, which is exothermic. Observations by Bromley and Pettifer (1997) document abiotic pyrite oxidation in concrete blocks containing pyritic aggregate where pH of pore fluids in the concrete were around pH >12. This reaction mechanism can also occur when pyrite bearing ground is treated using lime and cement.

The end product of pyrite oxidation processes is hydrous iron oxide/hydroxide yellow brown to orange brown amorphous precipitate known as ochre, typically evident as yellow-brown staining to surfaces. In the absence of calcite to buffer the acid, reactions with potassium feldspar and clay minerals result in jarosite-alunite.

More detailed reviews of the various pathways possible and reaction stages are found in Lowson (1982), Hawkins and Pinches (1987), and Reid et al (2001, 2005).

3 Implications for Highways and Construction

The oxidation of pyrite following exposure of pyrite bearing deposits during earthworks and construction activities has been observed to progress rapidly on a timescale significant to construction, and the process produces conditions that are chemically aggressive to engineering material particularly buried steel and concrete (Reid et al. 2001, 2005; BRE 2001). In some cases lowering of the water table associated with construction or mining activities has been responsible for exposing pyrite-bearing lithologies to oxidation (Hawkins and Higgins 1997). The rapid weathering process also causes adverse changes in the geotechnical properties of mudrock (Anderson and Cripps 1993) or ground heave due to precipitation of sulfate minerals (Wilson 1987; Cripps and Edwards 1997), particularly if a calcareous component is present.

The replacement of pyrite and calcite by gypsum in Eq. 2 is significantly expansive, because the reaction products occupy a larger volume than the original calcite and pyrite as simple replacement entails a volume increase of 103% (Taylor 1984). The precipitation of gypsum can exert pressures of up to 100–500 kPa in confined conditions leading to significant ground stresses with development of differential ground heave (Taylor 1984). Gypsum has low solubility (Deer et al. 1992), a significant factor for ground heave. While calcium and sulfate ions are carried in solution they are mobile and may travel some distance before precipitation occurs. But once gypsum is formed, it is not readily re-dissolved or removed by groundwater, unless acidic (Hawkins and Pinches 1987). The products tend to be precipitated as discrete crystals at fabric and structural interfaces such as joints in rock masses (Fig. 4), or at construction boundaries and in fill (Fig. 5) or at the embankment and subgrade interface (Fig. 6). Volume increases at the precipitation site can far exceed that caused by pyrite in the immediate vicinity (Cripps et al. 1993) and the growth of selenite crystals by nucleation involves the enlargement of discrete crystals. In indurated rocks this causes widening of cracks and fissures and where sub-horizontal fissility is present it causes vertical heave (Hawkins and Pinches 1987), whereas in clays and compaction mudrocks randomly distributed gypsum crystals produce more uniform heave (Fig. 7).

The amount of ground movement can be catastrophic to lightly loaded structures such as residential developments with documented cases from Japan (Yamanaka et al. 2002), Canada (Quigley and Vogan 1970), USA (Dougherty and Barsotti 1972) & Ireland (Matheson and Jones 2015). Many cases of lightly loaded highway construction in the UK have also experienced problems (Czerewko and Cross 2015). Ground disturbance and alkali conditions are both inherent in soil stabilisation, with pyrite oxidation causing sulfate attack with the formation of expansive materials such as ettringite and thaumasite (Higgins et al. 2002).

4 Ground Investigation and Assessment of Conditions

Due to a lack of appreciation of the potential consequences of pyritic oxidation processes, the need for long-term mitigation measures within the construction design may be missed. Furthermore, early stage signs of reactions may not be recognised, thus hindering early intervention (Fig. 8). Therefore these issues need to be clearly addressed at preliminary design stages before construction commences.

It is necessary to consider the type and distribution of all sulfides and sulfates in ground and fill. However it is also worth remembering that sulfides pose no threat to construction if oxygen and mobile water are absent, for example where strata are not disturbed, such as in some pile construction (BRE 2001). Generally a well-formulated ground investigation that documents the variation in ground conditions and distribution of potentially deleterious materials over and beyond the intended zone of construction is required to avoid problems. British Standards (BSI 2015), Eurocodes (BSI 2007), other international standards, and best practice technical documents (BRE 2001) offer invaluable guidance on sampling and investigation for determination of ground aggressiveness. The investigation should adopt a staged approach with initial desk study and review of available geological and ground reference data (BRE 2001); preliminary ground investigation to substantiate desk study assumptions; and detailed investigation to provide the detailed distribution of ground material necessary for detailed design and appropriate mitigation.

In the development of highway infrastructure, the potential for deterioration of materials is often overlooked, ignoring the consequences of rapid weathering of materials. Durability testing of material is needed with analysis for sulfate content of the water used and samples observed for precipitated minerals following drying (Fig. 9). Simple weathering exposure observations may also help elucidate the likely behaviour of materials, as seen in Figs. 10a–c (Czerewko et al. 2011). The designer must anticipate the likely engineering behavior of the material at different stages of construction and take the possibility of adverse weather conditions into account.

Characteristic factors indicative of the possible presence of pyrite include:

-

Dark coloured (grey or dark grey), organic rich mudrock, calcareous mudrock or clay.

-

Presence of finely disseminated gold and dark green-grey to bronze-grey coloured crystals often along partings or discrete lenses.

-

Orange-brown and brown staining or precipitates at exposed surfaces or associated with seepages (Fig. 11).

-

Sulfurous odour when the rock is hit or scratched.

-

Presence on surfaces of clear or white-grey crystals which it is possible to scratch with a finger nail or of a white surface coating when the material is dried.

Pyrite is often associated with organic carbon where <0.5% can impart a grey colour in mudstones, siltstones and sandstones. The weathering related change of these grey deposits to shades of brown is often accompanied by precipitation of granular saccharoidal selenite crystals in calcite rich materials, often mistaken for sand (Fig. 12).

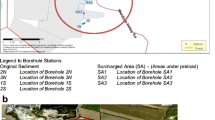

Comprehensive assessment and identification of potentially aggressive and deleterious ground conditions may be carried out by a combination of techniques as demonstrated in Fig. 13, including:

-

Inspection of the in situ ground conditions;

-

Inspection of sample material recovered from boreholes;

-

Selective chemical testing to determine sulfur and calcite presence.

Due to the difficulties posed by the visual identification of pyrite, dark coloured mudrocks, clays and limestone need to be tested for the presence of pyrite. Current guidance (Reid et al. 2001, 2005; BRE 2001) recommends that oxidisable-sulfur (total sulfur minus acid soluble sulfur, assumed as pyritic) >0.1%, then it is likely that pyrite is present. The distribution of sulfur compounds in soils and rocks can be highly variable so testing must be sufficient to ensure that sulfur-bearing horizons are not missed and a suitable value for design is selected. Material selected for laboratory trials and testing should focus on the construction zone but also evaluate other strata that may also be affected by construction activities. Although sulfate minerals can be present, sulfide minerals may predominate at greater depths where oxidation has not occurred. It is recommended that at least five samples should be tested from each location (Reid et al. 2001, 2005; BRE 2001), with the mean of the highest two values used for comparison with the limiting values. It is also necessary to consider the weather conditions at the time of sampling and the impact of adverse weather conditions during the construction period, as well as longer-term climatic changes that may affect the on-going environmental conditions.

Various chemical test methods for pyrite bearing materials are reviewed by Reid et al. (2017): the total sulfur content of samples is a useful screening test. When framboidal pyrite is suspected, then the amount of sulfide-sulfur (referred to as Oxidisable Sulfide—‘OS’ in (Reid et al. 2001, 2005; BRE 2001), is a good indicator of the potential for oxidation reactions.

5 Conclusions

The assessment of ground aggressivity and aggregate suitability in ground engineering forms part of the geotechnical design process for construction and includes verification of aggregates. At an early stage assessment is carried out to evaluate conditions and determine potential implications for mitigation during the design process. Although the mechanism of pyrite oxidation, which is one of the main cases of ground aggressivity has been discussed, the implications to construction and the success of the earthworks tend to be controlled by site specific conditions largely related to the type and properties of material present and the site environment. The site investigation may confirm the presence of significant quantities of pyrite, gypsum and calcite but these values alone do not facilitate assessments of the reaction rate and significance to construction.

The susceptibility of the materials to rapid deterioration and the oxidation of pyrite must be ascertained. Discolouration, softening and presence of selenite are all indicators of pyrite oxidation processes. Simple procedures such as block weathering, compaction tests, slake durability with determination of water soluble sulfate of extracts, may further inform the design process. Determination and evaluation in terms of the engineering operations, of the type and distribution of sulfur compounds in the ground and geological construction materials are of fundamental importance.

References

Anderson, W.F., Cripps, J.C.: The effects of acid leaching on the shear strength of Namurian shale. In Engineering Geology of Weak Rocks, Geol. Soc. Eng. Geol. Special Publication No. 8, Balkema, Rotterdam, 1993, pp. 159–168

Bracegirdle, A., Jefferis, S.A., Tedd, P., Crammond, N.J., Chudleigh, I., Burgess, N.: The investigation of acid generation within the Woolwich and Reading Beds at Old Street and its effect on tunnel linings. In: Mair, R.J., Taylor, R.N. (eds.) Geotechnical Aspects of Underground Construction in Soft Ground. Balkema, Rotterdam (1996)

BRE.: Concrete in sulphate-bearing soils and water. Digest No 363, 1991. BRE-IHS, Building Research Establishment, Bracknell, UK

BRE.: Concrete in Aggressive Ground. Part 1: Assessing the aggressive chemical environment. SD 1, 1st edn, 2001; 3rd edn. BRE-IHS, Building Research Establishment, Bracknell (2005)

Bromley A., Pettifer K.: Sulfide-related degradation of concrete in Southwest England (The mundic problem). Building Research Establishment, Watford, 1997, BRE Lab Report 325

BSI 2007. BS EN 1997-2:2007. Eurocode 7—Geotechnical design—Part 2: Ground Investigation and testing. British Standards Institution, London

BSI 2015. BS 5930:2015. Code of practice for ground investigations. British Standards Institution, London

Cripps, J.C., Edwards, R.L.: Some geotechnical problems associated with pyrite bearing rocks. In Hawkins, A.B. (ed.) Proceedings of International Conference on the Implications of Ground Chemistry/Microbiology for Construction, 77–87, Balkema, Rotterdam (1997)

Cripps, J.C., Hawkins, A.B., Reid, J.M.: Engineering problems with pyritic mudrocks. Geoscientist 3(2), 16–19 (1993)

Czerewko, M.A., Cross S.A.: The benefits of a granular interface over pyritic subgrade. Proc. Inst. Civ. Eng.—Geotech. Res. 2, 97–122 (2015)

Czerewko, M.A., Cross, S.A., Dumelow, P.G., Saadvandi, A.: Assessment of pyritic Lower Lias mudrocks for earthworks. Proc. Inst. Civ. Eng.—Geotech. Eng. 164, 59–77 (2011)

Czerewko, M.A., Longworth, I., Reid, J.M., Cripps, J.C.: Standardised terminology and test methods for sulfur mineral phases for the assessment of construction materials and aggressive ground. QJEGH, London 49, 245–265 (2016)

Deer W.A., Howie R.A., Zussman J.: An Introduction to the Rock-Forming Minerals, 2nd edn. Wiley (1992)

Dougherty, M.T., Barsotti, N.J.: Structural damage and potentially expansive sulfide minerals. Bull Assoc. of Eng. Geol. 9(2), 105–125 (1972)

Dunster, A.: Avoiding deterioration of cement-based building materials and components. Lesson from case studies: 4. BRE, Watford, 2001, BRE Report BR441

Floyd M., Czerewko M.A., Cripps, J.C, Spears D.A.: Pyrite oxidation in Lower Lias Clay at concrete highway structures affected by thaumasite, Gloucestershire, UK. Cem. & Concr. Comp. 25, 1015–1024 (2003)

Hawkins, A.B., Pinches, G.M.: Cause and significance of heave at Llandough Hospital, Cardiff—a case history of ground floor heave due to gypsum growth. QJEG, London 25, 17–30 (1987)

Hawkins, A.B., Higgins, M.D.: The generation of sulphates in the proximity of cast in situ piles. In Hawkins, A.B. (ed.) Ground Chemistry: Implications for Construction. Balkema, Netherlands (1997)

Higgins, D.D., Thomas, B., Kinuthia J.: Pyrite oxidation, expansion of stabilised clay and the effect of GGBS. In: Zoorob, S.E., Collop, A., Brown, S.F. (eds.) Performance of Bituminous and Hydraulic Materials in Pavements, pp. 161–167. CRC Press, Nottingham (2002)

Hoover, S.E., Lehman, D.: The expansive effects of concentrated pyritic zones within Devonian Marcellus Shale Formation of North America. QJEGH, London 42, 157–164 (2009)

Longworth, T.I.: Assessment of sulfate-bearing ground for soil stabilisation for built development. Ground Engineering, 56–59 (2004)

Lowson, R.T.: Aqueous oxidation of pyrite by molecular oxygen. Chem. Rev. 82(5), 461–497 (1982)

Matheson, G.D., Jones, G.L.I.: The habit and form of gypsum crystals in Irish mudstone aggregate affected by pyrite-induced swelling. QJEGH, London 48, 167–174 (2015)

Pugh, C.E., Hossener, L.E., Dixon, J.B.: Pyrite and marcasite surface area as influenced by morphology and particle diameter. Soil Sci. Soc. of Am. J. 45(5), 979–982 (1981)

Pye, E.K., Miller, J.A.: Chemical and biochemical weathering of pyritic mudrocks in a shale embankment. QJEG, London 23, 365–381 (1990)

Quigley, R.M., Vogan, R.W.: Black shale heaveing at Ottawa, Canada. Can. Geot. J. 7, 106–115 (1970)

Reid J.M., Czerewko M.A., Cripps, J.C.: Sulfate specification for structural backfills. TRL Report 447, 2001 & 2005, TRL Limited, Crowthorne

Reid, J.M., Czerewko, M.A., Longworth, I., Cripps, J.C.: Sulfur compounds in soils and rocks—avoiding pitfalls in terminology, test procedures and ground assessment. Ground Eng., 30–36 (2017)

Sasaki, M., Tsunekawa, M., Ohtsuka, T., Konno, H.: The role of sulfur-oxidising bacteria Thiobacillus thio-oxidans in pyrite weathering. Colloids Surf. A: Physiochem. and Eng. Aspects 133, 269–278 (1998)

Snedker, E.A., Temporal J.: M40 Motorway Banbury IV Contract—lime stabilisation. Highways and Transportation, 7–8 (1990)

Steward, H.E., Cripps, J.C.: Some engineering implications of chemical weathering of pyritic shale. QJEG, London 16(4), 281–289 (1983)

Taylor R.K., Cripps J.C.: Mineralogical controls on volume change. In: Attewell, P.B., Taylor, R.K. (eds.) Ground Movements and their Effects on Structures, pp. 268–302. Surrey Uni Press, UK (1984)

Thaumasite Expert Group.: The thaumasite form of sulfate attack: Risks, diagnosis, remedial works and guidance on new construction. DETR, London (1999)

Vear, A., Curtis, C.: A quantitative evaluation of pyrite weathering. Earth Surf. Proc. Land. 6, 191–198 (1981)

Wilson, E.J.: Pyritic shale heave in the Lower Lias at Barry, Glamorgan. QJEG, London 20, 251–253 (1987)

Yamanaka, T., Miyasaka, H., Aso, I., Tanigawa, M., Shoji, K.: 2002 Involvement of sulfur- and iron- transforming bacteria in heaving of house foundations. Microbiol. J. 19, 519–528 (2002)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Czerewko, M.A., Cripps, J.C. (2019). The Consequences of Pyrite Degradation During Construction—UK Perspective. In: Shakoor, A., Cato, K. (eds) IAEG/AEG Annual Meeting Proceedings, San Francisco, California, 2018 - Volume 2. Springer, Cham. https://doi.org/10.1007/978-3-319-93127-2_21

Download citation

DOI: https://doi.org/10.1007/978-3-319-93127-2_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-93126-5

Online ISBN: 978-3-319-93127-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)