Abstract

Ethyl6-methyl-2-oxo-4-phenyl-1,2,3,4 tetrahydropyrimidine-5-carboxylate, Bigenilli product (noted DHPMs) was synthesized in the presence of chlorides and nitrates of metals as catalysts, in mild free solvent conditions. High DHPM yields were obtained with Zn(NO3)2 (97%), ZnCl2 (90%) and CuCl2 (76%). The reaction heptagram inspired by the principles of green chemistry show that in our reaction conditions, Biginelli process complies with the principles of sustainable development.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nowadays, environmental protection is the focus of the economic and industrial world concern. Green chemistry using catalytic processes represents a framework for the pollution prevention by minimizing waste and the toxic products use. Important research axis in organic chemistry focused on the development of new clean and efficient processes, particularly in the heterocyclic systems synthesis including the Biginelli reaction [1].

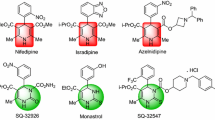

It is a multicomponent condensation reaction (MCR) of three reagents: a β-keto ester, an aldehyde and urea that leads to dihydropyrimidinones (DHPMs) formation in a single step, one-pot, (Fig. 1). DHPMs are an attractive class of organic compounds with important biological and pharmacological properties [2,3,4,5,6]. This reaction that dates back more than a century suffered from slowness (18 h) and low yields. In addition, the use of both corrosive mineral acids and toxic organic solvents in the original synthesis is far from the concepts of the ideal synthesis [7,8,9,10].

To remedy this, modern green practices give more attention towards the development of environmentally friendly, efficient and synthetic chemical procedures, in order to conquer the drawbacks of the above mentioned procedures and to accomplish most of the aspects of green and sustainable chemistry [11,12,13,14,15,16,17].

The ideal synthesis in organic chemistry as described by Bataille [18] is based on the construction of a reaction heptagram inspired from twelve principles of green chemistry suggested by Anastas and Warner [17]. It is a combination of following parameters: carbon efficiency (CE), atoms economy (AE) [16], Yield (ρ), mass reaction efficiency (MRE), material recovery parameter (MRP) and hazard and toxicity coefficients, whose the values are close to 1.

In this study, the synthesis of DHPMs via Biginelli reaction was carried out in the presence of ethanol as solvent and in free solvent, using nitrates or chlorides of zinc, copper, nickel or iron as catalysts. Reaction heptagrams were realized to determine the better conditions of sustainable development.

2 Materials and Methods

2.1 Biginelli’s Reaction

In a 25 ml single-neck round bottom flask, a mixture of benzaldehyde 1 (2 mmol), ethyl acetoacetate 2 (2 mmol), urea3 (3 mmol) and 0.2 g of catalyst was kept under regular stirring at 100 °C for 1 h (Fig. 1). Completion of the reaction was monitored by thin layer chromatography. The reaction product was washed with boiled ethanol. DHPM product was purified and recrystallized in hot ethanol, then placed in an ice bath to obtain a pure product. Identification of DHPM is obtained via its melting temperature, infrared (IR) spectroscopic analysis and 1H and 13C nuclear magnetic resonance (NMR).

2.2 Characterization

The melting points of the products were taken using a Stuart SMP11 capillary apparatus. TLC was carried out on silica gel plates 60 F254 (thickness: 2 mm); the eluant is a mixture of chloroform-methanol.

IR spectra were recorded on a Shimadzu FTIR-8400 Fourier Transform Spectrometer using KBr pellets and the NMR ones on a Bruker FT-NMR DPX250 (250 MHz for the proton and 62.5 MHz for the 13C). Chemical shifts were expressed in parts per million (ppm) relative to TMS (δ = 0 ppm) and coupling constant J in Hertz (Hz). NMR multiplicities are reported using the following abbreviations: br = broad, s = singlet, d = doublet, t = triplet, q = quartet, m = multiplet.

2.3 Reaction Heptagram

For a reaction with this following equation:

A: limiting reagent, B: co-reactant, P: main product, Q: identified byproduct a, b, p and q: stochrometric coefficients.

The used formulas for the reaction parameters calculations are as follows:

Carbon Efficiency:

Atom Economy:

Yield:

Reaction Mass Efficiency:

Material Recovery Parameter:

The danger and toxicity coefficients are also included in the heptagram.

3 Results and Discussion

3.1 Reaction Tests

After reaction conditions optimization (reaction time, temperature, reactants quantities and stoichiometric ratio of reagents), the parameters leading to the best yields were found to be: a mass of catalyst of 0.2 g, a stoichiometric ratio Benzaldehyde/ethyl acetoacetate/urea of 2/2/3 mmol under reaction temperature of 100 °C for one hour.

The results of the solvent free synthesis, summarized in Table 1 (entries 1–8) show that DHPMS yields are sensitive to both transition metal and anions natures. In the case of Zn and Ni, nitrate are more active than chloride parents (97 against 90 and 60 against 53% of DHPMS yields respectively). Contrarily, in the case of Fe and Cu, chloride are more active than nitrate parents (40 against 36 and 76 against 70% of DHPMS yields respectively). Among the tested salts, those based on zinc are the most efficient with 90–97 against 36–76% of DHPMS yields. Zinc is not a transition element; its effectiveness may be related to its metallic character similar to those of the alkaline and alkaline earth compared to Cu, Fe and Ni, transition metals, that have both acidic and oxidative character.

The same reaction has been carried out with addition of 5 ml of ethanol as solvent, in the presence of Zn based catalyst (Table 1, entries 9 and 10). The obtained results show a strong decrease from 90–97 to 10–50% of DHPMs yields, regardless of the anion nature. This is probably due to the polarity of the solvent molecules. Thus, the presence of hydrogen bonds, resulting from interaction between solvent hydrogen atoms and nucleophilic reagents, would lead to a slowdown of the condensation process.

3.2 Heptagrams of Reactions

Obtained Figs. 2 and 3, from the parameter calculations (Table 2) show the heptagrams of the Biginelli’s reactions, carried out in the presence of Zn(NO3)2 with and without solvent. The results show that the solvent-free mode is closer to the ideal synthesis as represented in Fig. 4.

Structure of the desired DHPM (ethyl 6-Methyl-2-oxo-4-phenyl-1,2,3,4-tetrahydropyrimidine-

5-carboxylate) (Fig. 5) was confirmed by several physical characteristics:

Melting point: 200–202 °C (Lit 202–204 °C).

IR (KBr): υmax = 3235, 3110, 1720, 1640, 1616, 1515, 1250 cm−1.

1H NMR (250 MHz, DMSO-d6): δ = 9.24 (s, 1H, NH), 7.75 (s, 1H, NH), 7.26 (s, 5H, C6H5), 5.14 (s, 1H, J = 2.87 Hz), 4 (q, J = 3.1 Hz, 2H, OCH2CH3), 2.24 (s, 3H, CH3), 1.11 (t, J = 7 Hz, 3H, OCH2 CH3) ppm.

13C NMR (62.5 MHz, DMSO-d6): δ = 165.4 (COOEt), 152.2 (C2), 148.4 (C6), 125.81–144.75 (C arom.), 99.83 (C5), 59.2 (OCH2CH3), 54 (C4), 17.8 (CH3), 14.1 (OCH2CH3) ppm.

4 Conclusions

In this study, the Biginelli reaction was performed in the presence of metal based nitrates and chlorides as catalysts. The zinc based system appear to be most efficient with high DHPMs yields, 97% in the presence of Zn(NO2)3 and 90% in the case of ZnCl2. Reaction heptagrams are in favor of free solvent condition. The present methodology offers several advantages as high DHPMs yields, low reaction time (1 h), one pot synthesis and eco-friendly reaction conditions. It can be an alternative to the conventional processes which are very long, less efficient and more polluting.

References

Biginelli, P.: Aldehyde-urea derivatives of aceto- and oxaloacetic acids. Gazz. Chim. Ital. 23, 360–413 (1893)

Kappe, C.O.: Biologically active dihydropyrimidones of the Biginelli-type – a literature survey. Eur. J. Med. Chem. 35, 1043–1052 (2000)

De Fátima, A., et al.: A mini-review on Biginelli adducts with notable pharmacological properties. J. Adv. Res. 6(3), 363–373 (2015)

Kappe, C.O.: Recent advances in the Biginelli dihydropyrimidine synthesis. Acc. Chem. Res. 33, 879–888 (2000)

Kappe, C.O.: Synthesis of octahydroquinazolinone derivatives using silica sulfuric acid as an efficient catalyst. Eur. J. Chem. 35, 1043–1052 (2000)

Rovnyak, G.C., et al.: Calcium entry blockers and activators: Conformational and structural determinants of dihydropyrimidine calcium channel modulators. J. Med. Chem. 38, 119–129 (1995)

Sweet, F., Fissekis, J.D.: Synthesis of 3,4-dihydro-2(1H)-pyrimidinones and the mechanism of the Biginelli reaction. J. Am. Chem. Soc. 95, 8741 (1973)

Sandhu, S., Sandhu, J.S.: Past, present and future of the Biginelli reaction: a critical perspective. ARKIVOC 66, 66–133 (2012)

Heravi, M.M., et al.: A catalytic method for synthesis of Biginelli-type 3,4-dihydropyrimidin-2 (1H)-one using 12-tungstophosphoric acid. J. Mol. Catal. A: Chem. 242, 173–175 (2005)

Debache, A., et al.: A one-pot Biginelli synthesis of 3,4-dihydropyrimidin-2-(1H)-ones/thiones catalyzed by triphenylphosphine as Lewis base. ChemInform 49(42), 6119–6121 (2008)

Kouachi, K., et al.: Mo/γ-Al2O3 catalysts for the Biginelli reaction: effect of Mo loading. J. Mol. Catal. A: Chem. 395, 210–216 (2014)

Khiar, C., et al.: Cobalt supported on alumina as green catalyst for Biginelli reaction in mild conditions: effect of catalyst preparation method, pp. 1–9 (2017)

Nasr-Esfahan, M., et al.: Efficient and green catalytic synthesis of dihydropyrimidinone(thione) derivatives using cobalt nitrate in solvent –free conditions. J. Chil. Chem. Soc. 59(1), 2311–2314 (2014)

Barbero, M., et al.: A bønsted acid catalysed enantioselective Biginelli reaction. Green Chem. 19, 1529–1535 (2017)

Shahid, A., et al.: Solvent-free Biginelli reactions catalyzed by hierarchical zeolite utilizing a ball mill technique. Catalysts 7(3), 84 (2017)

Trost, B.M.: The atom economy—A search for synthetic efficiency, 254, 1471–1477 (1991)

Anastas, P.T., Warner, J.C.: In Green Chemistry: Theory and Practice. Oxford University Press, New York (1998)

Bataille, X.: Une initiation à la chimie verte, ENCPB (2007)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Bennini, L., Mazari, T., Khiar, C., Menad, S., Halouane, M., Rabia, C. (2018). Zinc Based Materials as Efficient Catalysts for a Clean Synthesis of Biginelli Product. In: Abdelbaki, B., Safi, B., Saidi, M. (eds) Proceedings of the Third International Symposium on Materials and Sustainable Development. SMSD 2017. Springer, Cham. https://doi.org/10.1007/978-3-319-89707-3_39

Download citation

DOI: https://doi.org/10.1007/978-3-319-89707-3_39

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-89706-6

Online ISBN: 978-3-319-89707-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)