Abstract

In order to mine out the valuable minerals from the depths of the earth’s surface, huge amounts overlying material must be removed first. This overlying material, which in most cases is of no economic value to the mining operation, is called overburden (a mine waste), and has to be stored in the mine vicinity in order to keep on mining the underlying mineral effectively. Limited space available in a mining project renders it necessary for the overburden to be stored in form of dumps, which can reach huge dimensions as mining moves on to higher and higher stripping ratios. It hence becomes a necessity to ensure that these dumps are safe in all conditions and stages of mine working. Understanding of the mechanics and dynamics of the dumps and dump slopes therefore, becomes a crucial requirement for a mining engineers that will help them design safer dumps, simultaneously considering the economic aspects of mining. With this consideration, this chapter deals with a broad overview of the dumps and dump design, covering various details of the dumping methodologies, dump characterisations, and mechanics and dynamics of dump slope failure. Stress of this chapter is specifically focused on proper understanding of the various factors that affect the stability of the dump slopes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

In today’s mining industry, surface mining undoubtedly dwarfs the underground mining by a long margin in terms of production and productivity. For instance, almost 97% of United States’ metal mining is open pit mining, producing around 700 MT of ore as compared to 19MT of ore by underground mining methods [1]. In India, 92% of total coal production is from opencast mines [2]. Similar trends are observed around the world for major mineral exploration and mining operations. In conjugation to these huge amounts of production from open pit mines, there is a large requirement of waste material handling for the excavation to take place. In proportion to the stripping ratio of the mining operation, which is the amount of waste material handled per unit mineral excavated, huge amounts of overburden waste have to be removed and relocated in order to excavate the required mineral. The average stripping ratio for Indian open pit coal mining was 2.33 in the year 2015, implying that for the production of 612.44 MT of coal that year, 1427 MT of overburden was displaced from one location to another [2].

Historically, right from the time man started extracting valuable minerals from the rock, there has been a problem of waste management. In early days of mining, the waste management was simply done by moving the material out of the way, either down the hill slope or to any other available place. Many times, this waste material was thrown away in rivers, lakes etc., which, in due course of time, started getting blocked. Eventually laws were established to avoid such reckless practices and to regulate the disposal/storage of mine wastes [3].

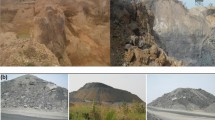

Today, these huge amounts of overburden material are either casted back in to the pits are is dumped either inside the mine (in form of internal dumps) (Fig. 2.1) or outside the mine (external dumps). Since the mine economics favours internal dumping, and the land area available inside the mine is always limited, it is critical to make steeper and higher dumps in order to put more and more material in the same amount of land area [4].

However, stability of these dumps is especially important for safe mine working, considering specifically that in most cases these dumps are very near to the haul roads or working face in opencast mines. Any failure in this case will result in catastrophic losses in terms of life, property and machinery as is seen in many of the past and recent examples such as in Rajmahal Coal Mine, Jharkhand in 2016 [5, 6] (Fig. 2.2), Sasti Mine in 2009, Jayant coal mine in 2008 [7], Kawadi Opencast mine in 2000, etc. [8,9,10]. Hence, it is imperative to know the intricacies of the dump slope design in order to plan the mining work ensuring safety as well as sound mine economics. This chapter will deal with basic understanding of the dumps, including the types of dump formation, the factors that affect the stability of the dump slope and the various modes in which the dump fails.

Catastrophic damage after dump failure in Rajmahal Coal mines in 2016 [5]

2 Dump Classification

Most mine dumps comprise of blasted out overburden that is highly heterogeneous in nature and the size of rocks can range from less clay size particles to big boulders (less than 0.1 mm to more than 1 m diameter). This is based on lots of factors including rock type, local geology, and blasting practices. Dumping operations that allow material to fall from some height undergo natural gravity segregation, however, obtaining an exact size distribution of material in a dump is very difficult [11]. Some especially designed dumps have layered positioning of set grade of material to allow formation of natural channels for water movement. In other cases the dump may have a layer of heavy rock covering the face of dump to avoid the fine grained particle flying off while dumping [12].

Shape of the dump is dependent on the topography of area on which the dump is made. Following are some of the shapes a mine dump can take:

2.1 Valley Fill

Valley Fill: As the name suggests it fills the valley. The filling starts from the higher level of the valley to the lower level of the valley (from upstream to downstream). In case the valley is not filled completely (partial valley fill), arrangement of culverts, rock drains etc. need to be provided for preventing water impoundment (Fig. 2.3).

Valley fill type of dumping [13]

2.2 Cross Valley Fill

Cross Valley fill: In this type of valley fill the layers cross the valley, in contrast to moving from upstream to downstream. These can be used as retention dams for fine coal or waste slurries, in which case proper drainage facilities are provided to ensure stability (Fig. 2.4).

Cross valley fill type of dumping [14]

2.3 Sidehill Fill

Sidehill fill: These are made on the existing natural or artificial slopes. These do not cross the valley bottom. They can be used to impound water in slopes or mine waste slurries (Fig. 2.5).

Sidehill fill type of dumping [13]

2.4 Ridge Embankment

Ridge Embankment: These are made above an existing ridge, with both sides of the crest being touched by the waste material (Fig. 2.6).

Ridge embankment type of dumping [14]

2.5 Heaped

Heaped: These are generally constructed on level or gently dipping terrain. These can be stacked or piled up fills where material is filled in one lift after another. The dump has slopes on all sides (Fig. 2.7).

Heaped type of dumping [13]

Apart from the shape a dump takes, dumps can also be classified based on the method of dumping.

2.6 End Dumping

End Dumping: This method simply involves dumping the waste rock on the dump face directly by the dumper or tippler. The layers of the material thus formed are parallel to the face (Fig. 2.8). Due to the movement of material from top to bottom of the dump face under gravity, some segregation of particle size takes place, with finer settling on the upper part of the dump while the coarser settling in the lower parts and near the toe of the dump.

Ending dumping in progress in one of the opencast coal mines [11]

2.7 Push Dumping

Push Dumping: This method is like the end dumping, except that in this case the dumper places the waste material on the top surface of the dump, from which the material is levelled and pushed with help of dozers to fall on the face of the dump (Fig. 2.9). This is generally done in case of weak dump edges, where there is a danger of failure of the slope when the dumper is unloading on the edge. Particle size segregation is similar to that in case of end dumping.

Dozer push dumping the overburden material in an opencast mine [15]

2.8 Free Dumping

Free dumping: In this method, the material is dumped on the surface in form of small piles that are then levelled and compressed into layers to eventually form lifts. These lifts act as the base for the next lift when sufficiently large enough (Fig. 2.10). Since all material is compressed, there is no practical segregation of material size.

Free dumping is seen in form of compressed lifts in an opencast mine [16]

2.9 Dragline/BWE Dumps

Dragline/BWE dumps: Typically used in coal mines, these are small heighted dumps, dropped from some height by bucket, conveyor belt etc. (Fig. 2.11). There is no lift making, nor any compaction of material that takes place. Hence size segregation does not take place to that extent since the size of the dumps is also small.

Dragline dumping the overburden material in an opencast mine [17]

3 Factors Affecting Dump Slope Stability

As discussed before it is very important to keep the dumps stable and safe for preventing any accidents and loss in life and property. A dump slope failure can cause unprecedented interruptions in mine production for e.g. by equipment burial in the debris, by blocking the haul road or the access way to the ore etc. Further to failure, the cost of clean-up and resumption of mine operation is substantial and will additionally be a burden to the mine economics. Hence it is important to understand the factors that affect the stability of dump slopes. Some of the major factors are:

3.1 Geometry of Dump

Geometry of dump: Perhaps one of the major factor that affects the stability of slope is the geometry of the dump. Specifically, parameters like the height of the dump, the overall slope of the dump, berm width/haul road width, etc. have a significant effect on the stability of slope [18]. Higher slopes and angles make the slope unsafe while the gentler slope gives a higher factor of safety as is shown in various studies [19] (Fig. 2.12).

The slope of these dumps is dictated based on the method of dumping as well. The end dumping technique makes loosely compacted slopes at an angle that is very close to the natural angle of repose. At the angle of repose, the slope is critically safe (factor of safety is 1), and since the material is loose, there is high chance of failure of such slopes [3]. In contrast to this, the lift type or free dumping involves compaction of material and hence there is an increase in density and internal friction, resulting in more stable material that can support higher and steeper slopes. The slopes which can be made here are determined by simulation methods for allowable heights and angles, keeping the dump safe [4, 20].

3.2 Geotechnical Properties of Dump Material

Geotechnical properties of Dump material: The geotechnical properties of the dump material are the main factors that affect the stability of the dump slope. Properties like density, shear strength, grain size distribution, compression index, degradation behaviour, saturation etc. are some of the primary characteristics of the dump material that need to be known in order to design a safe dump. These properties are mostly calculated in labs (Fig. 2.13) by series of standard testing procedures laid out by local or global standardising organisations like ISRM, ASTM, ISO, BS etc., though some tests can also be performed on field.

Most of the geotechnical properties are based on the way dumps are made. An intact rock like sandstone, mudstone or shale will possess inherent rock properties such as compressive, tensile and shear strengths, density, porosity and permeability, inherent saturation etc. based on the location of the rock and its base geology. However, since the dump material is not intact and is in fact the fragmented form of the intact rock, most of these properties will be highly dependent on the grain size distribution, compaction, saturation etc. For instance, density of dump waste material will be highly dependent on the compaction of the material while the dump is formed. For the dumps made by end dumping method, the density will be less due to simple gravity compaction, while in case of lift dumping, the density will be much higher as the dump is compacted in each lift stage. Density will also be based on the grain size distribution of dump material [3]. The finer grain size will give much denser dump materials than the coarser grain sizes. A gradual mix of finer and coarser grain size can give a much better packing efficiency, due to proper filling of pore spaces, as compared to the ones with only coarser grain sizes. This again is based on the type and purpose of dumping. The methods like end dumping and slide dumping involve gravity induced segregation of material, where the material is constantly added to the face of the dump, resulting in coarser particles to collect at the bottom and finer at the top, hence creating a density gradation from top to bottom. On the same lines, but in opposite trend, the free dumping, which uses lifts to create dump keep compacting the dump material at every step resulting in high densities, which keep on increasing as more number of lifts are added on the top of the dump. Typically, density of dump material may vary from 1.6 to 2.2 g per cubic centimetre based on the compaction.

Similar to density, shear strength of the dump material is also an important property affected by the variation of compaction and overlying load. The compaction of material changes its effective internal friction angle and cohesion. These factors are also affected by the degree to which the dump material is saturated. Based on the type of dump material, the cohesion and angle of friction will vary with moisture content of the dump. Increase in the surface moisture in some massive structured materials such as quarts increases the friction, while the same decreased in the minerals with layer like lattice such as mica [21]. It was also observed in many studies that the internal angle of friction increased with the increase in coarser grain sizes in a fine-grained soil sample, possibly due to better cross linking. However, for a given void ratio, the smallest size particles will have the highest internal angle of friction, which will decrease with further increase in grain size [12]. In most of the dump slope stability analysis, the simplest and most applicable model for the judging the stability of dump slope is the Mohr-Coulomb failure criteria (Fig. 2.14), which effectively states the shear strength to be a function of the normal stress, internal angle of friction and the cohesion.

3.3 Geotechnical Properties of Foundation

Geotechnical properties of Foundation: Since the full dump must stand on it, the geotechnical properties of the foundation also play a key role in stability of the dump slope. In fact, one of the major causes of dump slope failure is the failure of the weak foundation base. The properties like saturation, porosity, permeability, shear strength of the foundation, are hence quite significant in slope stability. The foundation can deform in case it is made of saturated soil or similar zones resulting in a toe failure, or a complete circular failure involving both the dump as well as the foundation. Many times, it is difficult to predict the behaviour of foundation before the dumping starts as the base rock behaves differently under the load of tonnes of dump material [22]. Many types of foundation materials such as low plasticity silts and clays are expected to settle based on the consolidation of the in-situ conditions, as the dumping material is pilled over them with time. This settlement can cause serious complications on dump stability and the drainage structures that are made in the dump. Apart from that, the hydrological aspects change drastically as the dumping proceeds. Porosity and permeability are the factors that will decide the pore dynamics and the generation of pore water pressure. The water table will rise as the dump height increases resulting in saturation of bottom layers of foundation. This shall reduce the shear strength of foundation as compared to the no dumping conditions, and hence can result in unexpected failures by liquidation of the foundation. Hence detailed laboratory testing for the foundation material is also required including its classification, strength, permeability, consolidation etc.

3.4 Method of Dumping

Method of dumping: As we discussed in the section on dump classification, method of dumping plays a role in dictating the mechanical behaviour of dump. Based on the type of dumping, the geotechnical properties like the pore sizes, porosity, permeability, density, grain size distribution etc. vary from one dumping method to the next, hence affecting the stability of the dumps. Apart from geotechnical properties, the steepness of the slope is often dictated by the method of dumping as well. The layered dumping methods and the end dumping methods show contrasting characters when it comes to these properties. The design of the dump also dictates the hydrology of the dump and in extension the stability of dump slope. The presence of drainage channels provided in the dump design can act as relieve points for hydrological build up and can reduce the static water head that is often built in dumps that have high compaction scenarios. On the other hand, the loosely compacted end dumping techniques mostly provide enough pore spaces for the water to pass through to the base and in the foundation.

3.5 Hydrological Conditions

Hydrological Conditions: One of the important factors for dump slope stability that is often overlooked is the effect of water. Overburden is majorly blasted out rock and soil, which is generally highly porous in nature due to the end-dumping techniques. This results in easy percolation of water through the dump to its lower layers, which may result in accumulation of water if proper drainage routes are not made (Fig. 2.15). Accumulation of water in dumps can be disastrous and can lead to massive failures of dump slope as was seen in 2008 in western section of Jayant opencast mine, Northern coalfield Ltd. India [7].

Hydrodynamics depicting water movement and water cycle in a dump slope [23]

Effect of accumulation of water in dumps can be threefolds. Firstly, water creates a hydrostatic pressure due to weight of the water itself, which increases the effective stress on the overall slope. Secondly, the presence of water creates pore pressure, which is the force of water present in voids of the overburden material. This pressure can be both positive (forcing the overburden particles away from each other) or negative (in form of suction/capillary pressure), and hence changes the dynamics of slope stability. Thirdly, oversaturation of water makes the particles loose due to dilution, which changes the internal properties of overburden material such as cohesion and internal angle of friction, hence causing instability in an originally stable slope [11]. Though proper drainage channels generally prevent the accumulation of water, these become ineffective with time due to build-up of fine soil at the base of dumps, transported from infiltration of rain water over time. Effective drainage hence becomes a key for keeping the hydrostatic pressure under check and keeping the dumps stable.

Apart from the hydrology of dump slopes, foundation hydrology also plays a vital role. The rise of the water table with increased dumping height makes the higher layers of foundation saturated. This results in decrease in shear strength and often a case of highly plastic behaviour of foundation resulting in massive failures due to dilation. Hence, factors like porosity, permeability, groundwater, and drainage are important considerations for designing a dump as well as for monitoring the stability of dump slopes. Porosity and permeability, both of which are responsible for the water statics and dynamics in the foundation (Fig. 2.16), will give idea of the void distribution and hence will be helpful in calculating water retention and static pressure heads.

Porosity and permeability are two different but important aspects in hydrology of a dump slope [24]

Another important aspect of the hydrology of dump slopes is the rainfall and surficial erosion. Rain water will both infiltrate the dump material as well as will run off from the surface based on the porosity and permeability of dump material. Surficial runoffs result in surficial erosion and hence can be detrimental to the design of dump as a whole [25]. These erosions can choke the drain channels as well as make the dump structurally weak if the toe area of the dump is eroded. Hence erosion studies are also conducted for getting an idea of the effect of water movement on and around dumps. In this case, vegetation on the dump also plays a significant role as the roots of the vegetation acts as binder for the soil/overburden material, hence holding it against the erosion [26].

3.6 Static and Dynamic Forces

Static and Dynamic Forces: Apart from the local static properties of material and nature, there are other dynamic properties that also effect the stability of dump slope. In seismically active areas, ground movement due to earth quake is also kept as a factor in dump design and stability analysis. Though there have been many models for dynamic behavioural analysis of dump slopes, the exact effect on the stability of dump slopes is still debatable, mostly because of the unpredictable transfer of energy from ground to the dump and the effect it will have thereof. The greatest stability risk that the dump has in case of seismic activity is the liquefaction of foundation, resulting in progressive unavoidable failure.

Similar to the seismic activity in local area, one of the major form of dynamic forces active on the waste dumps in regular mining conditions is that by the blasting operations in mining [27]. Though modern-day blasting is well planned and studied for the effect of its vibrations on local structures, there is always a possibility of misfires and unregulated blasting resulting in detrimental effects on local mine structures, specifically the internal dumps which are at proximity to the blast zone (Fig. 2.17). Dumps these days are hence analysed for blast induced vibration study as well as other stability analysis for their safer design [28, 29]. Apart from blasting and seismic forces, some of the other loads such as moving of heavy earth moving machinery on or near the dump also play a role in stability of dump slopes.

4 Modes of Failure

Any negative factor in the above discussed aspects affecting the stability of the dump slopes can lead to slope failure. The way, or mode, in which a slope fails is dictated by which of the factors are not up to the mark to make the slope stable. The prediction for the mode of failure is also important in case the failure is unavoidable and remedial measures have to be planned in advance. Based on the kinetics of failure there are three basic kinds of failure movements as seen in Fig. 2.18. In regressive failure, there are short term displacement cycles at a decelerating rate on the removal of the failure initiation event such as external loading, blasting vibration etc. On the other hand, in the progressive cycle, the displacement cycles are accelerating and won’t stop by themselves unless some stabilisation measures are introduced [30]. Various combinations of factors result in various modes of failures in dump slopes. Some of the main failure modes discussed in various literatures are mentioned here.

(a) Displacement vs time plot for repressive and progressive displacement cycles during the slope failure. (b) Corresponding structural conditions for slope kinetics [30]

4.1 Surface or Edge Slide

Surface or edge slide: These are some of the most common type of failure in mine dumps, where a layer of material, parallel to the surface of the slope, fails and translates down the slope (Fig. 2.19). These are generally seen in end dumping and push dumping methods and happen mostly due to over steepening of the crest regions of the dump. The steepening may happen due to higher cohesion of material, especially post rains, when the steepening is also coupled with weakening of the toe region of the dumps. A variation of this is the plane failure of the dumps where sliding occurs along a single plane either at an angle to the slope or parallel to it.

(a) Surface slump failure, (b) Edge slide failure [31]

4.2 Shallow Flow Slides

Shallow flow slides: These are shallower as compared to the surface slumping. The failure occurs here due to complete or partial saturation of dump material due to rains or snow melt in very cold regions, resulting in reduction in shear strength of the material [14]. Mostly restricted to the crest of the dump, the material translates from the top to bottom of the dump increasing the toe region (Fig. 2.20).

4.3 Rotational Circular

Rotational circular: Rotational failure again is one of the major failure modes seen in dumps, where the mass fails along a curved surface (Fig. 2.21). This is especially seen in dumps with excessive dump heights or loading materials. This can also happen during rains, especially due to loss of toe support and during earthquakes. Rotational failure may be limited to failure of the dump material or can extend to the foundation of the dump if the foundation material is weak soil type or due to high pore-water pressure development [14]. Creep is also characterised as a wider form of circular failure.

Rotational circular failure [31]

4.4 Block Translation

Block Translation: This happens in all the conditions similar to the rotational circular failure, however the translation generally occurs along a plane which is either in the foundation, or at the interface of foundation and dump material (Fig. 2.22). This type of failure is characterised by movement of the whole dump along the weak plane, which is further favoured by increasing steepness of the foundation.

Block translation failure [11]

4.5 Base Failure (Spreading)

Base Failure (spreading): This is a progressive type of failure where there a weak failure plane in the foundation which combines with the shear failure plane of the dump. This is specially seen in steeper foundations where the foundation base translates in advance of the dump failure and keeps failing at an incremental rate [31] (Fig. 2.23).

Base failure (spreading) [31]

4.6 Liquefaction

Liquefaction: Liquefaction happens when the effective stresses on the liquefiable material are effectively reduced to zero, which results in complete loss of shear strength. This quick sand like condition may happen due to seismic activity, cyclic loading process or due to excess pore water pressure as a result of heavy rains and water accumulation [14]. If the foundation faces liquefaction, whole dump may end up in progressive failure (Fig. 2.24).

Liquefaction of base [31]

5 Conclusion

A brief overview of the dumps and the dump slope stability was presented in this chapter. Starting from the understanding of the importance of the dump slope stability in today’s mining scenario, various models of dumping were analysed, both based on the shape of the dump, as well as based on the method of dumping. It was seen that some of the geotechnical and hydrological properties of the dump are directly dependent on the method of dumping itself. Consequently, the dumping method was discussed as one of the factors that affect the stability of dump slopes.

Factors affecting the stability of the dump slopes were discussed and compared further. Important factors such as the geometry of the dumps, the geotechnical properties of the dump material as well as the dump’s foundation were identified to be crucial parameters affecting the dump slope stability. However, hydrology of the dump slope system was not neglected and its effect on the stability of the dump slope was specifically discussed, especially recognizing the uncontrolled watery conditions to be one of the primary causes of dump failure. The effect of dynamic forces such as seismic activity, blasting vibrations and heavy earth moving machinery movement, on the stability of dumps was also discussed. Correlating these factors to the failure conditions, various modes of dump failure were finally analysed and understood in context of the dump slope stability.

References

Chadwick J (2008) Going underground, or not. Int Mining:48–54

GOI (2015) In: C.C.s. Organisation (ed) Provisional coal statistics. Ministry of Coal, Kolkata

Darling P (2011) SME mining engineering handbook, vol 1. Society of Mining, Metallurgy and Exploration Inc. (SME), Englewood

Gupta T, Yellishetty M, Singh T (2015) Optimization of ash content in overburden dumps: a numerical approach. In: Proceedings of MPES 2015-Smart innovation in mining. The Southern African Institute of Mining and Metallurgy Johannesburg, South Africa. pp 997–1004

Saran B, Kumar P (2016) Jharkhand coal mine collapse: eleven workers killed, over 50 trapped, in Hindustan Times, Hindustan Times, New Delhi

GOI (2016) Update on ECL Rajmahal coal mine accident. In: M.o.C. Government of India (ed). http://pib.nic.in

Sharma S, Roy I (2015) Slope failure of waste rock dump at jayant opencast mine, India: a case study. Int J Appl Eng Res 10(13):33006–33012

Rai R et al (2012) Sensitivity analysis of internal dragline dump stability: finite element analysis. Geotech Geol Eng 30(6):1397–1404

Kainthola A et al (2011) A coal mine dump stability analysis—a case study. Geomaterials 1(01):1

Gupta T et al (2014) Sensitivity analysis of coal rib stability for internal mine dump in opencast mine by finite element modelling. Geotech Geol Eng 32(3):705–712

NMEICT (2014) Mine waste dump. In: Rajesh R (ed) Slope engineering. The National Mission on Education through Information and Communication Technology, Varanasi

Orman M, Peevers R, Sample K (2011) Waste piles and dumps. In: SME mining engineers handbook, pp 667–680

Zahl EG et al (1992) Waste disposal and contaminant control. In: Hartman HL (ed) SME, mining engineering handbook. SME, Littleton

Cadwell J, Allan M, Bruce V (1981) The simplified analysis of mine waste embankments, US Forest Services

Latimer C (2014) Caterpillar launches new dozer. In: Australia mining. Prime creative media: Online

Asianet (2012) Mining dumps may cause pollution hazards

Bizj (2016) Titan America business grows with construction resurgence. S Fla Bus J. http://media.bizj.us/view/img/529551/titan-dragline*180.jpg

Singh P et al (2013) Estimation of critical parameters for slope instability in an in-pit mine dump. SGAT Bull 14(1):34–44

Verma D et al (2011) Evaluation of open pit mine slope stability analysis. Int J Earth Sci Eng 4(4):590–600

Vandre B (1980) Tentative engineering guide: stability of non water impounding mine waste embankments. U.S. Forest Service, Ogden

Lewis JG (1956) Shear strength of rockfill. In: 2nd Australia-New Zealand conference on soil mechanics and foundation engineering

Singh A, Singh T (2006) Assessing instability of coal mine waste dump. Ind Miner Ind J 113–118

Rahardjo H, Satyanaga A, Leong EC (2011) Unsaturated soil mechanics for slope stabilization

PGCE (2014) Rock and geology time. Weebly: PGCE Geography Classroom

Cho SE, Lee SR (2002) Evaluation of surficial stability for homogeneous slopes considering rainfall characteristics. J Geotech Geoenviron 128(9):756–763

Waldron L (1977) The shear resistance of root-permeated homogeneous and stratified soil. Soil Sci Soc Am J 41(5):843–849

Singh T, Singh V (2005) An intelligent approach to prediction and control ground vibration in mines. Geotech Geol Eng 23(3):249–262

Khandelwal M, Singh T (2007) Evaluation of blast-induced ground vibration predictors. Soil Dyn Earthq Eng 27(2):116–125

Kumar M, Jain AK, Singh TN (2009) Blast vulnerability analysis of waste dump during production blasting. J Mines Metals Fuels 57(10):313–316

Broadbent CD, Zavodni ZM (1982) Influence of rock structure on stability. In: Stability in surface mining, vol 2. Society of Mining Engineers, Denver

BCMDC, B.C.M.D.C.P.E.L. (1991) Investigation and design of mine dumps: interim guidelines. The Committee

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Gupta, T., Singh, T.N., Verma, D. (2019). Dump Slope Stability. In: Pradhan, S., Vishal, V., Singh, T. (eds) Landslides: Theory, Practice and Modelling. Advances in Natural and Technological Hazards Research, vol 50. Springer, Cham. https://doi.org/10.1007/978-3-319-77377-3_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-77377-3_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-77376-6

Online ISBN: 978-3-319-77377-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)