Abstract

This chapter deals with the problem of modelling the behaviour of massive concrete structures. In the last decades, the developments in the field of computational mechanics were significant, so nowadays several numerical techniques are available to this goal, depending on the scale level considered but also on which phenomena/processes are taken into account. In this chapter, we limit the description to approaches/models that can be implemented using the Finite Element Method, which is still the worldwide most used numerical technique. This chapter presents two distinct groups of models. The first group covers deterministic models starting from the simplest ones, which consider simply the thermo-chemo-mechanical behaviour of the material, to more sophisticated approaches which consider also the fluid phases; i.e., they consider concrete as a multiphase porous material. In this first part, a specific section is dedicated to mechanical behaviour modelling considering damage of the material, plasticity, etc. The second group of the models takes into consideration stochastic nature of cracking. These models are formulated specifically for giving a detailed information about cracks spacing and opening in concrete structures in service life conditions.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Massive Concrete Structures

- Multiphase Porous Media

- Steel Fibre-reinforced Concrete (SFRC)

- Autogenous Shrinkage

- Hydration Degree

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

7.1 Introduction

Computational analysis has become crucial in almost all disciplines, together with theory and experimental analysis. Every model is a simplification of reality intended to promote its understanding. A model uses a simplified physical formulation, mathematical framework and numerical tools in order to find the solution. Successful models pass the validation stage where modelling results correspond sufficiently well to reality.

Computational approaches are also playing an increasing role in industry. In fact, validated models can save significant amount of experiments, time, and resources, can mitigate potential problems and even find optimal solution. For instance, in the case of massive concrete structures, numerical modelling often follows objectives such as determination of temperature field during hardening, effect of concrete composition, estimation of cracking potential with consequences to durability, economical benefits.

In civil and environmental engineering, most of the processes/phenomena are mathematically described by a set of partial differential equations (PDEs), usually nonlinear in material laws. For example, a set of PDEs describes heat and mass transfer, mechanical effects, hydrodynamic effects, electric and magnetic fields, and all their interactions (multiphysics problems). There exists a significant amount of numerical techniques for solving such a kind of complex mathematical systems, some of them limited to the research world. In the context of this state-of-the-art report, we consider the most commonly used numerical method—the Finite Element Method. Often, obtaining a prediction from a theory requires massive computing, so it is necessary to develop and implement special algorithms for parallel computation to be able to exploit the full potential of the technology and maintain scientific and productive competitiveness. Virtually, all manufacturers of high-end chips in the last few years have adopted a multiprocessor organisation, typically with 4–8 processors per chip (but solutions with up to 18 cores are available). This number is expected to grow to 100–1000 in the next decade. Hence, high-parallelism and low-communication algorithms are no longer the prerogative of supercomputing and are instead becoming pervasive, but a description of such kind of solvers and tools is beyond the scope of this chapter.

Hardening concrete is undoubtedly one of the most difficult structural materials for modelling. The difficulties arise from a complex concrete microstructure, which is additionally subjected to transformations as a result of cement hydration. Initially, it is a mixture of liquids and solids of varying diameters and shapes. Such a multiphase medium is characterised by strong viscous and plastic properties. With progressing cement, hydration concrete becomes a solid, with elastic, viscous and plastic characteristics, where the mutual proportions of these features depend on the progress of the concrete hardening process. Moreover, in addition to the chemical reactions resulting in the hydration of the material, several physical phenomena take place (e.g. phase changes) and numerous fields are interacting with each other (thermal, hygral, mechanical, etc.) making the problem a typical multifield–multiphysics problem (Gawin et al. 2006a).

Concrete represents a multiscale material which spans characteristic lengths from about 10−10 to 10−2 m. The finest atomistic scale of C-S-H determines several macroscopic properties such as elasticity, strength, creep, shrinkage, which manifest on higher scales (Bernard et al. 2003; Pichler et al. 2011). Hydration takes place up to micrometre scale of cement paste, and large aggregates have impact on fracture properties.

Recent advances in multiscale models demonstrated models’ capabilities to capture those effects and to set up microstructure-property link. Indeed, nowadays several multiscale technics, of mathematical or numerical nature, are available for considering the material behaviour at different scales: the formulation of constitutive relationships starting from the microcomponents of the material up to the macroscale is an example of the application of multiscale strategy (see Chap. 3 for thermal properties).

Taking into account only concrete scale and its changes during hardening, two possibilities appear to model its early-age behaviour:

-

to use pure thermo-chemical, and possibly mechanical, models, or

-

to formulate a multifield model.

In the first class of models, concrete is treated as a continuum at macroscopic level and only the solid phase of the material is considered, taking into account the thermal field and the chemical reactions (e.g. the hydration process), which affect the mechanical performance of the material for a large extent.

The second group of models is based on the multifield concept; i.e., they consider one or more phases: not only the solid phase, which is typically the concrete skeleton, but also the liquid and gaseous components filling the pores of the material. Depending on the number of the phases considered and on the scale level chosen for the initial formulation of the mathematical model, the multifield models can be subdivided into two main groups corresponding to two different approaches.

The first approach is related to phenomenological models, where concrete is treated as a continuous medium. A detailed analysis of physical processes related to phase transitions and chemical processes occurring in hardening concrete is neglected in these models, and a macroscopic description of the thermal–moisture–mechanical phenomena is used as a multiphysical description.

The second approach is related to multiphase models based on Multiphase Porous Media Mechanics (MPMM), in which a precise analysis of the physical phenomena and the influence of the material’s internal structure on these phenomena are made. Starting from the microscopic level, appropriate constitutive equations are defined for the solid, liquid and gaseous phases of the medium and then averaged at macroscopic scale for a multiphase medium.

This state-of-the-art report gives a basic overview of the main approaches available in the literature for modelling the behaviour of concrete at early ages and beyond, starting from the simplest ones and then increasing the level of complexity.

First, the pure thermo-chemo-mechanical models are introduced in Sect. 7.2. Then, multifield single-fluid phase thermo-chemo-mechanical models and their extension with a moisture transport are presented and described in Sect. 7.3. Both these groups of models can be considered based on a typical phenomenological approach (i.e. concrete is treated as a homogeneous medium directly at macroscopic level). The last class of deterministic models taken into consideration is the one of multifield multiphase models described in Sect. 7.4 based on porous media mechanics. Each model group contains validation examples showing its effectiveness in the numerical simulation of the main phenomena/processes taking place in massive concrete structures.

Whatever is the model adopted for the description of the general behaviour of the material, it is needed to consider the effects of thermal field, chemical reactions and solid skeleton-fluid phase interactions on its mechanical performance. This means the necessity to choose an appropriate constitutive relationship, describing specifically its mechanical behaviour. Thus, damage and plasticity material models are briefly discussed in Sect. 7.5 in connection with Chap. 4. Section 7.6 focuses on models with stochastic nature. These models are formulated specifically for giving a detailed information about cracks’ spacing and opening in concrete structures in service life conditions.

7.2 Thermo-Chemo-Mechanical Models

Thermo-chemo-mechanical models consider coupling among heat transport, evolution of underlying microstructure via chemical reactions and solid mechanics. Moisture (humidity, water) transport is neglected, leading to zero drying shrinkage. Such simplification is feasible for massive structures in their early age (except for element surface), while for long-term calculation a chemo-hydro-thermo-mechanical model should be preferred (see Sects. 7.3 and 7.4).

During early age, several phenomena occur simultaneously. In thermal-chemo-mechanical models, the following ones are generally taken into account: hydration linked to the temperature evolution due to exothermic cement reaction, thermal conduction and dilatation, autogenous shrinkage, mechanical properties evolution and mechanical degradation due to cracks and/or damage (which could be visco-elastic damage models or plastic models).

7.2.1 Thermal Conduction Through the Concrete

The prediction of temperature evolution in a massive concrete structure is based on the heat equation with a source term:

in which Q ξ is the latent heat of hydration [Jm−3], T [K] is the temperature, α is the hydration degree, k is the thermal conductivity [Wm−1K−1], and c is the volumetric heat capacity [Jm−3K−1]. The latent heat of hydration, the thermal conductivity and the volumetric heat capacity could be kept constant (see Waller 2000; Mounanga 2004; Mounanga et al. 2006) or evolve slightly with the temperature (Morabito 2001) and the hydration (see Faria et al. 2006; Ruiz et al. 2001; Lura and Van Breugel 2001).

7.2.2 Constitutive Relationships/Couplings

One can distinguish between two types of couplings: thermo-chemical and chemo-mechanical couplings with the corresponding constitutive relationships, which are analysed and discussed in the following sections.

Thermo-chemical Coupling

The thermal properties, namely thermal conductivity, heat capacity and coefficient of thermal expansion, are generally functions of the temperature and also evolve at early age with the changes in the microstructure of the cement-based materials. For instance, Hansen et al. (1982) reported a decrease of thermal conductivity from 0.88 to 0.78 W/(mK) during hydration of rapid hardening Portland cement, w/c = 0.5 at T = 30 °C, while Mounanga (2004) obtained an increase. Generally, this aspect is not explicitly taken into account in simulations or even experimentally, but different authors report an impact of the variation of these properties on the structural response. For instance, Briffaut et al. (2012) performed simulations, at the structure level, in which the heat capacity and the thermal conductivity evolved with respect to the degree of hydration. In their simulation, the evolution of the heat capacity impacted the stress response more strongly than the evolution of the thermal conductivity. Lura and van Breugel (2001) reported that a given variation of the heat capacity may lead to a variation of the same order of magnitude in the computed temperatures and stresses. The same authors also found that up to 5% of variation in the thermal conductivity, an almost negligible effect is observed on the temperature and stress responses and that the CTE affects actively the thermo-chemo-mechanical response (a variation of 16% in the CTE is reported to increase the cracking risk by about 15%) (see Lura and Van Breugel 2001). On the other hand, Hilaire (2014) reported a not very pronounced impact of the CTE evolution on the mechanical response at early age.

The thermal source of the heat equation depends on the evolution of hydration which is achieved using chemical affinity (see Ulm and Coussy 1998, 2001; Lackner and Mang 2004; Regourd and Gauthier 1980):

where E a is the activation energy [Jmol−1], R is the ideal gas constant 8.3145 [JK−1mol−1], T is the temperature [K], α is the hydration degree, and \(\tilde{A}(\alpha )\) is the chemical affinity [s−1].

Many kinds of expression describing the evolution of the chemical affinity have been used (see among others Lackner and Mang 2004; Cervera et al. 1999a; Benboudjema and Torrenti 2008; Briffaut et al. 2012; Sciumè et al. 2013), but there remains experimental fitting. Buffo-Laccarière et al. (2007) proposed an expression for multiphasic hydration degree evolution linked to chemical activation and physical water accessibility to anhydrous cement product which allows for composed cement.

The energy of activation is also a function of the temperature and may vary as a function of the mechanisms deemed to drive hydration (Lothenbach et al. 2008). Again, the variation of the energy of activation with respect to age and temperature is often neglected in TC analyses.

Chemo-mechanical Coupling/Evolution of Mechanical Properties (Elastic, Plastic or Damage)

This kind of model is generally based on uncoupled strains decomposition:

where \({\varvec{\upvarepsilon}}_{M}\) is the mechanical strain tensor, \({\varvec{\upvarepsilon}}_{bc}\) is the basic creep strain tensor, \({\varvec{\upvarepsilon}}_{au}\) is the autogenous strain tensor, \({\varvec{\upvarepsilon}}_{T}\) is the thermal strain tensor, and finally, \({\varvec{\upvarepsilon}}\) is the total strain tensor. Nevertheless, some authors used coupling between creep and damage (see Chap. 4) and between creep and hydration (chemo-visco-elastic coupling see Chap. 4).

Autogenous shrinkage is directly related to the evolution of hydration in the material. Experimental results show that autogenous shrinkage evolution is almost linear with respect to the hydration degree as soon as the percolation threshold has been overcame (see Laplante 1993; Mounanga 2004; Mounanga et al. 2006). Therefore, autogenous shrinkage can be modelled by the following equation (Ulm and Coussy 1998):

where κ is a constant material parameter [-], α0 is the mechanical percolation threshold [-] (Torrenti and Benboudjema 2005), α ∞ is the final hydration degree (which depends on the concrete mix Waller 2000), and \(\left\langle \cdot \right\rangle\!_{+}\) is the positive part operator. A small expansion (so-called swelling) can also be measured at the beginning of hydration, depending on the w/c ratio and the type of cement.

The mechanical strains could be elastic ones (Faria et al. 2006) but could also consider plasticity (Ulm and Coussy 1998, 2001; Lackner and Mang 2004) or damage (Benboudjema and Torrenti 2008; Briffaut et al. 2011; Cervera et al. 1999b). In this last case, the relationship between apparent stress \({\varvec{\upsigma}}\), effective stress \({\tilde{\varvec{\upsigma}}}\), damage D, elastic stiffness tensor E, elastic strain and previously defined strain reads:

where \({\varvec{\upvarepsilon}}_{ttc}\) is the transient thermal creep strain.

The Young’s modulus E and the tensile strength f t increase due to hydration as follows (De Schutter 1999; Stefan et al. 2010, see also Chap. 4):

where ft∞ is the final tensile strength (i.e. when \(\alpha = \alpha_{\infty }\)) [Pa], E∞ is the final Young’s modulus [GPa], \(\bar{\alpha }^{{a_{E} }}\), and \(\bar{\alpha }^{{a_{ft} }}\) are constant material parameters.

The Poisson’s ratio is relatively stable for mature concrete. Neville et al. (1983) recommend a value equal to 0.2 for most of concrete mixes. However, De Schutter and Taerwe (1996) suggests an evolution depending on the hydration degree:

where ν is the Poisson’s ratio and α is the hydration degree. Note that for a hydration degree equal to 0, the Poisson’s ratio is equal to 0.5 which is the common value for an incompressible fluid.

The evolution of the damage is linked to the elastic equivalent tensile strain and could use strain from Rankine criterion (Cervera et al. 1999b) or Mazars approach (Benboudjema and Torrenti 2008; Briffaut et al. 2011).

Strain softening induces inherent mesh dependency and produces failure without energy dissipation (see Pijaudiet-Cabot and Bažant 1987). In order to dissipate the same amount of energy after mesh refinement, when strains localise in one row of finite elements, a characteristic length l c is introduced as a localisation limiter (Rots 1988; Cervera and Chiumenti 2006). Fracture energy of an element g f is related to the material fracture energy G f and the characteristic length l c :

where V ef is the volume of the finite element.

The fracture energy also depends on the hydration degree (De Schutter and Taerwe 1997):

where δ is a material property that must be fitted from experimental data and G f∞ is the material fracture energy at the end of hydration process.

Ulm and Coussy (1998) propose a chemo-mechanical cross-effect in a context where plasticity is considered. These authors link the chemo-plastic cross-effects to the strength growth and plastic hardening/softening properties of the material when irreversible skeleton evolutions occur.

Thermo-mechanical Coupling

The thermal strain \({\varvec{\upvarepsilon}}_{th}\) is linked to the temperature variation and to the coefficient of thermal expansion CTE which is a function of the hydration degree and of the temperature. Nevertheless, constant value allows to obtain sufficiently accurate prediction (Loukili et al. 2000):

where T0 is the reference temperature [K].

Thermo-chemo-mechanical Coupling

In thermo-chemo-mechanical model, when creep is taken into account, viscous parameter could also be affected by the hydration degree and the temperature. For instance, when rheological modelling is used, the viscosity and the stiffness of the component should be affected (Benboudjema and Torrenti 2008; Briffaut et al. 2012).

It is noteworthy that the properties such as heat capacity and CTE are, for thermo-elastic composites, linked according to some cross-relationships (Chen et al. 2012).

An additional thermo-chemo-mechanical coupling arises on the light of Bažant and collaborators micro-prestress solidification theory (Bažant et al. 1997, 2004). According to these authors, a micro-prestress relaxation within the concrete matrix appears at the microlevel and is related to the hydration reaction. This effect is thermo-activated per se (Bažant et al. 2004).

7.2.3 Validation of the Thermo-Chemo-Mechanical Models on Massive Structures at Early Age

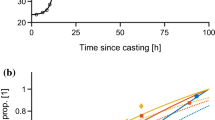

The chemo-thermal problem is often decoupled from the mechanical problem. Several comparisons of model estimations and experimental measurements can be found in the literature (e.g. Craeye et al. 2009; Fairbairn et al. 2004; Faria et al. 2006; Honorio et al. 2014; Ulm and Coussy 1998, 2001). An example of thermal prediction on a massive concrete structure (wall thickness 1.2 m; height 2.4 m) is given in Fig. 7.1.

Temperature prediction on Civaux Wall (thickness 1.2 m; height 2.4 m) during hydration (Briffaut 2010)

7.3 Multifield Models: Single-Fluid Models

This group of multifield models deals with the heat and moisture transport in a porous material accompanied with mechanical response. The material can represent cement paste, mortar, or concrete as a continuum directly defined at macroscale. Even if the model is a multifield model, it is still based on a phenomenological approach. In the view of the model description, thermo refers to heat transport, chemo stands for chemical reactions occurring due to cement hydration, and hygro describes moisture or water vapour transport as a single transported fluid phase, followed with solid mechanical analysis.

In the simplest approach, thermo-(chemo)-hygro models proceed using a staggered approach where temperature and relative humidity fields are computed first. Both fields are then passed to mechanical model which accounts for strain-related quantities, such as thermal strain caused by temperature, drying strain originating from relative humidity, autogenous shrinkage strain due to drop in relative humidity. Several mechanical parameters may depend on the microstructure evolution, such as increasing Young’s modulus or increasing tensile strength (de Shutter 2002). This section shows several examples of material sub-models, their coupling and validations on real structures.

7.3.1 Phenomena Taken into Consideration

Heat transport (thermo-) takes into account heat conduction (diffusion), heat convection and radiation. The transport is often enhanced with heat generated due to mostly exothermic cement hydration, or extended for enthalpy of water evaporation from concrete surface (Černý and Rovnaníková 2002). Modelling heat transport solely in hydrating concrete is used rarely; it finds its place especially in massive concrete structures where moisture gradient could be neglected and thermal gradients present substantial strains (Park et al. 2008).

Chemical phenomena deal mainly with the evolution of hydrating microstructure; i.e., it describes kinetics of hydrating clinker minerals, their hydration, evolution of volume fractions or generated heat. The most elaborated hydration models take into account cement chemistry, cement fineness, temperature, supplementary cementitious materials, and water availability (Thomas et al. 2011). Temperature acceleration often requires coupling with a heat transport model since reaction speed approximately doubles with a 10 °C increase (Černý and Rovnaníková 2002).

Moisture transport describes gas diffusion, effusion and solution diffusion, being driven by a gradient of water vapour pressure (Künzel 1995). The moisture in a porous material can be present in the form of solid, liquid or vaporous form, and it becomes convenient to quantify moisture as a total water content in this single-fluid model. Most hygral models express total water content as a relative humidity, using water vapour sorption isotherm for recalculation (Künzel 1995).

Mechanical part describes the effect of strains on structural behaviour in hydrating concrete. Under standard circumstances, strains contain autogenous shrinkage, temperature expansion/contraction or drying shrinkage. Mechanical models used in the analysis compute time-dependent material behaviour (creep, shrinkage) and time-independent load response (plasticity, damage).

Each part is represented with more or less sophisticated sub-model, which could operate on different scales using a multiscale formulation. For example, concrete can be treated as a heterogeneous material for prediction of hydration heat (Park et al. 2008), and elasticity and strength can be linked to cement hydration (Shutter 2002).

7.3.2 Coupled Formulation and Data Flow

The multiphysical thermo-(chemo)-hygro-mechanical formulation leads at least to three governing equations. Each sub-model contains a state variable to be solved and may depend on other state variable, leading to mutual coupling:

-

Thermo: enthalpy balance equation with unknown temperature field T [K], see Eq. 7.1.

-

Chemo: hydration kinetic equation could be added, with, e.g., unknown degree of hydration α [-], see Eq. 7.2.

-

Hygro: mass balance equation for moisture transport with unknown relative humidity h [-]. Some models use moisture content by mass w\([{\rm kg}_{H_{2}O}/m_{concrete}^{3}]\) instead, being a thermodynamically equivalent quantity related to h by sorption/desorption isotherm.

-

Linear momentum conservation equation (static equilibrium) with unknown displacement field u[m]. Various material constitutive laws (viscoelastic, plastic, damage) define stress/strain relationship between displacement field u and stress σ, see Sect. 7.5.

A monolithic formulation of thermo-(chemo)-hygro-mechanical problem requires that all unknowns are solved in one system of equations, leading generally to large systems. A simpler strategy for approximate solution is often employed, using one-way coupling when outputs from one sub-model are passed to another one, solving sub-models’ set of equations separately. Such staggered solution strategy is the most popular method of decoupling (Baggio et al. 1995; Červenka et al. 2014; Wu et al. 2014).

A characteristic thermo-hygro-mechanical model using a staggered approach is shown in Fig. 7.2. First, heat transport sub-model with a possible hydration sub-model computes temperature field T. Second, moisture transport sub-model evaluates field of relative humidity h which also depends on temperature. Alternatively, if hydration is formulated such as humidity-dependent, the corrector phase may be added to find equilibrium in both sub-models with compatible humidity field. Temperature and relative humidity fields are passed further to time-dependent mechanical sub-model.

Strain decomposition belongs to the key assumptions of the mechanical model. Under small deformations, total strain tensor could be decomposed to (Thelandersson 1987)

where the indices denote elastic, fracture, plastic, creep, thermal, autogenous, and drying shrinkage strain components, respectively. Several strain components may depend on temperature, such as creep, and on humidity, such as drying shrinkage strain (Bažant et al. 2015). T and h are known from the underlying sub-models.

Analysis of Eq. 7.14 shows that strain components could be separated into long-term and short-term contributions. Long-term (time-dependent) mechanical laws define strain evolution in time such as strains ε cr , ε T , ε au , ε d,sh . On the other hand, short-term (time-independent, frozen time) mechanical laws have no notion of time and evaluate ε e , ε f , ε p strains. These strains are related to concrete elasticity, concrete cracking and concrete crushing, where time-dependent evolution of concrete properties is often accounted for inside the constitutive laws (Červenka et al. 2014). Most of short-term constitutive laws are based on stress criteria, such as principal stress/tensile strength or plasticity surface.

7.3.3 Mathematical Formulation and Constitutive Relationships

7.3.3.1 Stand-Alone Heat Transport

Chapter 3 describes in detail the heat balance equation, heat source, boundary conditions with thermal properties of concrete and its components.

7.3.3.2 Stand-Alone Moisture Transport

Moisture transport in concrete has been modelled since the 1930s, and since that time, it has been recognised that concrete moisture diffusivity strongly depends on moisture content (Pickett 1942). Moisture transport model has been formulated by Bažant and Najjar (1972) who quantified nonlinear concrete diffusivity and showed it decreases an order of magnitude when passing from saturated to dry concrete state. The mass balance equation for water vapour transport reads:

where w [kg/m3] is moisture (evaporable water) content, t [s] is time, J w [kg/(m2s)] is moisture flux, and w s [kg/m3] is water source, e.g. water consumption during hydration. Defining concrete moisture capacity C h [kg/m3], one can relate moisture content w with relative humidity h [-] as

Bažant and Najjar (1972) assumed C h being a constant over the whole desorption range, see Fig. 7.3 for three w/cs.

Example of desorption isotherms for structural concrete (Hansen 1986) and linearisation

They arrived to the mass balance equation for moisture transport with h as the unknown:

where J [m/s] is the liquid and vapour diffusion flux density, C [m2/s] is diffusivity depending on h, h s captures humidity decrease due to self-desiccation during hydration, and K is a hygrothermic coefficient [K−1]. Bažant and Najjar proposed S-shape function for diffusivity as:

with characteristic values for mature concrete C1 = 150 × 10−12 − 2200 × 10−12 m2/s, α0 = 0.05 − 0.10 (it is the initial hydration degree), h c = 0.75 − 0.90, N = 6 − 16 (Bažant and Najjar 1972). Figure 7.4 shows such an example for structural concrete. More refined values for structural concrete were proposed (Fib 2010; Abbasnia et al. 2013) as well as simpler approximations (Ayano and Wittman 2002; Xi et al. 1994). Note that the S-shape function gives a nonlinear stationary profile of relative humidity across a concrete member, favouring higher relative humidity.

Example of concrete moisture diffusivity (Bažant and Najjar 1972)

Dirichlet boundary condition for (7.17) prescribes a fixed value of h, while humidity convection on a surface can be conveniently approximated with a humidity transfer coefficient as:

where h ∞ is relative humidity far away from a surface. β p can be approximated for concrete (Kwak et al. 2006):

which gives a value β p = 2.74 × 10−8 m/s for w/c = 0.44, advised also by other authors (Andreasik 1982; Aurich et al. 2009).

7.3.3.3 Heat and Moisture Coupled Transport

Coupling of heat and moisture transport leads generally to a system of two differential balance equations for heat and moisture transport

where H is the total enthalpy [J/m3], q is the heat flux density [W/m2], Q H is the heat source [W/m3], J is the liquid and vapour diffusion flux density [kg/(m2s)], and Q w is the moisture source [kg/(m3s)]. Constitutive equations defining flux densities q and J have been used by several authors (Andreasik 1982; Klemczak 2011), and their general forms yield:

where d ij are diffusion coefficients for heat or moisture transport.

Further, attention is focused to quite popular coupled model for building materials which was pioneered by Künzel (1995). He defined constitutive equations by taking into account separate liquid and moisture transport in a porous material, quantifying dependence of thermal conductivity on moisture content and dependence of water vapour permeability on temperature. Elaboration of Eqs. 7.22–7.25 leads to the final form:

where dH/dT [J/(m3K)] is a heat capacity, λ [W/(mK)] is a thermal conductivity, dQ s /dt [W/m3] is an outflow of heat per unit volume, e.g. hydration heat source, h v [J/kg] is evaporation enthalpy of water, δ p [kg/(msPa)] is water vapour permeability, p sat [Pa] is water vapour saturation pressure depending on temperature, dw/dh [kg/m3] is moisture storage capacity, D φ [kg/(ms)] is liquid conduction coefficient, and w n [kg/m3/s] is non-evaporable (chemically bound) water flux density, i.e. consumed water due to hydration. The moisture diffusivity depends again on relative humidity, in a similar fashion as in Fig. 7.4.

7.3.4 Validations of Single-Fluid Models

7.3.4.1 Validation of a Stand-Alone Moisture Transport Model

A short example of drying concrete cylinder illustrates the Bažant-Najjar’s model for moisture transport (Bažant and Najjar 1972). A concrete cylinder with 6 inches in diameter was exposed at 7 days to environmental humidity with 0.5 (Hanson 1968). The best fit over all datapoints gave parameters from Eq. 7.19 as C1 = 579 × 10−12 m2/s, α0 = 0.002, h c = 0.85, N = 3, better than in the original article (Bažant and Najjar 1972) (Fig. 7.5).

Validation of cylinder drying (Hanson 1968)

7.3.4.2 Validation of Oparno Bridge’s Arch

A reinforced concrete arch bridge, completed in 2010, was erected in the Czech Republic, on a highway between Prague and Dresden. Two arches with a span of 135 m support prestressed bridge decks, as shown in Fig. 7.6.

Emphasis on durability with reduced cracking and application of concrete with OPC 431 kg/m3 led to the need for internal cooling during concrete hardening. The analysed cross section is located above the scaffolding as shown in Fig. 7.6. The left symmetric part has outer dimensions of 3.5 × 2.17 m, the analysis considered first a 2D cross-sectional model (Červenka et al. 2014). The most critical time for the temperature evolution occurred during summer casting with the peak ambient air temperature over 30 °C. CEM I 42.5R was used for concrete C45/55, and its reaction kinetics was well known.

Figure 7.7 shows the temperature T and the moisture fields at 0, 32, 42, 60 h of hydration. It was exercised that water cooling efficiently mitigated hydration heat and maintained the core temperature under 65 °C. Without water cooling, the maximum temperature would exceed 85 °C, which was unacceptable. Figure 7.8 validates temperatures from the thermo-hygral model.

The results of the transport analysis entered mechanical analysis which computed cracks (see Fig. 7.8 for the evolution of temperature). The cracks’ pattern originates from heat dissipation through the surface (Fig. 7.9).

7.3.4.3 Validation of ConCrack’s Restrained Beam

The validation of the coupled hydro-thermo-hydro-mechanical analysis originates from the well-documented RG8 ConCrack experiment (Mazars 2014). Figure 7.10 shows the overall geometry of the RG8 beam with two massive heads on both sides and two restraining steel struts. The central beam part was made of reinforced concrete C50/60, w/c = 0.46, with dimensions of 0.5 × 0.8 × 5.1 m. The benchmark experiment provided material and structural data, internal temperature in three points, and displacements of two points C, D located on the beam axis 2.5 m apart. Maximum temperature in the core attained 53.7 °C at 30 h.

Thermo-hygro-mechanical simulation used Künzel’s heat-moisture model, B3 creep model and fracture-plastic material model in ATENA software (Červenka et al. 2014). Figure 7.10 validates further C-D displacement and displays strain decomposition in the core point. Note that thermal strain with subsequent cooling contributes the most to cracking at early ages.

7.3.4.4 Validation of a Restrained Wall in Oslo

A restrained wall served as a forerunner experiment for Bjørvika submerged tunnel project, built in Oslo between 2005 and 2012. The wall utilised low-heat concrete with a minimal risk of early-age cracking and high watertightness. Figure 7.11 shows two walls built on a raft concrete slab (Ji 2008). The left wall is made from SV-40 concrete containing low-heat OPC I with silica fume at the amount of 424 kg/m3. This left wall is validated using a thermo-chemo-mechanical model implemented in OOFEM (Patzák and Rypl 2012), neglecting moisture transport (Šmilauer et al. 2016).

Field test of a restrained wall in Oslo (Ji 2008)

A semi-adiabatic calorimeter gave temperature evolution on a concrete cube with 247-mm edge. This small-scale test served for calibration of affinity hydration model with perfect result (Leal da Silva et al. 2015).

The restrained concrete wall was cast on older concrete raft slab according to Fig. 7.11. The quarter-simulated wall had reduced dimensions of 0.5 × 2 × 7.5 m due to symmetry conditions. A fixed temperature 20 °C served at the bottom, fluctuating temperature between 8 and 21 °C provided ambient temperature-exposed surfaces. Heat transfer coefficients of 3.75 W/(m2K) acted on vertical surfaces covered with a formwork, the top had 5.75 W/(m2K) with a foil cover, and the bottom had 10 W/(m2K). The formwork removal at 216 h increased the coefficients to 19 W/(m2K). Figure 7.12 shows temperature field with the maximum temperature at 30 h and temperature validation in gage 15 which is located in the middle of the wall, 1.2 m above the bottom.

The mechanical part used B3 creep model for concrete with corresponding parameters, coefficient of thermal expansion of 10−5 K−1. The evolution of autogenous shrinkage, tensile strength and fracture energy was defined accordingly (Fib 2010). The wall’s bottom was supported with horizontal stiffness of 1000 MN/m3 to mimic high stiffness of the underlying old concrete. The first cracks on the surface appeared already in 12 h, but they closed by 60 h due to cooling. Minor cracks formed after 70 h close to the interface with the old concrete, where high shear stress led to tension on inclined planes. At time 260 h, vertical cracks formed through the whole beam section close to gage 15, leading to a drop of principal stress (Fig. 7.13). The widest cracks attained the width of 0.42 mm, and the maximum tensile stress in reinforcement reached 25 MPa (Fig. 7.14). The localisation into crack bands was not indicated in the experiment signalising better tensile strength of concrete than that adopted from Model Code (Fib 2010).

7.4 Multifield Models: Advanced Multiphase Modelling

In this part, the models will be discussed considering more than one fluid inside the pore network of concrete. This class of models regards concrete as a porous material and is based essentially on the mechanics of porous media.

This group of models aims at the simulation of the overall thermo-hygral and mechanical behaviour of the material, considering sometimes also some chemical aspects (e.g. the reactions of hydration and dehydration). To analyse hygro-thermal phenomena in porous media, two different approaches are currently used: phenomenological and mechanistic ones. In phenomenological approaches (e.g. Bažant and Thonguthai 1978, 1979; Bažant and Kaplan 1996), moisture and heat transport are described by diffusive-type differential equations with temperature- and moisture content-dependent coefficients. The model coefficients are usually determined by inverse problem solution, starting from experimental tests results, to obtain the best agreement between theoretical prediction and experimental evidence. An advantage of such a kind of models is that they are very accurate for interpolation but rather poor for extrapolation of the known experimental results. Moreover, various physical phenomena are lumped together and important processes, such as phase changes, are neglected. An example of such a class of models is described in Sect. 7.3.

Mechanistic models (Gawin et al. 2002, 2003, 2006a, b, c, 2008, 2009) are more complicated from the mathematical point of view, and contrary to phenomenological ones, their coefficients have a clear physical meaning. This kind of models is often obtained from microscopic balance equations written for each constituent of the medium, which are then averaged in space by applying special averaging operators.

Several mathematical and numerical models, usually based on extensive laboratory tests, have been developed for the analysis of heat and mass transfer in concrete at early ages and beyond, e.g. Benboudjema and Torrenti (2008), Cervera et al. (1999a, b), Gawin et al. (2006a, b). However, one should remember that every interpretation possesses all limitations and simplifications that are assumed in the mathematical model which the simulation is based on. Thus, for this purpose one should use models considering possibly the whole complexity and mutual interactions of the analysed physical processes. Hence, a proper choice may be models based on mechanics of multiphase porous media, taking into account chemical reactions (e.g. reactions related to hydration, silica-alkali reactions and other reactions due to chemically aggressive environments), phase changes, cracking and thermo-chemical material degradation, as well as their mutual couplings and influence on the hygral, thermal, chemical and mechanical properties of concrete. These physical aspects of the behaviour of concrete treated as a multiphase porous material are described in the following sections.

7.4.1 Concrete as Multiphase Porous Material

Concrete is essentially a mixture of two components: aggregates and paste. The aggregate component is usually sand, gravel or crushed stone. It is mainly responsible for the unit weight, the elastic modulus and the dimensional stability of concrete. The paste component is typically used to bind aggregates in concrete and mortar. It is a porous medium, which is composed of a solid skeleton, produced from the hydration of Portland cement, and pores, which are filled by different fluid phases. The principal solid phases generally present in the hydrated cement paste (hcp) that can be resolved by an electron microscope are the calcium silicate hydrates C-S-H which are very important in determining the properties of the paste such as strength and permeability, and the calcium hydroxide Ca(OH)2 (also called portlandite). The pore structure is relevant for concrete. It contributes to the mechanical strength of concrete, but it also allows the interaction with the external environment which takes place through the connected pores. Besides, it is the container of the liquid water and gas phases (vapour and dry air). Figure 7.15 gives a schematic representation of cement paste seen as a partially saturated medium.

For a given representative elementary volume (REV)Ω, the volume of pores Ω p allows to define the porosity \(n =\Omega _{p} /\Omega\). Furthermore, the degree of saturation of pores with liquid water is introduced as \(S_{w} =\Omega _{w} /\Omega _{p}\). It is an experimentally determined function of the relative humidity RH (obtained through the sorption isotherms). The remaining volume of pores is filled with a gaseous mixture with a gas saturation: \(S_{g} = \left( {1 - S_{w} } \right) =\Omega _{g} /\Omega _{p}\) (Ω w and Ω g are the volumes of the liquid and gas phases, respectively).

The interfacial surface tension of water in a capillary pore leads to a concave meniscus between liquid water and gas phase, as shown in Fig. 7.16. This may give rise to a discontinuity in fluid pressure. The difference between the liquid water pressure p w and the gas pressure (dry air p a + vapour p v ) is called the capillary pressure p c and is a function of the liquid water saturation S w :

Assuming the contact angle γ between liquid phase and solid matrix to be zero, the capillary pressure of water p c can be related to the pore radius r with the Laplace equation:

where σ(T) is the surface tension of water which depends upon temperature and χ is the curvature of the meniscus. Any change in the curvature of meniscus will change the equilibrium between liquid and vapour phases. A relation between the liquid water and the vapour can be obtained by means of Kelvin’s equation considering that liquid is incompressible and the vapour is a perfect gas.

Water can exist in the hydrated cement paste in many forms:

-

capillary and physically adsorbed water; their loss is mainly responsible for the shrinkage of the material while drying;

-

interlayer water; it can be lost only during strong drying, which leads to considerably shrinkage of the C-S-H structure.

All these types of water can evaporate up to 105 °C (at atmospheric pressure and slow rate of heating). Another type of water, which is non-evaporable water, is chemically bound water. It is considered to be an integral part of the structure of various cement hydration products, and it is released when the hydrates decompose on heating. Based on the Feldman–Sereda model (Feldman and Sereda 1968), the different types of water associated with the C-S-H are illustrated in Fig. 7.17.

Probable structure of hydrated silicates (based on Feldman and Sereda 1968)

In fact, there is a third phase in the concrete microstructure, known as transition zone, which represents the interfacial region between the particles of coarse aggregates and the hcp. Concrete has microcracks in the transition zone even before a structure is loaded. This has a great influence on the stiffness of concrete. In the composite material, the transition zone serves as a bridge between the two components: the mortar matrix and the coarse aggregate particles. Therefore, the broken bridges (i.e. voids and microcracks in this zone) would not permit stresses transfer.

For what has been described above, concrete can be treated as a multiphase/multicomponent porous material. Because of this, in the last fifteen years, mechanics of multiphase porous media proved to be a theory enabling an efficient modelling of cement-based materials (Gawin et al. 2003, 2006a, b, 2008, 2009; Pesavento et al. 2008, 2012). It allows for considering the porous and multiphase nature of the materials, their chemical transformations, water phase changes and different behaviour of moisture below and above the critical temperature of water, mutual interactions between the thermal, hygric and degradation processes, as well as several material nonlinearities, especially those due to temperature changes, material cracking and thermo-chemical degradation.

In modelling, it is usually assumed that the material phases are in thermodynamic equilibrium state locally. In this way, their thermodynamic state is described by one common set of state variables and not by separate sets for every component of the material, which allows reducing the number of unknowns in a mathematical model. Thus, there is, for example, one common temperature for the multiphase material and not different temperature values for the skeleton, liquid water, vapour and dry air, etc. When fast hygro-thermal phenomena in a material are analysed (e.g. during a rapid heating and/or drying), the assumption is debatable, but it is almost always used in modelling, giving reasonable results from a physical point of view and in part confirmed by the available experimental results.

Concrete is here considered to be a multiphase medium where the voids of the solid skeleton could be filled with various combinations of liquid and gas phases as in Fig. 7.16. In the specific case, the fluids filling pore space are the moist air (mixture of dry air and vapour), capillary water and physically adsorbed water. The chemically bound water is considered to be part of the solid skeleton until it is released on heating.

Below the critical temperature of water T cr , the liquid phase consists of physically adsorbed water, which is present in the whole range of moisture content, and capillary water, which appears when degree of water saturation S w exceeds the upper limit of the hygroscopic region, S ssp (i.e. below S ssp there is only physically adsorbed water). Above the temperature T cr , the liquid phase consists of the adsorbed water only. In the whole temperature range, the gas phase is a mixture of dry air and water vapour.

Thanks to the mechanics of porous media and the schematisation of the material described above, it is possible to analyse three different classes of phenomena which characterises the behaviour of concrete at early ages and beyond:

-

hygral phenomena,

-

thermal phenomena,

-

mechanical phenomena,

-

chemical processes.

7.4.1.1 Hygral Phenomena

In order to analyse the physical processes taking place in the material under variable conditions in terms of temperature and pressure, we can consider a concrete element heated from the environment.

When temperature increases in a concrete structure (e.g. in a wall), water vapour pressure is continuously increasing in a zone close to the heated surface. This derives principally from the evaporation of water inside the wall, when the temperature reaches and passes the boiling point of water. Vapour pressure is also due to the water that is liberated during the dehydration of cement paste. This increase in the water vapour pressure in the hot region will create a thermodynamic imbalance between the hot and the cold regions. This will entail a diffusion process of the water vapour and of the dry air through the wall and towards the external atmosphere to maintain the equilibrium between liquid and vapour (see Fig. 7.18).

For appropriate prediction of the moisture distribution in a concrete structure, one needs to know the material properties that control the movement of the fluids inside a porous medium. Permeability and diffusivity are the most important properties of the cementitious materials, from this point of view. These are very sensitive to porosity changes or microcracking phenomena. In fact, the increases in permeability and porosity of such materials are currently accepted as providing a reliable indication of their degradation whether it has thermal, mechanical or physicochemical origins. Therefore, in this document these properties and their evolutions will be analysed also in the view of what is described in Chaps. 3 and 4.

7.4.1.2 Thermal Phenomena

Concerning thermal phenomena, it can be stated that in most cases the main mechanism for heat transport is heat conduction. Heat conduction responds to gradients of temperature T. However, additional heat transfer will also be accomplished by advection due to the movement of the three phases: solid, liquid and gas. The latent heat inherent to phase changes may also have significant thermal effects (Gawin et al. 2003), see also Fig. 7.19.

The evolution of the temperature distribution in any structure is governed by the thermal properties of the material, particularly heat capacity and thermal conductivity. In case of concrete, it is difficult to determine these properties because of the numerous phenomena that occur simultaneously within the microstructure of concrete and cannot be separated easily. These phenomena are affected in particular by the evolution of the porosity, by the moisture content, by the type and amount of aggregate, by changes in the chemical composition and by the latent heat consumption generated by certain chemical phenomena. Because of these effects, a unique relation cannot rigorously describe the dependence of concrete properties on temperature.

7.4.1.3 Mechanical Phenomena

When mechanically loaded and simultaneously heated, the overall measured strain of concrete is assumed as an additive combination of different components. These components can be conventionally classified into three families according to the origin of driving mechanisms:

-

Mechanical strains that occur due to an applied mechanical load only. Elastic strain, cracking strain and basic creep strain are main mechanical components.

-

Thermo-hygral strains related to the occurrence of physicochemical processes within the material such as drying, temperature raising, hydration and other chemical reactions. Thermal expansion and shrinkage (both capillary and chemical shrinkage) are the most important components. They are carried out in (mechanically) load-free configurations.

-

Interaction strains are additional components generated when the above-mentioned physicochemical processes occur during a concomitant applied load. In this case, indeed, the overall measured strain differs from the sum of all strains induced by each single mechanism. For instance, additional elastic strain, due to the evolution of Young’s modulus with temperature, is an illustration of interaction strains. Also, drying and creep strains belong to this category. For example, drying creep is shown when the structural element can exchange water with the environment (i.e. shrinkage is taking place) and is loaded at the same time.

7.4.1.4 Chemical Processes

Description of chemical reactions taking place in concrete at early ages (and beyond) and their couplings with the thermo-hygral state of the material (e.g. self-drying) can be found in Chap. 3. Here, one underlines that in the numerical modelling the hydration is often considered as a single chemical reaction; i.e., only the overall process is described through the formulation of a proper evolution equation.

7.4.2 Heat and Mass Transfer

The general approach to heat and mass transfer processes in a partially saturated open porous medium is to start from a set of balance equations governing the time evolution of mass and heat of solid matrix and fluids filling the porous network, taking into account the exchange between the phases and with the surrounding medium. These balance equations are supplemented with an appropriate set of constitutive relationships, which permit to reduce the number of independent state variables that control the physical process under investigation.

The formulation of the mathematical model is based usually on here main approaches:

-

(1)

Mixture theories (Bear 1988);

-

(2)

Volume averaging theories (Whitaker 1980);

-

(3)

Hybrid mixture theories (Hassanizadeh and Gray 1979a, b, 1980).

In the first approach, the governing equations of the model and its constitutive equations are both formulated directly at macroscale. In the second and in the third approach, the governing equations are defined at microscopic level and then upscaled at macrolevel by applying some averaging operators (mass, volume, area operators, mainly). In the case of volume averaging approach also the constitutive relationships are formulated at microscale.

The Hybrid Mixture Theory and the Volume Averaging Theory allow for taking into account both bulk phases and interfaces of the multiphase system, assure that the Second Law of Thermodynamics is satisfied at macrolevel, that no un-wanted dissipations are generated and that the definition of the relevant quantities involved is thermodynamically correct.

Recently, it has been shown that with the combination of Hybrid Mixture Theory and the Thermodynamically Constrained Averaging Theory (TCAT, Gray and Miller 2005), also the satisfaction of the second law of thermodynamics for all constituents at microlevel is guaranteed (Gray et al. 2009).

Starting from this latter approach, in the following section a full set of balance equations is presented. They can be obtained by using the procedure of space averaging of the microscopic balance equations, written for the individual constituents of the medium (i.e. the governing equations at local level). The theoretical framework is based on the works of Lewis and Schrefler (1998), Gray and Schrefler (2007). A detailed description of the procedure can be found in (Pesavento 2000; Gawin et al. 2003, 2006a, b, c, 2008, 2009; Pesavento et al. 2008, 2012).

7.4.2.1 Final Form of the Governing Equations

The hygro-chemo-thermal state of cement-based materials considered as multiphase porous media is described by three primary state variables: the capillary pressure p c , the gas pressure p g and the temperature T, as well as one internal variable describing advancement of the hydration processes, i.e. degree of hydration, α. This choice is of particular importance: the chosen quantities must describe a well-posed initial-boundary value problem, should guarantee a good numerical performance of the solution algorithm and should make their experimental identification simple. A detailed discussion about the choice of state (i.e. primary) variables can be found in Sect. 7.4.3.

The mathematical model describing the material performance consists of three equations: two mass balances (continuity equations of water and dry air), enthalpy (energy) balance and one evolution equation (degree of dehydration). For convenience of the reader, the final form of the model equations, expressed in terms of the primary state variables, is listed below. The full development of the equations is presented in (Gawin et al. 2006a, b).

Mass balance equation of dry air takes into account both the diffusive (described by the term L.30.7) and advective air flow (L.30.8), the variations of the saturation degree of water (L.30.1) and air density (L.30.4), as well as the variations of porosity caused by: hydration process (L.30.5), temperature variation (L.30.2), skeleton density changes due to dehydration (L.30.6) and by skeleton deformations (L.30.3). The mass balance equation has the following form:

in which ρ π is the density of the π-phase (π = s, w, g) and β s is the thermal expansion coefficient of the solid phase, ρ a is the dry air density, α the hydration degree, and \({\mathbf{J}}_{g}^{a}\) the dry air diffusive flux. In the previous equation and in the following ones, vs is the velocity of the solid phase, while vπs is the relative velocity of the π-fluid phase (π = w, g) with respect to the solid skeleton.

Mass balance equation of water species (vapour + liquid water) considers the diffusive (L.31.6) and advective flows of water vapour (L.31.7) and water (L.31.8), the mass sources related to phase changes of vapour (evaporation–condensation, physical adsorption–desorption) (the sum of those mass sources equals to zero) and hydration (R.31.1), and the changes of porosity caused by variation of: temperature (L.31.3), hydration process (L.31.10), variation of skeleton density due to hydration (L.31.9) and deformations of the skeleton (L.31.2), as well as the variations of: water saturation degree (L.31.1) and the densities of vapour (L.31.4) and liquid water (L.31.5). This gives the following equation (Gawin et al. 2006a, b):

where ρ v is the water vapour density, \({\mathbf{J}}_{g}^{v}\) is the water vapour diffusive flux, and \(\dot{m}_{hydr}\) is the water mass source/sink due to hydration process.

In Eq. 7.31, β swg is the thermal expansion coefficient of the multiphase porous medium, defined by:

in which β π is the thermal expansion coefficient of each phase (π = s, w, g).

Enthalpy balance equation of the multiphase medium, accounting for the conductive (L.33.3) and convective (L.33.2) heat flows, the heat effects of phase changes (R.33.1) and dehydration process (R.33.2), and the heat accumulated by the system (L.33.1), can be written as follows:

where \(\widetilde{{\mathbf{q}}}\) is the conductive thermal flux, vw and vg are the velocities of the liquid and gas phase, respectively, and the thermal capacity of the multiphase porous medium (ρC p ) eff and the enthalpies of vaporisation \(\Delta H_{vap}\) and hydration \(\Delta H_{hydr}\) are:

in which \(C_{p}^{\pi }\) is the specific heat of the π-phase (π = s, w, g).

In Eq. 7.33, the vapour mass source is given by (Gawin et al. 2006a, b):

with:

Equation 7.35 considers the advective flow of water (R.35.4), the mass sources related to dehydration (R.35.7) and the changes of porosity caused by: variation of temperature (R.35.3), dehydration process (R.35.6), variation of skeleton density due to dehydration (R.35.5) and deformations of the skeleton (R.35.2), as well as the variations of water saturation degree (R.35.1).

The governing equations in the form described above are now complemented by the constitutive equations.

7.4.2.2 Constitutive Equations

Fluid state equations

The liquid water is considered to be incompressible such that its density depends on the temperature only. The vapour, dry air and the gas mixture are considered to behave as ideal gases, which gives (π = v, a, g):

where p π is the pressure, M π is the molar mass, and R is the universal gas constant. Furthermore, the pressure and density of the gas mixture can be related to the partial pressures and densities of the constituents through the Dalton’s law:

which gives:

Liquid–Vapour Equilibrium

By assuming that the evaporation process occurs without energy dissipation, that is, liquid and vapour water have equal free enthalpies, one can derive the generalised Clausius–Clapeyron equation, which is a relationship between liquid and vapour pressure:

where the capillary pressure at equilibrium

has been introduced for the porous medium and p vs is the saturation vapour pressure, which only depends on temperature.

Mass fluxes

According to the definition of the velocities in the governing equations (7.30) (Gawin et al. 2006a), the mass fluxes can be as follows:

which represents the Darcy’s law for the liquid (π = w) and gaseous (π = g) phases, respectively, and where k is the intrinsic permeability, k rπ is the relative permeability, μ π is the dynamic viscosity, and g is the gravity acceleration.

The mass fluxes related to the diffusion are defined as:

where \({\mathbf{J}}_{g}^{a}\) and \({\mathbf{J}}_{g}^{v}\) are the fluxes of the dry air and water vapour in the gas phases (i.e. the humid air), respectively, and \({\mathbf{D}}_{g}^{a}\) is the diffusion tensor of the dry air.

Conductive Heat Flux

In the energy balance Eq. 7.33, the heat conduction process in the porous medium can be described by Fourier’s law which relates the temperature to the heat flux as follows:

where λ(S w ,T) is the effective thermal conductivity which in general is a function of the temperature and of the degree of saturation with liquid water of the pores.

Sorption–desorption isotherm

Solving the presented equations aims at determining the spatial and temporal distribution of temperature, masses of constituents and corresponding pressures within the porous medium. By introducing the previous constitutive equations, the problem involves, at this stage, as main unknowns (S w , p c , p g , T, m vap ) or alternatively (S w , p v , p a , T, m vap ). This set is reduced by introducing an additional explicit relationship (van Genuchten 1980; Baroghel-Bouny et al. 1999; Pesavento 2000; Gawin et al. 2003):

which is the sorption–desorption isotherm, characterising phenomenologically the microstructure of the porous medium (pore size distribution).

Moreover, it is needed to consider that the microstructure of the cement paste shows important changes during hydration (refinement of the porous network), so it is important to take into account this aspect in the mathematical formulation of the isotherms.

To do this, the classical analytical expression proposed by Van Genuchten (1980) can be slightly modified to take into account the hydration degree (see Fig. 7.20), which is a measure of the hydration extent (see the next subsections for its definition):

(Adapted from Sciumé et al. 2013)

Desorption isotherms: the numbers in the diagram indicate the hydration degree.

where a and b are the classical parameters of the Van Genuchten’s law, and c and Γ i are the newly introduced parameters (Sciumè et al. 2013).

Using this additional relationship, the reduced set of unknowns is then (p c , p g , T, m vap ) where a choice is made here to retain the state variables (p c , p g ) instead of (p v , p a ) or (p w , p a ). Moreover, the set of unknowns can be further reduced. Because of this, mass conservation equations of liquid and vapour defined as in (Schrefler 2002; Gawin et al. 2003) have been summed to eliminate the evaporation source term m vap and thus obtain the mass balance equation for the water species (that means liquid water plus water vapour), Eq. 7.31.

7.4.3 Key Points for Modelling Cement-Based Materials as Multiphase Porous Media

Dealing with cement-based materials as multiphase porous media introduces some physical and theoretical difficulties, which should be overcome to be able to formulate a mathematical model giving reliable results for the material. These key points are discussed in the following subsections.

Choice of state variables

A proper choice of state variables for description of the multiphase porous materials is of particular importance. From a practical point of view, the physical quantities used should be possibly easy to measure during experiments, and from a theoretical point of view, they should uniquely describe the thermodynamic state of the medium. They should also assure a good numerical performance of the computer code based on the resulting mathematical model. As already mentioned previously, the necessary number of state variables may be significantly reduced if the existence of local thermodynamic equilibrium at each point of the medium is assumed (Schrefler 2002). In such a case, the physical state of different phases of water can be described by the same variable.

Having in mind all the aforementioned remarks, the state variables chosen for the presented model will be now briefly discussed. Use of temperature, which is the same for all constituents of the medium because of the assumption about the local thermodynamic equilibrium state, and use of solid skeleton displacement vector are rather obvious; thus, it needs no further explanation. As a hygrometric state variable, various physical quantities which are thermodynamically equivalent may be used, e.g. moisture content by volume or by mass, liquid water saturation degree, vapour pressure, relative humidity or capillary pressure. Analysing materials in the whole range of temperatures, one must remember that at temperatures higher than the critical point of water (i.e. 374.15 °C or 647.3 K) there is no capillary (or free) water present in the material pores, and there exists only the gas phase of water, i.e. vapour. Then, very different moisture contents may be encountered at the same moment in a cement-based material, ranging from full saturation with liquid water (e.g. in some nuclear vessels or in so-called moisture clog zone in a heated concrete, see England and Khoylou 1995, or in concrete at early ages), up to almost completely dry material. Moreover, some quantities (e.g. saturation or moisture content) which can be chosen as primary variables are not continuous at interfaces between different materials.

For these reasons, apparently it is not possible to use, in a direct way, one single variable for the whole range of moisture contents. However, it is possible to use a single variable that has a different meaning depending on the state. The moisture state variable selected in the model is capillary pressure (Gawin et al. 2002, 2003, 2006a) that was shown to be a thermodynamic potential of the physically adsorbed water and, with an appropriate interpretation, can be also used for description of water at pressures higher than the atmospheric one. The capillary pressure has been shown to assure good numerical performance of the computer code (Gawin et al. 2002, 2003, 2006a, b, c) and is very convenient for analysis of stress state in concrete, because there is a clear relation between pressures and stresses (Gray et al. 2009).

Therefore, as already shown, the chosen primary state variables of the presented model are the volume averaged values of: gas pressure, p g , capillary pressure, p c , temperature, T, and displacement vector of the solid matrix, u.

For temperatures lower than the critical point of water, T < T cr , and for capillary saturation range, S w > S ssp (T) (S ssp is not only the upper limit of the hygroscopic moisture range as mentioned earlier, but also the lower limit of the capillary one), the capillary pressure is defined according to Eq. 7.41.

For all other situations, and in particular for T ≥ T cr or where condition S w < S ssp is fulfilled (there is no capillary water in the pores), the capillary pressure substitutes—only formally—the water potential Ψ c , defined as:

where M w is the molar mass of water, R is the universal gas constant, and fvs is the fugacity of water vapour in thermodynamic equilibrium with a saturated film of physically adsorbed water (Gawin et al. 2002). For physically adsorbed water at lower temperatures (S w < S ssp and T < T cr ), the fugacity fvs should be substituted in the definition of the potential Ψ c , by the saturated vapour pressure p vs . Having in mind Kelvin’s equation, valid for the equilibrium state of capillary water with water vapour above the curved interface (meniscus) we can notice that in the situations where Eq. 7.47 is valid, the capillary pressure may be treated formally as the water potential multiplied by the density of the liquid water, according to the relation:

Thanks to this similarity, it is possible to “formally” use the capillary pressure during computations even in the low moisture content range, where the capillary water is not present in the pores and capillary pressure has no physical meaning.

7.4.4 Constitutive Laws for Crack Evolution

In the following, some peculiar aspects of the mechanical behaviour of the material strictly related to its porous nature are illustrated, taking into account that most of the phenomena/processes involved are described in Chap. 4, e.g. creep and microfracturing.

Furthermore, a more detailed discussion about the formulation of proper constitutive relationships for describing damage mechanics and visco-plasticity can be found in Sect. 7.5.

7.4.4.1 Momentum Balance

For completeness, the momentum balance equation is recalled here. Introducing the Cauchy stress second-order tensor σtotal (x, t) at any point x in the studied domain Ω, and at time t, and the applied forces per unit volume vector f (x, t), the momentum balance equations can be written, in a quasi-static case, i.e. neglecting the inertia effects, as:

These equations are complemented by the boundary conditions, which are either the prescription of displacements on some part of the boundary of the studied domain \(\Gamma _{u} = \partial\Omega _{u}\):

or the prescription of surface forces on the complementary part \(\Gamma _{u}^{q} = \partial\Omega _{u}^{q}\) the boundary:

where n denotes the outward normal vector.

7.4.4.2 Effective Stress Principle

Here, cement-based materials are treated as multiphase porous media; hence, for analysing the stress state and the deformation of the material, it is necessary to consider not only the action of an external load, but also the pressure exerted on the skeleton by fluids present in its voids. Hence, the total stress tensor σtotal acting in a point of the porous medium may be split into the effective stress ε s τ s , which accounts for stress effects due to changes in porosity, spatial variation of porosity and the deformations of the solid matrix, and a part accounting for the solid phase pressure exerted by the pore fluids (Pesavento et al. 2008; Gray et al. 2009)

where I is the second-order unit tensor, b H is the Biot coefficient, and p s is some measure of solid pressure acting in the system, i.e. the normal force exerted on the solid surface of the pores by the surrounding fluids.

Taking into account several simplifications (Pesavento et al. 2008; Gray et al. 2009), the relationship describing the effective stress principle can be written in the following manner:

where \(x_{s}^{ws}\) is the fraction of skeleton area in contact with the water and P s is an alternative measure of the “solid pressure”. The effective stress principle in the form of Eq. 7.54 allows to consider not only the capillary effects but also the disjoining pressure (Gawin et al. 2004; Pesavento et al. 2008; Gray et al. 2009).

7.4.4.3 Strain Decomposition

As already mentioned in Sect. 7.4.1.3, different strain components can be identified in a maturing element of concrete, both at early ages or at long term. Accordingly, the overall measured strain tensor ε may conventionally be split as following (Gawin et al 2004):

where ε el is the elastic strain, ε f is the cracking induced strain, ε T is the thermal strain, ε chem is the chemical strain (i.e. due to the hydration), ε cr is the creep strain which can be split into two parts: basic creep and drying creep.

In the following, some of these strain components will be analysed and discussed in view of a specific formulation of a mechanical constitutive model, also taking into account what has been presented in Chaps. 3 and 4.

7.4.4.4 An Example of a Mechanical Constitutive Model for Concrete

Concrete is modelled as a visco-elastic damageable material, whose mechanical properties depend on the hydration degree (De Schutter and Taerwe 1996). The relationship between apparent stresses σtotal, effective stresses \({\tilde{\varvec{\sigma}}}\) (in the sense of damage mechanics), damage D, elastic stiffness matrix E, elastic strains ε el , creep strains ε cr , shrinkage strains ε sh (caused by the fluid pressures as shortly described in Sect. 7.4.4.2), thermal strains- ε T and total strains ε reads:

Young’s modulus E, the tensile strength f t and the Poisson’s ratio ν vary due to hydration according to the equations proposed by De Schutter and Taerwe (1996) and De Schutter (2002).

Creep strain is computed using a rheological model made of a Kelvin-Voigt chain and two dashpots combined in serial way (see Fig. 7.21). The first two cells (aging Kelvin-Voigt chain and one single dashpot) are used to compute the basic creep, and the last cell (single dashpot) is dedicated to the drying creep strain. The scalar model in Fig. 7.21 is extended in 3D through the definition of a creep Poisson’s ratio (Sciumè et al. 2013).

The thermal strain ε th is related to the temperature variation:

in which β s is the thermal dilatation coefficient (kept constant) and 1 is the unit tensor.

To compute shrinkage, the elastic and the viscous parts have to be considered:

taking into account the solid pressure (see Eqs. 7.53–7.54), the constitutive model to compute the elastic shrinkage reads

where K T is the bulk modulus of the solid skeleton and b H is the Biot modulus. The viscous part of shrinkage strain, \(\dot{\varvec{\varepsilon}}_{sh}^{visc}\), is computed using the creep rheological model (represented in Fig. 7.21) in which the stress is now \(\dot{\varvec{\varepsilon}}_{sh}^{visc}\).

Damage D is linked to the elastic equivalent tensile strain, \(\hat{\varepsilon }\). To take into account the coupling between creep and cracking, the expression of \(\hat{\varepsilon }\) proposed by Mazars (1986) is modified by Mazzotti and Savoia (2003) and reads:

where β is a coefficient calibrated experimentally, which allows for considering that often cracking may occur even at lower tensile stress than the expected tensile strength. The damage criterion is given by:

where κ0(α) is the tensile strain threshold, which is computed from the evolution of tensile strength, and the Young’s modulus (De Schutter and Taerwe 1996). Considering the equivalent tensile strain, \(\hat{\varepsilon }\), and with respect to criterion Eq. 7.62 D is given by the equations proposed by Benboudjema and Torrenti (2008); the adopted damage model allows taking into account also evolution of fracture energy during hydration (De Schutter and Taerwe 1997).

To overcome the mesh dependency related to the local damage formulation, the model is regularised in tension with the introduction of a characteristic length related to the size of each finite element (Rots 1988; Cervera and Chiumenti 2006).

7.4.5 Boundary Conditions

With the momentum balance equation, the set of governing equations is complete, Eqs. 7.30, 7.31, 7.33 and 7.50. For the model closure, we need the initial and boundary conditions. The initial conditions (ICs) specify the values of primary state variables at time instant t = 0 in the whole analysed domain Ω and on its boundary Γ, (Γ = Γπ \(\Gamma _{\pi } \cup\Gamma _{\pi }^{q}\); π = g, c, t, u):

The boundary conditions (BCs) describe the values of the primary state variables at time instants t > 0 (Dirichlet’s BCs) on the boundary Γ π :

or heat and mass exchange, and mechanical equilibrium condition on the boundary \(\Gamma _{\pi }^{q}\) (the BCs of Cauchy’s type or the mixed BCs):

where n is the unit normal vector, pointing towards the surrounding gas, qa, qv, qw and qT are respectively the imposed fluxes of dry air, vapour, liquid water and the imposed heat flux, and \(\bar{\varvec{\sigma}}\) is the imposed traction, ρv∞ and \(T_{\infty }\) are the mass concentration of water vapour and the temperature in the far field of undisturbed gas phase, e is emissivity of the interface, and σ o the Stefan–Boltzmann constant, while α c and β c are convective heat and mass exchange coefficients.

The boundary conditions, with only imposed fluxes given, are called Neumann’s BCs. The purely convective boundary conditions for heat and moisture exchange are also called Robin’s BCs.

7.4.6 Numerical Formulation

The set of nonlinear partial differential equations that controls the processes of mass and heat transport (Eqs. 7.30 and 7.31) plus the one Eq. 7.33 is usually discretised in the space domain by means of Finite Element Method. Also Equation 7.50 is usually discretised in the space domain by means of Finite Element Method.

According to the FEM procedure, the governing equations are written by using the weighted residual method, and the standard Galerkin procedure is usually adopted. Time discretisation is achieved by means of the standard Finite Difference Method. A non-symmetric, nonlinear system is finally obtained, and linearisation, usually by means of the Newton–Raphson method, is required (Zienkiewicz and Taylor 2000).

The final set of discretised, linearised governing equations is solved as a monolithic system or, alternatively, by means of a staggered coupled procedure (see Gawin et al. 2003, 2006a, b, 2008; Sciumè et al. 2013).

Starting from the previous initial-boundary value problem, the variational formulation can be obtained. Then, the standard Galerkin discretisation, replacing the weighting functions with the shape functions, is adopted. For the state variables, we can write:

The resulting system of equations can be written in the following concise discretised matrix form:

with

where the nonlinear matrix coefficients C ij (xj), K ij (x j ) and (x j ) are defined in detail in Pesavento (2000), Gawin et al. (2003, 2006a, b).

The time discretisation is accomplished through a fully implicit finite difference scheme (backward difference):

where superscript i (i = g, c, t, u) denotes the state variable, n is the time step number, and Δt is the time step length.

The equation set (7.69) can be linearised according to the following scheme:

where k is the iteration index and \(\frac{{\partial {\varvec{\Psi}}_{i} }}{{\partial {\mathbf{x}}}}\) is Jacobian matrix.