Abstract

Unreinforced masonry infilled-RC frames are widely used in many developing countries. Even though the influence of the masonry walls on the behavior of structure was recognized from the experience of past earthquake disasters, but many practicing engineers still assume that the infill walls are non-structural walls due to incomplete knowledge of the behavior of such structures. In this paper, an experimental study of two ½ scale specimens with different RC frames and masonry infill walls were tested using a static cyclic loading protocol. The main parameter was the influence of changing the RC frame strength on masonry infill seismic capacity. The results showed that shear strength and deformation capacity of masonry infill greatly improved by increasing the strength of boundary frame. The investigation of strength, ductility and initial stiffness based on experimental results and comparative study with existing methods showed large variations between several methods commonly used to assess the seismic capacity of masonry infill.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Many of the reinforced concrete buildings in the world and particularly in developing countries use masonry infill as partition walls. The influence of masonry on the structural behavior was recognized from the experience of earthquake disasters and experiments by several researchers (i.e., Paulay and Priestley 1992). In general, masonry infill increases the frame strength, which is considered as a beneficial point. On the other hand, masonry infill exerts reaction forces on the RC frame causing additional moment and shear forces, which results in unexpected failure modes FEMA 306 (1998). In addition, the masonry infill greatly increases the frame stiffness that might changes the seismic demand due to significant reduction in natural period of the building. Despite of these distinctive characteristics, many practicing engineers still assume that the walls are non-structural elements due to incomplete knowledge concerning RC frames with masonry infill behavior and complexity in evaluating their failure modes. The seismic performance of masonry infill depends on several parameters such as the confinement effect, masonry type, aspect ratio, mortar strength, etc. Among these factors, the strength of boundary RC frame is a crucial parameter that not only governs the behavior and failure modes of the RC frame but also the masonry infill strength and failure mode, as shown in previous experiments conducted by Mehrabi et al. (1996). However, modelling and estimating strength of masonry infill commonly considers only the material characteristics of masonry and ignoring confining influences of boundary frame.

In brief, the influence of boundary frame strength and its influence on the seismic capacity infill and the overall frame have not been clearly identified. Thus, the objective of this paper is as follows: First, the experimental investigation of RC frame with unreinforced masonry infill is carried out with in-plane cyclic loading tests, where the only varying parameter is the lateral strength of surrounding frames. Second, the investigation of strength, ductility and stiffness based on experimental results and comparative study.

2 Experimental Program

2.1 Test Specimens

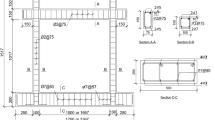

Two half-scaled specimens with different RC frames, having same unreinforced masonry infills, are designed. The main variance parameter for test specimens is the ratio of the boundary frame to masonry infill lateral strength defined as β index, as shown in Eq. (1). Specimens are named WF (weak frame) and SF (strong frame) with β of 0.4 and 1.5, respectively.

Where V f is the boundary frame lateral strength which is calculated to be the ultimate flexural capacity of a bare frame with plastic hinges at top and bottom of columns. The V inf is the masonry infill lateral strength calculated based on Eq. (2) which is a simplified empirical equation showing good agreement with experimental database studied by the author (Al-Washali et al. 2017)

where fm is the compressive strength of masonry prism, t inf is the infill thickness, l inf is the infill length.

The specimen dimensions and details are shown in Fig. 1. Both specimens are identical except for the column size and reinforcement, as shown in Fig. 1. The beams were designed to be stronger and stiff enough to simulate a typical case of a weak column and strong beam system observed in existing buildings of old designs.

2.2 Material Properties

The infill panels are constructed using 60 × 100 × 210 mm solid bricks conventionally used in Japan. A professional mason built the infill, after the frame construction, where its thickness is 100 mm and mortar head and bed joint thickness is about 10 mm. Tables 1 and 2 show the material properties based on material tests where the values represent the mean values of three samples. The masonry prism strength is the masonry prism compressive strength tested according to ASTM C1314 (2011). The material tests were conducted at the same time with the experimental loading for each specimen individually.

2.3 Test Setup and Instrumentation

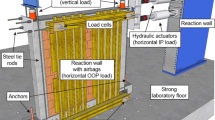

The loading system are shown schematically in Fig. 2. The vertical load was applied on RC columns by two vertical hydraulic jacks and was maintained to be 200 kN on each column. Two pantograph, attached with the vertical jacks, restricted any torsional and out-of-plane displacement. Two horizontal jacks, applying together an incremental cyclic loading, were attached at the beam level and were controlled by a drift angle of R%, defined as the ratio of lateral story deformation to the story height measured at the middle depth of the beam (h = 1600 mm). The lateral loading program consisted of 2 cycles for each peak drift angle of 0.05, 0.1, 0.2, 0.4, 0.6, 0.8, 1, 1.5 and 2%.

2.4 Experimental Results

The lateral load versus story drift angle of both specimens are shown in Figs. 3 and 4. Cracks and failure patterns after final drift cycle of 2.0% are shown in Fig. 5.

For Specimen WF:

very small cracks on mortar bed joint and diagonal cracks on bricks near loading corner of infill panel, less than 0.3 mm width, started at early stages of loading just when the drift angle was 0.05%. At drift angles of 0.2 and 0.4%, the longitudinal reinforcement in the tensile column (windward column) yielded at the upper critical section and above its mid-height, respectively, forming failure mechanism similar to a short column, as illustrated in Fig. 6a. Just after reaching the maximum lateral strength, there was a sudden drop of lateral load bearing capacity with extensive cracking and spalling of bricks. After the drift of 1%, the main failure mechanism from diagonal cracks changed to sliding cracks, and clear sliding movement at the mid-height of the infill was noticed. At drift story of 2% in the negative cycle, the concrete around the reinforcement of top compression column spalled-off and main bars buckled.

For Specimen SF:

Cracking of infill panel also started at the peak of the first loading cycle, which was relatively similar to the crack width observed in specimen WF at this stage. At drift angles between 0.6 and 0.7%, both columns yielded at the locations shown in Fig. 6b. As it reached its maximum strength, the lateral load gradually degraded (contrarily to the sudden degradation of strength in previous specimen WF) with the drift angle increase until the drift angle of 1.5%, where there was a slight drop of the lateral load, after the horizontal sliding between bricks clearly increased. At the drift angle of 2%, the loading stopped as planned, and the masonry infill damage at this point was much greater than observed in the previous specimen WF (see Fig. 5). In spite that columns had many cracks, there was no extensive damage or spalling of concrete cover.

3 Discussion of Experimental Results

3.1 Lateral Strength

The maximum lateral load contributed by the masonry infill (V inf ) is calculated by deducting the bare frame lateral strength (V f ) from the maximum lateral load of the overall structure (V max), as shown in Eq. (3):

where Mu is the minimum plastic moment of the column or beam calculated by AIJ provision (2010) and H is the clear height of column (taken here as infill height).

Table 3 shows the experimental shear strength of masonry infills in both specimens, which is the shear force (V inf ) divided by the infill cross-sectional area. Even though both infill panels are made by exactly same material and have similar prism compression strength, specimen SF has the shear capacity of 1.48 N/mm2 which is about 1.5 times the shear strength in specimen WF (0.93 N/mm2).

3.1.1 Comparison of Lateral Strength with Previous Literature

The in-plane capacity of the masonry infill depends mainly on the type of failure mechanism. The failure mechanism types and identification are different between building standards or researchers. The most recognized failure modes are diagonal compression failure and sliding shear failure modes. The failure mechanism observed in experimental results as mentioned earlier, is a mixture of both: compression and sliding failure. In this study, Table 4 shows the comparison of the infill strength with following methods: Diagonal compression and sliding equation by FEMA 306 (1996), Liauw and Kwan (1985) method, Flanagan and Bennett (1999) method, Paulay and Priestley (1992) method for sliding strength and simplified equation presented by author in previous study (Al-Washali et al. 2017).

As shown in Table 4, Liauw and Kwan (1985) method and simplified method of Flanagan and Bennett (1999) greatly overestimate the strength. The methods proposed to calculate sliding capacity by FEMA 306 (1996), and Paulay and Priestley (1992) greatly underestimate the infill strength. Diagonal compression strength by FEMA 306 (1996) and the simplified equation by AlWashali et al. (2017) showed relatively good estimation for specimen WF, but it underestimated that of Specimen SF. This underestimation is considered due to the ignorance of the confinement effect of the strong boundary frame.

3.2 Stiffness

The initial stiffness K0 of infilled frame is taken as the slope between the origin point of the load-displacement curve and the point with the major visible crack in the masonry infill and the RC frame, which was determined as the story drift of 0.1%.

Table 3 shows the comparison between the initial stiffness of overall frames and that of bare frames. Herein, the initial stiffness of bare frame is calculated based on its elastic gross concrete section. The masonry infill greatly increased the initial stiffness up to about 7.1 times that of bare frame in specimen WF. Therefore, in the seismic design, ignoring the contribution of masonry infill to stiffness and natural period of building may cause non-conservative design practice since buildings with lower natural period have greater seismic forces.

The most well recognized method for calculating the infill stiffness is using the equivalent diagonal compression strut, which has the same elasticity and thickness with the infill panel. Paulay and Priestley (1992) recommended using the effective width of strut, where W ef and d m is the diagonal length of infill panel in Eq. (5).

Table 5 shows the comparison between experimental and numerical initial stiffness based on the strut width recommended by FEMA 306 (1996) and Paulay and Priestley (1992). The Strut width calculated by FEMA 306 (1996) underestimates the initial stiffness by about 1.9 and 1.08 for specimen WF and specimen SF, respectively. On the other hand, Eq. (3) recommended by Paulay and Priestley (1992) agrees pretty well with specimen WF by the ratio of 0.94, but overestimated specimen SF by the ratio of 1.36. Based on these results, make a proposed assumption of the strut width W ef to be 0.2 d m (d m : diagonal length) gives relatively good estimation for the initial stiffness.

3.3 Deformation Capacity

In this study, a backbone curve for RC frames with masonry infills is suggested as shown in Fig. 7. R crack , R max and R u are the representative drift angles at the cracking, the maximum strength and the strength degradation point, respectively, where the strength degradation point is set to be 80% of the maximum strength.

The simplified backbone curves for specimens WF and SF are shown in Fig. 8. R crack and R max is estimated to be 0.1 and 0.8% for both specimens. For R u , it was found to be 0.9 and 1.6% for specimen WF and SF, respectively. Therefore, it can be concluded that the influence of surrounding frame strength on R crack and R max was slight, but greatly alters the strength degradation slope and R u . The smooth decrease of strength and improvement of ductility for specimen SF are considered to be due to the confinement by the stronger surrounding frame, which reduces the inelastic deformation of masonry infill.

4 Conclusions

Experimental results to investigate the seismic capacity of unreinforced masonry infilled-RC structure was presented. Based on this study results, the following conclusions can be drawn:

-

(a)

Increasing the ratio of the frame to masonry infill lateral strength named β, greatly improved the infill strength. However, most methods proposed to estimate the infill lateral strength, by previous researchers, underestimate or ignore the influence of β.

-

(b)

The initial stiffness of both frames were almost similar until story drift angle of 0.1%, which is considered the major cracking point. After drift story of 0.1%, the stiffness of both specimens degraded rapidly. Assuming diagonal strut width to be 0.2 times diagonal length gives relatively good estimation of initial stiffness in both specimens.

-

(c)

Drift angles R crack (cracking point) and R max (story drift at maximum strength) was not much influenced by parameter of boundary frame strength. However, R u drift (degradation point of 80% of maximum strength) was greatly improved by the confinement of stronger columns.

References

Al-Washali H, Suzuki Y, Maeda M (2017) Seismic evaluation of reinforced concrete buildings with masonry infill wall. In: The 16th world conference of earthquake engineering, Chile

American Society of Testing and Materials (ASTM) (2011) Standard test method for compressive strength of masonry prisms. ASTM C1314, West Conshohocken, PA

Architectural Institute of Japan (AIJ) (2010) AIJ standard for structural calculation of reinforced concrete structures

FEMA 306 (1998) Evaluation of earthquake damaged concrete and masonry wall buildings—basic procedures manual. Report No. FEMA 306 (ATC-43 Project)

Flanagan RD, Bennett RM (1999) In-plane behavior of structural clay tile infilled frames. J Struct Eng 125(6):590–599

Liauw TC, Kwan KH (1985) Unified plastic analysis for infilled frames. J Struct Eng 111(7):1427–1448

Mehrabi AB, Shing PB, Schuller M, Noland J (1996) Experimental evaluation of masonry-infilled RC frames. J Struct Eng ASCE 122(3)

Paulay T, Priestley MJN (1992) Seismic design of reinforced concrete and masonry buildings. Wiley, New Jersey

Acknowledgements

The study presented in this article was sponsored by the Science and Technology Research Partnership for Sustainable Development (SATREPS) project (Bangladesh, 2015 project headed by Professor Nakano Yoshiaki, University of Tokyo) and it’s gratefully acknowledged. Opinions expressed in this article are those of the authors, and do not necessarily represent those of the SATREPS project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Al-Washali, H., Jin, K., Maeda, M. (2018). Study of Seismic Capacity of Masonry Infilled Reinforced Concrete Frames Considering the Influence of Frame Strength. In: Vacareanu, R., Ionescu, C. (eds) Seismic Hazard and Risk Assessment. Springer Natural Hazards. Springer, Cham. https://doi.org/10.1007/978-3-319-74724-8_32

Download citation

DOI: https://doi.org/10.1007/978-3-319-74724-8_32

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-74723-1

Online ISBN: 978-3-319-74724-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)