Abstract

Site-specific application of pesticides has so far focused mainly on herbicides. The purpose of precision farming technologies in relation to herbicide use is to reduce herbicide cost and environmental impact from spraying, but at the same time to achieve acceptable weed control. Another purpose is to increase the spraying capacity, to reduce the number of sprayer refills, and finally to minimize time spent on weed monitoring. In this chapter the relevance and profitability of four precision herbicide application technologies, two weed detection technologies and a low dose decision support system (DSS) is analysed. With a low dose herbicide, cost can be reduced by 20–50%. It requires, however, proper monitoring of weeds, which can be a time-consuming task that again requires that the farmer is able to identify the dominant weed species. The current development of high-speed camera and software systems can help to detect and map individual weeds, and some systems have proved to be cost effective for certain weeds.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

Research into site-specific application of pesticides has focused mainly on herbicides, although some research has been carried out within the area of disease detection and variable application of fungicides (Pedersen 2003). Preventive and site-specific treatment with insecticides is complex because insects are difficult to monitor in the field. In contrast, weeds tend to have a patchy distribution in the field and some diseases also typically occur in the same areas in the field with specific micro climatic conditions, although weed distribution cannot be considered invariable. On the other hand, farmers are aware of the potential savings of chemicals through precision spraying , although they may also have reservations about the potential benefits because of technical difficulties and lack of decision support systems when using site-specific technologies (e.g. Pedersen et al. 2004).

Examples of precision technologies relevant for site-specific herbicide application are:

-

High precision cell and micro spraying

-

Boom section and nozzle control

-

Boom section control to reduce overlap

-

Direct injection

-

Real time weed detection with high speed cameras

-

DSS systems for low dose herbicide use recommendations

The purpose of these technologies is to determine what, where and when to control weeds efficiently preferably at a low cost . Farmers’ incentives for using these technologies are to (1) increase the spraying capacity and efficiency (more acreage covered per time unit, reduce number of sprayer refills), (2) minimize time-consuming activities like manual weed monitoring and (3) have access to decision support on herbicide choice and dose to reduce herbicide cost without loss of efficacy on the weeds. The incentive of the society to support the adoption of these technologies is to reduce the unintended environmental impact from spraying and at the same time maintain effective and competitive food production.

Site-specific application is about where to spray, while variable-dose application is about how much to spray. Knowledge of weed distribution in time and space is essential for both approaches. The main difference is that understanding weed response to herbicides, crop and weed competition and weed population dynamic is a prerequisite for variable-dose application.

High precision spraying of individual weed plants with broad-spectrum herbicides like glyphosate is the ultimate example of site-specific herbicide application. The system must distinguish between crop and weed. What isn’t a crop is a weed plant, or everything green outside the crop row or GPS located crop plant is a weed. Site-specific solutions focus mostly on technology and engineering and less on biology and agronomy. Depending on the weed species and density, site-specific spraying could ideally reduce herbicide use by a factor of 100 or 1000 compared to a full dose spraying of the whole field.

Assuming a density of 300 weeds per m2, Mathiassen et al. (2016) found that glyphosate doses applied at an early growth stage could be reduced from currently recommended glyphosate dose of 560–720 g ha−1 to 2.5–32.0 g ha−1 by using a Drop on Demand inkjet printer application system (DOD). Thus, specifically targeting the weed plants with the DOD system or similar devices may lead to significant reductions (factor 20–300) in herbicide field rates.

Weed detection , planning and spraying are the three dimensions in chemical weed control with variable-doses, and in this chapter we will evaluate the development and economic potential of some of the technologies above listed relating to these three dimensions. This evaluation will first of all be based on studies in the literature. In the case of automated weed detection and DSS systems for low dose herbicide recommendations we will, however, give an example of a potential 40% herbicide use reduction with a low dose DSS system that has not been exploited because of a lack of weed monitoring capacity, lack of economic incentive and a too great efficiency of pre-emergence herbicides. Profitability of investments in precision technology and future herbicide cost reductions will be calculated with a 4% discount rate and a 5 year lifetime of the investment, resulting in a capitalization factor of 4.6.

4.2 Application Technologies

4.2.1 Site-Specific Application and Variable-Dose

Variable-dose application can be achieved in many ways, from varying the application by turning on and off the sprayer while driving, adjustment of speed and tank pressure or by advanced high precision control of individual spray boom sections and nozzles (see e.g. Grisso et al. 2011). Conventional boom sprayers are usually mounted with a water tank with chemicals that are mixed with water. Usually 2–3 different chemicals are mixed at a time for each treatment. To conduct variable-dose application, some sprayers are equipped with devices to regulate the amount of chemicals simultaneously with the spraying. A GPS receiver and a tractor computer can be installed to regulate and carry out variable-dose application of pesticides. Conventional boom sprayers can also be divided into different sections to enable site-specific application along the boom. One example is described in the Sensispray development project, in which a 27-m length boom sprayer with seven sections was equipped with sensors to control spray volume per boom section, thereby having a length of about 3–4.5 m for each section (van de Zande et al. 2009).

4.2.2 Micro and “Cell” Spraying

As stated in Franco et al. (2017) the ultimate site-specific weed management strategy would be to apply one drop of herbicide per weed plant. This strategy was tested by Lund et al. (2006), with micro spray tubes that open and close individually with solenoid valves. In a field with 100 weed plants per m2 and 20 tubes per 100 mm, it was possible to obtain 84% weed control with as little as 27 g of glyphosate ha−1. Lund et al. (2008) has shown that with vision based spraying techniques one can treat areas of 100 × 100 mm individually (named ‘cell spraying’ by the authors). This approach could potentially reduce pesticide use by 50–70% compared to conventional boom spraying.

Compared to a full dose of conventional herbicides the micro spraying system offers a potential saving of 10–20 € ha−1 and the cell spraying system offers a saving of 5–14 € ha−1 (Franco et al. 2017). The main question is, however, whether the cost reductions can justify the investment in a system with the required remote controlled micro tubes, image or video devices for real-time detection of weeds or alternatively high precision weed maps in combination with RTK-GPS technology etc. On the other hand, the capacity of high precision systems is another challenge for their commercialization. Despite the low capacity, a small micro sprayer with a 1-m boom could be sufficient if the system is unmanned and RTK GPS guided. High precision micro tube systems are not yet available and affordable for farmers, and the video guided cell spraying systems are commercially available for row crops only (Franco et al. 2017).

4.2.3 Boom Section and Nozzle Control

A boom sprayer (Fig. 4.1) is usually supposed to apply exactly the same dose in its full length. There are, however, at lot of methods to control and adjust the dose and to open and close parts of the sprayer to produce a variable-dose or site-specific pesticide application.

The boom consists of sections (H) with several nozzles per section (I) that, on advanced sprayers, can be opened or closed by the operator or automatically according to a plan and a GPS position (F). The dose is determined by nozzle size, spray pressure and driving speed. With more advanced sprayers, the dose is controlled with a separate pump (M) that can be controlled by a computer that activates specific boom sections and nozzles (F). Using boom section and nozzle control units together with a crop scanner or GPS with RTK positioning, it is possible to vary the dose and do site-specific spraying applications. The challenge is, however, to identify and exploit the most profitable opportunities.

In cereal crops, high precision and reduced herbicide consumption could be achieved with traditional boom sprayers equipped with remote control of the individual nozzles or boom sections. With a traditional boom sprayer with between 2 and 4 nozzles per m boom spraying precision with remote control of every nozzle would be 250–500 mm. If we consider a weed density that varies from 25 to 200 plants per m2 and a spraying precision (wideness of the sprayed area per nozzle) between 250 and 500 mm, then it would almost certainly result in full spraying of the field. A precision of 30–100 mm would be needed to reduce the pesticide use significantly (Franco et al. 2017). However, in that case, the cost savings of reduced herbicide would probably not be sufficient to pay for video devices, weed mapping , RTK-GPS equipment and remote controlled solenoid valves for individual nozzles or boom sections. To make a precision of 250–500 mm spraying profitable, a very patchy variation in the weed density and distribution would be required, such as for thistles and couch grass, which tend to grow in colonies, patches, spots and clusters.

A study by Franco et al. (2017) showed that the profitability of increased precision in glyphosate spraying of thistle patches in cereals decreases significantly with an increasing precision. The marginal value (v) of an extra unit was found to be a power function of length of the boom (l), the length of the controlled units, either nozzles or boom sections, (w) and the cost of a full herbicide dose (H), such that:

The α and β values depend on the size and distribution of the weed patches. Below is an example with a 40-m boom, many and scattered patches of weeds (α=0.56 and β=-0.73) and few and concentrated patches of weeds (α=0.29 and β=−1.01). Figure 4.2 shows how the reduction in marginal costs decreases rapidly with an increased precision from an increased number of remotely controlled units (RC).

Marginal cost reduction (€ha−1)per an extra controlled unit (Franco et al. 2017)

Figure 4.2 shows that the first step from broadcast spraying to a simple (1 unit) open and closing of the whole sprayer reduces the herbicide cost by 6–9 € ha−1. With an extra control unit, the 40-m sprayer is divided into two 20-m sections, reducing the herbicide cost by an extra 2–3 € ha−1. With 5–6 units corresponding to 5–10-m sections the extra herbicide cost reduction is marginal. In this case a five- or 10-m precision is cost efficient, but this knowledge could be derived only by using a very detailed weed map that shows the thistle patches.

4.2.4 Boom Section Control and Reduced Overlap

Reducing overlap when spraying is a potential source for cost reduction. A rough estimate of a 5% reduction in pesticide use could be achieved by reducing overlapping when spraying along field edges (Petersen et al. 2017). It takes automated boom section control, GPS and software to realize this reduction. Most new sprayers are manufactured with electronic on/off switches for individual boom sections. To control the individual sections computer and software such as Rinex AS 7500 (by Leica Geosystems), GPSswitch (by Amazone), Swath Control Pro (by John Deere), AgGPS FieldManager (by Trimble) etc. are needed.

According to a Danish sprayer retailer (Mertz, 2017), 80% of all new sprayers are equipped with automated section control. Computer software and installation may sum to around 3000 €. If not already installed, a GPS unit is available at a cost of around 2000 €.

Given a 4% discount rate and a 5-year lifetime, a 3000 € investment in sprayer section control or GPS equipment must produce a yearly cost reduction that is equivalent to 649 €.

Table 4.1 provides the pesticide costs for Danish arable crops 2015 and the required area (ha) needed to make a cost reduction of pesticides.

Table 4.1 shows that a 5% pesticide cost reduction on 90 ha of winter wheat is sufficient to balance the 3000€ automated section control investment. A GPS is a requirement for automated section control and RTK may be a prerequisite for even finer control of individual nozzles (1 cm accuracy). If a 5% reduction in pesticide costs alone is needed to pay for these additional investments, an extra area of 60–388 ha of winter wheat or an extra area of 76–495 ha of a standard crop rotation is needed to achieve a breakeven of these investments.

Overlapping, however, does not just occur at field edges, but also between the spray tramlines. This kind of overlapping is possibly responsible for another 5% overlap (Petersen et al. 2017). However, to reduce this overlap, opening and closing of full sections is not enough. In this case, individual control of nozzles is needed to reduce the overlap. A solution with an additional control of the outermost two nozzles and the next two nozzles is available. It also takes a higher precision to exploit this overlap. If this is not installed, the investment in RTK may increase by approximately 13,000 € per unit. Instead of very precise spraying, it may be more cost efficient to invest in more precise seeding . The RTK may still be needed but the investments in the control of individual nozzles are saved and seeds (and fertilizers) can be saved.

The benefits of auto guidance and site-specific management are further described in an IPNI guideline (IPNI 2017).

4.2.5 Direct Injection

Farmers’ spraying strategies usually require the mixing of herbicides into an exact amount of water prior to spraying. Hence, they need to estimate the precise amount for each herbicide required for a particular field to avoid having to empty the tank after each operation in the field and potentially waste herbicide. This approach conflicts with the idea of precision spraying (Pedersen 2003). It is therefore vital that site-specific spraying systems (1) separate herbicides and water and (2) use efficiently the knowledge of weed susceptibility to herbicides and weed distribution for estimating the optimum herbicide mixture.

Injection sprayers provide these attributes as the various undiluted herbicides are kept in a container, separated from the water tank. Water is pumped through the nozzles and herbicides are injected into the water (Walter and Heisel 2001). Commercial injection systems usually have around five containers for different herbicides (Fig. 4.3). With the injection system there are no leftovers after spraying and there are no herbicides in the water tank. An injection system can, in principle, be mounted on any hydraulic sprayer. Although several injection systems are commercially available they need further improvement in regard to reaction time and cleaning of containers and costs are still very high (Anglund and Ayers 2003).

4.3 Planning and Low Dose DSS

4.3.1 CPO-Weeds

Weed detection , planning and spraying are the three dimensions in variable-dose chemical weed control . As indicated above, different spraying and application methods and strategies have different implications. The subsequent question related to the planning is which herbicides and doses to apply?

In most fields, the farmers face the challenge to control weed flora consisting of several weed species rather than just one or two species, and he/she can choose among a wide range of herbicides. Most herbicides control more than just one weed species, some weed species must be controlled more effectively than others. The effect of two or more herbicides is to some extent additive, but some herbicides cannot be applied together, and efficacy of the herbicides often depends on climatic conditions, crop density and weed growth stage. For that reason the optimal herbicide recommendation will often be a combination of smaller than recommended doses of different herbicides. A few days later, the optimal recipe may be different, e.g. due to weeds growing larger or changing climatic conditions. Many active ingredients of herbicides are sold as premixes, but often farmers are able to make up their own herbicide mixes, tailor-made for their specific weed problems and these mixtures are often cheaper. The problem is, however, to find the optimal ‘recipe’. Here a decision support system like CPO-weed is relevant.

Crop Protection Online-Weeds (CPO-Weeds) is a decision support system for chemical weed control developed in Denmark and subsequently adjusted to conditions in other countries. Several trade names have been used including PC Plant Protection (Denmark), Crop Protection Online (Denmark), VIPS-Ugras (Norway), CPOWeeds (Spain) and DSSHerbicide (Poland, Germany). In each country, the CPO-versions are adjusted according to herbicide availability and parameterized accordingly, whereas the algorithms and calculations follow the same concept (Sønderskov et al. 2016).

Herbicide recommendations in CPO-Weeds are calculated through a three step process following the user’s input on weed species as well as growth stage and density of each weed species in the field. The first and second step is to determine the need for control and the level of control required for each of the reported weed species, respectively. The threshold for each weed species depends on the crop, crop growth stage and crop density as well as the growth stage and density of the weed species. The most competitive and problematic weed species will be controlled effectively, whereas less competitive weed species at low densities are either tolerated or partly controlled. The assessment of need for control and required level of control is based solely on expert knowledge. The third step of the decision process is the selection of herbicide solutions including herbicide mixtures that can provide the required control of each of the weed species. Potential herbicide tank mixtures combining up to four different herbicides at specified doses are identified using the additive dose model (ADM). Finally, herbicide solutions are ranked according to either the costs, the TFI or the pesticide load using a linear programming (LP) method. The concept behind the three steps is explained in more detail in Sønderskov et al. (2016).

The development of CPO-Weeds was initiated following a political decision in Denmark to reduce pesticide use, and CPO-Weeds and field experiments in various countries have revealed the potential for reduction of between 20 and 40% compared to labelled rates or standard recommendations (Sønderskov et al. 2016).

Even though CPO-Weeds are considered robust and trustworthy by both farmers and advisors, the number of farmers subscribing to the system is relatively small. A survey (Jørgensen et al. 2007) revealed that even though most farmers expressed considerable confidence in the recommendations provided by CPO-Weeds, the DSS did not fit into their way of decision-making. The advisory service in Denmark, however, makes use of CPO-Weeds, and as many farmers receive their advice on herbicide use from the advisors, they are indirectly end users benefitting from CPO-Weeds. The survey also revealed that a limiting factor for an increased uptake of CPO -Weeds is the need for field monitoring of weeds, which can be a time-consuming task and requires high level of knowledge on weed identification that farmers often do not possess. Another limiting factor was a general lack of economic incentives for reducing herbicide doses.

4.3.2 CPO-Weed Scenarios

In CPO-Weeds all weeds are reported by name, density and growth stage, but some weeds are more important than others, in the sense that their presence will prompt higher doses or the need for more expensive herbicide. In theory, there is an unlimited number of weed scenarios in CPO-weed, but 24 typical weed scenarios related to five crops are available for batch calculations and demonstration purpose.

To give an impression of the functionality and input needed for CPO-weed recommendations and to stress that intelligent and cost effective weed control requires knowledge, we will go into some detail with the 24 weed scenarios and the corresponding CPO-weed herbicide recommendations. For simplicity, however, density thresholds and growth stages are not shown or discussed, but all weed species are treated either as pre-emergence or early post-emergence under ‘normal’ weather conditions.

Table 4.2 shows 23 key weed species found in the 24 weed scenarios and Table 4.3 shows the 24 weed scenarios and the required level of control for each of the key weed species.

4.3.3 Field Inspection and Weed Sampling

Weed scouting takes time and requires expertise on weed species identification at early growth stages.

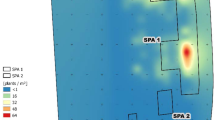

The CPO-weed holds a manual for weed scouting. It is recommends that five representative samples (50 × 50 cm) are taken per field to calculate the average weed density . In the case of large patches with a significantly higher weed density, it is recommended the field is divided into sections. It can be difficult to make a perfect inspection as is illustrated in Fig. 4.4, which shows a detailed registration in 10 × 10 m grids of three weed species.

Weed density for six weed species based on 10 m × 10 m grid. CAPBP = Capsella bursa-pastoris/Shepherd’s Purse, VIOAR = Viola arvensis/Field pansy, STEME = Stellaria media/Common Starwort (Origin M. Walter/T. Heisel, DJF) (http://pvo.planteinfo.dk/cp/documents/InfoMarkInsp.pdf)

International Plant Nutrition Institute (IPNI) (2017, point 15) has some nice thoughts and comments about the requirements and complexity of weed scouting:

The concept behind scouting for weeds is to provide accurate and timely information needed to make intelligent, cost effective decisions. Moreover, scouting is a key component in the design of effective weed management strategies that help to manage risks by providing information needed to optimize the correct timing of herbicides and accurately monitor weed management successes and failures (Wallace 1994).

This requires one to carefully think about the dynamic and flexible weed management systems to meet challenging demands. Adaptive sampling strategies (rather than fixed strategies such as grid sampling) are flexible and build on previous information and experience (…) However, we must recognize that here is no single scouting strategy that is best in all situations and that each strategy has advantages and disadvantages (IPNI 2017 point 15).

4.3.4 Herbicides

Herbicides may consist of more than one active ingredient, because herbicide products sold to farmers are formulated to optimize their use. The same product may be sold under different trade names and brands in different countries. The CPO-weed calculates recommendations in various units (e.g. litres, kgs, grams and tablets) using local product names. To communicate the CPO recommendations internationally, the product recommendations are transformed to gram active ingredients and the so-called treatment frequency index (TFI). A TFI of 1 is equivalent to one standard dose per ha.

Table 4.4 shows CPO-weed (batch version) recommendations for the 24 weed scenarios.

Table 4.5 shows herbicide use (TFI) and costs (€ha−1) in winter wheat reported by Danish farmers 2015 and calculated with CPO-weed (batch version).

CPO-weed recommendations reduce herbicide use and cost by around 45% and 52% respectively compared to the average herbicide use and estimated costs reported by Danish farmers 2015. It requires, however, 2–3 weed scoutings and planning with a DSS to obtain the potential 33 € ha−1 saving.

Some pre-emergence herbicides, like pendimethalin and prosulfocarb , control a broad spectrum of weeds. These herbicides are applied before the actual weed composition in a field can be determined, and selection of the dose will depend on knowledge of previous years’ weed infestations. For post-emergence herbicides, on the other hand, more information will be available and generally the potential for reductions in herbicide use is greater. Herbicide reductions are, however, only possible with due consideration of the actual weed flora combined with information on the competitiveness of the crop and climatic factors such as temperature or drought. This information is pivotal because of the very variable susceptibility of weed species to the various herbicides (Sønderskov et al. 2016).

4.4 Weed Detection

4.4.1 Real-Time Weed Scouting

Weed scouting is a prerequisite for using low dose DSS systems, but it takes time and skills to do it manually. Automated, real-time weed scouting and spraying systems that integrate a video devise or camera with weed detection software and algorithms for variable-dose application could solve the scouting and planning problem (Fig. 4.5).

It has now become possible to scout for weeds with high-speed cameras like H-sensor (AgriCon, Figs. 4.6 and 4.7) and DAT (Dimensions Agri Technologies AS, Figs. 4.5 and 4.8) mounted on the sprayer. According to Dimensions Agri Technologies AS (DAT) their DAT–sensor will reduce the use of herbicides by an average of 50% — by enabling simultaneous detection and spraying of weeds.

The DAT-Sensor Software image analysis software estimates coverage of broadleaved weeds and cereals in near-ground RGB images. The algorithm identifies weeds by shape, size, colour and texture. Dicot weeds highlighted in red (Fig. 4.5).

4.4.2 Weed Mapping with a Camera Mounted on an ATV

As already mentioned, weed detection (monitoring and scouting), planning and spraying are the three dimensions in chemical weed control with variable doses. Weed detection, planning and spraying, however, do not have to take place simultaneously. A weed map produced with automated weed scouting could be a cost efficient alternative to manual weed scouting, and an ideal basis for planning with a DSS like CPO-weed.

The Danish RoboWeedSupport project (Laursen et al. 2017) intends to bridge the gap between the potential herbicide savings using a decision support system like CPO-weed and the required weed monitoring. Their project has examined the cost of performing data collection based on a camera system with three cameras on a 24-m boom mounted on an all-terrain vehicle (ATV) able to drive and record data at up to 50 km h−1 with an image quality sufficient for identifying newly emerged grass weeds. Their economic estimates are based on approximately 100 hectares recorded at three different locations in Denmark. With an average image density of 99 images per hectare, the ATV had a capacity of 28 ha per hour, which is estimated to cost 6.6 € ha−1. Alternatively, relying on a boom mounted solution on a tractor, while applying fungicides or fertilizer before the last follow up herbicide application , it was estimated that a cost of 2.4 € per ha is obtainable under equal conditions.

4.5 Conclusion

Site-specific application of pesticides has so far focused mainly on herbicides. The purpose of precision farm ing technologies in relation to herbicide use is to reduce herbicide cost and environmental impact from spraying, but at the same time to maintain a satisfactory level of weed control . Another purpose is to increase spraying capacity, to reduce the number of sprayer refills and to minimize time spent on weed monitoring. In this chapter, the relevance and profitability of four precision herbicide application technologies, two weed detection technologies and a low dose decision support system (DSS) are analysed. Crop Protection Online-weeds (CPO-Weed) is a decision support system for chemical weed control developed in Denmark and subsequently adjusted to the conditions in several other countries. With lower than recommended herbicide doses provided by CPO-weed, herbicide cost can be reduced by 20–50%. It requires, however, a proper monitoring of weeds, which can be a time-consuming task that, furthermore, requires that the farmer is able to identify the weed species correctly. The current development of high-speed camera and software systems can take over the task of detecting and mapping weeds. However, at the moment no system is available that is able to distinguish and classify all common weed species correctly.

References

Anglund EA, Ayers PD (2003) Field evaluation of response times for a variable rate (pressurebased and injection) liquid chemical applicator. Appl Eng Agric 19:273–282

DST (2016) Economics of agricultural activities 2015. Statistics Denmark (DST), December 2016. http://www.dst.dk/Site/Dst/Udgivelser/GetPubFile.aspx?id=20725&sid=oko2017

Franco C, Pedersen SM, Papaharalampos H, Ørum JE (2017) The value of precision for imagebased decision support in weed management. Precis Agric 18(3):366–382

Grisso R, Alley M, Thomason W, Holshouser D, Roberson GT (2011) Precision farming tools: variablerate application. Resource document: Virginia Cooperative Extention. https://pubs.ext.vt.edu/442/442505/442505_PDF.pdf

IPNI (2017) Site-specific management guideline. International Plant Nutrition Institute, USA (IPNI). http://www.ipni.net/ssmg

Jørgensen LN, Noe E, Langvad AM, Jensen J, Ørum JE, Rydahl P (2007) Decision support systems: barriers and farmers’ need for support. Bull OEPP/EPPO Bull 37(2):374–377

Laursen MS, Jørgensen RN, Dyrmann M, Poulsen R (2017) RoboWeedSupport: sub millimeter weed image acquisition in cereal crops with speeds up till 50 Km/h. Paper accepted for 19th international conference on precision agriculture. Kyoto, Japan April 27–28, 2017

Lund I, Søgaard HT, Graglia E (2006) Microspraying with one drop per weed plant. Proceedings of Plantekongres 2006, Arhus, Denmark, January 10–11, 2006

Lund I, Christensen S, Jensen LA, Jensen PK, Olsen HJ, Søgaard HT et al (2008) Cellesprøjtning af ukrudt i majs. Pesticide research document no. 123 2008. Ministry of Environment of Denmark. http://www2.mst.dk/udgiv/publikationer/2008/9788770528511/9788770528511/pdf/9788770528528.pdf

Mathiassen SK, Lund I, Kudsk P (2016) Adjuvants for single droplet application of glyphosate proceedings ISAA 2016. https://www.researchgate.net/publication/304497893_ADJUVANTS_FOR_SINGLE_DROPLET_APPLICATION_OF_GLYPHOSATE

Mertz (2017) Personal communication. Leif Trane, Johannes Mertz A/S, Denmark. leif.trane@mertz.dk. +45 2343 5259

MST (2017) Bekæmpelsesmiddelstatistik 2015. Behandlingshyppighed og pesticidbelastning, baseret på salgsstatistik og sprøjtejournaldata. Orientering fra Miljøstyrelsen (MST) nr. 17. Januar 2017. http://www2.mst.dk/Udgiv/publikationer/2017/01/978-87-93529-63-2.pdf

Pedersen SM (2003) Precision farming—technology assessment of site specific input application in cereals. DTU: IPL

Pedersen SM, Fountas S, Blackmore S, Gylling M, Pedersen JL (2004) Adoption and perspectives of precision farming in Denmark. Acta Agric Scand B Soil Plant Sci 54:2–6

Petersen PH, Nørremark M, Jensen PK, Thierry AM, Hørfarter R, Jensen JE, Elbæk J, Lyngvig HS (2017) Udkast til notat om intelligent sprøjteudstyr/præcisionssprøjtning i jordbruget, der kan medvirke til minimering af brugen af pesticider. Memorandum draft on the potential of intelligent spraying equipment and precision spraying to minimize pesticide use in Danish agriculture (Draft January 31st 2017). SEGES P/S and Aarhus University (in prep for a final MST report)

Sønderskov M, Rydahl P, Bøjer OM, Jensen JE, Kudsk P (2016) Chapter 13: Crop protection online—weeds: a case study for agricultural decision support systems. In: Papathanasiou J et al (eds) RealWorld decision support systems, page 303320. Integrated series in information systems 37. Springer International Publishing, Switzerland 2016. https://doi.org/10.1007/9783319439167_13. http://springerlink.bibliotecabuap.elogim.com/chapter/10.1007%2F9783319439167_13

van de Zande JC, Achten VT, Kempenaar C, Michielsen JM, van der Schans D, de Boer J et al (2009) SensiSpray: sitespecific precise dosing of pesticides by online sensing. In: van Henten EJ, Goense D, Lokhorst C (eds) Precision agriculture’09. Wageningen Academic Publishers, Wageningen, pp 785–792

Wallace A (1994) High-precision agriculture is an excellent tool for conservation of natural resources. Commun Soil Sci Plant Anal 25:45–49

Walter AM, Heisel T (2001) Precision application of herbicides using injection sprayer systems. In: Grenier G, Blackmore S (eds) Proceedings of the 3rd European conference on precision agriculture. Agro, Montpellier, pp 611–616

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Ørum, J.E., Kudsk, P., Jensen, P.K. (2017). Economics of Site-Specific and Variable-Dose Herbicide Application. In: Pedersen, S., Lind, K. (eds) Precision Agriculture: Technology and Economic Perspectives. Progress in Precision Agriculture. Springer, Cham. https://doi.org/10.1007/978-3-319-68715-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-319-68715-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68713-1

Online ISBN: 978-3-319-68715-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)