Abstract

Base-metal smelters typically produce a large quantity of waste rocks, tailings and slags that are usually stored on site. In the early 1980s, metallurgical slags were considered chemically inert because metals are usually embedded in glass and silicate phases. Recently, several studies showed that metals leaching from slag dumps can lead to severe contamination of soils and water bodies. Predicting their environmental impact requires an understanding of the minerals at microscopic scales as well as the mineral-water interactions, i.e. the chemical and biological weathering techniques applied, the associated weathering rates and mechanisms.

Both lead and zinc slags are chemically and mineralogically diverse, depending on the smelting history (i.e. the mother ores), the smelting technologies and the flux minerals. The Pb and Zn concentration in slags indicates the recovery efficiency of the smelting technologies, the presence of S indicates if the mother ores are rich in either sulphides or carbonates, and the proportion of Ca, Fe and Si reflects the type of flux minerals added to decrease the viscosity of the melt. Similarly, the presence of the pyroxene group indicates a relatively slow cooling regime whereas the presence of amorphous glass indicates the rapid cooling of the slags. The presence of Fe oxides such as goethite or hematite on the top layer of the slags indicates the slag dump being weathered for some time.

Chemical alteration studies of slags focus on different experimental conditions such as the contact time, type of leachant, agitation rate, pH, liquid to solid (L/S) ratios, and particle size of the sample. The chemical protocol tests are batch tests, quick and simple to carry out with reproducible results, and they can give an idea of the leaching behaviour of metals under different leaching scenarios such as landfill, acid rain or soil dumping. On the other hand, there are only a few studies for biological alteration of slags in spite of the fact that the presence of microbial activity increases the dissolution rate of slags. Therefore, combining and enhancing the performance of both chemical and biological leaching reveals the great potential of metal mining and recovery of base metals from Pb and Zn metallurgical slags.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Metallurgical slags

- Alteration

- Weathering

- Heavy metals mobilisation

- Leaching

- Secondary precipitates formation

5.1 Metallurgical Slags

Metallurgical slags are predominantly vitreous by-products derived from the smelting of metallic ores and usually consist of metal silicates and oxides, and in some cases also sulphides and native metals (Hudson-Edwards et al. 2011). Slags are the wastes whose grade is too low for further treatment and which are of too low economic value in spite of being generated in great amounts by the mining industry. They are either dumped in the vicinity of the mining site and accumulated for long periods of time or reused as fill, ballast, abrasive and aggregate in concrete and cement production, and in road construction (Ettler and Johan 2003; Lottermoser 2002; Potysz et al. 2015). Ferrous slags from iron and steel industries are reused in construction (Saikia et al. 2012), whereas reuse of non-ferrous slags from lead, zinc, copper, nickel, and chromium industries is limited till now (Barna et al. 2004).

Slags derived from the processing and smelting of lead (Pb) and zinc (Zn) are defined as ‘hazardous waste’ by the European Waste Catalogue (Commission Decision 94/3/EC), but also as a ‘commercial substance’ by the European Inventory of Existing Commercial Substances (EINECS) adopted by Council Regulation no. 793/93 (Ettler et al. 2001, 2003). Many studies have already shown that Pb and Zn smelting activities are large contributors of anthropogenic Pb and Zn pollution in many environmental compartments: atmospheric heavy metal emissions and deposition (Van Alphen 1999), surface and ground water (Parsons et al. 2001), kitchen garden soil (Douay et al. 2008), woody habitat soil (Douay et al. 2009), agricultural topsoil (Pelfrene et al. 2011), river bank soil (Sivry et al. 2010), river and stream sediment (Audry et al. 2004; Vdovic et al. 2006; Yang et al. 2010) and seepage at slag dumps (Navarro et al. 2008) with a high potential of groundwater contamination, and evidence of high bio-accessibility of lead (Pb) and zinc (Zn) in the human body (Bosso and Enzweiler 2008; Ettler et al. 2012).

5.2 Composition of Slags

5.2.1 Chemical Composition

Slags are very heterogeneous materials where the chemical composition can be related to the smelting history, the constituents of the mother ores, the flux minerals (limestone, iron stone, ferrous silicate, silica) and fuels (coke, coal, firewood, charcoal) used (Lottermoser 2002). The chemical composition of lead and zinc slags from different countries is given in Table 5.1, whereas those generated during different time periods is given in Table 5.2.

Both Pb and Zn slags are chemically diverse materials where the lesser or higher concentration of Pb and Zn in the slags indicates the efficiencies of the smelting and processing technologies used in that particular country (Table 5.1). The enrichment of Ca, Fe and Si reflects the type of flux minerals added during smelting in order to lower the melting temperature as well as to modify the chemical properties, particularly to decrease the viscosity of the slags (Lottermoser 2002). In addition, the presence of Sulphur (S) in the slag indicates that the primary ores can be rich in sulphides rather than carbonates and oxides. The metals in slag melts can also be associated with the silicate phases, metallic droplets, and the leftover S in the form of sulphides (PbS, ZnS).

The heterogeneous Pb and Zn slags can be further compared to historical slags and car battery processing slags (Table 5.2). Historical slags are most likely subjected to weathering over time, thereby studying of these slags in comparison to Pb/Zn slags as well as modern slags can give a very useful insight into the behavior of metal release over time. Historical slags originating from France and Sweden, generated around the 3–4th and sixteenth century respectively, show the highest content of Si and Ca, with relative deficiency in Fe content and the absence of Pb and Zn (Table 5.2). Slags produced during the Middle Ages in the Czech Republic are deficient in Ca compared to other slags, as CaCO3 additives were introduced only later. On the other hand, the slags from secondary car batteries processing units and those from Australia, generated in the early twentieth century, or modern slags have a similar chemical composition of Si, Ca, and Fe, with relatively little amounts of Pb and Zn present. Thus, all historical slags produced before the nineteenth century have a similar chemical composition regardless of their native countries. The same goes for modern slags generated after the nineteenth century regardless of their native countries, as well as primary or secondary production sources.

5.2.2 Mineral Phases

Slags may possess many previously unknown mineral phases and their mineral species status cannot be identified because they are formed in a geologically modified environment under anthropogenic influences (Nickel 1995). As a result of quenching, slags can be mineralogically diverse, enriched in glass and crystalline phases. During smelting, both Pb and Zn ores are mixed with flux minerals and fuels on the charge floor inside the blast furnace. Oxygen is constantly provided by a blast of compressed air and the temperature inside the furnace reaches over 1500 °C. A lighter silicate melt accumulates over the liquid metal melt present at the bottom of the furnace. The above silicate melt is then drained off and cooled down under a massive shower of cold water.

As given in Table 5.3, Pb slags originating from France are mainly composed of non-silicate minerals such as the spinel group (magnesiochromite, franklinite, wüstite and magnetite) and other oxides (mixture of Zn and Fe oxides) as they contain only one silicate mineral, the melilite. In contrast, slags from Brazil and the Czech Republic show the presence of more silicate minerals: the olivine (fayalite and kirschsteinite), pyroxene (hedenbergite) and melilite (unidentified phase and willemite) group. Non-silicates have not been observed in the slags from the Czech Republic but these contain only substantial amounts of relict ores (galena, sphalerite, würzite and pyrrhotite).

As given in Table 5.4, Zn slags generated from France include only one silicate mineral (hardystonite), non-silicates group of spinel (wüstite), other oxides (mixture of Fe, Zn and Al), and traces of relict ores (wurzite and sphalerite). More diversity of silicates and oxides has been observed in slags from the USA and Poland. Slags from the USA contain the olivine (fayalite and olivine), pyroxene (clinoferrosilite and hedenbergite), feldspars (K-feldspar, hyalophane and labradorite), melilite (hardystonite) and alumino silicate (willemite, mullite, quartz and sillimanite) groups. Those from Poland contain olivine (kirschsteinite and olivine), pyroxene (wollastonite), feldspars (K-feldspar, hyalophane and leucite), melilite (melilite) and alumino silicate (willemite) groups.

5.2.3 Petrography

They are lustrous darker grey to brown in colour. The crystalline particles are 100 to 1000 μm in size across the slags (Puziewicz et al. 2007). The formation of mineral phases bears a direct relationship with the bulk composition of the melt and with the cooling regime, which controls the crystallization sequence in the slag. Slags can be classified into several assemblages based on their chemical and mineralogical composition.

-

Assemblage I: Dark gray slag located outer cast of slag pile containing spinel, olivine, clinopyroxene and glass,

-

Assemblage II: Dark gray slag located central of slag pile containing spinel, melilite, olivine and glass,

-

Assemblage III: Red slag located on top of slag pile containing feldspar, quartz, mullite, glass, spinel, and secondary goethite, hematite and gypsum,

-

Assemblage IV: Green slag composed mainly of willemite, hardystonite, gahnite and zincite.

The assemblage I is from the outer cast of slag dumped where the presence of the pyroxene group indicates the relatively slow cooling regime. Assemblage II is located in the central part of the slag dump where the absence of pyroxene indicates the rapid cooling (quenching effect) of the slag (Ettler et al. 2001). Being on the top of the slag pile, assemblage III is in constant exposure to water and the atmosphere, leading to the formation of secondary Fe oxides such as goethite, hematite and gypsum. A very different mineralogy of slag can be expected in the case of assemblage IV, which is enriched in Zn bearing phases such as willemite, hardystonite, gahnite and zincite (Piatak and Seal 2010).

Among all these assemblages, Zn and Pb are redistributed among several crystalline phases (silicates, oxides, sulfide or metallic phases) and residual glass. Zn, being dissolved in the silicate melt, is partially incorporated into the structures of oxides (spinels), silicates (clinopyroxene, melilite or olivine), sulphides (sphalerite or würtzite) and glass (Fig. 5.1). In contrast, Pb behaves as an incompatible element and is concentrated in residual glass and in Pb-rich sulfide or metallic inclusions trapped in the glass (Ettler et al. 2000, 2001).

Back-scattered electron images of Pb slags from France and the Czech Republic (a and b) and Zn slags from United States and Poland (c and d). (a): wustite (Wu), and metallic lead (Pb) embedded into the glass matrix (Gl) (van Hullebusch et al., unpublished picture). (b): prismatic crystals of melilite (Mel) including spinels (Spl), accompanied by long needles of olivine (Ol) and galena inclusions (Gn) inside glass (Gl) (Ettler et al. 2001). (c): skeletal plagioclase (Pl), spinels (Spl), Cu–Fe-sulfide blebs (Cu-Fe-S) with pyrrhotite (Po) in cracks, and dendritic pyroxene (Pyx) in matrix (Piatak and Seal 2010). (d): spinel (Spl), anhedral melilite (Mel) and zincite (Znc) embedded in matrix glass (Puziewicz et al. 2007)

5.2.4 Phase Composition

The olivine group is the most abundant crystalline phase found in slags which crystallised either early or as the last silicate filling spaces between the earlier-crystallised silicates (Ettler et al. 2001). It is present in different shapes such as a herring-bone pattern, in a thin-narrow-long strip laths pattern of several hundred of micrometers in length or very fine dendrites from several micrometers to tens of micrometers in size (Fig. 5.1). Olivine-group minerals are major Zn concentrators where the amount of Zn can be 1.98–6.28% in weight for Pb slags (Table 5.5) and 1.29% in weight for Zn slags (Table 5.6).

The clinopyroxene group is a QUAD pyroxene, i.e. a solid solution of Mg2[Si2O6] – Fe2[Si2O6] – CaMg[Si2O6] – CaFe[Si2O6] (Puziewicz et al. 2007). It can be found in both Pb and Zn slags, where the amount of Zn can vary from 0.1 to 4.8% in weight (Tables 5.5 and 5.6).

Feldspars are found only in Zn slags, indicating a high alkali content which originates from the limestone present in the primary ores. Primary crystallisation in the slag melt led to the formation of skeletal feldspars with spinifex texture (Piatak and Seal 2010). Silica was removed from the melt during the formation, leading to the absence of residual glass.

The melilite group is found abundantly in the Zn and Pb slags, either as irregular prisms with a star shape, as dendrites or as phenocrysts from 10–100 of micrometers in size. They are members of the åkermanite (Ca2Mg[Si2O7]), the gehlenite (Ca2Al2[SiO7]) solid solution series and their ferrous/ferric analogues (Puziewicz et al. 2007). They are main concentrators of Zn and Pb where hardystonite and willemite are major minerals found in both Pb and Zn slags (Tables 5.5, 5.6 and 5.7).

The spinel group is the first mineral phase formed in high-temperature silicate melts, where silicates nucleating simultaneously with the oxides usually enclose small crystals of spinel (Ettler et al. 2001). They can be found either in trace, abundant amount or generally as cubic or octahedral crystals several micrometers across the slag samples. Franklinite, magnesiochromite and magnetite are dominant spinel minerals found in Pb slags where the concentration of Zn varies from 8.92 to 19.91% in weight (Table 5.5). On the other hand, zincochromite and gahnite are found in Zn slags where the Zn content can be 18–31% in weight (Table 5.7).

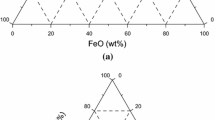

The glassy matrix can be heterogeneous with the oxide proportions varying significantly for both Pb and Zn slags where the composition can be described in terms of SiO2, CaO, total Fe (FeO + Fe2O3), Al2O3, ZnO and PbO. A relative viscosity of the melt simply relies on the ratio of (CaO + FeO + MgO + MnO + K2O + Na2O) / (SiO2 + Al2O3) in % weight (Manasse et al. 2001). Si is the main cation forming silicate network, whereas Al and Fe(III) are not only involved in network formation, but also in network modification. Only if Al is charge balanced with other cations such as K, Na or Ca, it can be considered as a network former.

5.3 Weathering of Slags

Unlike ferrous slags (Fe industries), non-ferrous slags from base metal smelters are composed of potentially toxic elements (e.g. As, Cd, Cu, Pb, Zn) and can lead to the contamination of surface and ground water (Parsons et al. 2001). Thus, many studies have contributed to the understanding of the stability of slags and their short and long term leaching behavior by simulating either chemically or biologically influenced weathering experiments.

5.3.1 Chemically Induced Weathering

5.3.1.1 Leaching Assessment of Slags

Several leaching tests have been extensively performed by various researchers to assess the stability of slags, the leaching behaviour of metals in terms of short-protocol leaching tests (Table 5.8) as well as long-term leaching tests by prolonging slag-water interaction time (Table 5.9). These studies focus on slags and smelter related samples (Pb slags, Zn slags, Pb-Cu slags, Cu-Zn slags, secondary Pb slags, fly ash of secondary Pb smelters) as well as many environmental conditions (pH, liquid-to-solid ratios, various leachant, agitation speed, oxic/anoxic conditions, and contact time).

Details of most common protocol tests applied to metallurgical slags are given in Table 5.8. Each test is different, based on different environmental simulations: the special waste extraction procedure (SWEP) developed by British Columbia intended only for metallurgical and mineral wastes; the diffusion-leaching NEN 7341 test developed in the Netherlands to simulate the successive pH drop from neutral to acidic conditions; the EN 12457–2 test developed by the European Union to simulate normal rainfall conditions; the synthetic precipitation leach procedure (SPLP) as developed by the American National Mining Association to simulate acid rain; the standard toxicity characterisation leaching procedure (TCLP) test developed by the USEPA to simulate the co-disposal scenario with municipal solid waste; and leaching assessment to test the reuse potential of Zn slags in cement.

Likewise, details of many long-term leaching assessment tests applied to metallurgical slags are given in Table 5.9. These studies at laboratory-batch-scale level cover equilibrium leaching tests under saturated conditions; intermittent or continuous leachant renewal conditions (Barna et al. 2004), kinetic leaching test (Ettler et al. 2008), pH-dependent leaching test (De Andrade Lima and Bernardez 2013; Ganne et al. 2006; Vítková et al. 2013), simulation of weathering in the soil environment (Ettler et al. 2005a; Ettler and Johan 2014) and remobilisation of contaminated sediments (Vdovic et al. 2006). In addition, many studies have been done at pilot scale or field level: column leaching tests as well as outdoor weathering of slag dumps (Seignez et al. 2006, 2007, 2008), field leaching experiments (Piatak et al. 2004), and the establishment of a relationship between laboratory-based test results and measured water compositions at a real site (Parsons et al. 2001).

Results of dynamic leaching assessment tests have been combined with several geochemical computer models such as PHREEQC-2 (Ettler et al. 2004, 2005a; 2008, 2009; Navarro et al. 2008), Minteq A2 (Ettler et al. 2005a; Ganne et al. 2006), Minteq A4 (Vítková et al. 2013) or more sophisticated geochemical codes such as WHAM (Model VI) or ECOSAT (NICA-Donnan model) for accurate prediction of the metal complexation by dissolved organic matter (Ettler et al. 2005a).

5.3.1.2 Applicability of Leaching Tests to Metallurgical Slags

The significant differences between both short-protocols and long-term leaching tests are the contact time, type of leachant, agitation rate, pH, liquid to solid (L/S) ratios, and particle size of the sample. All protocol assessment tests are batch tests, quick and simple to carry out with reproducible results. As they are intended for short-term risk assessment and characterisation of slags at a glance, a combination of these tests can give an idea of the leaching behavior of metals under different leaching scenarios (i.e., landfill, acid rain or soil dumping). However, the requirement for particle size reduction of the slags during these tests does not reflect the conditions in which metallurgical slags are generally processed or disposed of. They are usually rocklike, monolithic structures, where leaching is minimized.

Lewis and Hugo (2000) pointed out that the application of TCLP to mineral processing and metallurgical wastes has been challenged because of the high acid neutralising capacity (ANC) of the slags, rendering true assessment of the leaching potential impractical. Each leaching test protocol is different, based on the different environmental simulations and purposes, nature of targeted wastes or slags, nature of leachant used, different duration of each test, and the origin of the country where it is developed reflecting its country’s regulations and standards. The application of two or more tests (TCLP + SPLP + SWEP) to one single slag can overcome such controversy and might thus be beneficial for short-term assessment. Short-term assessment is quick, simple to carry out and provides reproducible results, and a combination of these tests can even be beneficial in assessing the environmental impact of slags in different weathering conditions.

Piatak et al. (2015) pointed out that many results from leaching tests are not consistent as potentially toxic trace elements are present among various phases whose relative reactivity and leachability can be the key to understanding the stability of slags. Partitioning of Zn can be related to the overall bulk Zn concentration: Zn was hosted mainly in spinel and silicate phases in Zn rich samples, whereas it was mainly present in sulphides in lower-bulk Zn concentrations (Piatak et al. 2015).

On the other hand, the long term leaching tests cover more criteria. As size reduction is not the requirement, they represent conditions closer to the field. They also consider whether or not the acid-base neutralising capacity of the slag will be depleted over longer periods of contact time. In addition, the flow conditions of the water (downward and horizontal flow) along with the simulation of rainfall (intermittent and cyclic wetting of the slag) are the main advantages of long-term leaching tests over short-term ones. The applicability can be challenging if only one test is applied and the amount of metals leached out can be either under or over-estimated. Thus, the application of both short and long-term leaching assessment tests should be considered to fully understand the leaching behavior of the metallurgical slags.

5.3.1.3 Chemical Weathering Mechanisms

Both Ettler et al. (2003) and Mahé-Le Carlier et al. (2000) observed that the alteration of Pb-Zn slags is initiated by the leaching of network modifier elements like Ca, Mg, Mn and Fe. Curtis (2003) further explained that it is due to the hydrolysis reaction and the nucleophilic property of water on the silicon atom (Eq. 5.1):

Conradt (2008) pointed out the three different equilibria during the slag alteration: (1) an electrochemical equilibrium at the slag surface, (2) a new thermodynamic equilibrium within aqueous solution owing to element dissolution, and (3) the equilibrium which involves the solubility formation of stoichiometric hydrates of hydroxide phases due to hydrolysis.

With increasing hydration energy, H–O–H bonds are eventually broken with loss of protons (H+ ions) during an exchange with cations (Curtis 2003). The exchange reaction between H+ ions and cations from the slags leads to an increase of the pH, creating a neutral to moderately basic environment. This accelerates the silica release phenomenon by a probable mechanism of breaking strong links of the residual glass by the hydroxyl ions of the solution. The condensation reaction between two silanol groups leads to the formation of hydrated silica gel (Eq. 5.2):

The newly formed silica gel or secondary phases serve as the protection layer on the surface of altered slag, thus limiting the contact between the slag and the solution, which consequently leads to the pore-diffusion control of the aqueous solution through this growing layer (Conradt 2008). Many silicates and non-silicate phases in the slags are observed to release metals into solution at different rates. The dissolution rates of several silicates and oxides are pH-dependent, depicting a U-shaped curve when dissolution is plotted against pH on a log scale during steady, but far-from-equilibrium dissolution (Brantley et al. 2008). The overall dissolution rate of the slag can be the sum of the rates of the individual silicate and oxide phases. The newly formed silica gel or secondary phases on the slag surface which is adjacent to the solution can also be key to control the overall dissolution rate of the slag, i.e. the solid/liquid interaction affects the rate more than the in-depth leached layers (Hamilton et al. 2001).

5.3.2 Biologically Induced Weathering

In contrast to the extensive studies on chemical alteration of slags, only a few studies have focused on the involvement of microbial activity in slags alteration. To fully describe the state of knowledge on the topic and better highlight the great potential of bioleaching for metal recovery from metallurgical slags, this section will be extended to the dissolution of single glass or silicate phases in the presence of bacteria, and the interaction of bacteria and heavy metals, rather than be limited just to the bio-alteration of lead and zinc metallurgical slags.

Microorganisms are well known for their participation in mineral formation and dissolution. Some microorganisms are able to (1) oxidize or reduce many dissolved inorganic species, (2) detoxify toxic ones, and (3) actively or passively take up one or many of them which are later converted into their cellular structure. Other microorganisms are able to utilize minerals as they are not only a reservoir of many trace elements but also of electron acceptors, thus, providing energy by respiration (Ehrlich 1996). Many bacterial strains from different genera have shown their ability to weather several minerals (Uroz et al. 2009). They can destabilise and dissolve a mineral either as a single strain or in association with other microbial species.

5.3.2.1 Bioleaching of Slags

Bio-weathering due to heterotrophic microorganisms is focused here, owing to the high acid-buffering capacity and alkaline nature of Pb/Zn metallurgical slags, and to the fact that these slags are dumped in soil where organic matter and nutrients are present and can, therefore, be used by heterotrophic microorganisms. There is a growing interest in the application of heterotrophic leaching of alkaline slags and filter dusts/oxides from metal processing, as most Thiobacilli cannot effectively solubilise alkaline wastes with pH values above 5.5 (Gadd 2000). Eleven heterotrophic microorganisms from an alkaline slag dump have been isolated, including nine bacterial strains, one fungus and one yeast isolate (Willscher and Bosecker 2003). In addition, the K-feldspar dissolution was enhanced in the presence of heterotrophic bacteria, where the degree of dissolution depended on the different bacterial strains and growth conditions applied: Serratia marcescens was very effective in enhancing feldspar dissolution (Hutchens et al. 2003). The influence of bacteria (Azotobacter chroococcum, Bacillus megaterium and Bacillus mucilaginosus) on Pb and Zn speciation, mobility and bioavailability in soil have been described in a series of single chemical extraction, sequential extraction and in situ soil solution extraction technologies (Wu et al. 2006). Heterotrophic microorganisms (Microbacterium sp., Promicromonospora sp. and Pseudomonas cedrina) solubilise many metals from minerals via oxidation as well as by secreting complexing agents (Willscher et al. 2007).

5.3.2.2 Sorption/Complexation of Metals by Bacterial Cells, EPS, Siderophores

During the alteration of basaltic glass and a vitrified bottom ash, the sorption of many dissolved elements (Si, Mg, Fe, Ti, Ba, Co, Zn, Cu, Ni and Cr) was found in the biofilm and adsorbed onto P. aeruginosa cells (Aouad et al. 2006). The three conceptual reactive sites are acidic (carboxyl and/or phosphodiester), neutral (phosphomonoester) and basic (amine and/or hydroxyl) groups. Three bacteria (Cupriavidus metallidurans CH34, Pseudomonas putida ATCC12633, and Escherichia coli K12DH5R) were further investigated for Zn sorption (Guine et al. 2006). The increasing Fe concentration observed was due to the production of pyoverdine and its chelation capacities (Aouad et al. 2006; Yin et al. 2014). Moreover, the production of chelating compounds (exopolymers, siderophores and pigments) was highlighted by Hutchens et al. (2003) as a possible mechanism behind enhanced K-feldspar dissolution.

Extracellular polymeric substances (EPS) secreted from bacteria also play an important role in binding with metal cations due to their anionic properties. Pb has a greater affinity for EPS than Cd where the mineral fraction of the EPS is probably involved to a large extent in the sorption and binding strength between metals and EPS (Guibaud et al. 2006). Similarly, the binding affinity of EPS from fungi (Pestalotiopsis sp.) for Pb is higher than for Zn (Moon et al. 2006). In addition, the pH plays an important role in metal sorption onto EPS: no or minimum sorption occurs at acidic pH and the percentage of metal adsorption increases with higher pH (Guibaud et al. 2006).

5.3.2.3 Sorption/Bio-weathering Mechanisms

The possible bio-alteration mechanism along with different biochemical interactions between the heterotrophic bacterium Pseudomonas aeruginosa and Pb slag (LBF) is illustrated in Fig. 5.2 Chemical alteration of slag induces solid-liquid reactions with the hydrolysis of Si4+ and dissolution of network modifying elements like Ca2+ and Mg2+. The matrix neutralisation reactions between cations and H+ from the liquid medium lead to the accumulation of OH− ions, which results in a pH rise. Under the bio-alteration of slags, Fe dissolution could be significantly enhanced by the siderophores and bacteria cells serve as bio-sorbent owing to their higher surface to volume ratio (Konhauser 2007). Depending on the moiety donating oxygen ligands for Fe3+ coordination, siderophores are grouped into three types: (i) catecholates or phenolates, (ii) hydroxamates or carboxylates, (iii) α-hydroxy-carboxylic groups and (iv) a mixture of these groups (Saha et al. 2013), where complexation occurs not only with Fe, but also with other metals like Cu and Zn (Potysz et al. 2016).

Alteration of Pb slag by the heterotrophic bacterium Pseudomonas aeruginosa (Modified from van Hullebusch et al. 2015)

5.3.3 Mineralogical Control on Metal Bioleachability

The primary mineral phases present in Pb and Zn slags (Tables 5.3 and 5.4) control the release of metals and metalloids into the environment under weathering conditions. The slag glass phase is more reactive and liberates minor relic sulfide ores, or metallic droplets entrapped in it (Ettler et al. 2003; Parsons et al. 2001). Zinc is probably leached either from sulfide/metallic droplets such as Fe-rich wurtzite ((Fe + Zn)S), or from Zn-bearing silicates (e.g. melilite) and glass. Spinels, main Zn concentrators, as well as willemite (Zn2SiO4), are most resistant to weathering and do not significantly contribute to Zn liberation (Ettler et al. 2003). On the other hand, Zn partitioned volumetrically into minor sulphides is prone to weathering and liberation of Zn (Piatak and Seal 2010). Other phases such as franklinite are not very reactive and are stable up to pH 2 (Ganne et al. 2006). Moreover, the formation of secondary precipitates such as amorphous hydrous ferric oxides (HFO) and aluminum oxyhydroxide (AlOOH) are also controlling the release and mobility of metal and metalloids through sorption and/or co-precipitation (Ettler et al. 2009).

More studies have been done on the bio-accessibility of Pb and Zn in soils from mining and smelter areas (Ettler et al. 2012), from slags (Bosso and Enzweiler 2008) and the Pb mineralogy control on leaching and relative bio-accessibility (Romero et al. 2008). Glass phases are very important in controlling heavy metal mobility as well as bio-accessibility when being ingested, while the heavy metals in a silicate matrix are protected against leaching. The presence of heterotrophic bacteria enhances the dissolution of minerals as olivine (clinochlore, lizardite, nimite and willemseite) was significantly reduced in quantity (Chiang et al. 2013). Similarly, the presence of Pseudomonas aeruginosa dramatically enhances the solubility, and therefore the mobility of metals contained in Pb slags, lead blast furnace (LBF) slags (van Hullebusch et al. 2015; Yin et al. 2014).

5.3.4 Secondary Bioprecipitates

Geochemical models are used to predict the species of many dissolved elements, to calculate the saturation indices of these species and to predict the formation of possible solid phases controlling the leachate composition (Piatak et al. 2004). Models such as PHREEQC-2 (Ettler et al. 2004, 2005a, 2008, 2009; Navarro et al. 2008), Minteq A2 (Ettler et al. 2005a; Ganne et al. 2006), Minteq A4 (Vítková et al. 2013), Visual MINTEQ version 3.0 (Yin et al. 2016) as well as more sophisticated geochemical codes such as WHAM (Model VI) or ECOSAT (NICA-Donnan model) were used for accurate prediction of the metal complexation by dissolved organic matter (Ettler et al. 2005a).

These models predict the possible secondary precipitation formation by calculating the saturation index (SI), as follows (Eq. 5.3):

where Q is the ion activity product and K the equilibrium constant for the dissolution reaction. If the SI is zero, it reflects equilibrium, negative values indicate under-saturation and a positive values indicate super-saturation, thus indicating the formation of possible secondary precipitates (Parsons et al. 2001).

Under oxidizing conditions, with a supply of atmospheric CO2 at pH 6–9, formation of cerussite (PbCO3) and amorphous hydrous ferric oxides (HFO) has been reported reflecting the long-term leaching assessment conditions (Ettler et al. 2003). Precipitation of HFO is mainly controlled by major dissolution of mainly Fe-bearing phases releasing Fe2+ into the solution with the contribution of other minerals (silicates, oxides and glass), and the time required for oxidation of Fe2+ to Fe3+ (Ettler et al. 2005a). In case of soil weathering environments with the presence of low or high molecular weight organic acids, the formation of well-developed calcite (CaCO3) crystals and an amorphous organo-mineral matrix of HFO and amorphous SiO2 was reported (Ettler et al. 2004). Metals like Pb, Zn, Cu and As present in the leachate were subsequently adsorbed onto newly formed HFO or trapped within the calcite structure. Zn exhibits a more pronounced mobility and is adsorbed on HFO/FO only at pH values higher than 7 (Ettler et al. 2005a). Similar adsorption of Pb onto HFO was also found after natural alteration of metallurgical slags from old dump sites (Mahé-Le Carlier et al. 2000).

In addition to HFO, AlO(OH) and phases such as chalcanthite (CuSO4.5H2O), siderotil (Fe2+CuSO4.5H2O), jarosite (KFe3+ 3(OH)6(SO4)2), brochantite (Cu4SO4(OH)6) and gypsum (CaSO4.2H2O) were reported at old base-smelter slag dump sites undergoing natural weathering (Piatak et al. 2004). Moreover, brianyoungite [Zn3(CO3,SO4)(OH)4], and less common phases like bechererite [(Zn,Cu)6Zn2(OH)13[(S,Si)(O,OH)4]2] were identified as a secondary coating and as fibrous/ bladed crystals filling in cavities of zinc slags on dump sites (Piatak and Seal 2010). Chiang et al. (2013) reported that the alkaline bioleaching of alkaline slags materials took place when solubilisation of primary minerals and precipitation of secondary minerals simultaneously occur. The alteration of primary minerals such as dicalcium-silicate, bredigite and periclase, and the formation of new secondary phases such as merwinite and calcite was reported.

5.4 Conclusion

Comprehensive and extensive studies have been established concerning chemical alteration of slags under different experimental conditions. These studies indicate that detailed characterization of slag mineralogy, surface area, and dissolution of slags and mobility of metals is required, as well as the application of at least two or even three simple leaching tests (TCLP + SPLP + SWEP). This might be beneficial for short-term risk assessment, as these tests provide reproducible results and their combination can be beneficial in assessing the environmental impact of slags in different weathering conditions. However, most studies have been restricted to laboratory-based leaching assessments only. Thus, many questions remain concerning field weathering conditions in order to predict the long-term (i.e. 10–100 of years) reactivity of these metallurgical wastes (Ettler and Johan 2014) or to relate laboratory test results with measured values in the field. In addition, it is still difficult to determine the alteration yields and kinetics of each individual crystalline or glassy phase present in metallurgical slags contributing to the overall alteration of slags even at the laboratory scale.

Compared to chemical alteration studies of metallurgical slags, the focus on the involvement of microbial activity in natural alteration of these slags is relatively poor. Further research is required to investigate the microorganisms involved in the leaching of alkaline slag dumps and to pinpoint the physiological processes involved in metal solubilisation. With such knowledge, heterotrophic leaching can be an alternative for bio-metal recovery from alkaline slags where improvement in the leaching performance can be achieved by manipulation of the leaching conditions.

Abbreviations

- ANC:

-

Acid neutralising capacity

- Ano:

-

Anorthite

- CaCO3 :

-

Calcium carbonate

- Clif:

-

Clinoferrosilite

- CliPy:

-

Clinopyroxene

- Cu-Zn slags:

-

Slags from a mixture of zinc and copper smelter

- EINECS:

-

European Inventory of Existing Commercial Substances

- EN 12457-2:

-

Euronorm leaching test

- EPS:

-

Extracellular polymeric substances

- Fr:

-

Franklinite

- Gah:

-

Gahnite

- Gl:

-

Glass

- Gn:

-

Galena

- Ha:

-

Hardystonite

- He:

-

Hedenbergite

- Hya:

-

Hyalophane

- Kfel:

-

K-feldspar

- Kir:

-

Kirschsteinite

- La:

-

Labradorite

- LBF:

-

Lead slags from lead blast furnace

- Leu:

-

Leucite

- Me:

-

Melilite

- Mg:

-

Magnetite

- MgCr:

-

Magnesiochromite

- Mul:

-

Mullite

- NEN 7341 test:

-

Diffusion-leaching test developed by the Netherlands

- Ol:

-

Olivine

- Pb slags:

-

Slags from lead smelter

- Pb-Cu slags:

-

Slags from a mixture of lead and copper smelter

- PbS:

-

Lead sulfide

- Pb-Si:

-

Lead silicate

- Pl:

-

Plagioclase

- Po:

-

Pyrrhotite

- Py:

-

Pyroxene

- S:

-

Sulphur

- SI:

-

Saturation index

- Spl:

-

Spinel

- SPLP:

-

Synthetic precipitation leach procedure

- SWEP:

-

Special waste extraction procedure

- TCLP:

-

Standard toxicity characterisation leaching procedure

- USEPA:

-

United States Environmental Protection Agency

- Wil:

-

Willemite

- Wo:

-

Wollastonite

- Zn slags:

-

Slags from zinc smelter

- Znc:

-

Zincite

- ZnCr:

-

Zincochromite

- ZnS:

-

Zinc sulfide

References

Aouad G, Crovisier JL, Geoffroy VA, Meyer JM, Stille P (2006) Microbially-mediated glass dissolution and sorption of metals by Pseudomonas aeruginosa cells and biofilm. J Hazard Mater 136:889–895. doi:10.1016/j.jhazmat.2006.01.026

Audry S, Schafer J, Blanc G, Jouanneau JM (2004) Fifty-year sedimentary record of heavy metal pollution (Cd, Zn, Cu, Pb) in the lot river reservoirs (France). Environ Pollut 132:413–426. doi:10.1016/j.envpol.2004.05.025

Barna R, Moszkowicz P, Gervais C (2004) Leaching assessment of road materials containing primary lead and zinc slags. Waste Manag 24:945–955. doi:10.1016/j.wasman.2004.07.014

Bosso ST, Enzweiler J (2008) Bioaccessible lead in soils, slag, and mine wastes from an abandoned mining district in Brazil. Environ Geochem Health 30:219–229. doi:10.1007/s10653-007-9110-4

Brantley SL, Kubicki JD, White AF (2008) Kinetics of water-rock interaction. Spring, Berlin, pp 1–843. doi:10.1007/978-0- 387-73563-4

Chiang YW, Santos RM, Monballiu A, Ghyselbrecht K, Martens JA, Mattos MLT, Gerven TV, Meesschaert B (2013) Effects of bioleaching on the chemical, mineralogical and morphological properties of natural and waste-derived alkaline materials. Miner Eng 48:116–125. doi:10.1016/j.mineng.2012.09.004

Conradt R (2008) Chemical durability of oxide glasses in aqueous solutions: a review. J Am Ceram Soc 91:728–735. doi:10.1111/j.1551-2916.2007.02101.x

Curtis CD (2003) The aqueous geochemistry of metals in the weathering environment: strengths and weaknesses in our understanding of speciation and process. Mineral Mag 67:235–246. doi:10.1180/0026461036720097

De Andrade Lima LRP, Bernardez LA (2011) Isotope source signatures for a primary lead smelter located close to Todos Os Santos bay, Brazil. Soil Sediment Contam: An Int J 20:672–687. doi:10.1080/15320383.2011.594109

De Andrade Lima LRP, Bernardez LA (2013) Evaluation of the chemical stability of a landfilled primary lead smelting slag. Environ Earth Sci 68:1033–1040. doi:10.1007/s12665-012-1805-x

Deneele D (2002) Caracterisation, simulations experimentales et thermodynamiques de l’alteration de dechets vitreux: les scories de première fusion de plomb et de zinc. PhD thesis Université de Lille I, France, pp 1–242

Douay F, Roussel H, Pruvot C, Loriette A, Fourrier H (2008) Assessment of a remediation technique using the replacement of contaminated soils in kitchen gardens nearby a former lead smelter in northern France. Sci Total Environ 401:29–38. doi:10.1016/j.scitotenv.2008.03.025

Douay F, Pruvot C, Waterlot C, Fritsch C, Fourrier H, Loriette A, Bidar G, Grand C, De Vaufleury A, Scheifler R (2009) Contamination of woody habitat soils around a former lead smelter in the north of France. Sci Total Environ 407:5564–5577. doi:10.1016/j.scitotenv.2009.06.015

Ehrlich HL (1996) How microbes influence mineral growth and dissolution. Chem Geol 132:5–9. doi:10.1016/S0009-2541(96)00035-6

Ettler V, Johan Z (2003) Mineralogy of metallic phases in sulphide mattes from primary lead smelting. Com Rend Geosci 335:1005–1012. doi:10.1016/j.crte.2003.09.005

Ettler V, Johan Z (2014) 12 years of leaching of contaminants from pb smelter slags: geochemical/mineralogical controls and slag recycling potential. Appl Geochem 40:97–103. doi:10.1016/j.apgeochem.2013.11.001

Ettler V, Johan Z, Touray JC, Jelínek E (2000) Zn partitioning between glass and silicates phases in historical and modern lead-zinc slags, Czech Republic. Earth Planet Sci 331:245–250. doi:10.1016/S1251-8050(00)01416-6

Ettler V, Legendre O, Bodenan F, Touray JC (2001) Primary phases and natural weathering of old lead–zinc pyrometallurgical slag from Príbram, Czech Republic. Can Mineral 39:873–888. doi:10.2113/gscanmin.39.3.873

Ettler V, Piantone P, Touray JC (2003) Mineralogical control on inorganic contaminant mobility in leachate from lead-zinc metallurgical slag: experimental approach and long-term assessment. Mineral Mag 67:1269–1283. doi:10.1180/0026461036760164

Ettler V, Komarkova M, Jehlicka J, Coufal P, Hradil D, Machovic V, Delorme F (2004) Leaching of lead metallurgical slag in citric solutions-implications for disposal and weathering in soil environments. Chemosphere 57:567–577. doi:10.1016/j.chemosphere.2004.07.022

Ettler V, Jehlicka J, Masek V, Hruska J (2005a) Leaching behaviour of lead metallurgical slag in high-molecular-weight (HMW) organic solutions. Mineral Mag 69:737–747. doi:10.1180/0026461056950284

Ettler V, Mihaljevic M, Sebek O, Strnad L (2005b) Leaching of APC residues from secondary Pb metallurgy using single extraction tests: the mineralogical and the geochemical approach. J Hazard Mater 121:149–157. doi:10.1016/j.jhazmat.2005.02.001

Ettler V, Sebek O, Grygar T, Klementova M, Bezdička P, Slavikova H (2008) Controls on metal leaching from secondary Pb smelter air pollution control residues. Environ Sci Technol 42:7878–7884. doi:10.1021/es801246c

Ettler V, Johan Z, Kříbek B, Šebek O, Mihaljevič M (2009) Mineralogy and environmental stability of slags from the Tsumeb smelter, Namibia. Appl Geochem 24:1–15. doi:10.1016/j.apgeochem.2008.10.003

Ettler V, Kříbek B, Majer V, Knésl I, Mihaljevič M (2012) Differences in the bioaccessibility of metals/metalloids in soils from mining and smelting areas (Copperbelt, Zambia). J Geochem Explor 113:68–75. doi:10.1016/j.gexplo.2011.08.001

Gadd GM (2000) Bioremedial potential of microbial mechanisms ofmetal mobilisation and immobilisation. Environ Biotech:271–279. doi:10.1016/S0958-1669(00)00095-1

Ganne P, Cappuyns V, Vervoort A, Buve L, Swennen R (2006) Leachability of heavy metals and arsenic from slags of metal extraction industry at Angleur (Eastern Belgium). Sci Total Environ 356:69–85. doi:10.1016/j.scitotenv.2005.03.022

Guibaud G, van Hullebusch E, Bordas F (2006) Lead and cadmium biosorption by extracellular polymeric substances (EPS) extracted from activated sludges: pH-sorption edge tests and mathematical equilibrium modelling. Chemosphere 64:1955–1962. doi:10.1016/j.chemosphere.2006.01.012

Guine V, Spadini L, Sarret G, Muris M, Delolme C, Gaudet JP, Martins JMF (2006) Zinc sorption to three gram-negative bacteria combined titration, modeling, and EXAFS study. Environ Sci Technol 40:1806–1813. doi:10.1021/es050981l

Hamilton JP, Brantley SL, Pantano CG, Criscenti LJ, Kubicki JD (2001) Dissolution of nepheline, jadeite and albite glasses toward better models for aluminosilicate dissolution. Geochim Cosmochim Acta 65:3683–3702. doi:10.1016/S0016-7037(01)00724-4

Hudson-Edwards KA, Jamieson HE, Lottermoser BG (2011) Mine wastes: past, present, future. Elements 7:375–380. doi:10.2113/gselements.7.6.375

Hutchens E, Valsami-Jones E, Mceldowney S, Gaze W, Mclean J (2003) The role of heterotrophic bacteria in feldspar dissolution–an experimental approach. Mineral Mag 67:1157–1170. doi:10.1180/0026461036760155

Konhauser KO (2007) Introduction to geomicrobiology. Blackwell publishing, Hoboken

Lewis AE, Hugo A (2000) Characterisation and batch testing of a secondary lead slag. J South Afr Inst Min Metall, 365–370. doi: v100n06p365

Lottermoser BG (2002) Mobilisation of heavy metals from historical smelting slag dumps, North Queensland, Australia. Mineral Mag 66:475–490. doi:10.1180/0026461026640043

Mahé-Le Carlier C, Le Carlier De Veslud C, Ploquin A, Royer JJ (2000) L’altération naturelle des scories de la métallurgie ancienne: un analogue de déchets vitrifiés. Earth Planet Sci 330:179–184. doi:10.1016/S1251-8050(00)88666-8

Manasse A, Mellini M, Viti C (2001) The copper slags of the Capattoli valley, Campiglia Marittima, Italy. Eur J Mineral 13:949–960. doi:10.1127/0935-1221/2001/0013/0949

Moon SH, Park CS, Kim YJ, Park YI (2006) Biosorption isotherms of Pb (II) and Zn (II) on Pestan, an extracellular polysaccharide, of Pestalotiopsis Sp. Kctc 8637p. Process Biochem 41:312–316. doi:10.1016/j.procbio.2005.07.013

Morrison C, Hooper R, Lardner K (2003) The use of ferro-silicate slag from ISF zinc production as a sand replacement in concrete. Cem Concr Res 33:2085–2089. doi:10.1016/S0008-8846(03)00234-5

Navarro A, Cardellach E, Mendoza JL, Corbella M, Domènech LM (2008) Metal mobilisation from base-metal smelting slag dumps in sierra Almagrera (Almería, Spain). Appl Geochem 23:895–913. doi:10.1016/j.apgeochem.2007.07.012

Nickel EH (1995) Definition of a mineral. Eur J Mineral 7:1213–1215. doi:10.1127/ejm/7/5/1213

Parsons MB, Bird DK, Einaudi MT, Alpers CN (2001) Geochemical and mineralogical controls on trace element release from the base-metal slag dump, California. Appl Geochem 16:1567–1593. doi:10.1016/S0883-2927(01)00032-4

Pelfrene A, Waterlot C, Mazzuca M, Nisse C, Bidar G, Douay F (2011) Assessing cd, pb, zn human bioaccessibility in smelter-contaminated agricultural topsoils (Northern France). Environ Geochem Health 33:477–493. doi:10.1007/s10653-010-9365-z

Piatak NM, Seal RR (2010) Mineralogy and the release of trace elements from slag from the Hegeler zinc smelter, Illinois (USA). Appl Geochem 25:302–320. doi:10.1016/j.apgeochem.2009.12.001

Piatak NM, Seal RR, Hammarstrom JM (2004) Mineralogical and geochemical controls on the release of trace elements from slag produced by base- and precious-metal smelting at abandoned mine sites. Appl Geochem 19:1039–1064. doi:10.1016/j.apgeochem.2004.01.005

Piatak NM, Parsons MB, Seal RR (2015) Characteristics and environmental aspects of slag: a review. Appl Geochem 57:236–266. doi:10.1016/j.apgeochem.2014.04.009

Potysz A, van Hullebusch ED, Kierczak J, Grybos M, Lens PNL, Guibaud G (2015) Copper metallurgical slags – current knowledge and fate, Critical Reviews in. Environ Sci Technol 45(22):2424–2488. doi:10.1080/10643389.2015.1046769

Potysz A, Grybos M, Kierczak J, Guibaud G, Lens PNL, van Hullebusch ED (2016) Bacterially-mediated weathering of crystalline and amosphous Cu-slags. Appl Geochem 64:92–106. doi:10.1016/j.apgeochem.2015.07.011

Puziewicz J, Zainoun K, Bril H (2007) Primary phases in pyrometallurgical slags from a zinc-smelting waste dump, Swietochlowice, upper Silesia, Poland. Can Mineral 45:1189–1200. doi:10.2113/gscanmin.45.5.1189

Romero FM, Villalobos M, Aguirre R, Gutierrez ME (2008) Solid-phase control on lead bioaccessibility in smelter-impacted soils. Arch Environ Contam Toxicol 55:566–575. doi:10.1007/s00244-008-9152-3

Saha R, Saha N, Donofrio RS, Bestervelt LL (2013) Microbial siderophores: a mini review. J Basic Microbiol 53:303–317. doi:10.1002/jobm.201100552

Saikia N, Cornelis G, Mertens G, Elsen J, Van Balen K, Van Gerven T, Vandecasteele C (2008) Assessment of Pb-slag, MSWI bottom ash and boiler and fly ash for using as a fine aggregate in cement mortar. J Hazard Mater 154:766–777. doi:10.1016/j.jhazmat.2007.10.093

Saikia N, Cornelis G, Cizer Ö, Vandecasteele C, Gemert D, Balen K, Gerven T (2012) Use of Pb blast furnace slag as a partial substitute for fine aggregate in cement mortar. J Mater Cycles Waste Manage 14:102–112. doi:10.1007/s10163-012-0043-3

Seignez N, Bulteel D, Damidot D, Gauthier A, Potdevin JL (2006) Weathering of metallurgical slag heaps: multi-experimental approach of the chemical behaviours of lead and zinc. Waste Manage Environ iii 1:31–40. doi:10.2495/WM060041

Seignez N, Gauthier A, Bulteel D, Buatier M, Recourt P, Damidot D, Potdevin JL (2007) Effect of Pb-rich and Fe-rich entities during alteration of a partially vitrified metallurgical waste. J Hazard Mater 149:418–431. doi:10.1016/j.jhazmat.2007.04.007

Seignez N, Gauthier A, Bulteel D, Damidot D, Potdevin JL (2008) Leaching of lead metallurgical slags and pollutant mobility far from equilibrium conditions. Appl Geochem 23:3699–3711. doi:10.1016/j.apgeochem.2008.09.009

Sivry Y, Munoz M, Sappin-Didier V, Riotte J, Denaix L, De Parseval P, Destrigneville C, Dupré B (2010) Multimetallic contamination from Zn-ore smelter: solid speciation and potential mobility in riverine floodbank soils of the upper lot river (SW France). Eur J Mineral 22:679–691. doi:10.1127/0935-1221/2010/0022-2060

Uroz S, Calvaruso C, Turpault MP, Frey-Klett P (2009) Mineral weathering by bacteria: ecology, actors and mechanisms. Trends Microbiol 17:378–387. doi:10.1016/j.tim.2009.05.004

Van Alphen M (1999) Atmospheric heavy metal deposition plumes adjacent to a primary lead-zinc smelter. Sci Total Environ 236:119–134. doi:10.1016/S0048-9697(99)00272-7

van Hullebusch ED, Yin NH, Seignez N, Labanowski J, Gauthier A, Lens PNL, Avril C, Sivry Y (2015) Bio-alteration of metallurgical wastes by Pseudomonas aeruginosa in a semi flow-through reactor. J Environ Manag:297–305. doi:10.1016/j.jenvman.2014.09.018

Vdovic N, Billon G, Gabelle C, Potdevin JL (2006) Remobilisation of metals from slag and polluted sediments (case study: the canal of the Deule river, northern France). Environ Pollut 141:359–369. doi:10.1016/j.envpol.2005.08.034

Vítková M, Hyks J, Ettler V, Astrup T (2013) Stability and leaching of cobalt smelter fly ash. Appl Geochem 29:117–125. doi:10.1016/j.apgeochem.2012.11.003

Willscher S, Bosecker K (2003) Studies on the leaching behaviour of heterotrophic microorganisms isolated from an alkaline slag dump. Hydrometallurgy 71:257–264. doi:10.1016/S0304-386X(03)00164-6

Willscher S, Pohle C, Sitte J, Werner P (2007) Solubilisation of heavy metals from a fluvial amd generating tailings sediment by heterotrophic microorganisms. J Geochem Explor 92:177–185. doi:10.1016/j.gexplo.2006.08.013

Wu SC, Luo YM, Cheung KC, Wong MH (2006) Influence of bacteria on Pb and Zn speciation, mobility and bioavailability in soil: a laboratory study. Environ Pollut 144:765–773. doi:10.1016/j.envpol.2006.02.022

Yang Y, Li S, Bi X, Wu P, Liu T, Li F, Liu C (2010) Lead, Zn, and cd in slags, stream sediments, and soils in an abandoned Zn smelting region, southwest of China, and Pb and S isotopes as source tracers. J Soils Sediments 10:1527–1539. doi:10.1007/s11368-010-0253-z

Yin NH, Sivry Y, Avril C, Borensztajn S, Labanowski J, Malavergne V, Lens PNL, Rossano S, van Hullebusch ED (2014) Bioweathering of lead blast furnace metallurgical slags by Pseudomonas aeruginosa. Int Biodeterior Biodegrad 86:372–381. doi:10.1016/j.ibiod.2013.10.013

Yin NH, Sivry Y, Guyot F, Lens PNL, van Hullebusch ED (2016) Evaluation on chemical stability of lead blast furnace (LBF) and imperial smelting furnace (ISF) slags. J Environ Manag 180:310–323. doi:10.1016/j.jenvman.2016.05.052

Acknowledgements

The authors would like to thank the European Commission for providing financial support through the Erasmus Mundus Joint Doctorate Programme ETeCoS3 (Environmental Technologies for Contaminated Solids, Soils and Sediments) under the grant agreement FPA n°2010-0009.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Yin, NH., Lens, P.N.L., Sivry, Y., van Hullebusch, E.D. (2017). Lead and Zinc Metallurgical Slags Mineralogy and Weathering. In: Rene, E., Sahinkaya, E., Lewis, A., Lens, P. (eds) Sustainable Heavy Metal Remediation. Environmental Chemistry for a Sustainable World. Springer, Cham. https://doi.org/10.1007/978-3-319-61146-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-61146-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61145-7

Online ISBN: 978-3-319-61146-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)