Abstract

A drawback of many cable-driven parallel robots is a relatively small orientation workspace. In this paper, two design variants for cable-driven parallel robots with nine and twelve cables are proposed that allow for large rotations. It is shown that the platform can perform a 360\(^{\circ }\) rotation while maintaining positive tension in all cables and without collisions amongst the cables. Furthermore, workspace studies of the total orientation workspace are provided. Surprisingly, this family of cable robot is capable to perform an unlimited rotation within a translational workspace of reasonable size. Finally, the efficiency and computation time of force distribution algorithms is compared for cable robots having twelve cables.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Cable-driven parallel robots, in the following simply called cable robots, mainly consist of a light weight platform, cables, and winches and therefore allow to design systems with an exceptional good power to mass ratio compared to conventional kinematics. The workspace of the robot mainly depends on the winch positions and platform anchor points. Cable robots have a relatively small rotational workspace compared to their translational workspace. Prototypes such as the CoGiRo [4] are able to rotate the platform by around 90\(^{\circ }\) which is considered to be a large orientation workspace for a cable robot. Handling tasks such as conveyer belt pick-and-place applications demand for a larger rotational workspace which can yet only be achieved by additional actuated axes on the platform.

In this paper, an approach is presented where the desired rotation is actuated by cables. This keeps the mass of the system low and avoids the need for power supply. Beside that, additional cables increase the safety of the system and even may be used to increase the translational workspace.

2 Cable Robot with Unlimited Rotation

The basic idea of a cable-driven parallel robot with one unlimited rotation axis was recently presented [7]. In this paper, we detail the properties of such robots by proposing a configuration with more cables that has the unlimited rotation property of the platform within a reasonably large wrench-feasible workspace. Additionally, we show that the robot does not suffer from cable–cable collisions in this workspace. Considering the connection of many cables to the platform in a spatial robot, it seems to be clear from intuition that large rotation is impossible for a cable-driven robot. However, this intuition is wrong and one way to achieve this effect is to use a platform that has the form of a crank shaft. Fixing three cables to each end of the shaft is basically a generic 2R3T design. Then, one uses an eccentric connection point on the shaft to independently control the rotation of the shaft (see Fig. 1). In this simple example, three cables share a common anchor point at each end of the shaft as well as on the crank. From a kinematic point of view, this yields exactly the desired rotational mobility of the platform. As shown in [7], each additional degree-of-freedom can be actuated on the platform and requires at least one extra cable. However, for a cable robot, we might need to add more cables for a degree-of-freedom to achieve a preferred geometry of the platform.

In the following, two archetypic robot designs are presented where the geometry of the robot is characterized by the proximal anchor points \(\mathbf{{a}}_i\) and the distal anchor points \(\mathbf{{b}}_i\). The number of cables is denoted by m.

The endless Z9 design is a minimal realization of the idea sketched above to achieve the rotation capabilities of the robot. The geometry of the robot consists of three triangular levels on different heights that respectively share a common distal anchor point \(\mathbf{{b}}_i\). The structure in layers shall avoid collisions amongst these groups of cables. Since all cables within a group share a common distal anchor point, the cables cannot interfere in any other point within the robot frame [11]. The endless Z9 is a 9-3 cable configuration. A parametric representation of this geometry is given in Table 1.

The endless Z12 is a cable robot in a 12-3 cable configuration (see Fig. 2). In order to match the mostly desired shape of a rectangular robot frame, the proximal anchor points are moved to the surface of a box providing also a larger possible workspace for the robot. The design has again three layers on the platform and on the base, where for this robot each layer consists of four cables. Again, given a proper geometry for the platform, cables on different layers shall not collide. For the sample robot, we have chosen the parameters as follows: \(r_{\!\text {B}}=2\), \(r_{\!\text {P}}=0.3\), \(H_{\!\text {B}}=3\), \(h_{\!\text {B}}=2\), \(H_{\!\text {P}}=0.5\), and \(h_{\!\text {P}}=0.3\).

3 Kinematic Properties

In the following, we briefly present the modelling and tools used to analyze the cable robots. The standard kinematic modelling for cable-driven parallel robots is used for the analysis in this paper. The platform position \(\mathbf{{r}}\) and rotation \(\mathbf{{R}}\) can be controlled by changing the cable length \(\mathbf{{l}}_i\) according to the inverse kinematics

where vectors \(\mathbf{{a}}_i\) relate to the cable’s outlet points at the winch side and \({\mathbf{{b}}_i}\) are the distal anchor points on the mobile platform. Considering the platform as a free floating body, a stable platform position is characterized by the force and torque equilibrium

where \(\mathbf{{f}}\) and \(\mathbf{{w}}\) denote the cable forces and external wrench, respectively, while \(\mathbf{{A}}^\mathrm{T}\) relates to the well-known structure matrix

The unit vectors \(\mathbf{{u}}_i\) describe the direction of the cables. Cables can only resist pulling forces so that Eq. 2 must be fulfilled under the constraint of positive forces \(f_i > 0\) for \(i = 1\ldots , m\). Under the consideration of the minimal and maximal allowed cable forces \(f_{\text {min}}\) and \(f_{\text {max}}\), it is possible to determine the set of allowed platform poses for a given wrench \(\mathbf{{w}}\) using Eq. (2), that is to find a positive solution for the cable forces \(\mathbf{{f}}\) within the allowed range \(f_{\text {min}}\le f_i \le _{\text {max}}\).

Cable robots with more cables than the six degree-of-freedom are over-constrained systems and therefore multiple valid force distributions for a single stable platform pose exist. This holds true especially for the endless Z robots at hand which exhibit a high degree-of-redundancy. Thus, for the determination of the cable force, different methods are considered that are capable of dealing with such highly redundant robots. For this study, we focus on the (advanced) closed-form method [10], the Dykstra method [5], and the wrench-set method [1]. However, only little can be found in the literature that analyze appropriateness and applicability of force distribution methods for robots with \(m=12\) cables. It is known that the computation time and also the convergence can degenerate if the degree-of-redundancy increases. Therefore, different approaches are used in this study to assess also the feasibility for this highly redundant case. Following the discussion in [10], we use amongst others a least squares approach

where \({\mathbf{{A}}^{\mathrm{{ + T}}}}\) is the Moore–Penrose pseudo inverse of \({{\mathbf{{A}}^\mathrm{{T}}}}\) and \({\mathbf{{f}}_\mathrm{{m}}}\) is the medium feasible force distribution \({\mathbf{{f}}_\mathrm{{m}}} = \left( {{\mathbf{{f}}_{\mathrm{{min}}}} + {\mathbf{{f}}_{\mathrm{{max}}}}} \right) /2\).

The concept of wrench-feasibility poses is recalled above and is applied to the workspace here. The wrench-feasible workspace (WFW) was defined in [2, 3, 12] as follows: The wrench-feasible workspace is the set \(\mathscr {W}\) of poses \((\mathbf{{r}},\mathbf{{R}})\) of the mobile platform. For any wrench \(\mathbf{{w}} \in \mathscr {Q}\) there exists a vector of cable tension \(\mathbf{{f}}\in [f_{\text {min}}, f_{\text {max}}]^m\) such that Eq. (2) is fulfilled. The pose \((\mathbf{{r}},\mathbf{{R}})\) is called wrench-feasible if it allows at least one solution \(\mathbf{{f}}\in [f_{\text {min}}, f_{\text {max}}]^m\). To test if a pose belongs to the wrench-feasible workspace, the methods mentioned above to compute force distributions are employed. For studying the workspace of the endless Z robots, one is interested in the total orientation workspace [6], i.e. the set of all positions where every orientation \(\mathbf{{R}}\in \mathscr {R}\) is wrench-feasible. In this study the orientation set \(\mathscr {R} = \left\{ \mathbf{{R}}\in \text {SO}_3\, |\, \mathbf{{R}}=\mathbf{{R}}_{\text {Z}}(\phi )\, \forall \, \phi \in [0,2\pi ]\right\} \) contains a full rotation around the z-axis of the platform.

For the workspace assessment, the hull method is used [9] which allows for very accurate computation of the workspace border also taking into account sets of orientations \(\mathscr {R}\). The hull methods uses a triangulation of a small sphere around the estimated center of the workspace and inflates this region using line search until the border of the workspace is found. However, similar results as presented here can be achieved by simple sampling the workspace with discrete positions.

For cable robots with many cables, the problem of colliding cables becomes an issue, especially if large rotation angles are considered. A very interesting technique to calculate the regions of cable interference within the constant orientation workspace was presented by Perreault [8]. Through purely geometric considerations, it is possible to determine the loci of cable–cable interference from the geometry of the frame \(\mathbf{{a}}_i\) and the relative geometry of the mobile platform \(\mathbf{{b}}_i\). The main concept of this approach is the simple fact that two cables can interfere only if the corresponding anchor points \(\mathbf{{a}}_i, \mathbf{{a}}_j, \mathbf{{b}}_i, \mathbf{{b}}_j\) lie in a common plane. Since the anchor points on the frame are fixed in space, the plane can be constructed as follows: As a model of the possible interference region, one computes the normals of the connection lines between pairs of proximal and distal anchor points from

If \(\mathbf{{a}}_{ij}\) and \(\mathbf{{b}}_{ij}\) are not parallel, one can construct two triangles [8]

with \(\lambda ,\nu >0\). Exploiting the normalized length of the vectors \(\mathbf{{a}}_{ij}\) and \(\mathbf{{b}}_{ij}\), one practically chooses a metric length for \(\lambda \) and \(\nu \) in the range of the size of the robot to receive finitely large triangles with the critical interference region. Note, that common anchor points as used in the robot geometries above decrease the collision region from triangles to lines. The lines and triangles can be used for visual or automatic detection of cable–cable interference. For many robot designs, one can see from first glance, if the triangles are within the workspace of interest or outside. Further information on dealing with parallel vectors can be found in the paper [8].

Relaxing the considerations for the fixed orientation, the vector \(\mathbf{{b}}_{ij}\) is transformed by the rotation matrix \(\mathbf{{R}}_{\text {Z}}(\phi )\) in order to study a full rotation of the platform. This leads to the collision area given by the following parametric volume

where for \(\mathbf{{R}}_{\text {Z}}(\phi )\) is the elementary rotation matrix around the z axis.

4 Results

For the endless Z12 cable robots with the parameters given in Table 1, a test trajectory was computed where the platform simply performs a full rotation around its z-axis with angle \(\phi \) at the position \(\mathbf{{r}}=[0,0,1.5]^\mathrm{T}\,\)m. The Dykstra method was used to compute force distribution for all angles in the given range \(\phi \in [-\pi ,\pi ]\) which force limits \(f_i\in [f_{\text {min}},f_{\text {max}}]=[1,10]\,\)N. The resulting forces are shown in Fig. 3 where one can easily see that all 12 cables can be kept under tension and no cable violated the given bounds for the cable forces. Thus, the orientation workspace of the sample pose indeed includes a full rotation of the platform.

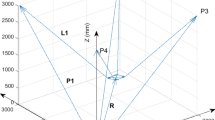

Interestingly, the full rotation maneuver is possible at different positions. To quantitatively study this property of the robot, the wrench-feasible total orientation workspace of the robot was computed using the hull algorithm for the rotation set \(\mathscr {R}\) given above. Using the Dykstra method and the same force limits as given above, a significantly large workspace was found (see Fig. 4).

The region of convergence and the computation time heavily differ amongst the considered methods for force distribution. As conjectured in [10], the closed-form method performs excellently in terms of computation time but is rather limited concerning the region where force distributions can be computed. The advanced closed-form method slows down the computation time by around a factor of four in average. From the analysis of the complexity of the algorithm at most, a slow-down of the degree-of-redundancy r is expected and the measured computation time is consistent with the expectations. Using the advanced closed-form method, the size of the computable workspace is largely extended by a factor of around eight. Finally, the Dykstra as reference method provides similar results in terms of workspace size compared to the advanced closed-form method. However, the alternative projections used in Dykstra’s iterative scheme are rather inefficient for highly redundant cable robots and lead to computation times that are one order of magnitude larger. Furthermore, the consideration of a larger region of feasible cable forces adds additional efforts to the Dykstra scheme where the computation time for closed-form and advanced closed-form remains almost constant (Table 2).

Using the technique described above, the cable–cable interference was studied. For this analysis, the following geometric parameters were used for the endless Z12 design: \(r_{\!\text {B}}=2\), \(r_{\!\text {P}}=0.3\), \(H_{\!\text {B}}=3\), \(h_{\!\text {B}}=2\), \(H_{\!\text {P}}=0.5\), and \(h_{\!\text {P}}=0.2\). Note, that the z coordinates of the points \(\mathbf{{b}}_5\)–\(\mathbf{{b}}_8\) are smaller in order to avoid collisions between the cable groups 1–4 and 5–8. It can be seen from Fig. 5 that the total orientation workspace and the region of interference is separated and thus cable–cable interference is avoided throughout the workspace.

5 Conclusion

In this paper, design archetypes of cable-driven parallel robots with a huge orientation workspace are proposed and studied. Surprisingly, such robots can execute a full rotation of their platform while maintaining tension in the cables and avoiding collisions amongst the cables. Also the size of the total orientation workspace is surprisingly large. However, the effect comes at the costs of employing a large number of actuators and additional challenges to cope with many cable. In the future, it is planned to experimentally study such designs. We conjecture that there exists an eight or even seven cable design that also has the unlimited rotation orientation workspace but until now no such configuration is known.

References

Bouchard, S., Moore, B., Gosselin, C.: On the ability of a cable-driven robot to generate a prescribed set of wrenches. J. Mech. Robot. 2(1), 1–10 (2010)

Ebert-Uphoff, I., Voglewede, P.A.: On the connections between cable-driven parallel manipulators and grasping. In: IEEE International Conference on Robotics and Automation, pp. 4521–4526. New Orleans (2004)

Gouttefarde, M., Merlet, J.P., Daney, D.: Wrench-feasible workspace of parallel cable-driven mechanisms. In: IEEE International Conference on Robotics and Automation, pp. 1492–1497. Roma (2007)

Gouttefarde, M., Collard, J.F., Riehl, N., Baradat, C.: Geometry selection of a redundantly actuated cable-suspended parallel robot. IEEE Trans. Rob. 31(2), 501–510 (2015)

Hassan, M., Khajepour, A.: Minimum-norm solution for the actuator forces in cable-based parallel manipulators based on convex optimization. In: IEEE International Conference on Robotics and Automation, pp. 1498–1503 (2007)

Merlet, J.P.: Parallel Robots, 2nd edn. Springer, Berlin (2006)

Miermeister, P., Pott, A.: Design of cable-driven parallel robots with multiple platforms and endless rotating axes. In: Proceedings of the Second Conference on Interdisciplinary Applications in Kinematics, pp. 21–29. Springer (2014)

Perreault, S., Cardou, P., Gosselin, C., Otis, M.J.D.: Geometric determination of the interference-free constant-orientation workspace of parallel cable-driven mechanisms. ASME J. Mech. Robot. 2(3), 031016 (2010)

Pott, A.: Forward kinematics and workspace determination of a wire robot for industrial applications. In: Advances in Robot Kinematics (ARK), pp. 451–458. Springer (2008)

Pott, A.: An improved force distribution algorithm for over-constrained cable-driven parallel robots. In: Computational Kinematics, pp. 139–146. Springer (2013)

Verhoeven, R.: Analysis of the workspace of tendon-based stewart platforms. Ph.D. thesis, University of Duisburg-Essen, Duisburg, Germany (2004)

Verhoeven, R., Hiller, M.: Estimating the controllable workspace of tendon-based stewart platforms. In: Advances in Robot Kinematics (ARK), pp. 277–284. Springer (2000)

Acknowledgements

The first authors would like to thank the German Research Foundation (DFG) for financial support of the project within the Cluster of Excellence in Simulation Technology (EXC 310/1) at the University of Stuttgart.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Pott, A., Miermeister, P. (2018). Workspace and Interference Analysis of Cable-Driven Parallel Robots with an Unlimited Rotation Axis. In: Lenarčič, J., Merlet, JP. (eds) Advances in Robot Kinematics 2016. Springer Proceedings in Advanced Robotics, vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-56802-7_36

Download citation

DOI: https://doi.org/10.1007/978-3-319-56802-7_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-56801-0

Online ISBN: 978-3-319-56802-7

eBook Packages: EngineeringEngineering (R0)