Abstract

This chapter aims to provide methods and tools for sustainable values creation in the context of high value engineering. First, a sustainable value-driven life cycle design framework is proposed for product and process engineering innovation for sustainability and provides a conceptual linkage with the value-creating activities such as design, production, supply chains, partnerships, and distribution channels. Then, approaches for the integration of ecological assessment (i.e. LCA) with computer-aided product development are proposed as a useful tool to support sustainable value-oriented product and process engineering. The proposed approaches and tools are expected to help bring experts in fields of product and process engineering, industrial management, and ecological assessments to a common vision, and therefore accelerate development of more sustainable products, processes, and business strategies.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Sustainable value

- Life cycle engineering

- Quantified sustainability assessment

- QFD

- Discrete-event simulation

- Feature technology

- Engineering sustainability

1 Introduction

Value is the reliable performance of functions to meet customer needs at the lowest overall cost, and it can be calculated as (SAVE 2007):

where Function is what the product or service is supposed to do, while Cost is the expenditure needed to create it. These three characteristics, denominated as the “survival tripod” by Cooper and Slagmulder (1997), are related as a rule for the success of companies, which should balance this tripod in accordance with market requirements and the company strategy.

However, the question arises as existing value concept and definitions sufficient when viewing values form broader perspectives of sustainability. Just to quote: Long-term thinking has to be instilled; old fashioned values have to be recovered so that a sustainable growth and survival becomes realistic again (Ostad Ahmad Ghorabi and Jerlich 2008). Sustainable value refers to a broad set of benefits derived by a stakeholder from an exchange, which, in the context of engineering sustainability, do not only include monetary profit, but also include social and environmental aspects (Adams 2006; Rana et al. 2013; Yang et al. 2014). Sustainable value should cover all three dimensions, and sustainable value creation is proposed as a promising way of integrating engineering sustainability into the life cycle systems . Therefore, the concept of sustainable value creation could be integrated into business in order to also consider environmental and social aspects of benefits. Figge and Hahn (2013) also proposed a sustainable value model that aims at the quantitative assessment of the value-creating use of environmental, economic, and social resources. The approach can be used to answer the financial-economic question of “where environmental and social resources should be allocated in order to achieve an optimal overall return”. This value-oriented approach is necessarily complementary with burden-oriented approaches, and both need to be considered to arrive at an optimal allocation of resources (Merante et al. 2015). The equation for sustainable value calculation is as follows:

where SV refers to the sustainable value of the evaluated system, R stands for the number of resources considered in the evaluation, r stands for the individual resource (e.g. water, land, energy), y i and y* stand for the value added of the evaluated system and the benchmark, respectively, and, finally, x ir and x r * stand for the amount of resources used by the evaluated system and the benchmark, respectively. The SV indicates the extent to which a system contributes to make the resource use more sustainable. To achieve this, the efficiency use of the company’s resource is compared against the efficiency use of the same resource at the benchmark level, such as a national economy, an industry sector, another company, or a performance target.

This chapter focuses on sustainable value creation in the context of high value engineering . First, the framework of sustainable value-driven life cycle design is presented for product and process engineering innovation for sustainability and provides the conceptual linkage with the value-creating activities of the firm such as design, production, supply chains, partnerships, and distribution channels. Then, approaches for the integration of ecological assessment (i.e. LCA) with computer-aided product development are proposed as a useful tool to support sustainability-oriented product and process engineering. The proposed approaches and tools are expected to help bring experts in fields of product and process engineering , industrial management, and ecological assessments to a common vision, and to accelerate development of more sustainable products, processes, and business strategies.

2 Product Life Cycle Design for Sustainable Value Creation

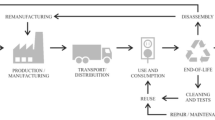

Sustainable product development helps to use a company’s resources, usually in terms of materials and energy in the most economical way which implies the least environmental impact. This constitutes a benefit for both, the organization and their customers at the same time. Life cycle design (LCD) is considered to be a promising approach for reduction of environmental impacts and promotion of product performance throughout its life cycle. The term LCD refers to an integrated design of a product and its life cycle from material extraction to disposal, even recovery. A sustainable product life cycle is defined as a life cycle which can minimize the material and energy consumption, amount of waste, and environmental emissions from the viewpoint of the whole life cycle while fulfilling function, quality, cost, and profit requirements. Thus, the life cycle offers a framework for innovation for sustainability and provides the conceptual linkage with the activities of the firm such as design, production, supply chains, partnerships, and distribution channels. For supporting the life cycle design, various concepts and Design for X (DfX) methodologies have been proposed; examples include industrial ecology (Graede and Alleby 1995), life cycle planning (Ishii et al. 1997; Kato et al. 2000; Kato and Kimura 2004; Kobayashi 2006; Umeda 2001), life cycle costing (LCC), design for the environment (Ray and Guazzo 1993; Zhang et al. 2011), design for disassembly (Kroll and Hanft 1998; Noller 1992), design for reuse and remanufacturing (Du et al. 2013; Umeda et al. 2006; Zwolinski et al. 2006), design for recyclability (Ishii and Lee 1996; Rose et al. 1998), end-of-life design (Kara et al. 2005; Umeda et al. 2006; Xing et al. 2003; Ziout et al. 2014), and modular design considering life cycle issues (Yu et al. 2011).

This study focused on the methods and tools for sustainable values creation and promotion in the context of product and process engineering . Given the advantages of LCD, this study tied to integrate the sustainable value concepts and LCD theory for development of sustainable value-driven product life cycle design methodologies. In order to accomplish this goal, three research problems are to be addressed. First, identification and description of the various sustainable value opportunities throughout the product life cycle. In life cycle design, a designer should consider various aspects of sustainability, including resource and energy efficiency, wastes and emissions, economic benefits and social benefits. Thus, the comprehensive understanding of design-driving factors is the very first and important step of all the design processes. In this step, it is important to select and carefully formulate the sustainable design goal indicator system, because these indicators are important to assessment of the design results and conclusion of the design process. Second is the generation of sustainable life cycle solution by translation of various sustainable value goals into operative engineering characteristics of product and its LC process. The design team proposes a set of life cycle design solutions that can achieve the design goals, focusing on interrelations among the goals, the product, and the life cycle flow. Though many researchers identified the importance of strategies required to integrate product design and life cycle processes in life cycle engineering (Ishii 1995; Ometto et al. 2008; Tchertchian et al. 2010), they mainly focused on the end-of-life strategy to close the material loop and design methods for realizing the end-of-life strategy. Therefore, an integrated life cycle design methodology must help engineers to estimate the life cycle implication of a candidate design, identify cost and profit drivers, and facilitate “simultaneous” design of the product and enlistment of the manufacturing specifications, service logistics, and product retirement plan throughout the engineering value chain associated with the life cycle. Third, design evaluation methods and tools. Life cycle assessment (LCA) is a strong tool for evaluating material and energy consumption and emissions of a life cycle. However, it cannot evaluate balances of a life cycle in terms of material, energy, and money, especially when the life cycle has loops such as remanufacturing, reuse, and recycling. LCA itself could not provide the rate of material circulation by means of, for example, part reuse, as it depends on various factors such as failure rate of the parts, the market life of the product, and the efficiency of the collection system, and the relation between these factors is complicated and cannot be represented by a simple mathematical model. Therefore, more powerful modelling and analysis supporting tools are needed.

2.1 Framework for Sustainable Value-Driven Product Life Cycle Design

Shown in Fig. 1 is the framework for sustainable value-driven life cycle design proposed by this study. The concept of “domain” (Suh 2001) is introduced. Three design domains which are the sustainability goals (SGs) domain, the life cycle function requirements (LcFRs) domain, and the LCD solution domain are then constructed. Based on the definition of the three domain, LCD is then organized as the structured and strategic mapping of SGs to functional requirements of both product and it major life cycle processes, and then simultaneously into operational engineering characteristics of both product and its major life cycle process. A three-dimensional model of sustainable value goals for life cycle design is first proposed. Then, a QFD-based life cycle scheming approach is proposed for sustainable product life cycle strategy formulation. Also, Life Cycle Simulation is then employed for modelling complicated closed-loop-type product life cycles and quantified evaluation of sustainable value potentials of different stages and stakeholders.

For readers’ comprehension of the sustainable value-driven life cycle design framework, the design elements in each domain are explained as follows:

-

Sustainability goals of life cycle design

It is proposed in the literature that value has multiple forms, including value destroyed, value missed, and value opportunity. Different forms of value can be converted into each other based on the mechanism between them (Bocken et al. 2013). However, the ultimate goal of value engineering is value creation. In order to map the sustainable value into the framework of life cycle engineering, the concept of sustainability goals for life cycle design is proposed in this paper. Sustainability goals (SGs) are the identified requirements on various potentially sustainable value-creating engineering activities throughout the engineering value chain associated with the product life cycle. Therefore, based on the definition of sustainable value, a three-dimensional model of SGs for life cycle design is proposed as shown in Fig. 2. First, SGs are identified throughout the life cycle from R&D to end-of-life treatment (EoLT) . It includes not only function and performance information required for product design and manufacturing, but also information of products status and users’ feedbacks during product use, and requirements on product end-of-life treatments. Second, SGs are identified from perspectives of different stakeholders associated with the life cycle, including product users, collaboration partners, managers, R&D teams. Third, SGs can be categorized into several different aspects including product and process engineering, business and management, and therefore has the strong capability of requirement description.

SGs can be categorized into requirements on product itself including function and performance, quality, structure, appearance, material, cost, etc. Collaboration requirements include those on outsourcing, collaborative design, planning and business, etc. Technological requirements include manufacturability flexibility, procession, environmental-friendliness, etc. Management requirements include process optimization, security, law and regulation obedience, cost and profit, etc.

-

Life cycle function requirements (LcFRs) :

Here, function requirements include those on both product and its life cycle process. For instance, function requirements of mechanical products generally include those on energy, motion, control, material, and environmental impacts (see Fig. 3).

Compared with traditional product design, the most important and distinguishing feature of life cycle design is the design of the circulation of products, components, and materials around the life cycle so as to minimize resource demands and environmental emissions. In order to realize life cycle design objectives, life cycle stage of maintenance and end-of-life treatment should be carefully considered and planned. Therefore, function requirements on maintenance and end-of-life stages of product life cycle were illustrated (see Fig. 4).

-

Sustainable LCD solutions:

LCD solutions refer to product and life cycle process design solutions. Product design solutions (ProdS) generally mean the basic structure of product such as major components and their key engineering characteristics such as material, weight, shape, etc. The product structure can be typically demonstrated by the hierarchical model as shown in Fig. 5.

The life cycle process solution here is defined as a combination of life cycle options (LOPs) such as sustainable manufacturing, maintenance, collection, recycle, and reuse of disposed products and components and describe the flows of products, components, and materials around the life cycle. And each option is further described by certain attributes (see Table 1). Based on the plan, the life cycle as a network of life cycle unit processes can be developed.

2.2 Generation of Sustainable Life Cycle Design Solutions by a Modified QFD Approach

In order to realize the LCD process proposed in the last section, a modified QFD method is developed in this paper. Applications to describe environmental requirements in a QFD matrix have been proposed (Masui et al. 2001; Sakao 2007; Sakao et al. 2001; Zhang et al. 1999). However, the methods are still focused on the design of product itself. The proposal of the QFD method in this paper is inspired by the study of An et al. (2008) on integrated product–service roadmap. As shown in Fig. 6, the modified QFD creates two interlinked mappings. The first mapping starts with SGs (inputs) and then translates these requirements into LcFRs. The second mapping follows through these LcFRs and translates them into the product characteristics (generally speaking, the structure elements, i.e. module, part, component, of the product) and LC process options and attributes (outputs).

Compared with the traditional QFD , several modifications have been done for the proposed approach. Similar to the study of An et al., two sets of product and process solutions are linked to the LcFRs in the second HoQ. Thus, the correlation matrix in the second HoQ is divided into three matrices: two self-correlation matrices of product (i.e. module, part, component, etc.) and LC process solutions, and one attaching matrix between each product solution with each life cycle process solution. For the relationships between SGs and LcFRs and those between LcFRs and LCD solutions, the relations can be rated on certain types of scale such as (0, 1, 5, 9), where 0 corresponds to no relationship and 9 to strongest relationship. The calculation of the weight of LcFRs, product, and LC process solutions is the same as that of the conventional QFD. By the proposed QFD approach, it can be convenient for the designers to conduct systematic analysis. Designers can quantify the strength of relations between SGs and engineering characteristics of product and its major life cycle processes, as well as those between product and process, i.e. components and its adaptive life cycle options. Therefore, the outputs of the second HoQ are then used to guide the simultaneous generation of product concepts and some feasible life cycle process plans.

2.3 Life Cycle Simulation for Sustainable Value-Driven Product Life Cycle Design Evaluation

Though Life Cycle Assessment (LCA, see Sect. 3.1 for more details) and Life Cycle Costing (LCC) are considered to be powerful tools to assess the environmental impacts and economic viability of a life cycle in a holistic and quantitative manner, they cannot handle the various stochastic factors throughout product life cycle, or execute complicated logics, or evaluate the balance between supply and demand of recycled materials and reusable components in closed-loop-type life cycles. Moreover, LCA and LCC heavily rely on data some of which might be difficult to acquire during the design stage. Instead, Life Cycle Simulation (LCS) as a powerful tool of describing and analysing product life cycles can effectively handle the complexity and innovation in product life cycle design. In particular, LCS makes it possible to estimate the effectiveness of circulation of product, components and materials, as it can simulate the flows of material, energy, information, and cost in product life cycles (Takata and Kimura 2003; Umeda et al. 2006; Matsuyama et al. 2014). By LCS, designers can find out useful information for life cycle design and determine life cycle solutions by constructing models of product and its product life cycle and executing what-if analyses by simulations on the models even with smaller amount of data that might be ambiguous. Though LCS is still under development, it is considered to be a promising supporting tool for life cycle design, especially for the early stage of design.

A product life cycle design evaluation model based on LCS is proposed in this research (see Fig. 7). First, a LCS input model which consists of sub-models of product, life cycle process, and market situations is proposed. It translates life cycle design information and background assumptions into LCS input parameters. The product model contains information of product hierarchical structure, material composition, function deterioration, and designed lifetime. The process model contains information of product life cycle process network which describes the sequential or conditional relations between various unit processes of product life cycle, and the environmental (i.e. materials, energy, emissions) and economic input and output of each unit process. The market model contains information of defined product demands in the market, end consumers’ behaviour characteristics (i.e. product use frequency, product load during operation) and preferences (i.e. maintenance preference such as maximum tolerant maintenance cost, minimum tolerant MTBF, etc.).

Second, a general Life Cycle Simulation model of discretely manufactured products is established based on discrete-event system simulation theory (Banks et al. 2005). Elements of product life cycle as a discrete-event system are defined, including “entities” such as product, components, materials, corporates, and end-users, “events” such as “generation of orders on new products”, “product arrival at end-users”, “product failure during use”, “generation of requirements of maintenance”, “product retirement”, etc., as well as “activities” (or life cycle processes) such as “manufacturing”, “use”, “maintenance”, “collection”, “recovery” and “disposal”. The event-based simulation strategy is adopted, and the simulation models including an engine model for advancing the simulation, and models for execution of all life cycle “activities” (or processes) are constructed. On start of the simulation, the engine model reads in the event list, finds the event nearest to happen, and then advances the simulation clock to the event happening time and initiates the process which is set to be triggered by the event. The manufacturing process is executed on the order of new products which is either generated according to a given demand pattern or due to retirement of products of end-users. Components can be manufactured using certain ratio of recycled materials provided by the recovery process. Product can be assembled using either newly manufactured components or reusable ones supplied by the recovery process. The ratio of use of the new components to that of the reusable ones is specified according to the life cycle plan. The newly manufactured products are randomly distributed to end-users in need. After the product’s arrival at an end-user, the use process is initiated. In the use process, the usage histories of products and components are updated. The usage of products is terminated due to product obsolescence, and interrupted by product failures (which is caused by component failure) or planned maintenance. Occurrence of product obsolescence or failures are determined, respectively, by product value lifetime and component physical lifetime, and the product value lifetime and component physical lifetime are set by random sampling on product purchase and component manufacturing, respectively. The product value lifetime function and component physical lifetime functions are defined in the product model. The products retired either due to obsolescence or being not repairable are then either “collected” or “disposed”. The collected used products are then to be recovered. In the recovery process, the products are first disassembled and inspected. The components are either recycled or reconditioned according to the life cycle plan. The maintenance process is executed on requirements of repair or scheduled conditioning. In the maintenance process, the failed components could be replaced by either newly manufactured ones or reusable ones, depending on the life cycle plan. The repaired or conditioned products are then returned to the end-users and continue their usage process. The failed components are either to be recovered or just casually disposed.

During the execution of each process, resource demands, waste amounts, end-user costs, and different corporate costs and revenues are calculated and recorded. The life cycle design alternatives are evaluated based on the simulation outputs which generally include resource and energy demands, waste amount, recovery rate, recycling and reuse rate, end-user costs, corporate costs and profits.

3 CAX–LCA Integration to Support Sustainable Value-Oriented Engineering

With an increasing awareness of environmental crises as well as the growing pressures from the competitors, manufacturers are receiving more concerns with the environmental performance of their products. Life Cycle Assessment is one of the most mature methods to quantify the environmental impacts of product through its life cycle (Baumann and Tillman 2004; ISO 2006). It is of great benefits to perform LCA along with various engineering activities throughout product life cycle, because it is a useful tool predicting the environmental consequences of product and process engineering solutions and therefore can help determine whether if the solution is better for the environment than the currently available ones. However, as comprehensive LCA requires great efforts in data collection, it is very difficult to be conducted during product development, especially in early phases such as conceptual design. Besides, LCA results do not efficiently and explicitly reflect the relations between product and process design factors and product environmental performance, and therefore require professional interpretations to bridge the gap between engineering and LCA domains. For the integration of LCA and product and process engineering, the knowledge needs to be represented in a way that it can efficiently and effectively be shared and used by the engineers from different domains.

Integration of ecological assessment into computer-aided product development environments (i.e. CAX, computer-aided X systems including CAD, CAPP, CAM, PLM, etc.) is proposed so as to potentially ease the difficulties of inclusion of LCA into engineers’ daily works (especially the early planning and design phase). Also, feature technology (FT) is considered to be a straightforward approach for realizing data migration between CAX and LCA systems. The feature concept was initially inspired from the desire to support information integration between CAPP (computer-aided process planning) and CAD systems in the manufacturing field. A commonly accepted feature definition is “a generic shape associated with some engineering semantics” (Shan and Mäntylä 1995). To facilitate such integration, the International Organization for Standardization (ISO) delivered the first edition of the standard for “Mechanical product definition for process planning using machining features” as one of the application protocols (APs) of the ISO10303 (industrial automation systems and integration—product data representation and exchange), otherwise known as the standard for exchange of product model data (STEP) (ISO 1994). However, STEP suffers from the rigidity and complexity in implementation and was not intended to share design intents, such as design history and constraints (Xie et al. 2013). Historically, two main research streams are feature recognition and feature-based modelling. Extensive research has been conducted in feature recognition over the past three decades (Vema and Rajotia 2010). The disadvantages of feature recognition algorithms were their complexity and limited types of features that could be recognized (Lam and Wong 2010). On the contrary, another mainstream technological approach is feature-based modelling, which builds models by using feature templates rather than recognizing features from an existing geometrical model. This approach contains rich information associated with design models (Xie et al. 2013). Traditional feature technology in the mechanical design domain has already been well established by many researchers (Babic et al. 2008), and the exploration of this research domain is not the focus of this paper. The concept of feature has been extended and used to bridge mechanical product design and engineering analysis, such as stress analysis with finite element method (FEM) (Lee 2009) as well as manufacturability analysis (Syaimak and Axinte 2011). In the last decade, many researches were proposed to integrate ecological assessment into CAD systems. Otto et al. (2001, 2003) proposed a framework for structured data retrieval in LCA using feature technology and integrating data from a product model and life cycle inventory (LCI) database. Friedrich (1998) tried to integrate LCA to CAD/CAE system and applied it to the product design, which could support the designers to cope with environmental challenges. Nawata and Aoyama (2001) proposed a system especially applicable to machined parts, which automatically generated LCA feedback for the design process. Marosky et al. (2007) presented the structure of an algorithm that allows mutual transfer of data between CAD (SolidEge) and LCA tool (SimaPro). Mathieux et al. (2005) have proposed a tool prototype based on feature technology in extracting CAD/PDM data, from CATIA (CAD) to EIME (LCA). Also, “SolidWorks Sustainability ” developed by Dassault Systems allows environmental assessment in real time (once a feature is attributed). However, these works are interested only in the manufacturing phase. In fact, the environmental impacts are generated throughout the life cycle, especially in the use or end-of-life (EOL) phase. However, research suggested that current LCA–CAX solutions are still inaccurate compared to professional LCA tools. This is because: the CAD model represents the final form of design intent, while environmental impacts are estimated from a process perspective; CAD systems do not support LCA data related to processes, machines, purchasing, user and suppliers. Most works of the CAX (i.e. CAD, CAM, CAPP) and LCA system integration are interested only in the manufacturing phase, though its known environmental impacts are generated throughout the whole life cycle. Given the limits of existing studies, the feature-based methodologies to integrate LCA with mechanical product, process engineering are explored in this chapter. The main content of this section include: (1) the feature definition and classification for LCA; (2) the framework of feature-based LCA; (3) the feature-based life cycle modelling approach is developed to address the scheme of representing life cycle processes, life cycle inventory analysis, and enable the exchange of valuable data between the domain of LCA and current computer-aided engineering tools.

3.1 Brief Introduction of LCA

LCA is a tool for quantifying the environmental performance of products taking into account the complete life cycle, starting from the production of raw materials to the final disposal of the products, including material recycling if needed. The leading standards for LCA are ISO 14040 : Principles and Framework and ISO 14044: Requirements and Guidelines. ISO 14040 considers the principles and framework for an LCA, while ISO 14044 specifies the requirements and guidelines for carrying out an LCA study. An LCA study consists of four main phases:

- Step 1::

-

Defining the goal and scope of the study.

- Step 2::

-

Making a model of the product life cycle with all the environmental inputs and outputs. This data collection effort is usually referred to as life cycle inventory (LCI).

- Step 3::

-

Understanding the environmental relevance of all the inputs and outputs. This is referred to as life cycle impact assessment (LCIA).

- Step 4::

-

The interpretation of the study.

LCA provides the quantitative and scientific basis for all these activities. In many cases, LCA feeds the internal and external discussions and communications. The most important applications for an LCA are:

-

Identification of improvement opportunities through identifying environmental hot spots in the life cycle of a product.

-

Analysis of the contribution of the life cycle stages to the overall environmental load, usually with the objective of prioritizing improvements on products or processes.

-

Comparison between products for internal or external communications, and as a basis for environmental product declarations.

-

The basis for standardized metrics and the identification of key performance indicators used in companies for life cycle management and decision support.

3.2 Feature-Based Multi-View Life Cycle Modelling

Feature, in this study, is described as a way to transfer geometric, technological, or functional information of a product entity between various stakeholders throughout the development process and the life cycle. Each feature can be specialized according to its own domain (design, manufacturing, assembly, LCA, etc.). Obviously, every stakeholder focuses on specific information and is only concerned by a set of properties of different entities, which is called the feature view (Bronsvoort and Noort 2004). Therefore, the employment of feature technology for CAX–LCA integration should not only enable the migrants of valuable data between the LCA and current computer-aided engineering tools such as CAD, CAM (computer-aided manufacturing), CAPP and PLM (Product Lifecycle Management) systems, but also to address the stakeholder focus on life cycle processes modelling and life cycle inventory analysis, thus facilitating the development of sustainable products. A feature-based approach is proposed in this chapter to address the problem of life cycle modelling and integrated data management for LCA. However, before going into the details of feature-based life cycle modelling, the definition and classification of features for LCA is presented here first. Generally speaking, the CAX tools can be categorized into types of product-focused such as CAD systems and process-focused such as CAPP and CAM systems. Thus, in order to enable the data exchange between CAX and LCA tools, two types of features which are the product features and operation features are defined in this study, based on engineering domains they are applied to.

-

Product features (PFs)

Product feature is defined as an information set for dynamic product representation throughout its life cycle. Product features are then classified into:

-

Form features form feature refers to a region of a part with some interesting geometric or topological properties. Form features contain both shape information and parametric information of a region of interest. Form features are commonly used as the primary means of creating 3D geometric models in CAD system. Examples of form features include extruded boss, loft, holes, etc.

-

Connectivity features connectivity feature refers to the relative position and mating relations between parts. Connectivity features can be characterized by the static attributes when the connection has been established or broken, as well as dynamic characteristics about how the connection can be established (during assembly) or can be broken (during disassembly). Thus, by specifying a connectivity feature in a product model, the assembly-specific information known by the feature is also available in the model. In this study, the connectivity feature may contain but not limited to information of: connected product entity; the reference entity for establishing the connectivity; tolerances required to establish the connection; geometric refinements of the connection to ease the assembly operation (e.g. rounds, chamfers, welding grooves).

-

Technical features technical features are non-geometry/topology-related features, including material features with attributes of material type, material properties, recyclability, status, as well as functionality features with attributes of product entity functionality description and performance parameters (i.e. useful life time, working power, reusability, etc.)

-

Operation Features (OFs)

Operation feature is defined as an information set of operations associated with physical and functional changes of product entity, and resulting in environmental impacts. Operation features are characterized by attributes of operation type, operation parameters, and equipment and tooling specifications.

Though product life cycle, in LCA study, is generally modelled as a network of processes such as manufacturing, operation, logistics, use, maintenance, collection, remanufacturing, recycling, and disposal, it can also be defined as a sequence of state changes of different product entities (Riou and Mascle 2009). Thus, a feature-based multi-view life cycle modelling approach is then proposed for integrated life cycle data management . As shown in Fig. 8, each process throughout the life cycle is modelled with views of product state, associated operations and the resulting life cycle inventory. The three life cycle views are integrated based on the feature mapping mechanism between the domains of product design, process design, and inventory. Thus, the structured relations between various product and process engineering parameters, and indicators of environmental impacts are then developed along with life cycle modelling. The product state view is the dynamic representation of product entities throughout the life cycle. Product state, which may include changes in product shape and form, material properties, functionalities associated with the process is characterized by product feature instances. Operations are defined as the activities causing the product state change and resulting in environmental impacts. The operation view is characterized by operation feature instances. For each process alternative, the operation features can be instantiated by product-to-operation feature mapping algorithms (i.e. STEP—“Standard for the Exchange of Product Model Data”-based process planning based on feature). Based on the product state and operation view modelling, the inventory view is then developed based on the domain mapping form product and operation feature to process inputs and outputs. The process input–output calculation equations should be first established based on process principles and the type of product and operation attributes adapt to the equations are then determined.

3.3 Feature-Based LCA–CAX System Integration to Support Sustainable Value-Oriented Engineering

In this section, the framework for feature-based LCA study is proposed (see Fig. 9). The feature-based life cycle model serves for the data exchange between CAD/CAPP/PLM and LCA systems. Based on the goal and scope definition, the product and process feature attributes required for life cycle modelling and LCI are identified. Necessary data from CAD, CAPP, and PLM systems are collected by feature extraction algorithms. The process inputs and outputs are calculated and then transferred to LCA systems for life cycle inventory analysis and the environmental impact evaluation. Also, by evaluating the sensitivity of impact of product and process feature change on LCA results, the critical engineering factors to environment impacts can be identified.

For the realization of the proposed feature-based LCA approach, the LCA–CAX system architecture is then proposed (Fig. 10). A feature-based LCA tool is proposed for multi-view life cycle modelling and data integration, LCI and impact assessment and improvement analysis. The feature-based data retrievers collect product- and process-related data according to the requirements of life cycle modeller of the LCA tool. The life cycle modeller then generates the multi-view life cycle model and sends the calculated life cycle process input–output data to the LCI and EI calculator. Based on the inventory and impact assessment results from the LCI & EI calculator, the improvement analysis provides modification suggestions based on identification of important feature instances to environmental impacts throughout product life cycle and opportunities for product and process sustainability improvements.

CAD is the most commonly used engineering software for product design. A CAD-LCA software prototype (Tao et al. 2017) to support sustainable value-oriented engineering consists of a plug-in integrator for different CAD systems, a life cycle database and a LCA module for feature-based life cycle modelling and assessment. The plug-in CAD integrator realizes product feature model extraction. The extracted product feature model is sent to the life cycle database with an index tag to distinguish each feature and make a quick search. The LCA system retrieves the product feature model, builds the life cycle process model based on PF-OF mapping, and then calculates the life cycle inventory and environmental impacts based on numerical data from product and operation feature instances.

4 Conclusion

This chapter presents the life cycle design methodologies for sustainable value creation and engineering sustainability in general. The proposed life cycle design framework denotes a systematic and concurrent development of a product and its life cycle process. The key concept of this frame is to organize the integrated product design and process planning as the strategic design mapping process between three domains, including the domain of sustainable goals which are identified sustainable value creation opportunities and potentials in engineering activities throughout the engineering value chain associated with the product life cycle, the domain of product and life cycle process functions, and the domain of life cycle engineering solutions of both product and process. The Life Cycle Simulation is employed for the description of complicated circulation in closed-loop-type life cycle and evaluation of life cycle engineering solutions for sustainable value potentials for different life cycle phases and involved stakeholders. Also, a feature-based CAX–LCA integration approach is proposed for engineering sustainability. It aims at helping engineers to incorporate sustainable value into their daily engineering activities by easier life cycle data retrieval, modelling and environmental assessment. The proposed life cycle design methodologies and tools are expected to help bring experts of product design and life cycle management to share a common vision, that helps avoid conflicts in the traditional design process.

References

Adams, W. M. (2006). The future of sustainability: Re-thinking environment and development in the twenty-first century. Report of the IUCN renowned thinkers meeting.

An, Y., Lee, S., & Park, Y. (2008). Development of an integrated product-service roadmap with QFD. International Journal of Service Industry Management, 19(5), 621–638.

Babic, B. R., Nesic, N., & Miljkovic, Z. (2008). A review of automated feature recognition with rule-based pattern recognition. Computers in Industry, 59, 321–337.

Banks, J., Carson, J., et al. (2005). Discrete-event system simulation (4th ed.). New York: Prentice Hall.

Baumann, H., & Tillman, A. M. (2004). The hitch hiker’s guide to LCA. Stockholm: Studentlitteratur.

Bocken, N. M. P., Short, S. W., Rana, P., et al. (2013). A value mapping tool for sustainable business modelling. Corporate Governance, 13(5), 482–497.

Bronsvoort, W. F., & Noort, A. (2004). Multiple-view feature modelling for integral product development. Computer Aided Design, 36(10), 929–946.

Cooper, R., & Slagmulder, R. (1997). Target costing and value engineering. Oregon: Productivity Press.

Du, Y., Cao, H., Chen, X., et al. (2013). Reuse-oriented redesign method of used products based on axiomatic design theory and QFD. Journal of Cleaner Production, 39, 79–86.

Figge, F., & Hahn, T. (2013). Value drivers of corporate eco-efficiency: Management accounting information for the efficient use of environmental resources. Management Accounting Research, 24(4), 387–400.

Friedrich, J., & Krasowski, H. (1998). Ecology-based product data model. SAE technical paper.

Graede, T., & Allenby, B. (1995). Industrial ecology. Englewood Cliffs: Prentice Hall.

Ishii, K. (1995). Life-cycle engineering design. ASME Journal of Vibration and Acoustics, 117(B), 42–47.

Ishii, K., & Lee, B. (1996). Reverse fishbone diagram: A tool in aid of design for product retirement. Paper presented at the proceedings of ASME design technical conference, irvine, CA,USA.

Ishii, N., Fuchino, T., & Muraki, M. (1997). Life cycle oriented process synthesis at conceptual planning phase. Computers & Chemical Engineering, 21, S953–S958.

ISO. (1994). ISO10303-1: Industrial automation systems and integration-product data representation and exchange-part 1: Overview and fundamental principles. Geneva: International Organisation for Standardisation (ISO).

ISO. (2006). ISO 14040 Environmental management—Life cycle assessment—Principles and framework. Geneva: International Organization for Standardization.

Kara, S., Mazhar, M., Kaebernick, H., et al. (2005). Determining the reuse potential of components based on life cycle data. CIRP Annals-Manufacturing Technology, 54(1), 1–4.

Kato, S., Hata, T., & Kimura, F. (2000). Decision factors of product life cycle strategies. Paper presented at the Proceedings of 7th CIRP international seminar on life cycle engineering.

Kato, S., & Kimura, F. (2004). The product life cycle design method using a strategic analysis. Paper presented at the proceedings of 11th international CIRP life cycle seminar on product life cycle quality management issues.

Kobayashi, H. (2006). A systematic approach to eco-innovative product design based on life cycle planning. Advanced Engineering Informatics, 20(2), 113–125.

Kroll, E., & Hanft, T. A. (1998). Quantitative evaluation of product disassembly for recycling. Research in Engineering Design-Theory Applications and Concurrent Engineering, 10(1), 1–14.

Lam, S., & Wong, T. (2010). Recognition of machining features—A hybrid approach. International Journal of Production Research, 38(17), 4301–4316.

Lee, S. H. (2009). Feature-based non-manifold modeling system to integrate design and analysis of injection molding products. Journal of Mechanical Science and Technology, 23, 1331–1341.

Masui, K., Sakao, T., & Inaba, A. (2001). Quality function deployment for environment: QFD (1st)—A methodology in early stage of DfE. Paper presented at the proceedings of eco-design 2001-second international symposium on environmentally conscious design and inverse manufacturing.

Marosky, N., Dose, J., Fleischer, G., et al. (2007). Challenges of data transfer between CAD and LCA software tools. In Proceedings of 3rd international conference on life cycle management.

Mathieux., F, Roucoules., L, Lescuyer, L, et al. (2005). Opportunities and challenges for connecting environmental assessment tools and CAD software. In Proceedings of LCM 2005-innovation by Life cycle management.

Matsuyama, Y., Matsuno, T., Fukushige, S., et al. (2014). Study of life cycle design focusing on resource balance throughout product life cycles. Procedia CIRP, 15, 455–460.

Merante, P., Van Passel, S., & Pacini, C. (2015). Using agro-environmental models to design a sustainable benchmark for the sustainable value method. Agricultural Systems, 136, 1–13.

Nawata, S., & Aoyama, T. (2001). Life-cycle design system for machined parts-linkage of LCI data to CAD/CAM data. In Environmentally conscious design and inverse manufacturing, 2001. Proceedings EcoDesign (pp. 299–302).

Noller, R. M. (1992). Disassembly for disassembly tactioes. Assembly Automation, 33(1), 24–26.

Ometto, A, Gueler, A., & Pigosso, D. (2008). A proposal for a framework for life cycle engineering. Paper presented at the proceeding of 15th CIPR international conference on life cycle engineering.

Ostad Ahmad Ghorabi, H., & Jerlich, J. (2008). Value based life cycle analysis for occupational. In Environmental and legal compliance in organizations 1st international conference on industry safety, occupational health and safety in organizations. Isfahan, Iran.

Otto, H.E., Mueller, K.G., & Kimura, F. (2001). A Framework for structured data retrieval in LCA using feature technology. In Proceedings of second international symposium on environmentally conscious design and inverse manufacturing (pp. 250–255).

Otto, H.E., Kimura, F, Mandorli, F., et al. (2003). Integration of CAD models with LCA. In Proceedings of 3rd international symposium on environmentally conscious design and inverse manufacturing.

Rana, P, Short, S., & Evans, S. (2013). D2.5—Lessons learned report, documenting the impact from use of the tools and methods and areas for improvement.

Ray, D. L., & Guazzo, L. (1993). Environmental overkill: Whatever happened to common sense? New York: Harper Collins.

Riou, A., & Mascle, C. (2009). Assisting designer using feature modeling for lifecycle. Computer-Aided Design, 41(12), 1034–1049.

Rose, C. M., Beiter, K. A., & Ishii, K. (1998). Characterization of product end-of-life strategies to enhance recyclability. Paper presented at the proceedings of design for manufacturing symposium, ASME, Atlanta, Gergia.

Sakao, T., Masui, K., & Kobayashi, M. (2001). Quality function deployment for environment: QFDE(2nd report)-verifying the applicability by two case studies. Paper presented at the proceedings of eco-design 2001—Second international symposium on environmentally conscious Design and inverse manufacturing.

Sakao, T. (2007). A QFD-centered design methodology for environmentally conscious product design. International Journal of Production Research, 45, 4143–4162.

SAVE International (Society of American Value Engineers). 2007. Value Methodology Standard, US.

Shah, J. J., & Mäntylä, M. (1995). Parametric and feature-based CAD/CAM. New York: Wiley.

Suh, N. P. (2001). Axiomatic design—Advances and applications. New York: Oxford University Press.

Syaimak, A.S., & Axinte, D. A. (2011). An approach of using primitive feature analysis in manufacturability analysis systems for micro-milling/drilling. International Journal of Computer Integrated Manufacturing 2011, 22(8), 727–744.

Takata, S., & Kimura, T. (2003). Life cycle simulation system for life cycle process planning. CIRP Annals—Manufacturing Technology, 52(1), 37–40.

Tao, J., Chen, Z., Yu, S., et al. (2017). Integration of life cycle assessment with computer-aided product development by a feature-based approach. Journal of Cleaner Production, 143, 1144–1164.

Tchertchian N, Millet D., & El Korchi A (2010). A method helping to define ecoinnovative systems (product architecture + reverse supply chain structure + use cycles scenario). Paper presented at the Proceedings of seventeenth CIRP International Conference on Life Cycle Engineering.

Umeda, Y. (2001). Toward a life cycle design guideline for inverse manufacturing. In Proceedings Second International Symposium on Environmentally Conscious Design and Inverse Manufacturing (pp. 143–148).

Umeda, Y., Kondoh, S., & Sugino, T. (2006). Analysis of reusability using ‘marginal reuse rate’. CIRP Annals-Manufacturing Technology, 55(1), 41–44.

Verma, A., & Rajotia, S. (2010). A review of machining feature recognition methodologies. International Journal of Computer Integrated Manufacturing I, 23(4), 353–368.

Xie, Y., Liu, J., Liu, H., et al. (2013). Features and interoperability of computer aided engineering systems. Semantic Modeling and Interoperability in Product and Process Engineering. London: Springer.

Xing, K., Abhary, K., & Luong, L. (2003). IREDA: An integrated methodology for product recyclability and end-of-life design. Journal of Sustainable Product Design, 3(3–4), 149–172.

Yang, M., Vladimirova, D., Rana, P., et al. (2014). Sustainable value analysis tool for value creation. Asian J. Management Science and Applications, 1(4), 2014.

Yu, S., Yang, Q., Tao, J., et al. (2011). Product modular design incorporating life cycle issues—Group Genetic Algorithm (GGA) based method. Journal of Cleaner Production, 19(9–10), 1016–1032.

Zhang, Y., Wang, H. P., & Zhang, C. (1999). Green QFDII: A life cycle approach for environmentally conscious manufacturing by integrating LCA and LCC into QFD matrices. International Journal of Production Research, 37, 1075–1091.

Zhang, L., Zhan, Y., Liu, Z. F., et al. (2011). Development and analysis of design for environment oriented design parameters. Journal of Cleaner Production, 19(15), 1723–1733.

Ziout, A., Azab, A., & Atwan, M. (2014). A holistic approach for decision on selection of end-of-life products recovery options. Journal of Cleaner Production, 65, 497–516.

Zwolinski, P., Lopez-Ontiveros, M. A., & Brissaud, D. (2006). Integrated design of remanufacturable products based on product profiles. Journal of Cleaner Production, 14(15–16), 1333–1345.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Author(s)

About this chapter

Cite this chapter

Tao, J., Yu, S. (2018). Product Life Cycle Design for Sustainable Value Creation. In: Zhang, Y., Gregory, M. (eds) Value Creation through Engineering Excellence. Palgrave Macmillan, Cham. https://doi.org/10.1007/978-3-319-56336-7_12

Download citation

DOI: https://doi.org/10.1007/978-3-319-56336-7_12

Published:

Publisher Name: Palgrave Macmillan, Cham

Print ISBN: 978-3-319-56335-0

Online ISBN: 978-3-319-56336-7

eBook Packages: Business and ManagementBusiness and Management (R0)