Abstract

In the paper, a modeling of electro-hydraulic servo drive is presented. The authors proposed implementation of a dynamic model of proportional valve with the one of most important non linearity, which is square root flow characteristic. Following model is useful when system has got direct information about position of slider in valve. The Authors proposed to extend that model to electro-mechanic parts with dedicated control cards. An input voltage of real valve was in range \(\pm 10\) V and was converted to position of slider by use of transfer function with transport delay and dead zone. The results of simulation and compared data with real object were presented. Similarity of the model and the real data was equal 94% (in the worst case: for a step response with input signal 2 V). The best result was achieved for the step response by input signal with 10 V (accuracy 99.42%).

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The hydraulic machines are very useful in industry. They are used eg. in building technology [1], airplane [2], agriculture [3], cranes [4] or press machine [5, 6]. Therefore hydraulic technology is still developing. A modeling of hydraulic parts is very important for simulation process and prototype this kind of system.

In the literature an implementation of control algorithm with a model of a plant can be found. Eg. in control method called Model Following Control, the model of an object can be used for create a robust system control (like changing force of load) [7]. This method works good when model of the object is equivalent to the real object. Another article [8] recalls modeling of proportional valve via second order transfer function without comparing with real data. In this research a model of electro-hydraulic servo drive was used to test a speed control with step response and ramp signal. The result of step response shows a time of adjust in range 80 ms and error at steady-state was \(\pm 0.02\). The electro-hydraulic valve controlled motor system with variable pressure supplied by accumulators was described in [9] to keep a constant rotational speed of the motor. A gas accumulator was used as an oil source in the system. The gas accumulator was a device which accumulates hydraulic oil by the principle of the compressibility of the gas (nitrogen) [10]. The Authors assumed the electro-hydraulic proportional valve as an ideal zero opening four-way valve. Its throttle window was matched as symmetric. The model was expressed by Laplace transform equation.

Therefor it is important to search and implement new fast algorithm with reference model. The presented study is a continuation of research given in [11]. The authors used an electro-hydraulic manipulator for testing a vision system feedback. Next step is create a simulation model of manipulator for tests propose control systems without danger of humans life which working close to manipulator.

2 The Testbed

The tests were performed with used of an electro-hydraulic manipulator (Fig. 1b) equipped in two proportional valves and industrial controller B&R company [11]. The Authors used two linear cylinders which had following parameters: piston diameters 40 mm and the stroke 300 mm, 19,5 mm. A lengths of cylinders were not measured directly by PLC. These values were determined from measurements angles in each of the manipulator joints by incremental encoders with resolution equal to 3600 impulses per revolution. The all dimensions of used manipulator are shown in Fig. 1a. The positions of hydraulic cylinders were controlled by two proportional valves connected to the dedicated control cards. Input signals in the cards were in a range of −10..+10 VDC. Internal controller in cards converted input voltage proportional into flow of liquid. The construction of valve will be discussed in the next chapter.

3 Mathematical Background and Experiment

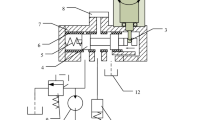

In the Fig. 2, technical construction of proportional valve is presented. A position of slider (3) in housing (1) was changed by the magnetic flux generate by a coils around permanent magnets (2, 4). The proportional solenoids were supplied by DC voltage [12]. A central position of the slider was set by two springs (5, 6) placed on both sides of slider. A position measurement x was performed by precise induction sensor (LVDT).

Symbols given in the Fig. 2 can be explained as follows:

-

\(p_0\) - is a supply pressure,

-

A - is an output of the valve, connected to the first input of the piston rod,

-

B - is an output of the valve, connected to the second input of the piston rod,

-

T - return to the main fluid tank.

Presented proportional valve (Fig. 2) are described by the following mathematical equations [13]:

where:

-

\(Q_a\), \(Q_b\) - flows,

-

\(Q_{ha}\), \(Q_{hb}\) - absorption of the actuator chambers,

-

\(Q_{sa}\), \(Q_{sb}\) - covering losses flow due to compressibility,

-

\(p_a\), \(p_b\) - pressure in the chambers,

-

\(A_a\), \(A_b\) - active surfaces of the piston,

-

\(V_a\), \(V_b\) - the volume of liquid in the chambers,

-

\(E_0 = 1,2 \cdot 10^9\) N/m\(^2\) - the modulus of elasticity.

The stroke of the hydraulic actuator is 300 mm. The diameters of the piston and the piston rod respectively, are \(A = 40\) mm and \(Aa = 63\) mm. The simulation includes linear stiffness and a linear coefficient of kinetic friction coulomb rate of \(D = 100000\) [Ns/m]. The value of the reduced mass is \(m = 18.3\) [kg] (mass of the piston and piston rod). The values of the coefficients given in the Eq. 7 are as follows: \(E_0/V_a= 9.63 \cdot 10^{12}\) Pa/m\(^3\) and \(E_0/V_b= 1,28 \cdot 10^{12}\) Pa/m\(^3\) (in the middle position of the piston).

To compute a position of the piston rod, Authors prepared simulation discrete model. In first step, Eqs. 7 and 1 are combined:

Next, Eqs. (4) and (6) are used:

Now it is possible to determine time derivative of pressure:

In the same way it is possible to write equation for \(\frac{d p_b (t)}{dt}\). To compute a pressure, integral operation must be applied. Last part is to compute the position of piston rod y based on Eq. (8):

To simplify Eq. (12) two forces can be written as follow:

Finally the equation of acceleration in hydraulic cylinder can be obtained:

For setting up position output, a two times integral must be computed. Due to compare simulation model with real data, an experimental research was performed. The Authors checked step responses of the hydraulic manipulator drive by given on the valve control card following input signal: 2, 4, 6, 8, 10 V. Measured signals in experiment were: slider position by LVDT sensor and an angle of first joint of the manipulator which was connected to the base and an arm. In simulation model a dead zone of valve must be included. In the presented valve it was 17.68% of range (measured value). Also the flow must be limited by saturation, because the hydraulic hoses and supply pump have got flow limitations. Using above assumptions in the simulation gave results shows in Fig. 3.

The simulation gave very good results of similarities to the data taken from the real manipulator y. In the second case, an input signal in model x was taken from measured slider position of the real valve. The measurement was performed for resolution to 16 Bits. The data from bits was converted to unit in [m]. This cause that the input signal was a real value and it was possible to adjustment constant parameters of the model like dead zone and flow saturation \(Q_a\). In the Fig. 4 a step response of slider position in valve was shown. Output signal contained also a dither signal which was fluctuating for all time. This was added, because a slider could be blocked in valve and dither signal protect it.

A response of slider can be approximate by second order of inertial model with transport delay. Before model implementation it is necessary to create a static characteristic of slider position. Next it is important to use rate limiter signal, because a force of magnetic field in valve coil is also limited by flow of current. The structure of model is shown in Fig. 5.

A static characteristic of the slider position was created with measurement in a stable state after 0,3 s. A main function was computed by using of linear regression. That produced a slope and offset value. Data was shown in Fig. 4b, but position of slider was represented by scale in %. Now a static characteristic can be equal to:

where y is a output of function, but it is also a input to Rate Limiter block (Matlab software). Last parts is a transfer function (TF) with transport delay:

A time constant in TF was tuning experimentally for achieve the best result of similarities of signal between model and real object. The results with comparison data were shown in Table 1 and charts with step response were shown in Fig. 6a. The worst accuracy were achieved for step response with input signal 2 an 4 V. But waveforms between model and object for 6, 8, 10 V are more accurate with result 97%.

The research proved that the model can be useful to simulate a complete electro-hydraulic drive. In the Fig. 6b a position of hydraulic drive compared with real measurement data was shown. Step responses of all waveforms are satisfying. Only first step for 2 V, has got the biggest error. That is cause by input value from slider model which also had the biggest differences between signals. The results of research were presented in Table 2. Almost all results of simulation model were in range 97–99% (only one was beyond the scope with 94%). Those numbers proved that model is convergent with real object and can be used in future works.

4 Conclusions

In the article a modeling and a simulation of electro-hydraulic proportional valve was presented. The first part of the article recalls state of the art. In the second section a research stand with electro-hydraulic manipulator was presented. A structure of control and measurement unit also was described. In the next chapter a mathematical equations used in simulation were described. Those model consist of two major parts: first one was equations which described flow and the cylinder position, the second one was a dynamic model of slider in the valve. Two main measurements were made, first was the output of manipulator’s position for step response with voltage input signal and second was a slider’s position. The valve model included one of the major non linearities like square root characteristics. Second part consists of valve’s position in time domain with static characteristic, rate limiter and transfer function with transport delay. The final results with complete model of the valve had got very good similarities about 94–99% in all range of control.

References

Andersson, A., Ülker-Kaustell, M., Borg, R., Dymén, O., Carolin, A., Karoumi, R.: Pilot testing of a hydraulic bridge exciter. In: Presented at the MATEC Web of Conferences, vol. 24 (2015)

Li, Y., Jiao, Z., Xu, Y.: Nonlinear analysis of oscillations in aero-hydraulic actuation system considering load effect. In: Presented at the Proceedings of 2015 International Conference on Fluid Power and Mechatronics, FPM 2015, pp. 934–938 (2015)

Rovira-Más, F., Zhang, Q., Hansen, A.C.: Dynamic behavior of an electrohydraulic valve: typology of characteristic curves. Mechatronics 17(10), 551–561 (2007)

Durrant-Whyte, H.F.: An autonomous guided vehicle for cargo handling applications. Int. J. Robot. Res. 15(5), 407–440 (1996)

Abduh, M.Y., Rasrendra, C.B., Subroto, E., Manurung, R., Heeres, H.J.: Experimental and modelling studies on the solvent assisted hydraulic pressing of dehulled rubber seeds. Ind. Crops Prod. 92, 67–76 (2016)

Zhang, Q., Wei, J., Fang, J., Li, M.: Nonlinear motion control of the hydraulic press based on an extended piecewise disturbance observer. Proc. Inst. Mech. Eng. Part I: J. Syst. Control Eng. 230(8), 830–850 (2016)

Milecki, A., Rybarczyk, D., Owczarek, P.: Application of the MFC method in electrohydraulic servo drive with a valve controlled by synchronous motor. In: Szewczyk, R., Zieliński, C., Kaliczyńska, M. (eds.) Recent Advances in Automation, Robotics and Measuring Techniques. AISC, vol. 267, pp. 167–174. Springer, Cham (2014). doi:10.1007/978-3-319-05353-0_17

Cheng, J., Liu, W., Zhang, Z.: Modeling and simulation for the electro-hydraulic servo system based on Simulink. In: 2011 International Conference on Consumer Electronics, Communications and Networks (CECNet), pp. 466–469 (2011)

Bingbing, W., Guanglin, S., Licheng, Y.: Modeling and analysis of the electro-hydraulic proportional valve controlled motor system supplied by variable pressure accumulator. In: International Conference on Fluid Power and Mechatronics (FPM), pp. 1165–1170 (2015)

Duym, S., Reybrouck, R.S.K.: Evaluation of shock absorber models. Veh. Syst. Dynam. Int. J. Veh. Mech. Mob. 27(2), 109–127 (1997)

Owczarek, P., Gośliński, J., Rybarczyk, D., Kubacki, A.: Control of an electro-hydraulic manipulator by vision system using central point of a marker estimated via kalman filter. In: Szewczyk, R., Zieliński, C., Kaliczyńska, M. (eds.) Challenges in Automation, Robotics and Measurement Techniques. AISC, vol. 440, pp. 587–596. Springer, Cham (2016). doi:10.1007/978-3-319-29357-8_51

Osiecki A.: Hydrostatyczny napęd maszyn, Wydawnictwo Naukowo Techniczne, wydanie drugie, Warszawa (2004)

Milecki, A., Rybarczyk, D., Owczarek, P., Sędziak, D., Raba, B.: Nowoczesne metody sterowania urządzeniami mechatronicznymi z napędami elektrohydraulicznymi. Wydawcnictwo Politechniki Poznańskiej, Poznań (2014)

Acknowledgement

The work described in this paper was funded from 02/22/DSPB/1320 project (Nowe techniki w urzadzeniach mechatronicznych).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Owczarek, P., Rybarczyk, D., Kubacki, A. (2017). Dynamic Model and Simulation of Electro-Hydraulic Proportional Valve. In: Szewczyk, R., Zieliński, C., Kaliczyńska, M. (eds) Automation 2017. ICA 2017. Advances in Intelligent Systems and Computing, vol 550. Springer, Cham. https://doi.org/10.1007/978-3-319-54042-9_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-54042-9_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-54041-2

Online ISBN: 978-3-319-54042-9

eBook Packages: EngineeringEngineering (R0)