Abstract

Integration of compliance into the Robotics hands proved to enhance the functionality of under-actuated hands for prosthetic or industrial applications. An appropriate design of the finger geometry with compliant joints allows the fingers to adapt to the shape of the object, and the soft and compliant skin allows for a higher contact area and contact friction. In this article, we describe how these properties were exploited for the development of compliant hands that are simple, efficient and easy to control. We also discuss integration of soft pressure and bending sensors into the digits of these hands.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

About a quarter of the motor cortex in the human brain (the part of the brain which controls all movement in the body) is devoted to the muscles of the hands. This shows the complexity of the human hand, which is composed of 34 muscles. It is clear that individual control of many of the hands joints and thus muscles requires considerable effort from the brain. However many of the tasks, such as grasping, is pretty instinctive for humans and does not involve a considerable brain effort.

Neuroscientists research shows that to control the complicated hand mechanism for a grasping action, the human brain does not control each joint and muscle individually, but utilizes some predefined motion pattern or synergies [1]. Therefore, as stated by Bicchi et al., all joint configurations belong to the s-dimensional manifold, where s expresses the number of synergies” [2]. This means that only a limited number of the vast possible joint configurations are used by humans.

The term synergy comes from the Attic Greek word synergia from synergos, meaning “working together”. A grasping synergy, thus makes the control of the hand “easier” for the brain. On the other hand, if we consider the human hand as a rigid mechanical system, the limited number of predefined synergies will result in a limited number of contact points which does not comply with the range of the objects that one grasps each day. When the size and shape of the objects slightly change, using the same synergy cannot result in a stable grasp. But the key point here is that the human hand is not a rigid system. Compliance of the musculoskeletal system, of the skin and of the object combine in an overall grasp stiffness. This results in a new definition of synergy, called soft synergy [3], since the hand compliance allows several possible contact point posture with the same joint posture. Thus, the integration of compliance into the anthropomorphic hands will help in increasing the range of the objects which can be grasped.

2 Compliance in “Soft-Hands”

Compliance allows several possible contact point posture with the same joint posture.One approach for integrating compliance into the hands, is to integrate compliant joints and soft skin into the hand. Pisa-IIT Softhand [4], ISR-Softhand [5], Flexirigid [6], SDM hands [7] and the UB hand [8] are examples of recent development of soft hands that directly integrate the compliance into the joints. In Pisa-IIT Softhand several elements are interconnected with elastic elements, while in UB hand the joint compliance is achieved by integration of springs into the joints.

One development of our group was ISR-Softhand. ISR-Softhand is a low cost and highly adaptive hand system that embeds elastic joints and soft elements. For more information, readers are invited to see [5].

Figure 1 shows the first prototype of the ISR-Softhand. Except the thumb palmar abduction joint (actuated manually), all other joints are composed of elastic materials. Each finger has a single tendon, which drives the MCP and PIP joints simultaneously in order to perform the finger flexion. The PIP joint is designed with a higher stiffness compared to the MCP joint. In this way, if the MCP joint is blocked (meaning that the first contact with the object is established) the tendon force is applied to the PIP joint and thereby the PIP closes until surrounding the object. With only 3 actuators for flexion of the thumb, the index finger and the other 3 fingers, ISR-Softhand can imitate 21 out of the 33 grasp forms that humans perform in their daily activity (from the feix taxonomy [9], and for more 10 grasp posture, ISR-Softhand can perform an approximate posture to the one of the human (Fig. 1) [10].

Another example of a soft anthropomorphic hand is the UC-Soft hand (Figs. 2 and 3) [11]. The UC-Softhand is also composed of soft digits, but also benefits from an innovative twisted string actuator, which is low-cost, light weight and non-backdrivable. We modelled and developed a novel twisted string actuation scheme that can fit into the palm of a human [12]. While the number of actuators is same as the ISR-Softhand, the actuation strategy is different. Here, the thumb’s Palmar abduction is actuated by scarficing the independent flexion of the thumb and index finger (coupled together).

In fact, this decision was the result of two independent and comprehensive analysis: on the actuation strategy of an anthropomorphic hand for a better anthropomorphism [13], and the other one on the actuation strategy for better functionality [10]. Selection of the actuation strategy for prosthetic hands is indeed one of the most important stages of optimization for the design of prosthetic hands. Therefore, in these two comprehensive analyses [10, 13], we showed how different actuation strategies can affect the functionality and anthropomorphism of the hand (in terms of grasping postures). These two benchmarks and the related analysis (anthropomorphism and functionality), helps a designer to choose the best actuation strategy for a prosthetic hand. For instance, both analysis showed the importance of the Palmar abduction in increasing both indices of anthropomorphism and functionality.

3 Soft Electronic Skin for Prosthetic Hands

For three main reasons we are interested in integration of an electronic skin into the hand.

-

First, since a sense of touch is an important, but a missing factor in the today’s prosthetic hands. The sense of touch, brings the feeling that the prosthetic terminal is a part of the body and not an external machine.

-

Second, because sensing the contact pressure, allows us to make a closed-loop control of the hand, thus we reduce the control effort from the amputee, and facilitate its usage

-

Third, since the bending profile of a soft and under-actuated finger, does not always correspond to the position of its tendon/ pulley, and depends on the shape of the object. Therefore, an encoder installed on the pulley does not provide the control system, precise information regarding the bending profile of the digits. Therefore a bend sensor integrated directly into the joints of the soft fingers is very beneficial (Fig. 4)

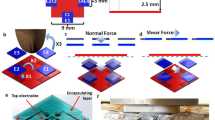

Details of the design and implementation of the electronic skin is out of focus of this article. But as can be seen in Fig. 5, the skin is composed of pressure sensors embedded in the finger tips and bend sensors that are embedded in the joints. The sensors are made from Ecoflex-30 (smooth-on) which is a biomedical grade silicone with mechanical properties similar to those of the human skin. The conductive layers of the sensors can be made by a stretchable silicone (e.g. Sylgard 184 or Ecoflex) dopped with conductive particles (usually silver or carbon). To pattern the specific shape of the sensor, several methods can be used, including screen printing, Laser patterning and lifting [14].

Integration of these sensors helps to make the hand more autonomous and less dependant to the amputee. For instance, closing the control loop of the hand with the force feedback feature, makes the hand more autonomous. Furthermore, the sense of touch can be transmitted to the amputee. Finally, this is a low-cost method that does not require integration of expensive pressure sensors.

4 Conclusions

Integration of compliance into robotic hands for prosthetic applications brings many advantages which were not possible with rigid hands. First, a better adaptability to objects on underactuated digits of the hand is possible, simply by an appropriate design of the elastic properties of each of the joints. Second, a soft skin can improve highly the quality of the contact between the object and the fingers (bigger contact area and higher contact friction). Third, with the recent advances on soft and stretchable electronics, it is possible to embed low cost pressure and bend sensors into the fingers. As a result of these sensors, the sense of touch can be transferred to the amputees and the control of the hand can be simpler for them.

References

Santello, M., Flanders, M., Soechting, J.F.: Postural hand synergies for tool use. J. Neurosci. 18(23), 10105–10115 (1998)

Bicchi, A., Gabiccini, M., Santello, M.: Modelling natural and artificial hands with synergies. Phil. Trans. R. Soc. B 366(1581), 3153–3161 (2011)

Catalano, M., Giorgio, G., Serio, A., Farnioli, E., Piazza, C., Bicchi, A.: Adaptive synergies for a humanoid robot hand. In: IEEE–RAS International Conference on Humanoid Robots (2012)

Godfrey, S.B., Ajoudani, A., Catalano, M., Grioli, G., Bicchi, A.: A synergy-driven approach to a myoelectric hand. In: 2013 IEEE International Conference on Rehabilitation Robotics (ICORR), pp. 1–6. IEEE (2013)

Tavakoli, M., de Almeida, A.T.: Adaptive under-actuated anthropomorphic hand: ISR-Softhand. In: 2014 IEEE International Conference on Robotics and Automation, ICRA, Chicago. IEEE (2014)

Tavakoli, M., Marques, L., de Almeida, A.T.: Flexirigid, a novel two phase flexible gripper. In: 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), pp. 5046–5051. IEEE (2013)

Dollar, A.M., Howe, R.D.: The highly adaptive SDM hand: design and performance evaluation. Int. J. Robot. Res. 29(5), 585–597 (2010)

Melchiorri, C., Palli, G., Berselli, G., Vassura, G.: Development of the UB hand IV. IEEE Robot. Autom. Mag. 1070(9932/13), 72–81 (2013)

Feix, T., Pawlik, R., Schmiedmayer, H., Romero, J., Kragic, D.: A comprehensive grasp taxonomy. In: Robotics, Science and Systems: Workshop on Understanding the Human Hand for Advancing Robotic Manipulation, pp. 2–3 (2009)

Tavakoli, M., Enes, B., Santos, J., Marques, L., de Almeida, A.T.: Underactuated anthropomorphic hands: actuation strategies for a better functionality. Robotics and Autonomous Systems 74, 267–282 (2015)

Tavakoli, M., Batista, R., Sgrigna, L.: The UC softhand: light weight adaptive bionic hand with a compact twisted string actuation system. Actuators 5(1), 1 (2015)

Tavakoli, M., Batista, R., Neto, P.: A compact two-phase twisted string actuation system: modeling and validation. Mech. Mach. Theor. 101, 23–35 (2016)

Tavakoli, M., Enes, B., Marques, L., Feix, T.: Actuation configurations of bionic hands for a better anthropomorphism index. J. Mech. Robot. 8(4), 044502 (2016)

Tong, L., Finkenauer, L., Wissman, J., Majidi, C.: Rapid prototyping for soft-matter electronics. Adv. Funct. Mater. 24(22), 3351–3356 (2014)

Acknowledgement

This research was supported by the Carnegie Mellon Portugal program and the Foundation of Science and Technology of Portugal under the contract CMUP-ERI/TIC/0021/2014.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Tavakoli, M., Rocha, R.P., Lourenço, J., Lu, T., Majidi, C. (2017). Soft Bionics Hands with a Sense of Touch Through an Electronic Skin. In: Laschi, C., Rossiter, J., Iida, F., Cianchetti, M., Margheri, L. (eds) Soft Robotics: Trends, Applications and Challenges. Biosystems & Biorobotics, vol 17. Springer, Cham. https://doi.org/10.1007/978-3-319-46460-2_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-46460-2_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-46459-6

Online ISBN: 978-3-319-46460-2

eBook Packages: EngineeringEngineering (R0)