Abstract

During the last few years, progress has been made in developing cleaner and more efficient bioenergy producing systems. Innovative processes and novel substrates were assessed at lab scale, in order to investigate and promote a sustainable development of photobiological hydrogen production. Recent and innovative processes and the use of novel substrates are discussed in this chapter. The main focus is on photofermentation systems conducted on biomass derived substrates, as these are considered to be the applicative goal of hydrogen production. Indeed, it is also present a short excursus on some synthetic media, investigated as interesting opportunities for enlarging applicability of the hydrogen technology. The number of new findings here reported demonstrates that it is worth continuing the efforts for increasing the knowledge on the photofermentation process for H2 production, in particular owing to the need of reducing the use of fossil fuels for mitigating the emissions of GHG in the atmosphere.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

Bioenergies and Biohydrogen

Bioenergy production and use is rising in many countries to diversify energy sources and to promote environmental quality, mitigation of climate change, energy security, and economic growth, including the development of rural economies (Weiland 2010; El Bassam 2010; Appels et al. 2011; IRENA 2013). Bioenergy derives from the conversion of biomass, where biomass may be used directly as fuel or processed into liquids and gases (IRENA 2013) and according to Directive 2009/28/EC of the European Parliament and the Council of 23 April 2009 on the promotion of the use of energy from renewable sources, the term biomass means “the biodegradable fraction of products, waste and residues of biological origin from agriculture (including vegetal and animal substances), forestry and related industries including fisheries and aquaculture, as well as the biodegradable fraction of industrial and municipal waste.”

Concerning policy target for energy from renewable sources in transport, the development of biofuels plays a fundamental role (El Bassam 2010). The importance of producing biofuels is linked to the need of reducing fossil fuel extraction and consumption, with the aim of decreasing the rise of atmospheric CO2 and in general to decrease fuel impact on global climate change (El Bassam 2010; Frigon and Guiot 2010; Appels et al. 2011). Biofuels are commonly separated into three different groups according to their level of development and the feedstocks used, though there is no universally agreed definition (IEA 2009; El Bassam 2010). In general, 1st generation biofuels include mature technologies for the production of bioethanol from sugar and starch crops, biodiesel from oil crops and animal fats, and biomethane from the anaerobic digestion of wet biomass; 2nd generation biofuels include several biofuels, such as bioethanol and biodiesel, produced from conventional technologies, but using novel feedstocks, like alternative starch, oil and sugar crops, or lignocellulosic materials (e.g., straw, wood, and grass); 3rd generation or advanced biofuels are at the earlier stages of research and development (e.g., biofuels from algae, hydrogen from biomass reforming, and biohydrogen) (IEA 2009; El Bassam 2010). The 2nd and 3rd generation biofuels are more sustainable, with biomass at lower costs and lower greenhouse gas emissions than 1st generation ones, avoiding the replacement of food and forage production by energy crops (IEA 2009).

In general, the increased bioenergy use can lead to increased demand for biomass, thus to a possible competition for land currently used for food production (IEA 2009; Appels et al. 2011). Several aspects are related to this concept, on one hand, the increasing global population (nine billions in the 2050, according to UN estimations) results in an increase of food and animal feed demand, on the other hand, the use of croplands and forests for energy crops production could be detrimental to biodiversity and to soil and water resources (IEA 2009). On these grounds, government policies and industrial efforts need to be directed to achieve bioenergy potential targets in the longer term, making sure of increasing biomass yield levels, global food production, promoting the technology development, the diffusion of best sustainable agricultural practices, and a sustainable use of residues and wastes for bioenergy, which present limited environmental risks and impacts and need to be encouraged and promoted globally (IEA 2009; Appels et al. 2011).

Hydrogen is a promising energy carrier, is the most abundant element in the universe, and represents a clean and renewable biofuel, with high conversion efficiency (Holladay et al. 2009; Christopher and Dimitrios 2012). Currently, about 96 % of hydrogen is synthesized from fossil fuels, in particular from methane reforming, and the remaining percentage is produced by water electrolysis and can be used directly in internal combustion engines or in fuel cells, after appropriate purification, without a direct combustion (Holladay et al. 2009; Christopher and Dimitrios 2012; Adessi and De Philippis 2014). Hydrogen can play an important role in decarbonizing the transport sector in the long-term period, as there is no CO2 emission during its combustion, and it can be derived from many renewable sources including biomass and water. However, the deployment of hydrogen vehicles and a related fueling infrastructure is still missing or inadequate for a successful market application in the contest of hydrogen economy (Holladay et al. 2009; IEA 2009). Comparing with anaerobic digestion, which is classified within the biochemical conversion processes as a robust and widely applied technology, the biological hydrogen production is a technology in progress (Frigon and Guiot 2010). Biohydrogen production processes can be classified into different groups, as follows: biophotolysis of water by microalgae and cyanobacteria; photodecomposition of organic compounds by photosynthetic bacteria, i.e., photofermentation; dark fermentation of organic compounds by anaerobic or facultative anaerobic bacteria; and bioelectrohydrogenesis (Das and Veziroglu 2008; Hallenbeck et al. 2009; Holladay et al. 2009). Combined systems can be created with the dark fermentation yielding biohydrogen as first stage followed by the second stage of either anaerobic digestion, yielding biomethane, or photofermentation, yielding biohydrogen (Hallenbeck and Ghosh 2009; Adessi et al. 2012a; Argun and Kargi 2011; Gómez et al. 2011; Hay et al. 2013).

This chapter will be focused on photofermentation as either a single stage process, or in dark fermentation/photofermentation systems both sequential (two stage) and combined (co-cultures), using novel biomass derived substrates.

Photofermentation by Purple Non Sulfur Bacteria

Photofermentation is carried out by purple non sulfur bacteria (PNSB), that are anoxygenic phototrophic bacteria, converting substrates to hydrogen, carbon dioxide, and microbial biomass (Heiniger et al. 2012; Adessi and De Philippis 2014; Hallenbeck and Liu 2016). During hydrogen biosynthesis, nitrogenase enzyme reduces molecular nitrogen and protons to ammonia and hydrogen (Eq. 1) (Heiniger et al. 2012; Adessi and De Philippis 2014; Hallenbeck and Liu 2016):

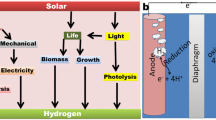

This reaction is energy demanding, requiring ATP produced through cyclic photophosphorylation in absence of oxygen with artificial or solar light as the energy source, and the reducing power from the catabolism of carbon compounds in the tricarboxylic acid (TCA) cycle , preferably low-molecular weight organic acids that can easily enter the TCA cycle (Fig. 1) (Adessi and De Philippis 2014; Hallenbeck and Liu 2016). Thus, photobiological hydrogen production using PNSB depends mainly on nitrogen fixation, ATP production, and carbon sources catabolism (Keskin et al. 2011; Adessi and De Philippis 2014). In absence of molecular nitrogen, nitrogenase can dissipate the reducing equivalents coming from other metabolic processes producing hydrogen (Heiniger et al. 2012; Adessi and De Philippis 2014). Otherwise, in cells with active nitrogenase, hydrogen can represent an electron donor, oxidized by the uptake hydrogenase enzyme (Keskin et al. 2011; Adessi and De Philippis 2013) (Fig. 1). It has to be stressed that even if the process is anaerobic, a microanaerobic nitrogenase activity was found in some PNSB with low oxygen concentration (Hallenbeck and Liu 2016). In general, PNSB are a diverse group of anoxygenic phototrophic bacteria with a versatile metabolism, which are able to use a variety of organic acids and sugars, depending on the species selected (Argun and Kargi 2011; Eroğlu et al. 2014). The most studied PNSB species for photobiological hydrogen production are Rhodobacter sphaeroides, Rhodopseudomonas palustris (Fig. 2), Rhodobacter capsulatus, Rhodobacter sulfidophilus, and Rhodospirillum rubrum (Argun and Kargi 2011). PNSB are capable of producing polyhydroxybutyrate (PHB) , that is a member of polyhydroxyalkanoate (PHA) family and represents a biodegradable polymer, that can be used for the production of biodegradable plastics (Keskin et al. 2011; Wu et al. 2012; Adessi and De Philippis 2014). PHB is a carbon storage polymer (visible in Fig. 2) that can be used as carbon and energy source during starvation, since it has low solubility, high molecular weight, and inert nature, causing negligible osmotic pressure on cell (Wu et al. 2012). In PNSB, PHB biosynthesis represents a competitive reductive reaction compared to the nitrogenase activity, which makes it undesirable in hydrogen producing systems (Hustede et al. 1993; Vincenzini et al. 1997; Redwood et al. 2009; Wu et al. 2012).

Main processes related to hydrogen production, under photoheterotrophic growth in non-nitrogen fixing conditions : anoxygenic photosynthesis, ATP synthesis, TCA cycle, hydrogenase, and nitrogenase activities. The straight black arrows indicate the electron flow. The lightning symbol indicates light excitation. Cyt bc 1 cytochrome bc 1 complex, Cyt c 2 cytochrome c 2, Fd ferredoxin, RC Reaction Center, Succinate – DH succinate dehydrogenase, NADH-DH NADH dehydrogenase. (Image from Adessi and De Philippis 2012)

Generally, the advantages of the photobiological hydrogen production mainly concern the high substrate to hydrogen conversion yields, the possibility to use a wide spectrum of sunlight, the absence of oxygen-evolving reactions, and the possibility of coupling the process with other kinds of fermentation, like the combined system with the dark fermentation (Keskin et al. 2011; Adessi and De Philippis 2014). PNSB can also directly use organic acids or sugars in the photofermentation process composing a single stage system, even if until now only a few studies have assessed the use of sugars as substrates for this purpose (Argun and Kargi 2011; Hallenbeck and Liu 2016) (see “Single Stage Photofermentation Processes”). Otherwise, PNSB can utilize organic acids coming from the dark fermentation, in combined processes: (a) sequential or two stage system (see “Sequential Dark/Photofermentation Processes (Two Stage Systems)”); (b) combined processes forming a co-culturing system (see “Combined Dark/Photofermentation Processes (Co-Cultures)”).

For what concerns process parameters, strict control of environmental conditions is essential for efficient hydrogen production. Optimal pH and temperature ranges were reported to be 6.8–7.5 and 30–35 °C, respectively (Argun and Kargi 2011; Eroğlu et al. 2014). Generally, the ammonium in the medium is used for growing until the ammonium concentration decreases under the inhibition threshold for nitrogenase, which is around 2.5 mM (45.1 mg L−1), so H2 production can start and cellular growth almost stops (Argun and Kargi 2011; Adessi et al. 2012b). Ammonium may be naturally present in the starting substrate, like it frequently happens in wastewaters, but also generated by protein degradation during dark fermentation step (Gómez et al. 2011). Optimum volatile fatty acids (VFA ) concentrations were reported to be between 1800 and 2500 mg L−1 (Argun and Kargi 2011). The photosynthetic efficiency, also known as light conversion efficiency, is an important and commonly used indicator of the photofermentation and it is defined as the efficiency on the basis of the hydrogen-related energy produced per unit of light energy absorbed (Adessi and De Philippis 2014). It can vary from 0.2 to 9.3 % depending on several factors, like the quality and quantity of light, the biological parameters, like pigment composition, quantum requirements and PNSB strain metabolism, and the kind of substrates used for the fermentation (Argun and Kargi 2011; Adessi and De Philippis 2014). Substrate to hydrogen conversion is another important indicator of the photofermentation, as the catabolism of carbon sources provides electrons in the photosynthesis process (Adessi and De Philippis 2014). This parameter represents the ratio between the moles of hydrogen produced and the moles theoretically obtainable if all the substrate consumed was converted to CO2 and H2 (Adessi and De Philippis 2014). Substrate to hydrogen conversion is affected by the C/N in the medium, because with high C/N values the nitrogenase activity is enhanced and with low C/N values the cell growth occurs, instead of hydrogen production (Keskin et al. 2011; Adessi and De Philippis 2014). Also the PHB production competes with the conversion of substrates to hydrogen, as it uses carbon and reducing power coming from carbon sources metabolism (Keskin et al. 2011; Adessi and De Philippis 2014).

Main problems to be faced in photofermentation are: (a) to avoid ammonia inhibition, (b) to increase VFAs availability, (c) to allow an effective light distribution through fermentation medium, and (d) to avoid the metabolic shift from H2 production to PHB synthesis (Argun and Kargi 2011; Keskin et al. 2011). Rate and yields of H2 production could be enhanced by metabolic engineering aimed at: (a) blocking competing pathways in order to increase the electron flux from substrate to hydrogen (e.g., by inducing PHB-defection); (b) inactivating uptake hydrogenase; (c) reducing pigment content and enhancing electron flow to nitrogenase; (d) deregulating nitrogenase in order to induce a low sensitivity to ammonium concentration; and (e) enhancing nitrogenase activity (Adessi and De Philippis 2014; Hallenbeck and Liu 2016).

Low light conversion efficiency, high energy demand, low turnover of nitrogenase, and high cost of hydrogen impermeable photobioreactors are some of the main critical issues to be addressed for making economically sustainable the production of hydrogen by photofermentation processes (Keskin et al. 2011; Adessi and De Philippis 2014; Hallenbeck and Liu 2016). In general, light distribution should be as uniform as possible, in particular when using as substrate complex biomasses, since they may interfere with the adsorption spectra of pigments or may contain particles that shade the cells. Moreover, feedstocks characterized by low C/N values favor cell growth instead of H2 production (Keskin et al. 2011; Adessi and De Philippis 2014). Design, scale-up, and optimization of photobioreactors are fundamental issues, since the cultivation system must be closed in order to maintain anaerobic conditions and to prevent hydrogen dispersion, and requires high illuminated surfaces, efficient mixing and gas exchange system, and temperature control (Adessi and De Philippis 2014). Systems for efficient solid–liquid–gas phase separation, for a higher gas recovery efficiency have been identified in cell immobilization (Tsygankov and Kosourov 2014), but only few studies have been carried out on large scale, or on biomass derived substrates. This issue will be discussed in “Immobilized Systems.”

Novel Fermentation Systems

In recent years, innovative processes and novel substrates were tested at lab scale in order to investigate and promote a sustainable development of the photobiological hydrogen production. The various photofermentation processes, that have been designed up to now, and the most investigated novel substrates are schematically represented in Fig. 3.

Novel fermentation systems for a sustainable development of the photobiological hydrogen production. Novel substrates can be used in the following innovative processes: (a) single stage photofermentation (Sect. “Single Stage Photofermentation Processes,” Table 1); (b) sequential two stage fermentation systems (Sect. “Sequential Dark/Photofermentation Processes (Two Stage Systems),” Table 2); and (c) combined systems or co-cultures (Sect. “Combined Dark/Photofermentation Processes (Co-Cultures),” Table 3)

Recent and innovative processes will be discussed in “Innovative Processes.” This section mainly focuses on photofermentation systems conducted on biomass derived substrates, as these are considered to be the applicative goal of hydrogen production. Afterwards, novel substrates will be described in “Novel Substrates,” first focusing on the most studied biomass derived substrates (“Biomass Derived Substrates”) and then reporting an excursus on some synthetic media, investigated as interesting opportunities for enlarging applicability of the hydrogen technology (“Synthetic Substrates”).

Innovative Processes

Single Stage Photofermentation Processes

A single stage system is composed by the sole photofermentation stage, where PNSB use substrates, containing mainly organic acids or sugars (Argun and Kargi 2011; Hallenbeck and Liu 2016). Only few and recent studies reported the single stage photofermentation of sugars, in most cases glucose, while several single stage studies have been carried out using various types of wastewaters, such as effluents from the food and agro-industry, or industrial wastes, like crude glycerol (Hay et al. 2013; Hallenbeck and Liu 2016). One of the first works on this issue was carried out by Zürrer and Bachofen (1981), who reported the hydrogen potential of lactate and lactate-containing wastes for photofermentation processes carried out by the PNSB Rs. rubrum.

In Table 1, recent studies on single stage photofermentation using substrates rich in organic acids are reported. Several works investigated the photofermentation of olive mill wastewaters (OMWW) with different operational conditions. Eroğlu et al. (2006) carried out the single stage photofermentation of OMWW with Rb. sphaeroides OU001, reporting a higher potential with a clay pretreatment (35.0 L (L medium)−1), than with the row substrate (8.0 L (L medium)−1). Eroğlu et al. (2008b) reported a single stage assay using a temperature controlled flat plate solar bioreactor, in order to assess the photobiological hydrogen production from Rb. sphaeroides O.U.001 in outdoor conditions, and they obtained a H2 production of 11.4 L (L medium)−1. In another work, Eroğlu et al. (2008a) reported that the photofermentative hydrogen production with OMWW was doubled by using the clay pretreated effluent (31.5 L (L medium)−1), comparing with the not pretreated one. The effectiveness of using the clay treatment as the optimal method for a fast and low-cost treatment of OMWW was afterwards confirmed by Eroglu et al. (2010). The investigation on batch cultures grown under continuous light or light/dark diurnal cycles with OMWW as substrate gave a similar hydrogen production between the two conditions tested (0.05 L (L medium)−1), but the light/dark diurnal cycles condition showed a pronounced lag in biomass and hydrogen accumulation (Eroglu et al. 2010). Different irradiances for hydrogen production using dephenolized OMWW from Rp. palustris 42OL were investigated by Pintucci et al. (2013), who found that the higher was the irradiance, the higher were the hydrogen yield and rate. Pintucci et al. (2015) investigated different culture mixing using dephenolized OMWW from Rp. palustris 6A and reported the highest hydrogen production using an impeller equipped with five turbines.

Some experiments were performed in order to investigate different starting concentrations of the substrate, such as the photofermentation assays reported by Seifert et al. (2010a, b), who investigated the hydrogen production from Rb. sphaeroides O.U.001, using different concentrations of dairy and brewery wastewaters. Kapdan et al. (2009) analyzed the effects of initial sugar concentration on hydrogen yield with hydrolyzed wheat starch, reporting the best photofermentation performance at 5 g L−1, equal to 1.23 mol (mol glucose)−1. Ghosh et al. (2012a) investigated the effects of nitrogen source and different concentrations of crude glycerol on hydrogen production using Rp. palustris CGA009. They reported that at 20 mM of glycerol and 4 mM of glutamate the highest hydrogen yield was obtained, equal to 6.1 mol H2 (mol crude glycerol)−1, a yield of 87 % of the theoretical. In another study, Ghosh et al. (2012b) investigated the interactive effects among several process parameters: light intensity and concentrations of crude glycerol and glutamate on the stoichiometric conversion of crude glycerol to hydrogen. They observed the optimal conditions with a light intensity of 175 W m−2, 30 mM of glycerol, and 4.5 mM of glutamate, resulting in 6.69 mol (mol crude glycerol)−1, a yield 96 % of the theoretical.

Sequential Dark/Photofermentation Processes (Two Stage Systems)

The two stage system is composed by a first stage of dark fermentation, which is followed by a second stage of photofermentation in separated reactors. During dark fermentation, heterotrophic bacteria convert organic substrates, mainly carbohydrate-rich materials, into organic products, hydrogen, and carbon dioxide (Holladay et al. 2009; Abo-Hashesh and Hallenbeck 2012; Ghimire et al. 2015). The key enzyme of the process is hydrogenase , that in anaerobic condition reduces protons to hydrogen, neutralizing the electrons coming from the organic compounds oxidation (Argun and Kargi 2011; Ghimire et al. 2015). Dark fermentation effluents are characterized by the presence of large amounts of volatile fatty acids and lactate. Since the main fermentation end products of dark fermentation are acetic and butyric acids, being the latter in excess with respect to the former, the process is also called acetate/butyrate-type fermentation (Hawkes et al. 2007; Argun and Kargi 2011; Abo-Hashesh and Hallenbeck 2012; Ghimire et al. 2015). The pathways leading to the synthesis of H2 and to the formation of these two acids allow the highest theoretical conversion of glucose to H2 compared those producing other acids. In particular, the conversion of 1 mol of glucose to acetic acid involves the production of 4 mol of H2, while the conversion of glucose to butyric acid involves the production of 2 mol of H2 (Hawkes et al. 2007; Argun and Kargi 2011; Abo-Hashesh and Hallenbeck 2012; Ghimire et al. 2015). In order to have a high H2 yield, dark fermentation processes need to be carried out under anaerobiosis and with a low partial pressure of hydrogen (Guo et al. 2010; Abo-Hashesh and Hallenbeck 2012). Strict anaerobic conditions are necessary if the inoculum is composed by strict anaerobic species, such as those belonging to the Clostridium genus. Otherwise, oxygen can be present in traces if the inoculum is composed of facultative anaerobic species, such as those belonging to the Enterobacter genus, or mixed cultures (Bartacek et al. 2007; Guo et al. 2010; Abo-Hashesh and Hallenbeck 2012). When the inoculum is a non-sterile culture, e.g., digestate of biogas plants or sewage sludge, a pretreatment (e.g., heat shock, acid or alkaline treatment, aeration, and sonication) is recommended in order to reduce the activity of H2 consumer microorganisms such as homoacetogens, methanogens, nitrate, and sulfate reducing bacteria (Guo et al. 2010; Argun and Kargi 2011; Abo-Hashesh and Hallenbeck 2012; Ghimire et al. 2015).

The oxidation of organic compounds for hydrogen production requires a low hydrogen partial pressure (Guo et al. 2010; Abo-Hashesh and Hallenbeck 2012). Among the techniques used to decrease the hydrogen concentration in order to increase the hydrogen yield of the system, the most frequently used are the agitation of the medium, the insufflation of molecular nitrogen, and hydrogen stripping (Guo et al. 2010; Abo-Hashesh and Hallenbeck 2012). The pH value is another important factor, which can affect the hydrogen yield, the metabolic products, and the structure of the microbial community (Cappai et al. 2014; Guo et al. 2010). Better process performances can be achieved at pH values ranging between 5 and 6 for food wastes, while a neutral pH (7–7.5) is advisable for plant residues and for livestock wastes (Cappai et al. 2014; Guo et al. 2010). In particular, pH 5 is the minimum value that most heterotrophic bacteria can tolerate (Abo-Hashesh and Hallenbeck 2012). By literature, studies on hydrogen production by dark fermentation in batch, without pH correction and using sucrose as a substrate, appear to be quite frequently carried out (Argun and Kargi 2011; Guo et al. 2010). Typical dark fermentation processes were carried out under mesophilic conditions. However, it was shown that thermophilic conditions lead to higher hydrogen yields due to: (a) higher rates of substrate decomposition; (b) better hydrolysis of recalcitrant molecules such as lignocellulosic constituents of vegetable residues, and (c) faster metabolic activity of H2 producing thermophilic bacteria. Moreover, high temperatures also inhibit growth and activity of hydrogen consuming microorganisms (Guo et al. 2010; Argun and Kargi 2011; Abo-Hashesh and Hallenbeck 2012). However, thermophilic conditions imply a higher energy consumption than mesophilic conditions (Argun and Kargi 2011; Guo et al. 2010), even if it is possible to use the widely available hot waters deriving from the cooling systems of many industrial processes.

In the sequential system, the effluents derived from the dark fermentation processes are subsequently used as substrate for the photofermentation stage. The investigation of renewable substrates for the sequential systems started some years ago and one of the first study was carried out by Fascetti et al. (1998), reporting the photosynthetic hydrogen production using Rb. sphaeroides RV on acidogenic fermentation effluents of municipal solids wastes, mainly consisting of fruit and vegetables wastes. Recent studies on the use of biomass derived substrates such as energy crops, crop residues, agroindustrial and industrial residues in dark/photofermentation sequential systems are reported in Table 2. Heat treated inocula for the dark fermentation stage and mesophilic conditions are usually used; as inocula, pure cultures of Rb. sphaeroides or Rp. palustris were most frequently used. Concerning OMWW, they are rich in organic acids and, as above reported, can be used in one stage photofermentation. However, since the light penetration is difficult due to the dark color of OMWW , Eroglu et al. (2010) first reported that the dark fermentation step implies a positive effect on the subsequent photofermentation, enhancing the efficiency of the process.

Various operational conditions have been tested in order to maximize hydrogen yield and to optimize the process (Table 1). For example, Su et al. (2009) investigated different starting raw cassava starch concentrations, from 10 to 25 g L−1, using heat-shocked anaerobic sludge and Rp. palustris as inocula of the first and the second stages, respectively, and obtained the maximum hydrogen yield of 240.4 mL (g starch)−1 and of 131.9 mL (g starch)−1, in the dark fermentation and the photofermentation stages, respectively, using a starch concentration of 10 g L−1. Another study assessed the effect of the starting concentration of the substrate, Laurinavichene et al. (2010) reported that a starting concentration of potato homogenate of 400 g L−1 allowed to obtain an overall maximum hydrogen production equal to 5.6 mol (mol glucose)−1, using a microbial consortium for the first stage and Rb. capsulatus B10 for the second one. Also Cheng et al. (2011a) reported different starting substrate concentrations, obtaining the highest overall hydrogen yield of 463 mL (gVS)−1 with a concentration of microwave-assisted alkali pretreated rice straw of 50 g L−1. Su et al. (2010) reported the highest overall hydrogen yield in a sequential system of 596.1 mL (gVS)−1, using pretreated water hyacinth at a concentration of 10 g L−1.

Concerning the kind of light source for the photobiological hydrogen production, Argun and Kargi (2010a) found that halogen lamp was the most suitable light source for the photofermentation of dark fermentation effluents of ground wheat solution, yielding the highest cumulative hydrogen production of 2.68 mol (mol glucose)−1.

Cheng et al. (2012) assessed the ammonium concentration effect on the photobiological hydrogen production and they reported that the reduced content of ammonium, from 2.2 to 2.7 mM, in the dark fermentation effluent of Arthrospira platensis, enhanced the hydrogen potential from 96.6 to 337.0 mL (g DW)−1. Also Adessi et al. (2012b) investigated the ammonium concentration using in the photofermentation stage the mutant strain Rp. palustris CGA676, which constitutively expresses nitrogenase genes, reporting the highest hydrogen production rate of 9.6 mL L−1 h−1 in the 3-fold diluted medium containing 2.03 mM of ammonium. The same PNSB strain was used by Corneli et al. (2016a, b, submitted) in a process, reported in the patent filed F1.S0061.12.IT.1 (Adessi et al. 2016a), aimed at assessing the photofermentative hydrogen potential of the effluents of the dark fermentation of ensiled maize, ensiled giant reed, ensiled olive pomace, and wheat bran. Under the conditions tested, the highest performance of the strain was observed in the presence of maize and wheat bran (228.7 and 463.0 NL (kgVS)−1, respectively).

Xia et al. (2014) investigated the effect of different C/N based on different ratios of Chlorella pyrenoidosa and cassava starch in a codigestion . Their higher dark and photofermentative hydrogen potential was equal to 664.2 mL (gVS)−1 at a C/N of 25.3. Chookaew et al. (2015) focused on the optimal conditions for hydrogen production from Rp. palustris TN1 on dark fermentation effluent of crude glycerol and they found that the fivefold diluted effluent, without the supplement of yeast extract and NaHCO3 and 2 mM glutamate corresponded to the optimum condition, with a cumulative hydrogen production of 0.68 mmol g COD−1.

A novel and high yielding experiment was reported by Dipasquale et al. (2015); they carried out the photofermentation using capnophilic lactic fermentation effluents of seawater supplemented with glucose utilized by Thermotoga neapolitana and they reported an overall hydrogen potential of 9.4 mol molglucose−1.

Combined Dark/Photofermentation Processes (Co-Cultures)

The co-culture system is composed by dark and photofermentative bacteria in a coupled fermentation for biohydrogen production, both fermentations taking place simultaneously in the same bioreactor (Keskin et al. 2011; Adessi et al. 2012a; Eroğlu et al. 2014; Pachapur et al. 2015a; Hallenbeck and Liu 2016). Co-culturing is considered advantageous in comparison with sequential fermentation due to: (a) a possible reduction in the fermentation time; (b) an increase in hydrogen production yields, rate, and substrate conversion efficiencies; and (c) the elimination of some operations needed for using the effluents of dark fermentation to feed light-dependent fermentation (e.g., H adjustment, medium sterilization or dilution), being the process carried out in only one bioreactor (Keskin et al. 2011; Adessi et al. 2012a; Eroğlu et al. 2014; Singh and Wahid 2015; Hallenbeck and Liu 2016). On the other hand, the main drawback concerns the differences in nutrients requirements and growth conditions (e.g., growth rate and acid-resistant capacity) that the two different types of microorganisms might have (Adessi et al. 2012a; Zagrodnik and Laniecki 2015; Sargsyan et al. 2016). The possible accumulation of organic acids and ammonium, and the decrease of pH can negatively affect the overall process, which can also be affected by a decrease in light penetration due to suspended solids and cell growth (Singh and Wahid 2015; Zagrodnik and Laniecki 2015). The rate of volatile fatty acids production by dark fermentative bacteria can be higher than the utilization rate by photofermentative bacteria and thus the growth of the former can be limited by the decrease of the pH value (Liu et al. 2010; Singh and Wahid 2015). Thus, the system should be carefully controlled in media composition, in environmental conditions and in bacteria ratio in order to promote the growth and the activity of all the bacterial species in the co-culture (Liu et al. 2010; Adessi et al. 2012a; Singh and Wahid 2015; Zagrodnik and Laniecki 2015; Sargsyan et al. 2016). By the literature, only few studies reported the co-culture system for dark and photofermentation. Typically, studies tested co-cultures of pure bacterial strains, being glucose the most frequently studied substrate (Liu et al. 2010; Adessi et al. 2012a; Zagrodnik and Laniecki 2015). However, recent investigations on biomass derived substrates reported some co-culture assays, some of them using pure bacterial cultures, while others used mixed cultures, such as heat-shocked anaerobic sludge for dark fermentation, and selected bacterial consortia for photofermentation (Table 3). In general, these studies reported mesophilic batch tests assessing the potential of simple carbohydrate-rich substrates. The comparison among the different studies on complex substrates is quite difficult, because of the different operational conditions adopted and the units of measure of the results.

Several studies carried out a co-culture system using ground wheat solution as substrate in mesophilic batch tests (Argun et al. 2009a, b; Argun and Kargi 2010c; Ozmihci and Kargi 2010) (Table 3). Argun et al. (2009a) assessed the effects of the substrate and of cell concentration on hydrogen production, using heat-shocked anaerobic sludge and a photofermentative bacterial consortium, as inocula, and they reported the highest hydrogen potential equal to 156.8 mL (g starch)−1 with a biomass to substrate ratio of 0.22 g cells (g substrate)−1. A similar result (176 mL (g starch)−1) was obtained by Argun et al. (2009b) with the dark to light biomass ratio of 1/7. Argun and Kargi (2010c) investigated different light sources, intensities, and illumination regime and reported the highest hydrogen potential (218 mL (g starch)−1) using a halogen lamp. Ozmihci and Kargi (2010) compared different mixed cultures for hydrogen production and reported the highest performance (0.36 mol (mol glucose)−1) using heat-shocked anaerobic sludge and Rb. sphaeroides NRRL, as inocula.

Also Argun and Kargi (2010b) reported a co-culture study using ground wheat solution as substrate, but in a continuous system. They used Clostridium beijerinkii DSMZ-791 and Rb. sphaeroides RV, as dark and photofermentative strains, respectively, and they reported the highest hydrogen potential of 90 mL (g starch)−1 at hydraulic residence time of 6 days.

Other studies reported hydrogen potentials of co-culture systems using different kinds of biomass derived substrates (Table 3). Vatsala et al. (2008) evaluated the hydrogen production of a mixture of pure cultures (Citrobacter freundii 01, Enterobacter aerogenes E10, and Rp. palustris P2) using sugarcane distillery effluent in a mesophilic 100 m3 scale reactor and they reported a hydrogen potential of 0.53 kg 100 m−3 h−1. In another study, Calophyllum inophyllum oil cake was investigated as substrate in a co-culture system of E. aerogenes and Rb. sphaeroides under dark and photofermentative conditions in a mesophilic batch test and the hydrogen potential was 7.95 L L−1 (Arumugam et al. 2014). Sargsyan et al. (2016) reported a co-culture batch system using distillers wheat grains with mixed cultures of Escherichia coli, as dark fermentative bacteria, and Rb. sphaeroides, as photofermentative bacteria. Their maximal rate of H2 production was 5.16 mmol L−1 day−1 in the twofold diluted medium.

Immobilized Systems

Immobilized whole cell techniques represent a reliable approach to dark and photofermentation for the enhancement of continuous hydrogen production, compared to suspended cell systems, since they are more efficient in solid/liquid/gas separation and can be operated at high dilution rates without the risk of biomass washout (Chang et al. 2002).

Methods of immobilization can be either natural or artificial: natural immobilization refers to the spontaneous or enhanced formation of biofilm and granules; oppositely, artificial cell entrapments assume the use of matrices or substrates for attachment, entrapment, or encapsulation of microorganisms. Immobilized cells, and in particular cells in biofilms, are usually characterized by enhanced resistance to the presence of toxic components or other extreme culture conditions as compared to cells in suspension, due to the diffusion barrier constituted by the matrix (Tsygankov and Kosourov 2014).

In every immobilized system there is a natural separation of solid, liquid, and gaseous phases; this not only facilitates gas recovery, but also the repeated use of biomass. The separation of phases makes immobilized cultures have higher volumetric rates of hydrogen production, compared to suspended cell systems (Tsygankov and Kosourov 2014). However, in some cases the yield of hydrogen production can still be lower than that of the suspended cell systems. This could be due to low substrate conversion efficiency, or mass transfer limitations arising from the matrix barrier. In order to obtain higher yields of hydrogen production in immobilization process, it is necessary to develop new immobilized materials for cell entrapment (Singh and Wahid 2015).

At the present time, a number of materials for immobilization are under investigation for the immobilization of PNSB, such as latex (Gosse et al. 2007), carbon fibers (Xie et al. 2012), or a mixture of different immobilizing materials (Wang et al. 2010, 2012). Biofilm reactors are starting to be studied intensively as well (Tian et al. 2010; Zhang et al. 2010; Guo et al. 2011).

However, at present all the immobilized systems have been studied under lab conditions, in batch, with relatively small-volume photobioreactors and mostly with synthetic substrates.

Only a limited number of studies have been carried out on this specific topic, recently, and are indicated in Table 2. Su et al. (2010) reported a study on immobilized Rp. palustris, in the second stage of a sequential system degrading water hyacinth biomass. Pure Rp. palustris cultures were immobilized in alginate granules of 3–4 mm of diameter. The authors tested four different water hyacinth concentrations: the volumetric hydrogen production increased with increasing the amount of water hyacinth, while the yields decreased. This confirmed that the phase separation allows a very good separation and recovery of the gas produces, but immobilization in alginate beads may interfere with optimal nutrient exchange when the concentration of substrate increases, thus giving lower yields.

Cheng et al. (2011a, b) used the same immobilization system, but for entrapping mixed photosynthetic bacteria. A preliminary compared study on immobilized Rp. palustris and immobilized mixed photosynthetic bacteria showed increased volumetric production and yields (20 % and 24 % yield increase, respectively) as compared to suspended cell systems (Cheng et al. 2011b), but this part of the study was conducted on synthetic media containing acetate. Synthetic media surely allow a faster diffusion than complex waste derived substrates. However, the yields reported for the conversion of rice straw (Cheng et al. 2011a) showed the best result, 328 mL H2 (g TVS)−1, with the highest substrate concentration tested. Cassava starch (Cheng et al. 2011b) resulted to be a very interesting substrate, yielding 3.54 mol of H2 per mole of initial glucose.

The number of recent studies about the use of immobilized systems with biomass derived substrates is very poor, unfortunately. Moreover, they all report very standard immobilization matrixes and in batch processes. As above mentioned, the main advantages in using immobilized cells are the stability of the process and the possibility of carrying out continuous feeding. This feature would be the best solution in particular when working with wastes, whose organic matter content needs to be reduced.

Novel Substrates

Biomass Derived Substrates

One interesting feature of PNSB is their capability to use, for the production of H2, biomass derived substrates, like residues deriving from industrial or agricultural processes, that are, in many cases, available in large amounts. However, the sustainability of fermentative process mainly depends on the kind of substrate employed as carbon source (Bartacek et al. 2007; Frigon and Guiot 2010).

A large portion of possible wastes for energy recovery is composed of food and agricultural wastes. Depending on their composition, those wastes have to be treated before using them for photofermentation. Indeed, most frequently it is indicated a previous fermentation step, either hydrogenogenic or not as reported in Table 2.

Several substrates have been proposed and studied for two stage sequential systems, varying among energy crops, crop residues, biodegradable residues and byproducts produced by the livestock and agroindustrial sectors, food waste, and organic fraction of municipal solid waste (Frigon and Guiot 2010; Weiland 2010; Appels et al. 2011). The use of substrates rich in fermentescible sugars or of complex matrix deeply affects the overall efficiency of the process, because of the different physico-chemical properties: simple sugars typically lead to obtain higher energy potential and production rate than complex organic materials (Frigon and Guiot 2010). Nevertheless, often the highest is the biodegradability of the biomass, the highest is the environmental cost (Bartacek et al. 2007; Frigon and Guiot 2010). The use of conventional arable crops , like maize and sorghum, for energy use need careful consideration of land availability and food demand, while, at least in the medium term, lignocellulosic crops (both herbaceous and woody) provide environmental advantages, since they can be produced on marginal and degraded lands, requiring lower technical input (Lewandowski et al. 2003; Angelini et al. 2009; Frigon and Guiot 2010). An interesting opportunity for the bioenergy supply chain is represented by the perennial grasses, like giant reed, switchgrass, and miscanthus, that are high yielding no-food crops with good adaptability to marginal areas (Lewandowski et al. 2003; Angelini et al. 2009; Dragoni et al. 2015). They have resistance to drought stress and to pathogens and phytophagous insects, are good competitor against weeds, and can be used for phytoremediation (Lewandowski et al. 2003; Angelini et al. 2009). Only recently the fermentation product deriving from the dark fermentation of the above-mentioned no-food crops has been used for photofermentation (Adessi et al. 2016a; Corneli et al. 2016a, b submitted).

Another interesting opportunity consists in the use of agroindustrial residues, that are renewable, abundant, economic, and no land-demanding (Schievano et al. 2009; Guo et al. 2010). A bioenergy valorization implies no additional costs for other treatments or disposals (Schievano et al. 2009; Guo et al. 2010). Agroindustrial systems produce abundant and diverse feedstocks, such as lignocellulosic materials, crop residues, vegetable oils, animal fats, protein-rich waste, pre-digested wastewater sludges, animal slurries and manures, waste paper, and household waste, that can contribute to the biomass demand for bioenergy supply chain (Schievano et al. 2009). Bioenergy use of these substrates needs to properly face and respect other uses of residues, like the use of crop and agroindustrial residues as animal feed (Nonhebel 2007), in order to be not in conflict with food production. One of the main issues about energy crops (i.e., crop and agroindustrial residues) is the lignocellulosic content, characterized by its low biodegradability (Frigon and Guiot 2010).

Some agroindustrial and food residues are already rich in organic acids and can be used in one stage photofermentation, such as olive mill and dairy wastewaters (Table 1). However, since the light penetration may result difficult due to the dark color of the medium, especially for olive mill wastewaters, Eroğlu et al. (2006) reported that pretreatments such as dark fermentation (Table 2) can enhance hydrogen production in the photofermentation stage, not only by increasing the amount of readily available organic acids, but also by color depletion.

Carbohydrate-rich substrates such as molasses, hydrolyzed wheat starch, hydrolyzed bagasse, or substrates composed of a mixture of acids and sugars, such as soy sauce or dairy wastewaters, have been used as well for direct photofermentation, since some PNSB species are able to convert sugars to hydrogen with interesting rates (Table 1).

In general, renewable resources constitute an abundant and low-cost material for biohydrogen production and their use is fundamental for large-scale sustainable application. Hence, investigations on novel substrates in order to enlarge the knowledge on photobiological hydrogen production are needed.

Among them, crude glycerol was studied as a possible industrial waste to be used for further energy recovery. Indeed, the current technology for biodiesel production (a base-catalyzed trans-esterification of oils) produces 1 kg of crude glycerol per 10 L of biodiesel, thus the glycerol fraction has become a waste disposal problem (Ghosh et al. 2012a; Johnson and Taconi 2007). A certain number of research papers have been published recently on the topic (Sects. “Single Stage Photofermentation Processes and Sequential Dark/Photofermentation Processes (Two Stage Systems),” and Tables 1 and 2), most of them reporting single stage photofermentation processes using Rp. palustris (Sabourin-Provost and Hallenbeck 2009; Ghosh et al. 2012a, b, c; Pott et al. 2013), giving conversion efficiencies ranging from 75 to 100 %. Chookaew et al. (2015) reported a dark/photofermentation sequential process conducted by Klebsiella sp. and Rp. palustris, giving a much lower conversion, namely 10.4 % of the theoretical yield.

Besides the chemical characteristics of all the substrates mentioned earlier, biomass storage is essential for the sustainability of the overall fermentation technology . Up to now, ensiling is the common way of storage for biomasses, and is widely used, for example, in anaerobic digestion plants (Weiland 2010; Dragoni et al. 2015). Wet feedstocks (25–35 % of total solids) can be ensiled with the purpose to maintain and use them in time, as in the livestock industry (Weiland 2010; Dragoni et al. 2015). In the case of using substrates for photofermentation, ensiling could be an opportunity for degrading the fermentescible substrates to organic acids thus enhancing both fermentation and photofermentation (Corneli et al. 2016a; Corneli et al. 2016a, b submitted). Indeed, during ensiling, after a short initial aerobic phase, the fermentation starts under anaerobic conditions with the production of lactic acid by lactic acid bacteria, with the consequent decrease of pH to about 4.0 (Weiland 2010). With this level of acidity, in few days, the growth of undesirable microorganisms, such as enterobacteria, clostridia, and yeasts, which consume nutrients and energy, is inhibited and subsequently the process settles (Weiland 2010; Herrmann et al. 2011). Thus, anaerobic conditions together with a rapid production of lactic acid allow a good conservation of the biomass, in terms of both nutrients and energy (Weiland 2010; Herrmann et al. 2011) also giving an excellent substrate for photofermentation with PNSB.

Synthetic Substrates

The use of synthetic media for hydrogen production processes is important, since it gives the possibility to investigate the behavior of the microorganisms in a controlled system, where the culture medium is completely defined. Thus, synthetic substrates are used for research studies on very innovative culturing systems, for the characterization of new or engineered strains, or for exploring new metabolic routes. However, in this section only the synthetic substrates investigated for broadening the range of the biomass derived substrates utilizable for photofermentation will be discussed. Indeed, part of the research on substrates investigates the possibility of expanding the medium composition combinations, thus increasing the range of applicability of the hydrogen production process.

A few recent research papers were focused on the possibility of using glucose for direct photofermentation, in order to skip the dark fermentation step when using sugar-containing waste substrates. The feasibility of the process majorly stands in the fact that the hydrogen yield obtained (mol H2 mol glucose−1) has to be higher or comparable to the ones obtained by combined dark/photofermentation systems. Indeed, from the initial low values of 3.3 mol H2 (mol glucose)−1 (Abo-Hashesh et al. 2013), an increase to 5.5 mol H2 (mol glucose)−1 (Ghosh et al. 2012c) and finally to 9.0 mol H2 (mol glucose)−1 (Abo-Hashesh et al. 2013) was obtained with a hup− strain of Rb. capsulatus. Recently, an interesting study carried out on a mixture of sugars and acids (namely, glucose, xylose, and acetate, that are the main products in palm oil hydrolysates) using Rb. sphaeroides S10, reported a 45 % substrate-to-hydrogen conversion efficiency when the substrate was composed of 5 mM glucose, 18 mM xylose, and 7 mM acetate (Pattanamanee et al. 2015). Another recent study was conducted with a mutant strain of the marine organism Rhodovulum sulfidophilum, giving a yield of 7.1 mol H2 (mol glucose)−1 (Cai and Wang 2014). These authors used in their experiments marine water, which opens a completely different scenario for possible low-cost substrates. Indeed, the application of seawater for bacterial fermentative production is of increasing interest (Maeda et al. 2000), since large-scale cultivation systems need to be sustainable in terms of water resources. Hence, brackish water, wastewater, and seawater seem the most appropriate for large-scale culturing. Most of hydrogen production studies on salt containing media were conducted using marine photosynthetic bacteria such as Rhodobium marinum (Ike et al. 1997), Rhodovulum sulfidophilum P5 (Cai and Wang 2012, 2013, 2014), as well as a marine mixed phototrophic bacterial consortium (Cai and Wang 2012). Recently, a study on the use of freshwater Rp. palustris was conducted on a substrate derived from threefold diluted seawater (Dipasquale et al. 2015). In order to further increase the possible combinations of processes that can be carried out Adessi et al. (2016b) investigated a range of salt concentrations that can be suitable for hydrogen production with the same freshwater Rp. palustris strain, up to 3.9 % salt content. Thus, the possibility of using Rp. palustris, that is extremely versatile in terms of carbon sources utilization (Larimer et al. 2004; Adessi et al. 2016c), also on salt containing substrates, would enhance the applicability of the hydrogen production process and the prospect of its cost-reduction.

Another interesting substrate with a direct applicability is glycerol . As above mentioned, crude glycerol is produced as a side product of the biodiesel manufacturing industry. Direct photofermentation of pure glycerol was studied prior to the use of crude glycerol by Sabourin-Provost and Hallenbeck (2009) and by Pott et al. (2013), giving a conversion of glycerol to hydrogen of 75 % and 80–85 %, respectively.

Ethanol has recently reached some attention in photofermentation. The possibility of using substrates containing small percentages of ethanol is an opportunity for increasing the number of wastes that can be used. Recently, Kim et al. (2014) demonstrated that ethanol can increase lactate utilization in Rb. sphaeroides, acting as an enhancer for addressing reducing power to nitrogenase: the yield was increased from 1.5–2.2 mol H2 (mol lactate)−1, by adding 0.2 % of ethanol. It was first demonstrated that hydrogen could be produced from ethanol as the sole substrate by Rhodopseudomonas sp. (Fuji et al. 1983). This was brought up again by Liu et al. (2015) with a culture of Rp. palustris grown in presence of ethanol up to 2 %; this culture gave a yield of 2 mol H2 (mol ethanol)−1 (i.e., 33 %).

Conclusions

In recent years, progress has been made in developing cleaner and more efficient bioenergy producing systems. In order for bioenergies to become increasingly competitive with other energy sources, logistics and infrastructures must be addressed and further technological innovation should lead to more efficient and cleaner conversion of a diverse range of feedstocks, in the view of promoting clean biofuel production, and the subsequent decarbonization of energy sources and fuels.

Facing the increasing relevance of the hydrogen economy, improving biohydrogen production yields, investigating novel substrates, and developing the technology at plant scale represent imperative tasks and photofermentation systems may be considered as alternatives capable of attaining these goals. The investigation on abundant and low-cost renewable biomass derived substrates is of relevant importance, trying to find sustainable feedstocks for novel fermentation systems, and this chapter showed how novel substrates can be suitable for biohydrogen producing applications, with limited pretreatments.

The photobiological hydrogen production is a technology in progress, which can be classified as single stage process and as dark/photofermentation systems both sequential (two stage) and combined (co-cultures). Furthermore, the cell immobilization techniques could enhance the continuous hydrogen production, compared to suspended cell systems.

However, at the current state, the design of suitable and efficient photobioreactors is still to be achieved and no cost-effective approaches have been developed yet both for dark fermentation, where biogas plant-like technology could be used, and for photofermentation, where new and efficient photobioreactors need to be realized at plant scale. Investigations should focus on several issues, such as (a) a longer retention time for the low biodegradable substrates; (b) the research of novel, robust, and versatile inocula; (c) the codigestion of biomasses in order to balance the C/N ratio; and (d) the study of fermentation systems using continuous culture, with the view to translate the process from lab to plant scale. Many aspects have still to be optimized, but in the last few years the number of new findings demonstrates that it is worth continuing the efforts for increasing the knowledge on the photofermentation process for H2 production, in particular owing to the need of reducing the use of fossil fuels for mitigating the emissions of GHG in the atmosphere.

Abbreviations

- DW:

-

Dry weight

- OMWW:

-

Olive mill waste waters

- PHA:

-

Polyhydroxyalkanoate

- PHB:

-

Poly-β-hydroxybutyrate

- PNSB:

-

Purple non sulfur bacteria

- VFAs:

-

Short chain volatile fatty acids

- VS:

-

Volatile solids

References

Abo-Hashesh M, Hallenbeck PC (2012) Fermentative hydrogen production. In: Hallenbeck PC (ed) Microbial technologies in advanced biofuels production. Springer, pp 77–92

Abo-Hashesh M, Desaunay N, Hallenbeck PC (2013) High yield single stage conversion of glucose to hydrogen by photofermentation with continuous cultures of Rhodobacter capsulatus JP91. Bioresour Technol 128:513–517

Adessi A, De Philippis R (2013) Purple bacteria: electron acceptors and donors. In: Lennarz WJ, Lane MD (eds) The encyclopedia of biological chemistry, vol 3. Academic, Elsevier, Waltham, MA, pp 693–699

Adessi A, De Philippis R (2014) Photosynthesis and hydrogen production in purple non sulfur bacteria: fundamental and applied aspects. In: Zannoni D, De Philippis R (eds) Microbial bioenergy: hydrogen production, vol 38. Springer, pp 269–290

Adessi A, De Philippis R, Hallenbeck PC (2012a) Combined systems for maximum substrate conversion. In: Hallenbeck PC (ed) Microbial technologies in advanced biofuels production. Springer, pp 107–126

Adessi A, McKinlay JB, Harwood CS et al (2012b) A Rhodopseudomonas palustris nifA* mutant produces H2 from-containing vegetable wastes. Int J Hydrogen Energy 37:15893–15900

Adessi A, De Philippis R, Corneli E et al (2016a) Produzione fotobiologica poliidrossibutirrato da biomasse con batteri rossi non sulfurei. Italian patent F1 S0061 12 IT 1, filed March 17, 2016

Adessi A, Concato M, Sanchini A et al (2016b) Hydrogen production under salt stress conditions by a freshwater Rhodopseudomonas palustris strain. Appl Microb Biotechnol 100:2917–2926

Adessi A, Spini G, Presta L et al (2016c) Draft genome sequence and overview of the purple non sulfur bacterium Rhodopseudomonas palustris 42OL. Stand Genomic Sci 11:1

Anam K, Habibi MS, Harwati TU et al (2012) Photofermentative hydrogen production using Rhodobium marinum from bagasse and soy sauce wastewater. Int J Hydrogen Energy 37:15436–15442

Angelini LG, Ceccarini L, Nassi o Di Nasso N et al (2009) Comparison of Arundo donax L. and Miscanthus x giganteus in a long-term field experiment in Central Italy: analysis of productive characteristics and energy balance. Biomass Bioenerg 33:635–643

Appels L, Lauwers J, Degrève J et al (2011) Anaerobic digestion in global bio-energy production: potential and research challenges. Renew Sust Energ Rev 15:4295–4301

Argun H, Kargi F (2010a) Photo-fermentative hydrogen gas production from dark fermentation effluent of ground wheat solution: effects of light source and light intensity. Int J Hydrogen Energy 35:1595–1603

Argun H, Kargi F (2010b) Bio-hydrogen production from ground wheat starch by continuous combined fermentation using annular-hybrid bioreactor. Int J Hydrogen Energy 35:6170–6178

Argun H, Kargi F (2010c) Effects of light source, intensity and lighting regime on bio-hydrogen production from ground wheat starch by combined dark and photo-fermentations Int J Hydrogen Energy 35:1604–1612

Argun H, Kargi F (2011) Bio-hydrogen production by different operational modes of dark and photo-fermentation: an overview. Int J Hydrogen Energy 36:7443–7459

Argun H, Kargi F, Kapdan IK (2009a) Effects of the substrate and cell concentration on bio-hydrogen production from ground wheat by combined dark and photo-fermentation. Int J Hydrogen Energy 34:6181–6188

Argun H, Kargi F, Kapdan IK (2009b) Hydrogen production by combined dark and light fermentation of ground wheat solution. Int J Hydrogen Energy 34:4305–4311

Arumugam A, Sandhya M, Ponnusami V (2014) Biohydrogen and polyhydroxyalkanoate co-production by Enterobacter aerogenes and Rhodobacter sphaeroides from Calophyllum inophyllum oil cake. Bioresour Technol 164:170–176

Bartacek J, Zabranska J, Lens PN (2007) Developments and constraints in fermentative hydrogen production. Biofuel Bioprod Bior 1:201–214

Cai J, Wang G (2012) Hydrogen production by a marine photosynthetic bacterium, Rhodovulum sulfidophilum P5, isolated from a shrimp pond. Int J Hydrogen Energy 37:15070–15080

Cai J, Wang G (2013) Screening and hydrogen-producing characters of a highly efficient H 2-producing mutant of Rhodovulum sulfidophilum P5. Bioresour Technol 142:18–25

Cai J, Wang G (2014) Hydrogen production from glucose by a mutant strain of Rhodovulum sulfidophilum P5 in single-stage photofermentation. Int J Hydrogen Energy 39:20979–20986

Cappai G, De Gioannis G, Friargiu M et al (2014) An experimental study on fermentative H2 production from food waste as affected by pH. Waste Manage 34:1510–1519

Chang JS, Lee KS, Lin PJ (2002) Biohydrogen production with fixed-bed bioreactors. Int J Hydrogen Energy 27:1167–1174

Cheng J, Su H, Zhou J et al (2011a) Microwave-assisted alkali pretreatment of rice straw to promote enzymatic hydrolysis and hydrogen production in dark-and photo-fermentation. Int J Hydrogen Energy 36:2093–2101

Cheng J, Su H, Zhou J et al (2011b) Hydrogen production by mixed bacteria through dark and photo fermentation. Int J Hydrogen Energy 36:450–457

Cheng J, Xia A, Liu Y et al (2012) Combination of dark-and photo-fermentation to improve hydrogen production from Arthrospira platensis wet biomass with ammonium removal by zeolite. Int J Hydrogen Energy 37:13330–13337

Chookaew T, Sompong O, Prasertsan P (2015) Biohydrogen production from crude glycerol by two stage of dark and photo fermentation. Int J Hydrogen Energy 40:7433–7438

Christopher K, Dimitrios R (2012) A review on exergy comparison of hydrogen production methods from renewable energy sources. Energ Environ Sci 5:6640–6651

Corneli E, Adessi A, Dragoni F et al (2016 submitted) Agroindustrial residues and energy crops for the production of H2 and PHB via photofermentation. Biores Technol (under review)

Corneli E, Dragoni F, Adessi A et al (2016b) Energy conversion of biomass crops and agroindustrial residues by combined biohydrogen/biomethane system and anaerobic digestion. Bioresour Technol 211:509–518

Das D, Veziroglu N (2008) Advances in biological hydrogen production processes. Int J Hydrogen Energy 33:6046–6057

Dipasquale L, Adessi A, d’Ippolito G et al (2015) Introducing capnophilic lactic fermentation in a combined dark-photo fermentation process: a route to unparalleled H2 yields. Appl Microb Biotechnol 99:1001–1010

Dragoni F, Ragaglini G, Corneli E et al (2015) Giant reed (Arundo donax L.) for biogas production: land use saving and nitrogen utilisation efficiency compared with arable crops. Ital J Agron 10:192–201

El Bassam N (2010) Handbook of bioenergy crops: a complete reference to species, development and applications. Earthscan, London/Washington, DC

Eroğlu E, Eroğlu İ, Gündüz U et al (2006) Biological hydrogen production from olive mill wastewater with two-stage processes. Int J Hydrogen Energy 31:1527–1535

Eroğlu E, Eroğlu İ, Gündüz U et al (2008a) Effect of clay pretreatment on photofermentative hydrogen production from olive mill wastewater. Bioresour Technol 99:6799–6808

Eroğlu İ, Tabanoğlu A, Gündüz U et al (2008b) Hydrogen production by Rhodobacter sphaeroides OU 001 in a flat plate solar bioreactor. Int J Hydrogen Energy 33:531–541

Eroğlu E, Eroğlu İ, Gündüz U et al (2009) Treatment of olive mill wastewater by different physicochemical methods and utilization of their liquid effluents for biological hydrogen production. Biomass Bioenerg 33:701–705

Eroglu E, Gunduz U, Yucel M et al (2010) Photosynthetic bacterial growth and productivity under continuous illumination or diurnal cycles with olive mill wastewater as feedstock. Int J Hydrogen Energy 35:5293–5300

Eroğlu I, Özgür E, Eroğlu E et al (2014) Applications of photofermentative hydrogen production. In: Zannoni D, De Philippis R (eds) Microbial bioenergy: hydrogen production, vol 38. Springer, pp 237–267

Fascetti E, D’addario E, Todini O et al (1998) Photosynthetic hydrogen evolution with volatile organic acids derived from the fermentation of source selected municipal solid wastes. Int J Hydrogen Energy 23:753–760

Frigon JC, Guiot SR (2010) Biomethane production from starch and lignocellulosic crops: a comparative review. Biofuel Bioprod Bior 4:447–458

Fuji T, Nakazawa A, Sumi N et al (1983) Utilization of alcohols by Rhodopseudomonas sp No 7 isolated from n-propanol–enrichment cultures. Agr Biol Chem Tokio 47:2747–2753

Ghimire A, Frunzo L, Pirozzi F et al (2015) A review on dark fermentative biohydrogen production from organic biomass: process parameters and use of by-products. Appl Energ 144:73–95

Ghosh D, Tourigny A, Hallenbeck PC (2012a) Near stoichiometric reforming of biodiesel derived crude glycerol to hydrogen by photofermentation. Int J Hydrogen Energy 37:2273–2277

Ghosh D, Sobro IF, Hallenbeck PC (2012b) Stoichiometric conversion of biodiesel derived crude glycerol to hydrogen: response surface methodology study of the effects of light intensity and crude glycerol and glutamate concentration. Bioresour Technol 106:154–160

Ghosh D, Sobro IF, Hallenbeck PC (2012c) Optimization of the hydrogen yield from single-stage photofermentation of glucose by Rhodobacter capsulatus JP91 using response surface methodology. Bioresour Technol 123:199–206

Gómez X, Fernández C, Fierro J et al (2011) Hydrogen production: two stage processes for waste degradation. Bioresour Technol 102:8621–8627

Gosse JL, Engel BJ, Rey FE et al (2007) Hydrogen production by photoreactive nanoporous latex coatings of nongrowing Rhodopseudomonas palustris CGA009. Biotechnol Progr 23:124–130

Guo XM, Trably E, Latrille E et al (2010) Hydrogen production from agricultural waste by dark fermentation: a review. Int J Hydrogen Energy 35:10660–10673

Guo CL, Zhu X, Liao Q et al (2011) Enhancement of photo-hydrogen production in a biofilm photobioreactor using optical fiber with additional rough surface. Bioresour Technol 102:8507–8513

Hallenbeck PC, Ghosh D (2009) Advances in fermentative biohydrogen production: the way forward? Trends Biotechnol 27:287–297

Hallenbeck PC, Liu Y (2016) Recent advances in hydrogen production by photosynthetic bacteria. Int J Hydrogen Energy 41:4446–4454

Hallenbeck PC, Ghosh D, Skonieczny MT et al (2009) Microbiological and engineering aspects of biohydrogen production. Indian J Microbiol 49:48–59

Hawkes FR, Hussy I, Kyazze G et al (2007) Continuous dark fermentative hydrogen production by mesophilic microflora: principles and progress. Int J Hydrogen Energy 32:172–184

Hay JXW, Wu TY, Juan JC (2013) Biohydrogen production through photo fermentation or dark fermentation using waste as a substrate: overview, economics, and future prospects of hydrogen usage. Biofuel Bioprod Bior 7:334–352

Heiniger EK, Oda Y, Samanta SK et al (2012) How posttranslational modification of nitrogenase is circumvented in Rhodopseudomonas palustris strains that produce hydrogen gas constitutively. Appl Environ Microbiol 78:1023–1032

Herrmann C, Heiermann M, Idler C (2011) Effects of ensiling, silage additives and storage period on methane formation of biogas crops. Bioresour Technol 102:5153–5161

Holladay JD, Hu J, King DL et al (2009) An overview of hydrogen production technologies. Catal Today 139:244–260

Hustede E, Steinbüchel A, Schlegel HG (1993) Relationship between the photoproduction of hydrogen and the accumulation of PHB in non-sulphur purple bacteria. Appl Microb Biotechnol 39:87–93

IEA (International Energy Agency) (2009) Bioenergy–a sustainable and reliable energy source. International Energy Agency Bioenergy, Paris, France

Ike A, Toda N, Tsuji N et al (1997) Hydrogen photoproduction from CO2-fixing microalgal biomass: application of halotolerant photosynthetic bacteria. J Ferment Bioeng 84:606–609

IRENA (2013) Statistical issues: bioenergy and distributed renewable energy. http://www.irena.org/DocumentDownloads/Publications/Statistical%20issues_bioenergy_and_distributed%20renewable%20_energy.pdf

Johnson DT, Taconi KA (2007) The glycerin glut: options for the value‐added conversion of crude glycerol resulting from biodiesel production. Environ Progr 26:338–348

Kapdan IK, Kargi F, Oztekin R et al (2009) Bio-hydrogen production from acid hydrolyzed wheat starch by photo-fermentation using different Rhodobacter sp. Int J Hydrogen Energy 34:2201–2207

Keskin T, Hallenbeck PC (2012) Hydrogen production from sugar industry wastes using single-stage photofermentation. Bioresour Technol 112:131–136

Keskin T, Abo-Hashesh M, Hallenbeck PC (2011) Photofermentative hydrogen production from wastes. Bioresour Technol 102:8557–8568

Kim DH, Lee JH, Kang S et al (2014) Enhanced photo-fermentative H2 production using Rhodobacter sphaeroides by ethanol addition and analysis of soluble microbial products. Biotechnol Biofuel 7:79

Larimer FW, Chain P, Hauser L et al (2004) Complete genome sequence of the metabolically versatile photosynthetic bacterium Rhodopseudomonas palustris. Nat Biotechnol 22:55–61

Laurinavichene TV, Belokopytov BF, Laurinavichius KS et al (2010) Towards the integration of dark-and photo-fermentative waste treatment. 3. Potato as substrate for sequential dark fermentation and light-driven H2 production. Int J Hydrogen Energy 35:8536–8543

Lazaro CZ, Varesche MBA, Silva EL (2015) Sequential fermentative and phototrophic system for hydrogen production: an approach for Brazilian alcohol distillery wastewater. Int J Hydrogen Energy 40:9642–9655

Lewandowski I, Scurlock JM, Lindvall E et al (2003) The development and current status of perennial rhizomatous grasses as energy crops in the US and Europe. Biomass Bioenerg 25:335–361

Liu BF, Ren NQ, Tang J et al (2010) Bio-hydrogen production by mixed culture of photo-and dark-fermentation bacteria. Int J Hydrogen Energy 35:2858–2862

Liu Y, Ghosh D, Hallenbeck PC (2015) Biological reformation of ethanol to hydrogen by Rhodopseudomonas palustris CGA009. Bioresour Technol 176:189–195

Maeda, I., Mizoguchi, T., Miura, Y., Yagi, K., Shioji, N., & Miyasaka, H. (2000). Influence of sulfate-reducing bacteria on outdoor hydrogen production by photosynthetic bacterium with seawater. Current microbiology, 40(3), 210–213

Nonhebel S (2007) Energy from agricultural residues and consequences for land requirements for food production. Agr Syst 94:586–592

Özgür E, Mars AE, Peksel B et al (2010) Biohydrogen production from beet molasses by sequential dark and photofermentation. Int J Hydrogen Energy 35:511–517

Ozmihci S, Kargi F (2010) Comparison of different mixed cultures for bio-hydrogen production from ground wheat starch by combined dark and light fermentation. J Ind Microbiol Biot 37:341–347

Pachapur VL, Sarma SJ, Brar SK et al (2015) Co‐culture strategies for increased biohydrogen production. Int J Energ Res 39:1479–1504

Pattanamanee W, Chisti Y, Choorit W (2015) Photofermentive hydrogen production by Rhodobacter sphaeroides S10 using mixed organic carbon: effects of the mixture composition. Appl Energ 157:245–254

Pintucci C, Giovannelli A, Traversi ML et al (2013) Fresh olive mill waste deprived of polyphenols as feedstock for hydrogen photo-production by means of Rhodopseudomonas palustris 42OL. Renew Energ 51:358–363

Pintucci C, Padovani G, Giovannelli A et al (2015) Hydrogen photo-evolution by Rhodopseudomonas palustris 6A using pre-treated olive mill wastewater and a synthetic medium containing sugars. Energ Conver Manage 90:499–505

Pott RW, Howe CJ, Dennis JS (2013) Photofermentation of crude glycerol from biodiesel using Rhodopseudomonas palustris: comparison with organic acids and the identification of inhibitory compounds. Bioresour Technol 130:725–730

Redwood MD, Paterson-Beedle M, Macaskie LE (2009) Integrating dark and light bio-hydrogen production strategies: towards the hydrogen economy. Rev Environ Sci Biotechnol 8:149–185

Sabourin-Provost G, Hallenbeck PC (2009) High yield conversion of a crude glycerol fraction from biodiesel production to hydrogen by photofermentation. Bioresour Technol 100:3513–3517

Sargsyan H, Trchounian K, Gabrielyan L et al (2016) Novel approach of ethanol waste utilization: biohydrogen production by mixed cultures of dark-and photo-fermentative bacteria using distillers grains. Int J Hydrogen Energy 4:2377–2382

Schievano A, D’Imporzano G, Adani F (2009) Substituting energy crops with organic wastes and agro-industrial residues for biogas production. J Environ Manage 90:2537–2541

Seifert K, Waligorska M, Laniecki M (2010a) Hydrogen generation in photobiological process from dairy wastewater. Int J Hydrogen Energy 35:9624–9629

Seifert K, Waligorska M, Laniecki M (2010b) Brewery wastewaters in photobiological hydrogen generation in presence of Rhodobacter sphaeroides OU 001. Int J Hydrogen Energy 35:4085–4091

Singh L, Wahid ZA (2015) Methods for enhancing bio-hydrogen production from biological process: a review. J Ind Eng Chem 21:70–80

Su H, Cheng J, Zhou J et al (2009) Improving hydrogen production from cassava starch by combination of dark and photo fermentation. Int J Hydrogen Energy 34:1780–1786

Su H, Cheng J, Zhou J et al (2010) Hydrogen production from water hyacinth through dark-and photo-fermentation. Int J Hydrogen Energy 35:8929–8937

Tian X, Liao Q, Zhu X et al (2010) Characteristics of a biofilm photobioreactor as applied to photo-hydrogen production. Bioresour Technol 101:977–983

Tsygankov A, Kosourov S (2014) Immobilization of photosynthetic microorganisms for efficient hydrogen production. In: Zannoni D, De Philippis R (eds) Microbial bioenergy: hydrogen production, vol 38. Springer, pp 321–347

Vatsala TM, Raj SM, Manimaran A (2008) A pilot-scale study of biohydrogen production from distillery effluent using defined bacterial co-culture. Int J Hydrogen Energy 33:5404–5415

Vincenzini M, Marchini A, Ena A et al (1997) H and poly-β-hydroxybutyrate, two alternative chemicals from purple non sulfur bacteria. Biotechnol Lett 19:759–762

Wang YZ, Liao Q, Zhu X et al (2010) Characteristics of hydrogen production and substrate consumption of Rhodopseudomonas palustris CQK 01 in an immobilized-cell photobioreactor. Bioresour Technol 101:4034–4041

Wang X, Yang G, Feng Y et al (2012) Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour Technol 120:78–83

Weiland P (2010) Biogas production: current state and perspectives. Appl Microb Biotechnol 85:849–860

Wu SC, Liou SZ, Lee CM (2012) Correlation between bio-hydrogen production and polyhydroxybutyrate (PHB) synthesis by Rhodopseudomonas palustris WP3-5. Bioresour Technol 113:44–50

Xia A, Cheng J, Ding L et al (2014) Enhancement of energy production efficiency from mixed biomass of Chlorella pyrenoidosa and cassava starch through combined hydrogen fermentation and methanogenesis. Appl Energ 120:23–30

Xie GJ, Liu BF, Ding J et al (2012) Enhanced photo-H2 production by Rhodopseudomonas faecalis RLD-53 immobilization on activated carbon fibers. Biomass Bioenerg 44:122–129

Yang H, Shi B, Ma H et al (2015) Enhanced hydrogen production from cornstalk by dark-and photo-fermentation with diluted alkali-cellulase two-step hydrolysis. Int J Hydrogen Energy 40:12193–12200

Zagrodnik R, Laniecki M (2015) The role of pH control on biohydrogen production by single stage hybrid dark-and photo-fermentation. Bioresour Technol 194:187–195

Zhang C, Zhu X, Liao Q et al (2010) Performance of a groove-type photobioreactor for hydrogen production by immobilized photosynthetic bacteria. Int J Hydrogen Energy 35:5284–5292

Zong W, Yu R, Zhang P et al (2009) Efficient hydrogen gas production from cassava and food waste by a two-step process of dark fermentation and photo-fermentation. Biomass Bioenerg 33:1458–1463

Zürrer H, Bachofen R (1981) Hydrogen production from lactate and lactate-containing wastes by the photosynthetic bacterium Rhodospirillum rubrum. Stud Environ Sci 9:31–36

Acknowledgements

AA and RDP acknowledge CNR (Italian National Research Council) (EFOR project), and Ente Cassa di Risparmio di Firenze (Project HYDROLAB2) for funding their researches cited in this review. RDP would also like to mention the contribution given to his activities by the participation in the IEA-HIA (International Energy Agency—Hydrogen Implementation Agreement), Annex 34. EC acknowledges Scuola Superiore Sant’Anna of Pisa for supporting and funding her PhD research project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Adessi, A., Corneli, E., De Philippis, R. (2017). Photosynthetic Purple Non Sulfur Bacteria in Hydrogen Producing Systems: New Approaches in the Use of Well Known and Innovative Substrates. In: Hallenbeck, P. (eds) Modern Topics in the Phototrophic Prokaryotes. Springer, Cham. https://doi.org/10.1007/978-3-319-46261-5_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-46261-5_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-46259-2

Online ISBN: 978-3-319-46261-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)