Abstract

Phenolic compounds and other antioxidants are of great interest since they have the potential to stabilize food products against lipid deterioration. Also, because many diseases such as diabetes and certain forms of cancer are linked to oxidative stress, phenolic compounds from food products and other plant sources are of interest for disease prevention. Thus, there is a demand to measure phenolic compounds in food products and to evaluate the antioxidant capacity of individual food constituents, extracts, and ingredients. Assays described in this chapter are of four types: (total) phenolics, hydrogen atom transfer-based antioxidant capacity assays, single-electron transfer-based antioxidant capacity assays, and accelerated lipid oxidation assays. Methods to determine the total phenolic contents of food products such as the Folin-Ciocalteu assay are unspecific and do not, depending on the overall composition of the food product, necessarily reflect the phenolic contents. Therefore, wherever possible, it is advised to study individual phenolic compounds by using various chromatography approaches. The chapter includes cautions regarding the types of antioxidant capacity assays used to screen compounds for delaying lipid oxidation and potential health benefits.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The term phenolics refers to several thousand aromatic plant metabolites, which possess at least one hydroxyl group attached to the phenyl ring. In the plant, phenolic compounds are important as structural components [1], in particular for the stabilization of the plant cell wall, and as a response to wounding and infestation. In addition, a plethora of nonstructural constituents, which are important as plant defense mechanisms against biotic and abiotic stress, establishing color, etc., has been identified from plants and plant-based foods. In food products, phenolics such as tocopherols and gallates are long known to increase the oxidative stability of lipids. They are also used as food colorants (e.g., anthocyanins) and contribute to the flavor of food products (e.g., vanillin). More recently, interest in phenolics was generated from studies suggesting potential health-promoting effects of phenolics in general or protective effects of specific phenolic compounds against specific diseases such as coronary heart disease and certain forms of cancer [2]. However, a general protective health effect of phenolics is highly unlikely, especially because many toxic phenolic compounds are known, too. Most importantly, many health-promoting effects of specific components were suggested based only on in vitro assays.

Currently, phenolics are often classified as either simple phenolics, which contain only one phenolic ring, for example, hydroxybenzoic acids and (monomeric) hydroxycinnamic acids, or polyphenols, which are made up of at least two phenolic units such as flavonoids, stilbenes, or lignans (Fig. 25.1). Polyphenolic food constituents with more than two phenolic rings are, for example, hydrolyzable and non-hydrolyzable tannins. However, besides these comparably low-molecular-weight phenolic compounds, plant-based foods contain high-molecular-weight phenolic compounds such as lignin or the phenolic domain of suberin. In addition to the naturally occurring phenolics synthesized by the plant, food processing leads to the formation of new phenolic compounds or significant modifications of plant-based phenolics. For example, the Maillard reaction results in the formation of phenolic products, and naturally occurring phenolics are incorporated into melanoidins, with coffee melanoidins (containing modified chlorogenic acids) being one of the most prominent examples [3].

Assays described in this chapter are of four types: (total) phenolics, hydrogen atom transfer-based antioxidant capacity assays, single electron transfer-based antioxidant capacity assays, and accelerated lipid oxidation assays. Many of the methods are given in more detail than in most other chapters in this book because this is a relatively recent field in food science and there are few official methods of analysis. Also, because all of the described methods have limitations, these are discussed in more detail in this chapter.

2 Analysis of (Total) Phenolics

Based on the diverse array of phenolic compounds, which are often associated with non-phenolic compounds such as carbohydrates or organic acids as well, it is not possible to determine all phenolic compounds with a single assay as the term “total phenolic assays” may suggest. Also, many tests that are used to measure sum parameters are rather unselective, a fact which is also true for total phenolic assays. Thus, a critical evaluation of the results is necessary instead of claiming specific total phenolic contents of food products and food ingredients. A critical step in the application of total phenolic assays is choosing the extraction procedure, which defines the phenolic compounds to be included in the test results. Also, due to the poor selectivity of the total phenolic assays, specific extraction procedures may be used to exclude matrix compounds otherwise being determined in the assays.

2.1 Sample Preparation

Clear beverages such as white wine or clear apple juice usually do not require any further preparation but are either used directly or after dilution depending on the concentration of phenolic compounds. Fresh fruits, vegetables, cereals, and processed food products are directly ground and extracted, or they are lyophilized, ground, and extracted. Direct extraction after grinding requires information about the water content of the food product to reliably adjust the organic solvent/water ratio during the extraction step, a requirement that is often neglected in practice. Although lyophilization is the gentlest way to dry food products, small losses of phenolic compounds due to degradation may still occur during this process. After crushing fresh fruits or vegetables, the mash needs to be processed quickly due to potential losses of phenolics by the oxidizing action of the enzyme polyphenol oxidase found in plant tissues.

Many phenolic compounds are located in vacuoles and can easily be extracted with different solvents after cell wall and membrane rupture. Phenolic compounds that are bound to plant polymers need to be liberated by hydrolytic procedures [4].

2.1.1 Extraction

Phenolic compounds and their soluble conjugates such as sugar derivatives are extracted with water, polar organic solvents, or mixtures of polar organic solvents and water [5]. Extraction temperatures from room temperature up to 90 °C are used, depending on the analyzed food product and the stability of the phenolic compounds to be extracted. In some cases, less polar organic solvents such as ethyl acetate are used, which extract less polar phenolic compounds but exclude very polar phenolics (especially phenolic glycosides and other polar conjugates). Polar solvents, which are frequently used, include methanol, ethanol, and acetone, often as an 80/20 (vol/vol) or 50/50 (vol/vol) mixture with water. Aqueous 80 % ethanol or methanol solutions work well for most food products, solubilizing the bulk of phenolic compounds and, at the same time, precipitating out many polymers such as polysaccharides and proteins. Acidifying the extraction solutions may assist in stabilizing certain phenolic compounds such as anthocyanins.

2.1.2 Hydrolysis

Depending on the purpose of the analysis, it may be of interest to measure insoluble phenolics in addition to soluble phenolics. Common types of linkages involving phenolic compounds are glycosidic linkages and ester linkages. Especially in cereal products, but also in other plant-based foods, phenolic acids are ester linked. Their liberation requires alkaline hydrolysis (e.g., 2 M NaOH, room temperature, 16 h) of the solvent-extracted residue (Sect. 25.2.1.1). Alkaline conditions may partially degrade phenolic acids such as hydroxycinnamic acids. To reduce oxidative degradation, NaOH solutions should be purged with nitrogen, and the headspace of the capped hydrolysis tubes should be flushed with nitrogen as well. Liberated phenolic acids are often extracted from the hydrolysate after acidification, which protonates the phenolic acids and makes them suitable for extraction with less polar organic solvents such as ethyl acetate or diethyl ether.

2.2 Colorimetric Assays for Determination of “Total” Phenolics

2.2.1 Principles and Characteristics

Colorimetric assays to determine total phenolic contents are often based on the ability of phenolic compounds to be oxidized. Permanganate and ferric ions were applied as oxidation reagents in the past, with ferric ions still used to measure the antioxidant capacity of plant foods. At present, two other reagents are more commonly used, which were originally developed to measure tyrosine and the aromatic but non-phenolic amino acid tryptophan: the Folin-Denis reagent [6, 7] and the Folin-Ciocalteu reagent [8]. Both reagents contain complex polymeric ions formed from phosphomolybdic and phosphotungstic heteropoly acids. Phenolates are formed under alkaline conditions and then oxidized, thereby reducing the initially yellow phosphotungstic-phosphomolybdic reagent. Reduction of the phosphotungstic-phosphomolybdic reagent results in the formation of a blue color (“molybdenum-tungsten blue”), which can be measured spectrophotometrically at a wide range of wavelengths, with 750 nm or 760 nm often being used. Because the phenolic compounds are only oxidized under alkaline conditions, but both the oxidizing reagent and the formed molybdenum-tungsten blue were occasionally described as unstable in alkaline solutions, several procedures with different sequences of reagent addition and time periods in between reagent addition and spectrophotometric analysis have been suggested. Also, when using the initially developed Folin-Denis reagent, a precipitate may form. The Folin-Ciocalteu reagent addresses this issue through the addition of lithium sulfate to the reagent. In addition, the Folin-Ciocalteu reagent has been described as being more sensitive than the Folin-Denis reagent [9]. The molar absorptivity (Chap. 7, Sect. 7.2.1) depends on both the reagent used and the phenolic compounds tested. For example, ortho-diphenols produce much larger (in many cases nearly twice as high, but varying) absorptivities than monophenolic compounds or meta-diphenols, demonstrating the empirical nature of this approach. Color formation by a sample is compared to color formation of a standard compound, preferentially gallic acid, (+)-catechin, or, more traditionally, tannic acid (Fig. 25.2), and the results are reported as gallic acid, (+)-catechin, or tannic acid equivalents.

Poor selectivity is a major shortcoming of both Folin reagent-based total phenolic assays. Several studies demonstrated that other reducing compounds besides phenolics can reduce the Folin reagents and are thus incorrectly determined as phenolic compounds in this assay. Besides ascorbic acid and some other vitamins, many other compounds such as thiols (e.g., cysteine and glutathione), nucleotide bases, and redox-active metal ions were reported to be active in this test [10]. In some reports, reducing sugars were described to be active, too. Due to their reactivity toward other non-phenolic reducing compounds, the Folin-based phenolic assays were also suggested as candidates for measuring the antioxidant or reducing activity of a sample rather than estimating total phenolics.

2.2.2 Outline of Folin-Ciocalteu Procedure

-

1.

A clear sample solution is added to distilled water in a volumetric flask.

-

2.

The Folin-Ciocalteu reagent (commercially available) is added, and the contents are mixed.

-

3.

After 1 min and before 8 min, 20 % sodium carbonate solution is added, and the volume is adjusted (a pH of about 10 should be achieved after mixing with the Folin-Ciocalteu reagent and the sample solution) [11].

-

4.

After about 2 h (the blue color has been demonstrated to be comparably stable), the generated color is determined spectrophotometrically in a 1-cm cuvette at 760 nm.

-

5.

The average absorbance of phenol-free blanks (a yellow color should fade to colorless) is subtracted.

-

6.

The amount of “total phenolics” is determined by using a standard curve.

-

7.

Depending on the standard compound used (most often gallic acid or (+)-quercetin), the amount of total phenolics is reported, for example, as mg gallic acid equivalents per liter (if liquid samples such as white wine were used).

2.3 Chromatographic Methods

Chromatographic methods are widely used to quantify individual phenolic compounds or to monitor phenolic profiles of food products. However, they are not well suited for measuring the total phenolic contents of food products unless they contain only a few phenolic compounds, which are all known and available as standard compounds, a rather unlikely scenario. The choice of the chromatographic method depends on the phenolic compounds to be determined. Whereas all extractable phenolics are theoretically appropriate for liquid chromatographic methods, significantly less phenolic compounds are volatile enough to be analyzed by gas chromatography (GC) without prior derivatization.

2.3.1 High-Performance Liquid Chromatography

High-performance liquid chromatography (HPLC)/ultra-performance liquid chromatography (UPLC) (Chap. 13, Sect. 13.2.3.3) is the method of choice for most phenolic compounds. Following extraction of the phenolic compounds as described in Sects. 25.2.1.1 and/or 25.2.1.2, the samples are either directly (after membrane filtration using suitable filter materials or sample centrifugation) injected into the HPLC system, or the extracts are further purified by means of liquid/liquid extraction or solid-phase extraction (SPE) (Chap. 14, Sect. 14.2.2.5). Reversed-phase SPE cartridges such as C18-cartridges are conditioned and loaded with the sample. Unwanted matrix components are eluted with water or mixtures of water with (typically) low amounts of organic modifiers and discarded, and the analytes are eluted with solvents containing large portions of organic modifiers such as methanol. Recoveries depend on the phenolics to be analyzed and the exact outline of the procedure. Capacity of the selected SPE cartridges, the solvent choice for the elution of unwanted matrix components, and eluent volumes are usually critical parameters requiring optimization to achieve high recoveries. If SPE is used to separate phenolic acids from neutral phenolic compounds, the pH of the solvents is another parameter that may be adjusted to optimize SPE conditions [12].

Separation of phenolic compounds is usually achieved on reversed-phase columns (Chap. 13, Sect. 13.3.2), with C18- and phenyl-hexyl-stationary phases being preferentially used in the analysis of phenolics from food products. Phenyl-hexyl-columns may, depending on the gradient system used, provide extra selectivity for aromatic compounds due to π-π interactions (non-covalent attractive interactions that involve π-electron systems, often formed between two aromatic rings, also known as π-π stacking) between the stationary phase and the phenolic analytes. Mobile phases are mostly water and varying amounts of organic modifiers, with methanol and acetonitrile being most often used. Depending on the phenolic compounds to be separated, the addition of small amounts of an acidic modifier, such as trifluoroacetic acid or formic acid, to the eluent may be required to achieve good separation. For example, acid addition to the eluent is necessary to separate phenolic acids. Without acid addition peaks become broad due to partial deprotonation of the carboxyl group, whereas acid addition to the eluent ensures protonated carboxyl groups and results in narrow, symmetric peaks. If mass spectrometric (MS) detection is used (Chap. 11), trifluoroacetic acid should be avoided because it suppresses ionization using electrospray ionization (ESI); formic acid may be used to adjust the pH instead [13].

Due to their phenyl unit, all phenolic compounds are UV active, making UV detection the preferred detection mode [14]. Depending on the conjugation of the π-electron system, the maximum of UV absorption can vary considerably. For example, ferulic acid with its extended π-electron system (propenylic side chain) shows a UV maximum (depending on the solvent and pH) around 325 nm, whereas 3-(3-hydroxy-4-methoxyphenyl) propionic acid has a UV maximum around 275 nm (Fig. 25.3). With the now routine presence of photodiode array detectors (capable of measuring the full UV-visible spectrum simultaneously (Chap. 7, Sect. 7.2.6.3) in analysis laboratories, each compound can be measured at its individual UV absorption maximum simultaneously. When only single-wavelength UV detectors are available, 280 nm or, more traditionally, 254 nm (main UV emission line of mercury vapor lamps) are most often used to monitor all phenolic compounds. Because phenolic compounds can easily be oxidized, their detection with electrochemical detectors is also an option, which, however, has not achieved broad application in the analysis of phenolics. Depending on the analyzed phenolic compounds, fluorescence detection, with its obvious advantages of increased selectivity and sensitivity (Chap. 7, Sect. 7.3), may be used. With state-of–the-art MS detectors becoming more affordable, MS and MS/MS detection (Chap. 11) is not only increasingly used in research but also more routinely in analytical testing laboratories.

2.3.2 Gas Chromatography

Because many phenolic compounds are not volatile without decomposition, gas chromatographic analysis of phenolics requires prior derivatization (Chap. 14, Sect. 14.2.3). Silylation using derivatization reagents such as N,O-bis(trimethylsilyl)trifluoroacetamide (BSTFA) is a commonly used derivatization method for phenolic compounds, replacing an active hydrogen by a trimethylsilyl (TMS) group. Applied in aprotic solvents with pyridine as catalyst, BSTFA reacts with both hydroxyl and carboxyl groups of phenolic compounds, which results in TMS ethers and esters, respectively (Fig. 25.4). Silylation often can be performed directly in the silylation reagent with or without addition of a catalyst [15]. In particular, the silylation of sterically hindered hydroxyl groups may be improved by using aprotic solvents and/or catalysts. Whereas derivatization sufficiently improves volatility of simple phenolic compounds and enables GC separation, larger phenolics, especially if conjugated with sugars, are still not suitable analytes for GC procedures. The TMS derivatives of simple phenolics such as hydroxybenzoic and hydroxycinnamic acids are well separated on nonpolar stationary GC phases (100 % methyl-substituted polysiloxane or 5 % diphenyl-95 % dimethyl polysiloxane). Detection can be carried out nonspecifically using a flame ionization detector (FID) or more specifically using MS detection. Depending on whether MS detection is performed in the selected ion-monitoring mode or in the scan mode (resulting in total ion chromatograms) (Chap. 11), MS detection either shows the additional advantage of higher sensitivity compared to FID detection or supplies additional structural information for the compound, respectively, which also helps to ensure peak purity [15].

3 Antioxidant Capacity Assays

3.1 General Principles and Limitations of Antioxidant Capacity Assays

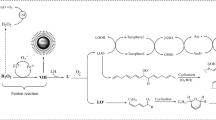

Traditionally, the antioxidant capacity of individual compounds or plant extracts has been measured to identify suitable antioxidants for the development of food products with enhanced stability against lipid deterioration. Because several mechanisms are involved in oxidative lipid degradation, including photooxidation, lipoxygenase-catalyzed oxidation, and autoxidation, different compounds such as radical scavengers, metal ion chelators, enzyme inhibitors, and singlet oxygen quenchers all have the potential to delay lipid oxidation in food products. However, the vast majority of studies performed in the recent past did not target food products but rather biological processes occurring in the human body [2]. Hundreds of individual, mostly phenolic compounds and, most often undefined, food and plant extracts were analyzed for their in vitro antioxidant capacity, with the intention of evaluating antioxidants potentially involved in the prevention of diseases such as atherosclerosis, diabetes, and cancer, i.e., diseases in which oxidative processes are thought to be critically involved. However, the use of simple in vitro antioxidant tests (as described below) has been criticized because it is not possible to mimic complex in vivo environments with these test systems. Compared to food, the evaluation of antioxidants from the perspective of human health and disease is even more complicated because many phytochemicals are not necessarily effective because of their own antioxidant capacity but, among other factors, due to their stimulation of a phase II response, which includes the induction of classical phase II enzymes (antioxidant and detoxifying enzymes) [16, 17]. Because of these concerns, the USDA’s Nutrient Data Laboratory (NDL) removed the “USDA Oxygen Radical Absorbance Capacity (ORAC) Database for Selected Foods” from the NDL website. They concluded that “there is no evidence that the beneficial effects of polyphenol-rich foods can be attributed to the antioxidant properties of these foods. The data for antioxidant capacity of foods generated by in vitro (test-tube) methods cannot be extrapolated to in vivo (human) effects and the clinical trials to test benefits of dietary antioxidants have produced mixed results” [18].

If any of the antioxidant capacity tests described below are used to determine the antioxidant capacity of individual food constituents or extracts, one must clearly define the goal of performing this test and ask whether this assay is suitable to obtain appropriate answers. Critical interpretation of results from these tests must go beyond just producing numbers. It is particularly important to reflect whether the chosen test system simulates a complex food system (or other biological systems) in sufficient detail [19]. A critical factor is whether the food system is an emulsion, with oil in water being most important for food products, or bulk oil. If the food product of interest is an emulsion but the test system uses only water (to test for “hydrophilic antioxidants”) or an organic solvent (to test for “lipophilic antioxidants”), the results from these assays are hard to interpret because the distribution of the antioxidants in an emulsion and at the interface is not reflected by the test system. If the test system is able to simulate an emulsion, it should be asked whether the oxidized substrate employed by the assay represents the compounds to be oxidized in the food product. For example, many test systems use free fatty acids, which form micelles and therefore behave very differently from emulsified triglycerides. Other factors that need to be evaluated are radical initiators or radicals used in these test systems.

Several antioxidant capacity assays in numerous variations have been applied in the past [20, 21]. Efforts to standardize these test systems are underway but were not successful for all tests yet. Even where standardization was achieved, many different protocols are still used. To broadly classify assays that are supposed to measure radical scavenging capacities, they were divided into hydrogen atom transfer (HAT) reaction-based assays and single electron transfer (SET) reaction-based assays [22]. HAT assays determine the ability of an antioxidant or a mixture of antioxidants to scavenge free radicals by hydrogen donation. SET assays measure the ability of antioxidants to transfer one electron, thereby reducing radicals and also other compounds such as redox-active metal ions. By accepting an electron, the radical is converted into an anion, which can accept a proton to form a stable compound.

3.2 Hydrogen Atom Transfer (HAT) Assays

3.2.1 Oxygen Radical Absorbance Capacity (ORAC) Assay

3.2.1.1 Principle

The ORAC assay utilizes azo compounds (compounds with the functional group R–N=N–R) as radical generators and monitors the progression of oxidation via disappearance of a fluorescent probe. Upon gentle heating (37 °C), the azo compound [2,2′-azobis(2-amidinopropane) dihydrochloride, AAPH, Fig. 25.5] disintegrates, releasing nitrogen gas and two carbon-centered radicals (Fig. 25.6). In an oxygenated environment, these carbon-centered radicals rapidly form peroxyl radicals, which attack the fluorescent probe (usually fluorescein, Fig. 25.5). In the presence of HAT-acting antioxidant compounds that quench the peroxyl radicals, the loss of fluorescein is delayed until the antioxidants are consumed. The loss of the fluorescent probe is monitored over time with a fluorescence spectrophotometer, and fluorescence intensity vs. time is plotted. The antioxidative capacity of tested samples is measured as the total area under the curve for the sample (TAUCsample) minus the total area under the curve for the blank (TAUCblank). These unitless areas are converted into Trolox (a water-soluble vitamin E analog, Fig. 25.5) equivalents based on the area generated by Trolox in the same assay. The ORAC assay conditions may be modified to accommodate either lipophilic or hydrophilic antioxidants.

3.2.1.2 Measurement Procedure

Early ORAC procedures are based on the methods described by Prior et al. [23] and Wu et al. [24]. A helpful discussion of technical challenges related to the ORAC assay may be found in Schaich et al. [25]. However, the ORAC assay described here largely reflects the AOAC Method 2012.23 for Total Antioxidant Activity [26]:

-

1.

Sample Extraction . Solid samples should be lyophilized, ground, and extracted with acetone/water (1:1, vol/vol) for hydrophilic ORAC analysis. The acetone/water extract is made up to a defined volume with 0.075 M phosphate buffer (pH 7.4) and analyzed under the hydrophilic ORAC assay conditions. Liquid samples are centrifuged, and the supernatant is diluted with 0.075 M phosphate buffer (pH 7.4) and analyzed under the hydrophilic ORAC assay conditions. Sample preparation for lipophilic samples is not clearly outlined in the AOAC method, although the preparation of an lipophilic ORAC extraction solution made up of hexane and ethyl acetate (3:1, vol/vol) is described.

-

2.

Preparation of Standard Solutions and Calibration. A Trolox calibration curve is prepared in 0.075 M phosphate buffer (pH 7.4) for the hydrophilic ORAC assay. For the lipophilic ORAC assay, a calibration curve is produced by dissolving Trolox in a 1.4 % randomly methylated β-cyclodextrin (RMCD) solution prepared in 0.075 M phosphate buffer (pH 7.4). Fluorescein solution and AAPH solution, which must be freshly made before each sample run, are also prepared in 0.075 M phosphate buffer (pH 7.4).

-

3.

Hydrophilic ORAC Assay. A fluorescence microplate reader should be set to an excitation wavelength of 485 nm and an emission wavelength of 530 nm, with an incubator temperature of 37 °C. All solutions should be sparged with oxygen immediately before use [25]. Appropriately diluted hydrophilic sample extract, Trolox calibration solutions, or phosphate buffer for blank are pipetted into sample wells, and fluorescein solution is added. The sample is mixed, AAPH solution is added, and the solution is mixed again. Fluorescence is measured at 1-min intervals for 35 min.

-

4.

Lipophilic ORAC Assay. The assay is performed using the same conditions as the hydrophilic assay except that samples are diluted with 7 % RMCD solution prepared in acetone/water (50:50, vol/vol).

3.2.1.3 Calculation of Results

The area under the curve (AUC) is calculated according to Eq. 25.1:

where:

-

f 0 = initial fluorescence intensity upon addition of all solutions

-

f i = fluorescence intensity at time i

Net AUC for a sample or calibration point is calculated by subtracting AUC of the blank from that of the sample or calibration point. Net AUC for the calibration points vs. Trolox concentration is plotted in graphing software, and a linear or quadratic standard curve equation is calculated. ORAC values for samples should be expressed as μmol Trolox equivalents and normalized to dry weight.

3.2.1.4 Advantages and Limitations

The ORAC assay utilizes a controlled source of peroxyl radicals, which creates a better model of real-life antioxidant interactions with lipids in food systems than other antioxidant assays that use stable radical compounds. However, the assay is comparatively difficult to perform properly, and several points need to be considered. First, reaction temperature must be exactly controlled at 37 °C to ensure consistent, reproducible peroxyl radical generation. Uniform dissolved oxygen concentrations between analyses must also be ensured. Additionally, the concentrations of fluorescein, AAPH, and sample must be optimized [25]. If the reaction proceeds slowly (>1 h required for loss of fluorescence), the AAPH concentration should be increased. Fluorescein concentrations that are too high result in fluorescence quenching via π-π-stacking of the aromatic rings and hydrogen bonding between phenol groups; fluorescence quenching can be recognized when a solution’s fluorescence intensity remains the same upon dilution or even increases. A range of sample dilutions also should be measured to test for non-radical sample interactions with fluorescein, as well as potential depression of fluorescence by sample components (see Schaich et al. [25]).

3.2.2 Crocin Bleaching Assay

3.2.2.1 Principle

Similar to the ORAC assay, the crocin bleaching assay also uses a controlled source of peroxyl radicals to assess HAT activity. Crocin (Fig. 25.5), a water-soluble carotenoid isolated from saffron, absorbs UV-Vis light strongly at 440–443 nm but loses color (“bleaches”) upon radical oxidation and is therefore used as probe.

3.2.2.2 Measurement Procedure

The crocin bleaching assay has not been studied as extensively as the ORAC assay, and no standardized method exists in the literature. Although earlier reports utilized photolysis of hydroperoxides to produce alkoxyl radicals [27], most recent studies have used peroxyl radicals generated by heating azo compounds (e.g., AAPH). No specific sample preparation method has been recommended, but the sample preparation and extraction procedures described in Sect. 25.2.1 may be used. For hydrophilic antioxidants, the reaction is typically carried out in buffer (either sodium phosphate buffer or phosphate-buffered saline, pH 7.0 or 7.4) at 37 °C, crocin stock solutions are prepared in methanol, the sample is incubated at 37 °C, and absorption decline following addition of free radical generator (azo compound) is monitored at 440, 443, or 450 nm. For application of the crocin bleaching assay to lipophilic antioxidants, a lipophilic azo compound as free radical initiator in an organic solvent environment [e.g., dimethylformamide (DMF) or a toluene: DMF mixture (1:4, vol/vol)] may be used [28].

3.2.2.3 Calculation of Results

The ability of antioxidant compounds to hinder color loss has been varyingly expressed as Trolox or α-tocopherol equivalents [28], “percent inhibition of crocin bleaching value” [29], IC50 (dose of substance causing a 50 % inhibition of crocin bleaching) [30], and relative rate constants [27].

3.2.2.4 Advantages and Limitations

Advantages of the crocin bleaching assay include its sensitivity and reproducibility [30]. Like the ORAC assay, temperature must be tightly controlled during the crocin bleaching assay to ensure a consistent generation of peroxyl radicals between samples. Additionally, many food components (e.g., carotenoids) absorb at the same wavelengths used in the crocin bleaching assay. However, the greatest current limitation for this assay is the lack of a standardized, accepted method of analysis and a format for expressing results.

3.3 Single Electron Transfer (SET) Assays

3.3.1 Trolox Equivalent Antioxidant Capacity (TEAC) Assay

3.3.1.1 Principle

The TEAC assay, also known as the 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS•+) assay utilizes the stable, nitrogen-based ABTS•+ radical. The ABTS•+ radical is strongly colored, but ABTS is colorless, which allows for easy monitoring of appearance/disappearance of the radical via UV-Vis absorbance. Early versions of this method used a metmyoglobin-H2O2-system to generate hydroxyl radicals, which then oxidized ABTS to its radical form. Antioxidant compounds were added to the system before radical formation, and inhibition of radical formation was related to antioxidant activity. However, this order of reagent addition was confounded by the fact that antioxidants could react with the hydroxyl radicals, metmyoglobin, and ABTS•+, which resulted in inaccurate estimation of antioxidant activity [20, 25]. Therefore, current TEAC/ ABTS•+ methods first generate high ABTS•+ concentrations, followed by antioxidant addition and monitoring ABTS•+ decline [31].

3.3.1.2 Measurement Procedure

-

1.

Generation of ABTS •+. Fresh stock solutions of ABTS•+ should be prepared weekly. Potassium persulfate is added to an ABTS solution in deionized water, and this mixture is allowed to stand for 12–16 h at room temperature until a deep blue-green color develops. Before each analysis session, a working solution is created by diluting aliquots of the ABTS•+ stock solution in water until an absorbance of 1.0 at 734 nm is reached.

-

2.

Sample Measurement. The ABTS•+ working solution is pipetted into a cuvette followed by the addition of the antioxidant solution or extract (see Sect. 25.2.1). The absorbance at 734 nm is monitored and recorded at a fixed time point after addition of the antioxidant solution (6 min is the time point most often used). The absorbance of the ABTS•+ working solution without antioxidant solution is measured using the solvent of the sample solution in place of sample. For assessment of more lipophilic antioxidants, the TEAC assay also may be performed in ethanol instead of water.

-

3.

Measurement of Trolox Standards. A Trolox stock solution is created in the same solvent as used for the antioxidant samples and appropriately diluted to create an equidistant (i.e., calibration points are equally spaced), five-point calibration curve. The calibration points are measured using the same method as for samples.

3.3.1.3 Calculation of Results

The decrease in absorbance for calibration points vs. Trolox concentration is plotted with graphing software, and a linear standard curve equation is calculated. The standard curve equation is used to convert drop in absorbance for antioxidant samples (A 0–A f) to equivalent Trolox concentrations.

3.3.1.4 Advantages and Limitations

Although results from the TEAC/ABTS•+ method should not be extrapolated into food or biological systems, the assay provides a rapid and easy possibility for an initial screening of samples for antioxidant activity or for monitoring changes in the same samples over time [25, 32]. The TEAC/ABTS•+ method is primarily governed by steric considerations of the large nitrogen-based ABTS•+ radical molecule. Antioxidants that function primarily via SET or do not have bulky ring systems react rapidly, whereas unwieldy antioxidant structures or antioxidants functioning via HAT react slowly. Therefore, a strong response in the TEAC/ABTS•+ method does not necessarily correlate well with radical-quenching capabilities in real-world food or biological systems. Additionally, because effective HAT-acting antioxidants react only slowly in this system, the typical method of measuring absorbance after a given time may underestimate the activity of many extracts.

3.3.2 2,2-Diphenyl-1-Picryhydrazyl Radical (DPPH) Assay

3.3.2.1 Principle

The DPPH assay was first proposed by Blois over 50 years ago for “the antioxidant assay of biological materials” [33]. It is now the basis of AOAC Method 2012.04, for antioxidant activity in foods and beverages [26]. DPPH is a stable organic nitrogen radical (Fig. 25.5) and produces deeply blue-violet solutions that strongly absorb at 517 nm. Upon quenching of the radical by antioxidant compounds, which can occur both by electron transfer and hydrogen atom transfer, solutions are decolorized, and the absorbance at 517 nm decreases. Quenching of the DPPH radical was shown to happen rapidly by the SET mechanism, but antioxidant compounds that act primarily by HAT quenching also show activity. However, hydrogen-bonding solvents, such as the methanol or ethanol often used for this assay, impede the HAT mechanism and thus favor SET-acting antioxidant compounds [34, 35].

3.3.2.2 Measurement Procedure

The AOAC Method 2012.04 described here adds a DPPH standard solution directly to solid samples without a separate extraction step, which maximizes extraction efficiency, but many methods in the literature first prepare sample extracts, preferably in methanol, from solid samples. A DPPH reagent solution in methanol/water (approx. 50:50, vol/vol) is prepared; the solution should be protected from light, and it is advised to prepare fresh stock solutions daily. DPPH reagent solution is added directly to lyophilized, ground solid samples (which can be appropriately diluted with corn starch) or homogenous liquid samples (which can be appropriately diluted with deionized water). An equidistant, four-point Trolox calibration curve is prepared by mixing aliquots of a Trolox stock solution (also prepared in methanol/water, 50:50, vol/vol) with DPPH solution. All samples are incubated at 35 °C for 4 h on an orbital shaker and filtered (if cloudy). Following incubation, the absorbance at 517 nm is measured against a distilled water blank.

3.3.2.3 Calculation of Results

The amount of DPPH radical quenched by the sample extract is calculated as μmol Trolox equivalents/100 g of sample.

3.3.2.4 Advantages and Limitations

The DPPH assay is simple to perform and may be useful as an initial qualitative screening tool to identify the presence of SET-acting antioxidant compounds. However, the assay is hampered by major drawbacks. The nitrogen-based, bulky DPPH radical is a poor model for the radicals encountered in food and biological systems. Determining the total amount of DPPH consumed by the sample after several hours (or, as described in other procedures, after reaching a reaction plateau) and its “total antioxidant capacity” ignores the short lifetimes (seconds or less) of free radicals in food systems [36]. However, focusing on reaction rate in the DPPH assay as a means of ranking antioxidants has also proven futile, because reaction rates are almost exclusively governed by the steric accessibility of the antioxidant molecule to the bulky DPPH’s radical site [34]. Additionally, both the “total antioxidant capacity” and reaction rate of individual antioxidants are affected by antioxidant concentration, with stoichiometry (moles of DPPH consumed/mole of antioxidant) decreasing with increased antioxidant concentration [34]. Mixtures of antioxidants display more activity depression than can be explained by steric interferences [25], meaning that the assay is completely irrelevant for ranking samples containing multiple components in varying concentrations, such as plant extracts. Finally, the assay does not capture antioxidants which function primarily via the HAT mechanism. Based on these limitations, the assay should not be used for quantitative ranking of the antioxidant capacity of individual compounds or mixtures.

3.3.3 Ferric Reducing Antioxidant Power (FRAP) Assay

3.3.3.1 Principle

In contrast to the TEAC/ABTS•+ and DPPH assays, which operate under mixed SET and HAT mechanisms, the FRAP assay measures exclusively SET-active compounds. The assay monitors the reduction of a ferric salt (ferric 2,4,6,tripiridyl-s-triazine, TPTZ), producing a colored product which absorbs at 593 nm. The redox potential of Fe(III)-TPTZ (0.7 V) is similar to that of ABTS•+ (0.68 V), so compounds that show activity in the TEAC/ABTS•+ assay will also react in the FRAP assay. However, because the FRAP assay must be performed at an acidic pH value of 3.6 to protect iron solubility, which increases the redox potential, FRAP values are usually lower than TEAC/ABTS•+ assay values [20].

3.3.3.2 Measurement Procedure and Calculation of Results

Fresh working solutions of Fe(III)-TPTZ are prepared by mixing acetate buffer (pH 3.6) with TPTZ and FeCl3•6H2O stock solutions before sample analysis. Samples (see extraction procedure described in Sect. 25.2.1), typically dissolved in aqueous solutions, are measured by mixing FRAP working solution with sample and measuring the increase in absorbance at 593 nm against a FRAP reagent blank after a set time (typically 4 or 8 min). Calibration is calculated via Fe(II) equivalents by preparing equidistant, five-point calibration curves with FeSO4 • 7H2O solution [37].

3.3.3.3 Advantages and Limitations

Because the assay’s mechanism is purely SET based, it can be used to screen antioxidants for SET functionality. Additionally, the assay is rapid and robust. However, the active mechanism of the FRAP assay [the ability to reduce Fe(III)] has little correlation to the radical-quenching mechanisms (HAT) displayed by many antioxidants.

3.4 Assays Based on Oxidation of Lipids

Besides the assays described in Sects. 25.3.2 and 25.3.3, which were often designed for a high sample throughput and all possess the limitation of being oversimplified test systems, the effects of individual compounds, mixtures of antioxidants, or plant extracts on oxidative stability in more complex systems or the actual food product to be protected from oxidative degradation can be tested in accelerated lipid oxidation tests. These test systems are described in detail in Chap. 23, Sect. 23.5. Using, for example, the Rancimat® does not necessarily require a lipid extraction, but direct measurement of food products is possible (e.g., cookies, nuts, and microwave popcorn). However, foods containing high water or protein contents such as salad dressings or sausages require a prior lipid extraction. Using the whole food product is closest to what happens during storage with the limitations arising from using accelerated oxidation conditions as described in Chap. 23, Sect. 23.5.1. If the lipid phase needs to be extracted from an emulsion-based food product such as salad dressings, the same limitations as described earlier occur (i.e., partition of the antioxidants between the phases and at the interface cannot be modeled).

4 Summary

Phenolic compounds and other antioxidants are of great interest as they have the potential to stabilize food products against lipid deterioration. Because many diseases such as diabetes and certain forms of cancer are linked to oxidative stress, phenolic compounds from food products and other plant sources are discussed in terms of disease prevention, too. Thus, there is a demand to measure phenolic compounds in food products and to evaluate the antioxidant capacity of individual food constituents, extracts, and ingredients. Methods to determine the total phenolic contents of food products such as the Folin-Ciocalteu assay are unspecific and do not, depending on the overall composition of the food product, necessarily reflect the phenolic contents. Wherever possible, it is therefore advised to study individual phenolic compounds by using HPLC/UPLC or GC approaches. A plethora of antioxidant capacity assays has been described in the past that differ in the applied principle and, more often, in details of the procedure such as probes, radical initiators, solvents, etc. Because several of these tests were designed as high-throughput methods, they can be used to screen many compounds/extracts, but suffer from oversimplification and do not reflect the complexity of oxidative degradation of lipids and other organic compounds in biological systems. Therefore, it is not advised to use these assays to screen for compounds with potential health benefits. If these assays are used to screen compounds to improve the shelf life of food, the assays should be critically evaluated in terms of whether they are suitable models for the food system to be protected from oxidative degradation. The efficacy of antioxidants identified in these test systems to delay lipid oxidation and to improve shelf life needs to be confirmed in real food products under real storage conditions.

5 Study Questions

-

1.

Why do compounds such as ascorbic acid and glutathione show a positive response in the Folin-Ciocalteu assay, a test often selected by researchers to measure the total phenolic contents of food products?

-

2.

Name different ways to extract food products with or without prior hydrolysis for the analysis of phenolic compounds and give examples of phenolic compounds that are either included or excluded in the analysis depending on the extraction procedure.

-

3.

Why does RP-HPLC analysis of phenolic acids usually require a pH adjustment of the mobile phase?

-

4.

Why does the GC analysis of phenolic compounds often require a prior derivatization? What is a suitable derivatization procedure for many phenolic compounds?

-

5.

Why did the USDA’s Nutrient Data Laboratory remove the USDA ORAC database for Selected Foods from the NDL website?

-

6.

Why do many antioxidant capacity assays fail to model food products that are emulsions?

-

7.

What is the difference between HAT and SET antioxidant capacity assays?

-

8.

How does the ORAC assay aim to measure hydrophilic versus lipophilic antioxidants?

-

9.

What are some major limitations of the DPPH assay due to the structure of the stable radical DPPH used in this assay?

-

10.

What is the difference between preparing the ABTS•+ radical before and after addition of the sample solution to be tested?

References

Ralph J, Bunzel M, Marita JM, Hatfield RD, Lu F, Kim H, Schatz PF, Grabber JH, Steinhart H (2004) Peroxidase-dependent cross-linking reactions of p-hydroxycinnamates in plant cell walls. Phytochem Rev 3(1):79–96

Halliwell B (2007) Dietary polyphenols: Good, bad or indifferent for your health. Cardiovasc Res 73(2):341–347

Gniechwitz D, Reichardt N, Ralph J, Blaut M, Steinhart H, Bunzel M (2008) Isolation and characterisation of a coffee melanoidin fraction. J Sci Food Agric 88(12):2153–2160

Barberousse H, Roiseux O, Robert C, Paquot M, Deroanne C, Blecker C (2008) Analytical methodologies for quantification of ferulic acid and its oligomers. J Sci Food Agric 88(9):1494–1511

Naczk M, Shahidi F (2004) Extraction and analysis of phenolics in food. J Chromatogr A 1054(1–2):95–111

Folin O, Denis W (1912) On phosphotungstic-phosphomolybdic compounds as color reagents. J Biol Chem 12:239–243

Folin O, Denis W (1912) Tyrosine in proteins as determined by a new colorimetric method. J Biol Chem 12:245–251

Folin O, Ciocalteu V (1927) On tyrosine and tryptophane determinations in proteins. J Biol Chem 73:627–650

Singleton VL, Rossi Jr. JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 65(3):144–158

Everette JD, Bryant QM, Green AM, Abbey YA, Wangila GW, Walker RB (2010) Thorough study of reactivity of various compound classes toward the Folin-Ciocalteu reagent. J Agric Food Chem 58(14):8139–8144

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol 299:152–178

Robbins JR (2003) Phenolic acids in foods: An overview of analytical methodology. J Agric Food Chem 51(10):2866–2887

Jilek ML, Bunzel M (2013) Dehydrotriferulic and dehydrodiferulic acid profiles of cereal and pseudocereal flours. Cereal Chem 90(5):507–514

Dobberstein D, Bunzel M (2010) Separation and detection of cell wall-bound ferulic acid dehydrodimers and dehydrotrimers in cereals and other plant materials by reversed phase high-performance liquid chromatography with ultraviolet detection. J Agric Food Chem 58(16):8927–8935

Bunzel M, Ralph J, Marita JM, Hatfield RD, Steinhart H (2001) Diferulates as structural components in soluble and insoluble cereal dietary fibre. J Sci Food Agric 81(7): 653–660

Stevenson DE, Hurst RD (2007) Polyphenolic phytochemicals – just antioxidants or much more? Cell Mol Life Sci 64(22):2900–2916

Dinkova-Kostova AT (2002) Protection against cancer by plant phenylpropenoids: Induction of mammalian anticarcinogenic enzymes. Mini Rev Med Chem 2(6):595–610

USDA (2010) Oxygen radical absorbance capacity (ORAC) of selected foods, Release 2 [updated 01/2/2016]. Agricultural Research Service, US Department of Agriculuture. Available from: http://www.ars.usda.gov/Services/docs.htm?docid=15866.

Frankel EN, Meyer AS (2000) The problems of using one-dimensional methods to evaluate multifunctional food and biological antioxidants. J Sci Food Agric 80(13):1925–1941

Prior RL, Wu X, Schaich K (2005) Standardized methods for the determination of antioxidant capacity and phenolics in foods and dietary supplements. J Agric Food Chem 53(10):4290–4302

Moon J-K, Shibamoto T (2009) Antioxidant assays for plant and food components. J Agric Food Chem 57(5):1655–1666

Huang D, Ou B, Prior RL (2005) The chemistry behind antioxidant capacity assays. J Agric Food Chem 53(6):1841–1856

Prior RL, Hoang H, Gu L, Wu X, Bacchiocca M, Howard L, Hampsch-Woodill M, Huang D, Ou B, Jacob R (2003) Assays for hydrophilic and lipophilic antioxidant capacity (oxygen radical absorbance capacity (ORACFL)) of plasma and other biological and food samples. J Agric Food Chem 51(11):3273–3279

Wu X, Beecher GR, Holden JM, Haytowitz DB, Gebhardt SE, Prior RL (2004) Lipophilic and hydrophilic antioxidant capacities of common foods in the United States. J Agric Food Chem 52(12):4026–4037

Schaich KM, Tian X, Xie J (2015) Hurdles and pitfalls in measuring antioxidant efficacy: A critical evaluation of ABTS, DPPH, and ORAC assays. J Funct Foods 14:111–125

AOAC International (2016) Official methods of analysis, 20th edn., 2016 (online). AOAC International, Rockville, MD

Bors W, Michel C, Saran M (1984) Inhibition of the bleaching of the carotenoid crocin a rapid test for quantifying antioxidant activity. Biochim Biophys Acta, Lipids Lipid Metab 796(3):312–319

Tubaro F, Micossi E, Ursini F The antioxidant capacity of complex mixtures by kinetic analysis of crocin bleaching inhibition. J Am Oil Chem Soc 73(2):173–179

Ordoudi SA, Tsimidou MZ (2006) Crocin bleaching assay step by step: observations and suggestions for an alternative validated protocol. J Agric Food Chem 54(5):1663–1671

Lussignoli S, Fraccaroli M, Andrioli G, Brocco G, Bellavite P (1999) A microplate-based colorimetric assay of the total peroxyl radical trapping capability of human plasma. Anal Biochem 269(1):38–44

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biol Med 26:1231–1237

Tian X, Schaich KM (2013) Effects of molecular structure on kinetics and dynamics of the Trolox equivalent antioxidant capacity assay with ABTS+•. J Agric Food Chem 61(23):5511–5519

Blois MS (1958) Antioxidant determinations by the use of a stable free radical. Nature 181:1199–1200

Xie J, Schaich KM (2014) Re-evaluation of the 2,2-diphenyl-1-picrylhydrazyl free radical (DPPH) assay for antioxidant activity. J Agric Food Chem 62(19):4251–4260

Foti MC, Daquino C, Geraci C (2004) Electron-transfer reaction of cinnamic acids and their methyl esters with the DPPH• radical in alcoholic solutions. J Org Chem 69(7):2309–2314

Pryor WA (1986) Oxy-radicals and related species: their formation, lifetimes, and reactions. Annu Rev Physiol 48(1):657–667

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239(1):70–76

Acknowledgments

The authors wish to thank Baraem Ismail, Andrew Neilson, and Jairam Vanamala for reviewing the chapter and providing helpful comments.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing

About this chapter

Cite this chapter

Bunzel, M., Schendel, R.R. (2017). Determination of (Total) Phenolics and Antioxidant Capacity in Food and Ingredients. In: Nielsen, S.S. (eds) Food Analysis. Food Science Text Series. Springer, Cham. https://doi.org/10.1007/978-3-319-45776-5_25

Download citation

DOI: https://doi.org/10.1007/978-3-319-45776-5_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-45774-1

Online ISBN: 978-3-319-45776-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)