Abstract

Volumetric glassware, mechanical pipettes, and balances are used in many analytical laboratories, including those doing food analysis. The use of this glassware and equipment must be mastered to help ensure accurate and precise results. The objective of this laboratory exercise is to familiarize, or refamiliarize, oneself with the use of balances, mechanical pipettes, and volumetric glassware, and to assess the accuracy and precision of the data generated.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Mechanical Pipette

- Volumetric Glassware

- Laboratory Exercises

- Volumetric Pipette

- Food Analysis Laboratory Manual

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

1.1 Background

Volumetric glassware, mechanical pipettes, and balances are used in many analytical laboratories. If the basic skills in the use of this glassware and equipment are mastered, laboratory exercises are easier and more enjoyable, and the results obtained are more accurate and precise. Measures of accuracy and precision can be calculated based on data generated, given the glassware and equipment used, to evaluate both the skill of the user and the reliability of the instrument and glassware.

Determining mass using an analytical balance is the most basic measurement made in an analytical laboratory. Determining and comparing mass is fundamental to assays such as moisture and fat determination. Accurately weighing reagents is the first step in preparing solutions for use in various assays.

Accuracy and precision of the analytical balance are better than for any other instruments commonly used to make analytical measurements, provided the balance is properly calibrated and the laboratory personnel use proper technique. With proper calibration and technique, accuracy and precision are limited only by the readability of the balance. Repeatedly weighing a standard weight can yield valuable information about the calibration of the balance and the technician’s technique.

Once the performance of the analytical balance and the technician using it has been proven acceptable, determination of mass can be used to assess the accuracy and precision of other analytical instruments. All analytical laboratories use volumetric glassware and mechanical pipettes. Mastering their use is necessary to obtain reliable analytical results. To report analytical results from the laboratory in a scientifically justifiable manner, it is necessary to understand accuracy and precision.

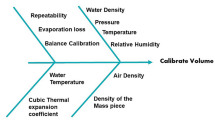

A procedure or measurement technique is validated by generating numbers that estimate their accuracy and precision. This laboratory includes assessment of the accuracy and precision of automatic pipettors. An example application is determining the accuracy of automatic pipettors in a research or quality assurance laboratory, to help assess their reliability and determine if repair of the pipettors is necessary. Laboratory personnel should periodically check the pipettors to determine if they accurately dispense the intended volume of water. To do this, water dispensed by the pipettor is weighed, and the weight is converted to a volume measurement using the appropriate density of water based on the temperature of the water. If replicated volume data indicate a problem with the accuracy and/or precision of the pipettor, repair is necessary before the pipettor can be reliably used again.

It is generally required that reported values minimally include the mean, a measure of precision, and the number of replicates (Smith 2017). The number of significant figures used to report the mean reflects the inherent uncertainty of the value, and it needs to be justified based on the largest uncertainty in making the measurements of relative precision of the assay. The mean value is often expressed as part of a confidence interval (CI) to indicate the range within which the true mean is expected to be found. Comparison of the mean value or the CI to a standard or true value is the first approximation of accuracy. A procedure or instrument is generally not deemed inaccurate if the CI overlaps the standard value. Additionally, a CI that is considerably greater than the readability indicates that the technician’s technique needs improvement. In the case of testing the accuracy of an analytical balance with a standard weight, if the CI does not include the standard weight value, it would suggest that either the balance needs calibration or that the standard weight is not as originally issued. Accuracy is sometimes estimated by the relative error (%E rel) between the mean analysis value and the true value. However, %E rel only reflects tendencies and in practice is often calculated even when there is no statistical justification that the mean and true value differ. Also, note that there is no consideration of the number of replicates in the calculation of %E rel, suggesting that the number of replicates will not affect this estimation of accuracy to any large extent. Absolute precision is reflected by the standard deviation (SD), while relative precision is calculated as the coefficient of variation (CV). Calculations of precision are largely independent of the number of replicates, except that more replicates may give a better estimate of the population variance.

Validation of a procedure or measurement technique can be performed, at the most basic level, as a single-trial validation, as is described in this laboratory that includes estimating the accuracy and precision of commonly used laboratory equipment. However, for more general acceptance of procedures, they are validated by collaborative studies involving several laboratories. Collaborative evaluations are sanctioned by groups such as AOAC International, AACC International, and the American Oil Chemists’ Society (AOCS) (Nielsen 2017). Such collaborative studies are prerequisite to procedures appearing as approved methods in manuals published by these organizations.

1.2 Reading Assignment

Neilson A.P., Lonergan D.A., and Nielsen S.S. 2017. Laboratory standard operating procedures. Ch.1, in Food Analysis Laboratory Manual, 3rd ed., Nielsen S.S. (Ed.), Springer, New York.

Nielsen, S.S. 2017. Introduction to food analysis. Ch. 1, in Food Analysis, 5th ed. S.S, Nielsen (Ed.), Springer, New York.

Smith, J.S. 2017. Evaluation of analytical data. Ch. 5, in Food Analysis, 5th ed. S.S. Nielsen (Ed.), Springer, New York.

1.3 Objective

Familiarize, or refamiliarize, oneself with the use of balances, mechanical pipettes, and volumetric glassware, and assess accuracy and precision of data generated.

1.4 Principle of Method

Proper use of equipment and glassware in analytical tests helps ensure more accurate and precise results.

1.5 Supplies

-

Beaker, 100 mL

-

Beaker, 20 or 30 mL

-

Beaker, 250 mL

-

Buret, 25 or 50 mL

-

Erlenmeyer flask, 500 mL

-

Funnel, approximately 2 cm diameter (to fill buret)

-

Mechanical pipettor, 1000 μL, with plastic tips

-

Plastic gloves

-

Ring stand and clamps (to hold buret)

-

Rubber bulb or pipette pull-up

-

Standard weight, 50 or 100 g

-

Thermometer, to read near room temperature

-

Volumetric flask, 100 mL

-

2 Volumetric pipettes, one each of 1 and 10 mL

1.6 Equipment

-

Analytical balance

-

Top loading balance

1.7 Notes

Before or during the laboratory exercise, the instructor is encouraged to discuss the following: (1) difference between dispensing from a volumetric pipette and a graduated pipette and (2) difference between markings on a 10-mL versus a 25- or 50-mL buret.

2 Procedure

(Record data in tables that follow.)

-

1.

Obtain ~400 mL deionized distilled (dd) H2O in a 500-mL Erlenmeyer flask for use during this laboratory session. Check the temperature of the water with a thermometer.

-

2.

Analytical balance and volumetric pipettes.

-

(a)

Tare a 100-mL beaker, deliver 10 mL of water from a volumetric pipette into the beaker, and record the weight. Repeat this procedure of taring the beaker, adding 10 mL, and recording the weight, to get six determinations on the same pipette. (Note that the total volume will be 60 mL.) (It is not necessary to empty the beaker after each pipetting.)

-

(b)

Repeat the procedure as outlined in Part 2a but use a 20- or 30-mL beaker and a 1.0-mL volumetric pipette. Do six determinations.

-

(a)

-

3.

Analytical balance and buret.

-

(a)

Repeat the procedure as outlined in Part 2a, but use a 100-mL beaker and a 50-mL (or 25-mL) buret filled with water, and dispense 10 mL of water (i.e., tare a 100 mL beaker, deliver 10 mL of water from the buret into the beaker, and record the weight). (Handle the beaker wearing gloves, to keep oils from your hands off the beaker.) Repeat this procedure of taring the beaker, adding 10 mL, and recording the weight, to get six determinations on the buret. (Note that the total volume will be 60 mL.) (It is not necessary to empty the beaker after each addition.)

-

(b)

Repeat the procedure as outlined in Part 3a but use a 20- or 30-mL beaker and a 1.0-mL volume from the buret. Do six determinations.

-

(a)

-

4.

Analytical balance and mechanical pipette. Repeat the procedure as outlined in Part 2a but use a 20- or 30-mL beaker and a 1.0-mL mechanical pipette (i.e., tare a 20- or 30-mL beaker, deliver 1 mL of water from a mechanical pipettor into the beaker, and record the weight). Repeat this procedure of taring the beaker, adding 1 mL, and recording the weight to get six determinations on the same pipettor. (Note that the total volume will be 6 mL.) (It is not necessary to empty the beaker after each pipetting.)

-

5.

Total content (TC) versus total delivery (TD). Tare a 100-mL volumetric flask on a top loading balance. Fill the flask to the mark with water. Weigh the water in the flask. Now tare a 250-mL beaker and pour the water from the volumetric flask into the beaker. Weigh the water delivered from the volumetric flask.

-

6.

Readability versus accuracy. Zero a top loading balance and weigh a 100-g (or 50-g) standard weight. Record the observed weight. Use gloves or finger cots as you handle the standard weight to keep oils from your hands off the weight. Repeat with the same standard weight on at least two other top loading balances, recording the observed weight and the type and model (e.g., Mettler, Sartorius) of balance used.

3 Data and Calculations

Calculate the exact volume delivered in Sect. 6.2, Parts 2–5, using each weight measurement and the known density of water (see Table 6.1). Using volume data, calculate the following indicators of accuracy and precision: mean, standard deviation, coefficient of variation, percent relative error, and 95 % confidence interval. Use your first three measurements for n = 3 values requested and all six measurements for n = 6 values.

Data for Sect. 6.2, Parts 2, 3, and 4:

Volumetric pipette | Buret | Mechanical pipettor | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

1 mL | 10 mL | 1 mL | 10 mL | 1 mL | ||||||

Rep | Wt. | Vol. | Wt. | Vol. | Wt. | Vol. | Wt. | Vol. | Wt. | Vol. |

1 | ||||||||||

2 | ||||||||||

3 | ||||||||||

4 | ||||||||||

5 | ||||||||||

6 | ||||||||||

n = 3 | ||||||||||

Mean | – | – | – | – | – | |||||

SD | – | – | – | – | – | |||||

CV | – | – | – | – | – | |||||

% E rel | – | – | – | – | – | |||||

CI95% | – | – | – | – | – | |||||

n = 6 | ||||||||||

Mean | – | – | – | – | – | |||||

SD | – | – | – | – | – | |||||

CV | – | – | – | – | – | |||||

% E rel | – | – | – | – | – | |||||

CI95% | – | – | – | – | – | |||||

Data for Sect. 6.2, Part 5:

Wt. | Vol. | |

|---|---|---|

Water in flask = | ||

Water in beaker = |

Data for Sect. 6.2, Part 6:

Balance | Type/model of balance | Standard weight (g) |

|---|---|---|

1 | ||

2 | ||

3 |

4 Questions

(Questions refer to parts of Sect. 6.2)

-

1.

Theoretically, how are standard deviation, coefficient of variation, mean, percent relative error, and 95 % confidence interval affected by (1) more replicates and (2) a larger size of the measurement? Was this evident in looking at the actual results obtained using the volumetric pipettes and the buret, with n = 3 versus n = 6 and with 1 mL versus 10 mL? (See table below)

Theoretical | Actual, with results obtained | |||

|---|---|---|---|---|

More replicates | Larger mesurement | More replicates | Larger mesurement | |

Standard deviation | ||||

Coefficient of variation | ||||

Mean | ||||

Percent relative error | ||||

95 % confidence interval | ||||

-

2.

Why are percent relative error and coefficient of variation used to compare the accuracy and precision, respectively, of the volumes from pipetting/dispensing 1 and 10 mL with the volumetric pipettes and buret in Parts 2 and 3, rather than simply the mean and standard deviation, respectively?

-

3.

Compare and discuss the accuracy and the precision of the volumes from the 1 mL pipetted/dispensed using a volumetric pipette, buret, and mechanical pipettor (Parts 2, 3, and 4). Are these results consistent with what would be expected?

-

4.

If accuracy and precision using the mechanical pipettor are less than should be expected, what could you do to improve its accuracy and precision?

-

5.

In a titration experiment using a buret, if you expect to use much less than a 10-mL volume in each titration, would you expect your accuracy and precision to be better using a 10-mL buret or a 50-mL buret? Why?

-

6.

How do your results from Part 5 of this lab differentiate “to contain” from “to deliver”? Is a volumetric flask “to content” or “to deliver”? Which is a volumetric pipette?

-

7.

From your results from Part 6 of this lab, would you now assume that since a balance reads to 0.01 g that it is accurate to 0.01 g?

-

8.

What sources of error (human and instrumental) were evident or possible in Parts 2–4, and how could these be reduced or eliminated? Explain.

-

9.

You are considering adopting a new analytical method in your lab to measure the moisture content of cereal products, how would you determine the precision of the new method and compare it to the old method? How would you determine (or estimate) the accuracy of the new method?

Resource Materials

Neilson AP, Lonergan DA, and Nielsen SS (2017) Laboratory standard operating procedures, Ch. 1. In: Food analysis laboratory manual, 3rd ed., Nielsen SS (ed.), Springer, New York

Nielsen SS (2017) Introduction to food analysis, Ch. 1. In: Nielsen SS (ed) Food analysis, 5th edn. Springer, New York

Smith JS (2017) Evaluation of analytical data, Ch. 4. In: Nielsen SS (ed) Food analysis, 5th edn. Springer, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2017 Springer International Publishing

About this chapter

Cite this chapter

Nielsen, S.S., Carpenter, C.E. (2017). Accuracy and Precision Assessment. In: Food Analysis Laboratory Manual. Food Science Text Series. Springer, Cham. https://doi.org/10.1007/978-3-319-44127-6_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-44127-6_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-44125-2

Online ISBN: 978-3-319-44127-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)