Abstract

Best practice for acid rock drainage (ARD) risk assessment predominately relies on the geochemical properties of sulfidic rocks. Consequently, a plethora of geochemical tests are routinely utilised by the mining industry to predict ARD formation. Due to limitations associated with these tests and their relatively high costs, analysis of recommended best practice sample numbers is rarely achieved, thus reducing the accuracy of waste management plans. This research aimed to address this through identifying potential geometallurgy indicators using drill core samples (n = 70) obtained from the Comstock Chert, a new prospect proximal to Mount Lyell, western Tasmania, Australia. Samples were subjected to a range of mineralogical analyses, routine ARD geochemical tests (i.e., paste pH; acid-base accounting , ABA; net acid generation, NAG), field-based techniques (e.g., portable X-ray fluorescence, pXRF; short-wave infrared spectrometry, SWIR), and geometallurgical analyses (i.e., HyLogger, Equotip). This study demonstrated: (1) HyLogger data allows identification of acid-neutralizing carbonate minerals; (2) Equotip hardness data provide a conservative indication of lag-time to acid formation; (3) CARD risk grading accurately identifies high and low risk ARD domains; and (4) pXRF data provides a sound indication of the abundance of environmentally significant elements. Consequently, the application of geometallurgical techniques to drill core allows the prediction of ARD characteristics that inform waste characterization and management plans.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

Determining the propensity of a rock unit to produce ARD is possible through the use of established and emerging geometallurgical tools and techniques. The geochemistry-mineralogy-texture (GMT) approach is one such protocol allowing for improved ARD prediction . Through using the GMT approach, it is possible to pursue best practice sample numbers (cf. Price 2009) for deposit-wide ore and waste characterization, rather than through using other protocols such as the Wheel Approach (Morin and Hutt 1998). Despite the merits of the GMT approach and the use of such simple pre-screening tests for deposit-wide domaining, it can be argued that the undertaking of such specialised ARD focused analyses (e.g., geochemical tests) is financially limiting as these data are fit-for-purpose and cannot be used to characterize other features of the ore body. Instead, to facilitate deposit-wide characterization and to add value to already existing datasets, proxies for ARD data must be identified. Geometallurgical tests and data are the most appropriate proxies. Whilst a vast range of data is collected for geometallurgical modelling, no published examples exist of it being utilised for predictive ARD characterization. Yet, existing sampling strategies of 2 m intervals, utilised as part of geometallurgical campaigns (e.g., Alruiz et al. 2009; Leichliter et al. 2011), represent an appropriate sampling approach for deposit-scale ARD domaining.

This aim of this study was to determine whether geometallurgical data can be utilised effectively to domain acid neutralizing capacity and acid forming potential in drill core materials. Geometallurgical data and its environmental implications examined in detail were: (1) hyperspectral infrared HyLogger data to assess the accuracy of acid neutralizing capacity (ANC) data; and (2) mineral hardness Equotip data to determine the weathering rate of rock units. In addition to geometallurgical data, information derived from field-based instrumentation (i.e., SWIR, pXRF) is also presented and evaluated in terms of application for accurate deposit-wide ARD domaining. For validation , geometallurgical data were compared with data generated from field tools (e.g., staining), and established geochemical (e.g., NAPP and NAG) and mineralogical (e.g., XRD) tests.

Deposit Geology

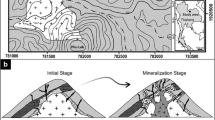

The Comstock Valley is located on the northern end of the Mount Lyell mineral field, Queenstown, Tasmania (McLoughlin and Morrison 2013). The deposit is part of the large Cambrian hybrid volcanogenic-magmatic Cu-Au-Ag system at Mount Lyell, which has been exploited for approximately 120 years from 22 separate mine workings. The Mount Lyell mineral field occupies the southern end of a belt of polymetallic base and precious metal deposits within the late Middle Cambrian Mount Read Volcanics (MRV) succession of western Tasmania (Fig. 1).

The Copper Chert deposit is considered to represent a new style of volcanic hosted, copper-rich polymetallic mineralization for the Mount Lyell mineral field (McLoughlin and Morrison 2013). The mineralization is largely Cu-Au-Ag but also contains significant intersections of Pb-Zn-Ag ore. The deposit is hosted in an intense microcrystalline silica alteration package known as the Comstock Chert.

Acid Rock Drainage at Mount Lyell

ARD is actively produced from mine wastes produced by the former Mount Lyell mine (Fig. 2) and is under the management of the State Government. These mine wastes are the consequence of a century of continuous copper mining and processing at the Mount Lyell mine. Amongst the impacts arising from discharge of metal-enriched ARD, slag and tailings are the pollution of fresh and marine waters and the deposition of tailings and slag in the Queen and King Rivers and Macquarie Harbour. Considering the ARD legacy at Mount Lyell, it is imperative that any new operations such as the Copper Chert adopt and maintain best practice in terms of their ARD testwork and waste management planning.

Sample Selection and Handling

A 70 m section of drill core (drill hole CCD007), which showed lithological and mineralogical variability, was selected for this study. The upper portion of this drill core section (304–345 m) is representative of the Tyndall Group Lynchford Member, which comprises of sedimentary sandstones, limestones and conglomerates and demonstrated a variety of textures (e.g., fragmental, clastic, veined). The lower portion (345–375 m) sampled the Lyell Schist, which demonstrated increasing degrees of mineralization with depth (i.e., contained greater proportions of chalcopyrite and pyrite towards the base of the drill hole). For the majority of the Tyndall Group Lynchford Member, half core samples were taken. Due to the increased degree of mineralization in the Lyell Schist, only quarter core samples were provided. The materials were shipped directly to Mineral Resources Tasmania (MRT). On receipt of samples, drill core was unpacked and laid out in sequence in metal drill core trays in preparation for HyLogger analysis . However, it was noted that quarter core samples had not transported well and were highly fragmented, causing difficulty when reassembling the drill core material. In some instances, recovery of the whole 1 m interval was not possible. Despite this, the drill core material was arranged so that the best possible fit was achieved, samples were then cleaned thoroughly with water and left to air-dry.

Geometallurgical Analyses

Hyperspectral Mineralogy

Hyperspectral mineralogy data was collected using a HyLogger instrument housed at MRT. HyLoggingTM systems are automated platforms used to rapidly and systematically collect infrared spectroscopic reflectance data at dense sample spacing from drill core, chips or powders (Huntington et al. 2006). 40 m of material (304–345 m; representative of the Tyndall Group Lynchford Member) were analysed both pre- and post-carbonate chemical staining . Approximately >5000 hyperspectral reflectance measurements were collected, with the data acquisition rate ca. 5 min for a three section core tray. Measurements were captured from a 10 × 10 mm field-of-view along the middle of the core, and continuous imagery across the full width of the core was synchronously acquired. Hyperspectral data analysis and mineral interpretation were carried out in version 8.1 of The Spectral Geologist (HotCore). Hylogging derived mineralogy was intended for comparison with: (1) carbonate staining results; (2) SWIR data; (3) XRD data; and (4) domaining of neutralizing capacity using carbonate relative intensity values and total sulfur data.

Equotip Analysis

Circa 3000 measurements were collected from the whole 70 m length of the sampled drill hole using an Equotip 3 instrument (manufactured by Proceq). An average value was calculated for each 1 m interval based on measurements taken at 2.5 cm intervals as recommended by Keeney (2008). Equotip values were compared against total-sulfur values graphically and sample intervals were then classified in terms of lag-time to ARD generation. These classifications were compared against those determined using a NAG pH versus paste pH geochemical plot. This allowed for a critical assessment of the application for ARD risk domaining using Equotip versus total sulfur data.

CARD Risk Grading

Mineralogical and textural data were collected using a mineral liberation analyser (MLA) instrument at the Central Science Laboratory, University of Tasmania (FEI Quanta 600 SEM equipped with 2 EDAX ultra-thin window Si (Li) energy dispersive X-ray detectors). The CARD grade used the XMOD technique, a simpler and lower-cost MLA method than those more routinely used (e.g., XBSE, SPL-Lite). XMOD is based on a point counting method, whereby mineral identification is determined by one X-ray analysis at each counting point. The input parameters used here were: frames, 300; particles, 20,000; time, 60 min; with the BSE standard set to nickel . On average, data acquisition took approximately 30 min or less per sample. Data processing and CARD calculations were performed following the methodology presented in Chap. “Prediction of Acid Rock Drainage from Automated Mineralogy”.

Field Based Tests

Chemical Staining

Only the Tyndall Group Lynchford Member material (304–345 m) was subjected to staining given its high carbonate contents as indicated by the geological logging of these samples. Prior to staining, drill core was etched using dilute HCl for 2–3 min and subsequently washed with water. Samples were then left to dry for approximately 30 min. Next, samples were stained directly with a paintbrush using a dual stain comprising the organic dye Alizarin Red-S (ARS) and Potassium Ferricyanide (PF) dissolved in HCl. After staining, samples were re-run on the HyLogger to collect high-resolution photographic images for comparison against unstained core images.

Geochemical and Mineralogical Testwork

Sulfur Analysis

Rapid and accurate measurement of sulfur (wt%) for comparison against Equotip and HyLogger values and calculation of maximum potential acidity (MPA) was performed on all samples using an Eltra C-S 2000 instrument at UTAS. Analysis requires the use of two accelerants (tungsten and iron) which were carefully weighed into a crucible, with a measure (c. 200 mg) of powdered (<63 µm) sample added. Individual crucibles were placed onto the instrument stage, loaded into the machine, and heated to >800 °C. The evolved gases were measured and values for carbon and sulfur calculated, in under 1 min. The instrument was regularly calibrated (i.e., once after every 10 samples analysed), using two calibration materials provided by the instrument supplier (calcium carbonate and barium sulfate). As a further measure, two ore standards (purchased from Choice Analytical) were also run in addition to sample blanks (i.e., before instrument calibration).

Paste and NAG pH

The ASTM D4972-01 (2007) paste pH method was used in this study. These data were used in this study for comparison against NAG pH to geochemically classify ARD risk. This pH test measures pH in a 0.01 M CaCl2 solution at a 1:1 solid to solution ratio. The pH value of each sample (n = 55) was measured in triplicate, with the standard deviation calculated as <0.5. To compliment NAPP testing and for comparison against paste pH values, multi-addition net acid generation (mNAG) pH tests were performed following the method of Smart et al. (2002). Essentially, the mNAG test procedure involves the stepped addition of H2O2 in three increments (100 ml, 100 ml and 50 ml). This allows more time for sulfide oxidation. Powders (<63 µm) from all samples (n = 51) were tested with appropriate sample duplicates used during the analysis.

Acid Neutralizing Capacity (ANC)

All samples from the Tyndall Group Lynchford Member material (304–345 m; CCD007) were sent to ALS Brisbane for the calculation of acid neutralizing capacity (ANC) by the Sobek method (ALS code: EA013). This data was collected to determine NAPP values for the carbonate -rich Tyndall Group Lynchford Member materials. This data was also used to assist in determining whether carbonate staining and hyperspectral mineralogy data had identified calcite in the correct intervals.

X-ray Diffractometry (XRD)

To determine the mineralogy of supplied drill core (for evaluation of field-based and geometallurgical data), milled material from each 1 m interval was subjected to powder XRD analysis . A benchtop Bruker D2 Phaser X-ray diffractometer with a Co X-ray source was used to perform these analyses. Prior to each daily sample run, a corundum standard was analysed to check the X-ray beam alignment and ensure the correct collection of peaks. Each sample was ground in an agate pestle and mortar and loaded into the sample holder and placed into the machine chamber. Samples were analysed for 1 h (fixed divergence slit: 1 mm; range 4–900 2-theta; 0.020 step size, Fe-filter), with the resulting spectra processed in Eva 2.1 software, where minerals were identified using the ICDD PDF 2012 database. In addition, nine samples were chosen for further processing using Topas 2.0 software, to verify the accuracy of carbonate staining. A fundamental parameters approach was applied, and preferred crystal orientation corrected for.

Results

Domaining Acid Neutralizing Capacity

Static Geochemical Data

Acid neutralizing capacity (ANC) measurements collected for the Tyndall Group Lynchford Member (304–345 m) are shown in Fig. 3a. ANC values ranged from 40 to 954 kg H2SO4/t. On consultation of geological logs for this drill hole, zones of very high ANC correlated to the presence of sandy limestone (e.g. 339–343 m). However, consistent zones of ANC were not observed due to abundance of limestone clasts in the Tyndall Group Lynchford Member.

Downhole static geochemical results for Tyndall Group Lynchford Member samples (n = 40): a acid neutralizing capacity (ANC) values (kg H2SO4/t); b paste pH values (n = 21) with the pure calcite paste pH line shown for comparison, and the paste pH cut-off criterion of pH 5.5 used to classify acid forming from non-acid forming materials; c total sulfur values (wt%) with 0.3 wt% used as the classification cut-off criterion (Parbhakar-Fox et al. 2011); d net acid producing potential (NAPP) values (kg H2SO4/t) with a cut-off value of 20 kg H2SO4/t (Parbhakar-Fox et al. 2011) used to classify non-acid forming from potentially acid forming samples (reprinted from Parbhakar-Fox and Lottermoser (2014), with permission from ACMER)

Paste pH values for select samples of the Tyndall Group Lynchford Member (n = 21) indicated that currently, all tested samples are non-acid forming (Fig. 5b; range: pH 7.6–8.2), when using a cut-off value of pH 5.5 to classify acid forming from non-acid forming materials (Parbhakar-Fox et al. 2011). All values plotted to the left of the pure calcite paste pH line (shown at pH = 8.33), suggesting that minerals such as dolomite and magnesite , which have higher paste pH values (8.87 and 9.32 respectively; Noble et al. 2015), are not present in these samples.

Downhole total-sulfur values (Fig. 3c) identified four distinct zones of relatively high sulfur with potential for acid formation when using a cut-off value of 0.3 wt% sulfur (Parbhakar-Fox et al. 2011). This indicated that either sulfur is present in sulfide species which are slow to react in water (e.g., chalcopyrite) or lesser acid forming sulfides dominate in these samples (e.g., galena and sphalerite ). Net acid producing potential (NAPP) values classified 15 % of samples as potentially acid forming (PAF > 20 kg H2SO4/t), with a distinct zone identified from 330 to 335 m. This was logged as green, chloritic, polymict conglomerate, with fragments of chert, volcanics, limestone and sulfides.

As both carbonate and sulfide minerals are present in the Tyndall Group Lynchford Member, a geochemical plot of ANC versus MPA (calculated conservatively from total-sulfur values) is shown in Fig. 4. The same 15 % of samples were classified as having an increased risk for acid formation, indicating that there is not sufficient ANC in these samples to neutralize any acid formed.

Acid neutralizing capacity (ANC) versus maximum potential acidity (MPA) for Tyndall Group Lynchford Member samples (CCD007: 304–344 m; n = 40), with potential acid forming risk fields shown (from Parbhakar-Fox 2012)

Carbonate Staining

The dominant carbonate textures observed in this material comprised of clasts (in limestone conglomerates) and veins. The ARS-PF stain appropriately reacted with calcitic material in both textural forms, with a pink stain indicating the presence of calcite (cf. Hitzman 1999) (Fig. 5). Towards the base of the stained portion of CCD007, a blue-purple colour was observed suggesting the presence of either ferroan calcite or ferroan dolomite (Fig. 6). As dolomite was not logged, it is considered that these bluish portions represent ferroan-calcite. However, to confirm the staining colours, specific verification samples were carefully chosen, prepared and analysed by XRD, with an example presented in Fig. 7. Interpretation of XRD patterns indicated the presence of ferroan dolomite rather than ferroan calcite. Considering the overall slight discoloration of the drill core in the Tyndall Group Lynchford Member after staining, and the measured range of ANC values (Fig. 3a), it is most likely that the matrix of this lithology contains calcite, hence why it has consistently been identified downhole by XRD. However, in terms of domaining effective ANC, precisely resolving the presence of calcite against dolomite is of lesser significance when considering their similar ANC values (1000 and 1086 kg H2SO4/t respectively; Jambor et al. 2007). Thus, carbonate staining using the ARS-PF stain can be considered a very useful domaining tool for recognising effective neutralizing minerals in drill core materials.

Photographic images of drill core CCD007 304–307 m (unstained) with two carbonate stained portions shown, with the pink colour indicating the presence of calcite, thus confirming domains of high acid neutralizing capacity within the Tyndall Group Lynchford Member. (Reprinted from Parbhakar-Fox et al. (2015), with permission from Gecamin) (color figure online)

a Carbonate stained drill core sample from drill core CCD007 327 m, blue colour indicating the presence of ferroan calcite or dolomite; b X-ray diffraction pattern of area starred in (a) confirming the dominance of ferroan dolomite, however traces of calcite were also identified. Abbreviations Cal calcite, Dol dolomite, Ms muscovite, Qz quartz (color figure online)

Hyperspectral Logging

Thermal infrared (TIR) data collected by HyLogger from the Tyndall Group Lynchford Member samples identified the dominant mineralogy as quartz , chlorite, muscovite and carbonate . Two distinct zones of high carbonate were identified and correlated directly with two zones of high acid neutralizing capacity (Fig. 8).

a Mineralogical identification performed by HyLogger (Thermal infrared; TIR) of drill core material from CCD007 (304–345 m; Tyndall Group Lynchford Member); b measured downhole acid neutralizing capacity (ANC) values, with zones of high ANC correlating to high carbonate zones identified by HyLogger (reprinted from Parbhakar-Fox and Lottermoser 2014, with permission from ACMER) (color figure online)

Comparison of qualitative (i.e., relative proportions) carbonate mineralogy measured by HyLogger against normalised carbonate XRD data is shown in Fig. 9. In general, HyLogger identified more carbonate phases than XRD analyses with the presence of minor siderite identified and distinct ankerite dominated zones, particularly towards the base of the Tyndall Group Lynchford Member. However, during XRD data interpretation, common carbonates minerals were searched for and siderite phases were not recognised, suggesting that carbonate mineral identification by HyLogger is not wholly accurate. For ANC domaining, distinguishing between calcite , dolomite and ankerite is of lesser importance when considering their neutralizing potential values (1000, 1086, and 970 kg H2SO4/t respectively; Jambor et al. 2007). However, it is necessary to correctly recognise the presence of siderite, as its neutralizing potential is often disregarded due to its potential to form acid (cf. Plumlee 1999). Based on these data , HyLogger should primarily be used to indicate the relative presence of carbonates, and not be relied upon exclusively to resolve carbonate mineralogy. Such data can be used to guide additional mineralogical testwork (i.e., XRD, electron probe microanalysis), which will allow the identification of individual carbonate minerals.

Parbhakar-Fox et al. (2013) demonstrated the application of HyLogger and total-sulfur values for ARD domaining, thus this dataset was considered as such (Fig. 10). Carbonate relative intensity (Fig. 10a) and total sulfur (Fig. 10b) were used to produce classifications shown in Fig. 10c. When compared against ANC (Fig. 3a) and NAPP classifications (Fig. 3d), HyLogger/total sulfur domaining appears reasonably accurate, with ANC and PAF zones clearly identified. Thus, these results confirm the application of HyLogger for ANC domaining when used alongside total-sulfur values (using the criteria: relative intensity, >5; total-sulfur, <0.3 wt%). In addition, this information can be used to guide sampling campaigns (e.g., for geochemical testwork) through identifying zones with distinct ARD characteristics.

Downhole static geochemical results from the Tyndall Group Lynchford Member samples: a carbonate relative intensity measured by HyLogger; b Total sulfur values (wt%; n = 40) with 0.3 wt% used as the classification cut-off criterion (Parbhakar-Fox et al. 2011); c Predicted acid forming characteristics based on HyLogger relative carbonate intensity data and total-sulfur values. Abbreviations: ANC acid neutralizing capacity, NAF non-acid forming, PAF potentially acid forming (reprinted from Parbhakar-Fox and Lottermoser 2014, with permission from ACMER) (color figure online)

Classification of ARD Risk

NAG pH Versus Paste pH

The use of NAG pH versus paste pH values was proposed by Weber et al. (2006). However, its application has not been widely demonstrated, despite the fact that it offers an assessment of lag-time to ARD and thus classifies risk. The use of this classification was performed on Lyell Schist drill core material (345–375 m; n = 30) as shown in Fig. 11. All samples but one were identified as either acid-forming or potentially acid forming, and classified as medium-low risk, with the rate of ARD formation determined as rapid to having a short-lag time (in the case of potentially acid forming samples). This assessment confirms: (1) the necessity of undertaking systematic sampling down drill holes due to the geological and mineralogical heterogeneity and variability indicated by these static geochemical data ; and (2) the suitability of the Lyell Schist drill core material for evaluating the application of Equotip for classifying ARD risk.

Mineral Hardness

Mineral hardness (using Equotip) data was collected from all drill core materials. Comparisons against total sulfur and paste pH values are shown in Fig. 12. When considering the Tyndall Group Lynchford Member, if a mineral hardness value (measured in leeb—Ls) was measured as <648 Ls, it was classified as soft in accordance with Keeney (2008). If samples were identified as non-acid forming by both paste pH and total-sulfur classifications and also classified as soft (e.g., 309–315 m; Fig. 12d), then these materials were considered to represent the most effective short-term neutralizers. The Lyell Schist was classified in a similar manner, with samples identified as potentially acid forming by paste pH and total sulfur methods and with soft mineral hardnesses (i.e., greater likelihood of acid formation) here classified as acid forming at a relatively rapid rate. These findings are in agreement with data shown in Fig. 11, thus indicating the potential application of Equotip when performing ARD domaining. Moreover, in the absence of paste pH data, mineral hardness and total sulfur data would have been sufficient to conservatively classify the behaviour of these materials.

Geochemical and geometallurgical data from drill hole CCD007 (304–375 m): a total sulfur values (wt%; n = 70) with 0.3 wt% used as the classification cut-off criterion (Parbhakar-Fox et al. 2011); b mineral hardness values as measured by Equotip and reported in Ls, with criteria for defining hard, medium and soft samples shown (Keeney 2008); c Paste pH values (n = 55) with pH 5.5 used as the classification cut-off criterion (Parbhakar-Fox et al. 2011); d ARD classifications based on total sulfur, mineral hardness and paste pH values. Abbreviations: AF acid forming, high risk with rapid ARD formation (after Weber et al. 2006); ANC acid neutralizing capacity, NAF non-acid forming, PAF potentially acid forming, medium risk with lag-time to ARD formation (after Weber et al. 2006) (reprinted from Parbhakar-Fox and Lottermoser 2014, with permission from ACMER) (color figure online)

CARD Risk Grading

CARD risk grading performed downhole (Fig. 13) confirmed classifications assigned by routine geochemical methods for both lithologies. In general, the Tyndall Group Lynchford Member was classified as very low risk, with the exception of a low-potential risk zone (i.e., CARD risk ratio = 1–9.9) at approximately 330–335 m depth, which correlates with the PAF zone identified by geochemical methods (Fig. 3d). All Lyell schist samples were classified as extreme risk by CARD risk grading, but were identified as intermediate-low risk by NAG pH versus paste pH. However, these samples contained 2.7–35.7 wt% total sulfur which can be taken to represent sulfide sulfur (i.e., chalcopyrite and pyrite) as only trace (<1 wt%) sulfate phases were identified in XRD analyses of these materials. Therefore, geochemical classifications underestimated the ARD risk of these samples. Based on these results; the Tyndall Group Lynchford Member represents a significant ANC source, and the Lyell Schist is extremely acid forming. Such accurate information is critical for designing an appropriate waste management strategy.

Conclusions

The objective of this study was to determine whether geometallurgical data can be utilised effectively to domain acid neutralizing capacity and acid forming potential in selected drill core from the Comstock Chert prospect, Tasmania. We evaluated the application of two geometallurgical techniques (HyLogger and Equotip) and chemical staining for domaining acid rock drainage (ARD) characteristics. The major outcomes and implications from this study for site-specific ARD recognition and waste classification were as follows:

-

Paste pH testing successfully identified materials with significant neutralizing capacity and inferred that calcite was the dominant carbonate mineral in drill core materials of the Tyndall Group Lynchford Member.

-

Carbonate staining was confirmed as a simple and accurate technique appropriate for drill core from the Copper Chert deposit (inspite of the textural diversity of carbonates present i.e., breccia clasts, veins). Staining allows for rapid identification of calcite and ferroan dolomite, information which will enable deposit-wide ANC domaining at early stages of operations and guide the selection of samples for in-depth geochemical static testing.

-

Thermal infrared data from HyLogger testing accurately reported carbonate intensity. However, it was less accurate when speciating carbonate minerals compared to quantitative XRD data. If used in conjunction with total-sulfur values, accurate ANC domaining when compared against laboratory measured ANC values was achieved.

-

The Equotip hardness versus total sulfur geometallurgical classification is best used to provide a conservative indication only of lag-time to acid formation. It allows for the classification of ARD risk for potentially acid forming materials like the Lyell Schist.

-

Utilisation of Equotip hardness and total sulfur data alongside paste pH data also allows for further domaining of effective acid neutralizing capacity.

-

CARD risk grading better classified ARD risk, with the Tyndall Group Lynchford Member classified as very low risk (with the exception of one moderate risk zone correlating to the presence of chalcopyrite and pyrite). The Lyell Schist was classified as extreme risk.

-

Adoption of such an environmental geometallurgy approach for further exploration in an area, where there is a legacy of ARD, is recommended. This will allow cost-effective domaining of ARD risks.

References

Alruiz OM, Morrell S, Suazo CJ, Naranjo A (2009) A novel approach to the geometallurgical modelling of the Collahuasi grinding circuit. Min Eng 22:1060–1067

Corbett KD, Quilty PG, Calver CR (2014) Geological evolution of Tasmania. Geological Society of Australia (Tasmanian Division), Hobart

Hitzman MW (1999) Routine staining of drill core to determine carbonate mineralogy and distinguish carbonate alteration textures. Mineralium Deposita 34: 794–798

Huntington JF, Quigley M, Yang K, Roache T, Young C, Roberts I, Whitbourn LB, Mason P (2006) A geological overview of HyLogging 18,000 m of core from the Eastern Goldfields of Western Australia. In: Proceedings from the 6th international mining geology conference, AusIMM publication series no. 6, Darwin, Australia, pp 45–50

Jambor JL, Dutrizac JE, Raudsepp M (2007) Measured and computed neutralization potentials from static tests of diverse rock types. Environ Geol 52:1019–1031

Keeney L (2008) EQUOtip hardness testing: Aqqaluk (including a guide on how to use EQUOtip). Technical report 2, P843 GeM, Australian Mineral Industries Research Association (AMIRA), Melbourne

Leichliter S, Hunt J, Berry R, Keeney L, Montoya PA, Chamberlain V, Jahoda R, Drews U (2011) Development of a predictive geometallurgical recovery model for the La Colosa, Porphyry Gold Deposit, Colombia. In: Proceedings from the 1st AusIMM international geometallurgy conference. THE Australasian Institute of Mining and Metallurgy, Melbourne, pp 85–92

McLoughlin J, Morrison K (2013) The copper chert discovery, Mount Lyell mineral field Tasmania. In: AUSIMMM mines and wines conference, Orange, NSW, Australia, pp 1–5

Morin KA, Hutt NM (1998) Kinetic test and risk assessment for ARD. In: Proceedings of the 5th annual BC metal leaching and ARD workshop, Vancouver, Canada

Noble TN, Lottermoser BG, Parbhakar-Fox A (2015) Evaluation of pH testing methods for sulfidic mine waste. Mine Water Environ. doi:10.1007/s10230-015-0356-2

Parbhakar-Fox A (2012) Establishing the value of an integrated geochemistry-mineralogy-texture approach for acid rock drainage prediction. PhD thesis, University of Tasmania, Australia

Parbhakar-Fox A, Lottermoser BG (2014) Domaining acid rock drainage risks using geometallurgical data. In: Proceedings from the 8th Australian workshop on acid and metalliferous drainage, ACMER, Brisbane, pp 483–494

Parbhakar-Fox A, Edraki M, Walters S, Bradshaw D (2011) Development of a textural index for the prediction of acid rock drainage. Min Eng 24:1277–1287

Parbhakar-Fox A, Lottermoser BG, Bradshaw D (2013) Evaluating waste rock mineralogy and microtexture during kinetic testing for improved acid rock drainage prediction. Min Eng 52:111–124

Parbhakar-Fox AK, Aalders J, Lottermoser BG (2015) Effective field-based testing tools for rapid ARD prediction. In: 10th international conference on acid rock drainage and IMWA annual conference, Santiago, Chile, pp 890–905

Plumlee GS (1999) The environmental geology of mineral deposits. In: Plumlee GS, Logsdon MJ (eds) The environmental geochemistry of mineral deposits part a: processes, techniques and health issues. Reviews in economic geology, vol 6A, pp 71–116

Price WA (2009) Prediction manual for drainage chemistry from sulphidic geologic materials. CANMET Mining and Mineral Sciences Laboratories, Canada

Smart R, Skinner WM, Levay G, Gerson AR, Thomas JE, Sobieraj H, Schumann R, Weisener CG, Weber PA, Miller SD, Stewart WA (2002) ARD test handbook: project P387A, prediction and kinetic control of acid mine drainage. AMIRA International Ltd, Melbourne

Weber PA, Hughes JB, Conner LB, Lindsay P, Smart RC (2006) Short-term acid rock drainage characteristics determined by paste pH and kinetic NAG testing: cypress prospect, New Zealand. In: Proceedings from the 7th international conference on acid rock drainage, Missouri, pp 2289–2310

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Parbhakar-Fox, A., Lottermoser, B. (2017). Predictive Waste Classification Using Field-Based and Environmental Geometallurgy Indicators, Mount Lyell, Tasmania. In: Lottermoser, B. (eds) Environmental Indicators in Metal Mining. Springer, Cham. https://doi.org/10.1007/978-3-319-42731-7_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-42731-7_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-42729-4

Online ISBN: 978-3-319-42731-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)